I once got two quotes for the same CNC part.

Same drawing. Same material. But one price was nearly double the other.

At first, I thought someone was trying to rip me off.

Then I looked closer to the more expensive quote included a tighter surface finish tolerance.

The supplier wasn’t overcharging. I was under-specifying.

That experience opened my eyes to how much finish affects price and performance.

This article will help you understand:

- What surface finish tolerances really are

- How they affect fit, function, and appearance

- Why do they impact cost and lead time

- And how to choose the right level for your project

I’ll share what I’ve learned the hard way, so you don’t have to.

Let’s start!

1. What Are Surface Finish Tolerances?

Surface finish tolerance refers to how smooth or rough a surface needs to be. It’s a way to measure and control the texture left behind after machining, grinding, or any finishing process.

Think about sanding a piece of wood.

If you use coarse sandpaper, the surface feels rough. If you switch to fine grit, it feels smooth and soft. Surface finish tolerance works the same way—but for metal, plastic, and other materials.

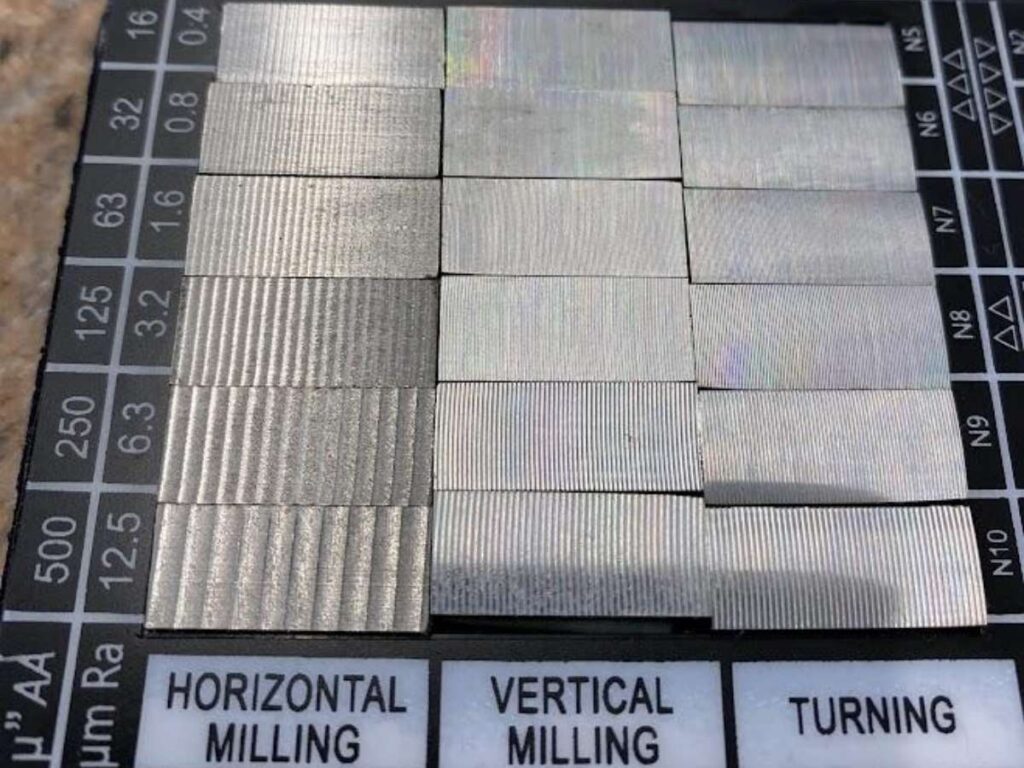

One of the most common ways to measure this is with Ra, which stands for Roughness Average.

Ra tells you the average height of the tiny peaks and valleys on a surface. The lower the number, the smoother the finish.

Here’s a quick way to picture it:

- Ra 12.5: Like rough concrete.

- Ra 3.2: Similar to fine sandpaper.

- Ra 0.8: Feels like smooth plastic.

- Ra 0.4: Almost mirror-smooth.

But Ra isn’t the only measure.

