From Prototyping to Production

Top Precision CNC Machining & Custom Manufacturing Partner in China

- ISO 9001:2015 certified with ±0.01mm machining tolerance

- 60+ materials and 20+ surface finishes available

- Parts delivered as fast as 1 day with 30% shorter lead time

- End-to-end support from DFM to mass production

Explore MachMaster's manufacturing capabilities

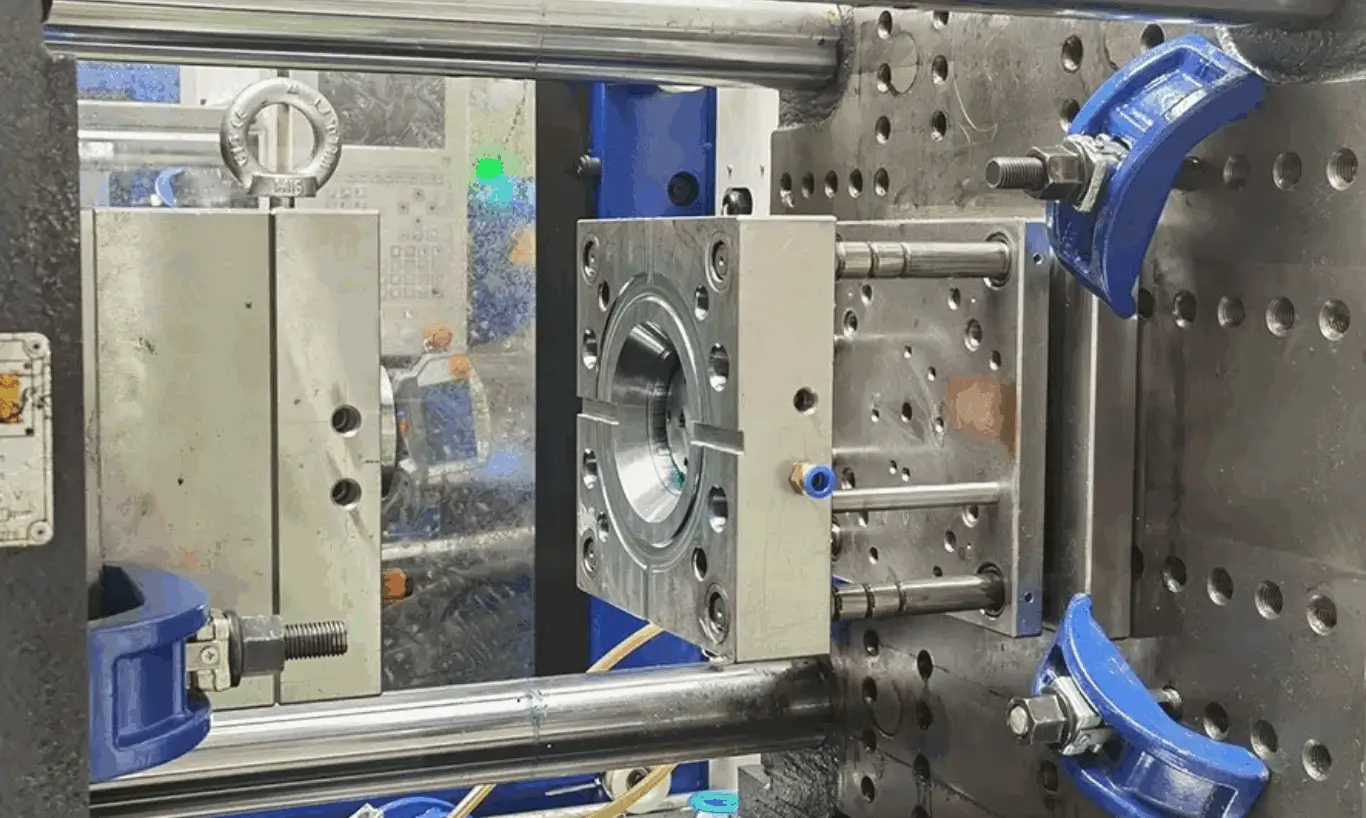

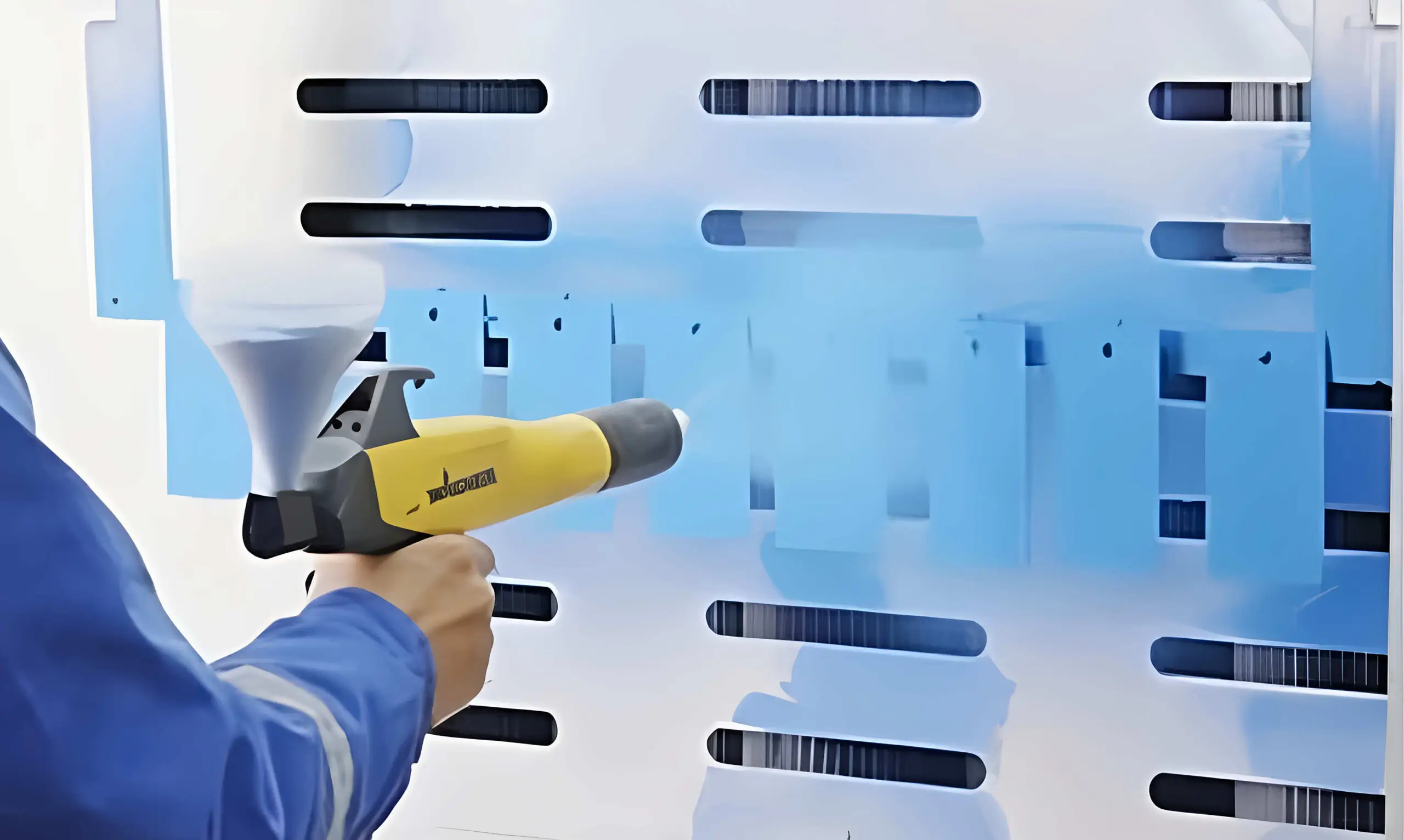

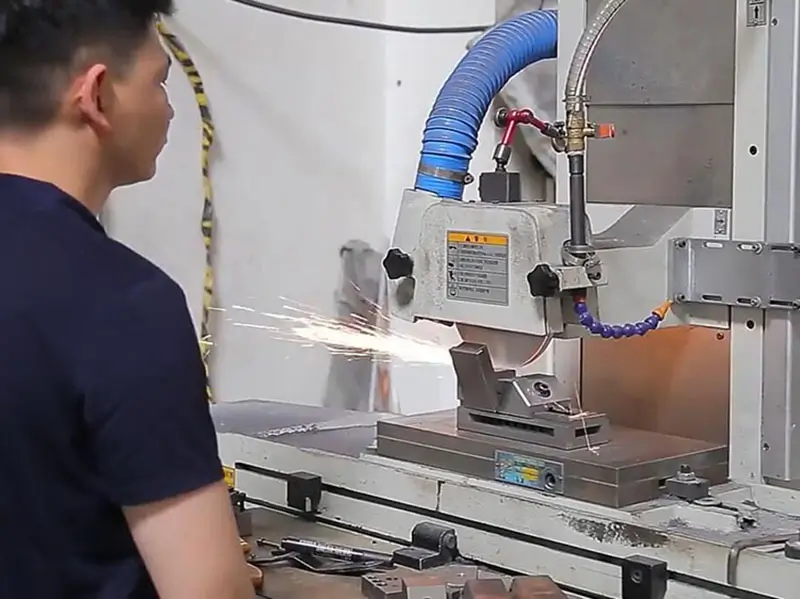

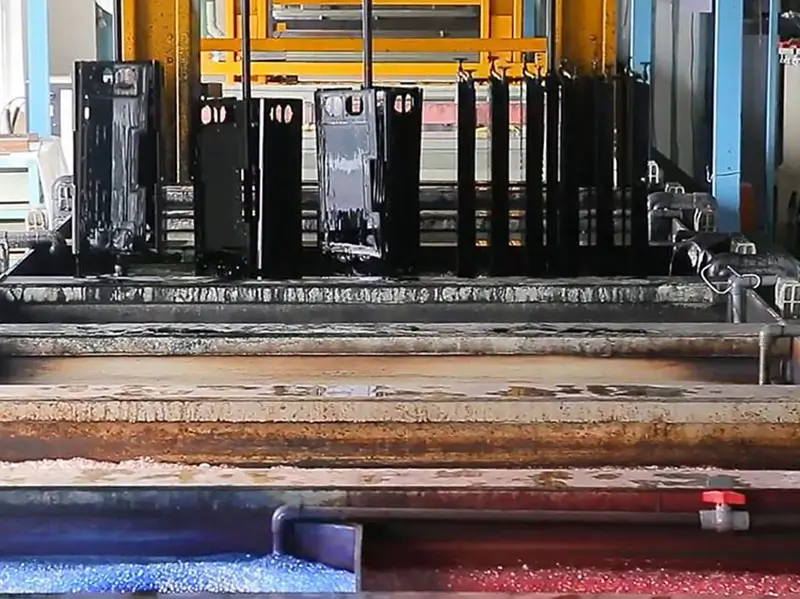

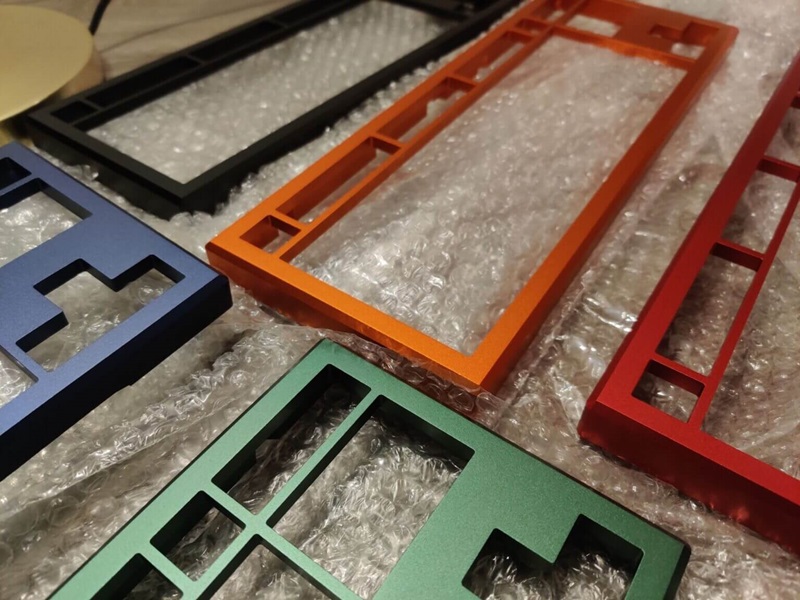

We provide one-stop manufacturing services including CNC machining, injection molding, sheet metal fabrication, and surface finishing, supported by a professional anodizing production line. Whether you need fast-delivery R&D prototypes or production from small-batch trials to large-scale volumes, we can be your trusted manufacturing partner. We specialize in producing structurally complex, highly customized precision components, ensuring every product is delivered on time with high efficiency and reliable accuracy.

Manage Your Machining Needs with MachMaster

Our Process from File to Finished Part

01 Upload CAD File

Submit CAD drawings and RFQs with part specs and application details to get fast engineering support.

02 Review & Quote

Receive pricing and DFM feedback to ensure your design is ready for manufacturing.

03 Start Production

We begin machining or molding with selected materials and strict quality standards.

04 Parts Delivered

Parts are carefully inspected, securely packed, and shipped on time—ready for your next stage.

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