You might also see:

- Rz: The average difference between the highest peak and lowest valley across multiple points.

- Rt: The total height from the tallest peak to the deepest valley over one area.

So, why do these numbers matter?

Because how smooth a surface is can change how your part performs. It affects how pieces fit together, how they wear over time, and even how they look.

Now let’s clear up a common confusion: surface finish tolerance is not the same as dimensional tolerance.

- Dimensional tolerance is about size: how big, long, or wide something can be and still work.

- Surface finish tolerance is about texture: how rough or smooth the surface should feel.

Both matter. But they solve different problems.

Have you ever had a part that fit right but felt wrong in use? The size was fine, but the surface was too rough—or too smooth—and it didn’t perform as expected.

That’s why understanding surface finish tolerance isn’t just technical. It’s practical.

2. Common Surface Finish Grades and Their Applications

Now that you understand what surface finish tolerance is, let’s talk about the different grades and where they’re used.

Each grade tells you how smooth a surface is. But these numbers aren’t just for show. They connect directly to performance, price, and purpose.

Here’s a breakdown to help you decide what fits your needs.

Ra 12.5–6.3 μm

This is a rough surface.

Think castings, internal cavities, or hidden parts inside machinery. They don’t need to look pretty. They just need to function.

You’ll see this finish in industries like:

- Automotive

- Heavy equipment

- Construction machinery

When I worked on a custom gearbox housing, we went with Ra 6.3 for the inner walls. No one would see them, and the rougher finish helped keep costs down.

Ra 3.2–1.6 μm

This range is the workhorse.

You’ll find it on parts that need decent fit and function—but not extreme smoothness. These could be covers, brackets, or casings.

This finish is common in:

- General manufacturing

- Aerospace structural parts

- Consumer products

It’s the go-to when you want good performance without extra polishing.

Ra 0.8–0.4 μm

Now we’re getting smooth.

This grade is all about reducing friction. If the surface is too rough, moving parts wear out faster. If it’s too smooth, some seals won’t work properly.

You’ll see this in:

- Bearing housings

- Pump shafts

- Hydraulic pistons

I once ordered shafts at Ra 0.8. They ran quieter and lasted longer. It made a real difference.

Ra 0.2–0.1 μm and Below

This is where precision hits the highest level.

Surfaces at this grade are nearly flawless to the eye and touch. They’re used in:

- Optical lenses

- Surgical tools

- Semiconductor components

These finishes usually require fine grinding or polishing. And yes cost goes up.

Choosing the right grade isn’t about picking the smoothest one. It’s about what works best for your part.

3. How to Specify Surface Finish Tolerances Correctly

Knowing which surface finish you need is one thing.

Telling your supplier clearly is another.

I’ve made that mistake—once leaving out surface finish symbols on a drawing and ending up with a rougher-than-expected part. It still worked, but it caused delays, back-and-forth emails, and extra polishing.

Here’s how you can avoid that.

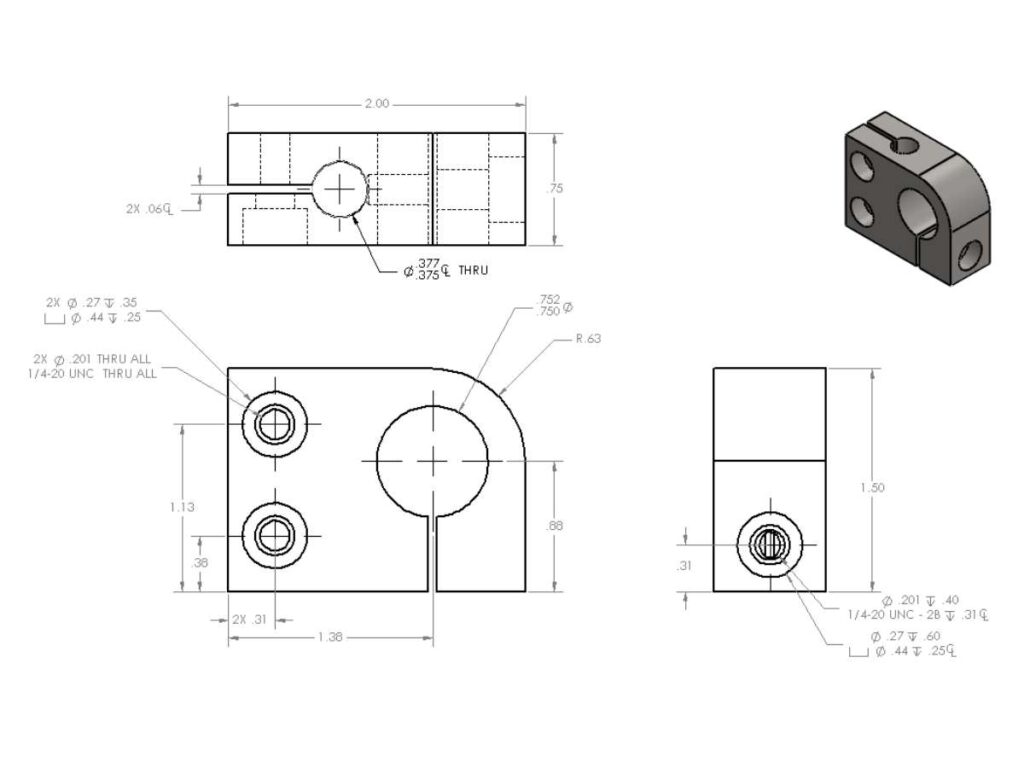

Include Finish Symbols on Technical Drawings

The most common way to show surface finish is with a small check mark–shaped symbol. It’s usually placed right on the drawing, next to the surface or feature you want to control.

Make sure to:

- Add the Ra value next to the symbol

- Use the correct units: micrometers (µm) or microinches (µin)

- Put the symbol near critical surfaces or directly on the surface of concern

This helps your manufacturer know exactly what you expect—without having to guess.

Use Notes or Tables for Multiple Surface Finishes

Sometimes, you need more than one finish on a single part. That’s common.

Instead of repeating symbols everywhere, you can:

- Add a general note: “All surfaces Ra 3.2 µm unless noted”

- Use a surface finish table: list the areas and their Ra values

This keeps your drawing clean and easier to read.

When I design parts with sliding fits and visible surfaces, I’ll often call out Ra 0.8 on just those faces and leave the rest at 3.2. It saves time and money.

Coordinate with Your Manufacturer

Even if your drawing is clear, it helps to talk it through.

Ask your supplier:

- “What’s your standard finish?”

- “Can you hit Ra 0.8 reliably?”

- “Do you have samples I can review?”

Sometimes a range is a better call. Asking for Ra 1.6–3.2 gives your supplier room to work—and keeps your cost down.

If you’re looking for a supplier who can consistently hit Ra 0.8—or even tighter—MachMaster can help. As a technology-driven precision manufacturer, we handle surface finishes and dimensional tolerances up to ±0.01mm with confidence.

4. The Real Cost of Surface Finish Tolerances

So you’ve chosen a surface finish. It looks good on paper.

But here’s where reality kicks in: cost.

Every time you lower that Ra number, your price goes up. Sometimes a little. Sometimes a lot.

I learned this the hard way. I once ordered a batch of brackets at Ra 0.4. I thought smoother meant better. But I didn’t need that level of polish—those parts were never seen, never moved, and didn’t seal against anything.

That one decision increased my cost by over 40%. I could’ve spent that money elsewhere.

So, what exactly affects the cost?

- Lower Ra = more time: Finer finishes need slower feeds, more passes, or extra polishing.

- More tools: You may need finer inserts, abrasive pads, or even special equipment.

- Higher inspection costs: Smoother finishes often require detailed checks with advanced tools.

Here’s a rough guide to help you understand the cost jump:

- Ra 12.5–6.3: Rough machining. Lowest cost.

- Ra 3.2–1.6: General machining. Add 5–10%.

- Ra 0.8–0.4: Precision surfaces. Add 15–30%.

- Ra 0.2–0.1 or below: Polished or lapped. Add 40–100% or more.

Let’s say a part costs $50 at Ra 3.2. That same part at Ra 0.2 could cost you $80 or even $100.

Is that smoother finish giving you better performance? Or just draining your budget?

Ask yourself:

- Is this surface functional or just nice to have?

- Can I use a range like Ra 1.6–3.2 instead of locking in a tight number?

Specifying a finish that fits the job—and the budget—can save you time, money, and rework.

If you’re unsure whether a finish is worth the added cost, MachMaster can walk you through your options. We’ll help you find the right balance between function and budget—no overkill, just what your part needs.

5. Red Flags and Cost Traps to Avoid

Surface finish decisions affect more than cost—they also affect timing, supplier options, and final part quality. Let’s look at the common mistakes that can throw off your entire project.

Specifying Ra 0.8 or Better Without a Need

It sounds good to ask for a smoother finish. But if your part doesn’t slide, seal, or carry a cosmetic requirement, you might be wasting money. Tighter finishes require more effort. And unless performance demands it, that extra cost doesn’t pay off.

Applying Tight Specs to Hidden or Internal Surfaces

I once reviewed a part where Ra 0.4 was called out on every surface—even internal cavities no one would ever see. The quote came back almost triple. We removed the unnecessary finishes, and the price dropped immediately.

Stick to critical surfaces only:

- Sealing faces

- Sliding fits

- Visible exterior surfaces

Leave the rest at a looser Ra like 3.2 or 6.3.

Assuming All Shops Can Hit Sub-Micron Ra

Not every manufacturer is set up for ultra-fine finishes. Some lack equipment. Others can hit the numbers—but with long lead times or high cost.

Always ask:

- “Can you consistently hold Ra 0.8?”

- “What’s your normal surface finish?”

Not Verifying the Finish on Prototypes

Skipping this step is risky. You might approve a design, send it to production, and realize too late that the finish doesn’t match expectations.

Request a sample or finish photo up front. It saves trouble later.

Finish tolerance mistakes aren’t just technical—they’re financial. Knowing where the real value is will help you avoid surprise costs.

6. Tips on How to Choose the Right Surface Finish Tolerance

By now, you know that surface finish tolerance affects performance, cost, and production time. But how do you actually pick the right one?

Here’s what’s worked for me and what can help you make a smart decision.

Start With the Function of the Part

Ask yourself: What does this part need to do?

- If it seals against another surface, you may need a smoother finish like Ra 0.8 or 0.4.

- If it slides or rotates, friction matters. Choose a finish that reduces wear.

- If it’s just a bracket or structural piece? You can probably go with Ra 3.2 or 6.3.

Look at Where the Part Is Used

Is it visible to the end user? Or buried inside a machine?

You don’t need a polished finish on something no one sees. I learned that the hard way. I once ordered Ra 0.4 for a part that sat behind a panel. Nobody saw it, and it didn’t move. That extra polish added days to lead time—and it made no difference.

Consider What Materials You’re Using

Some materials finish easier than others. Aluminum can reach Ra 0.8 fairly quickly. Stainless steel may take more time and cost. Knowing this can help set realistic goals.

Balance Cost with Performance

If you’re unsure, ask your supplier:

- “What finish do you normally provide?”

- “Can you show me sample parts at different Ra values?”

Sometimes a range is a better call. Asking for Ra 1.6–3.2 gives your supplier room to work—and keeps your cost down.

Choosing surface finish is about value, not perfection. The right finish is the one that helps your part do its job—without slowing down production or blowing your budget.

Conclusion

That gearbox housing I told you about? We changed the finish from Ra 0.8 to Ra 3.2 on the internal surfaces and instantly saved both time and money.

Now I ask better questions. You can too.

You’ve learned what surface finish tolerances are, how they affect cost and performance, and how to pick the right one.

So, what’s your next step? Where can you reduce waste or avoid over-specifying?

You don’t have to figure this out alone.

Reach out today—let’s talk about your part and make sure your finish works for your budget and your design.

Recommended Reads for You

If you need more options, take a look at our full range of products. You might find just what you need:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.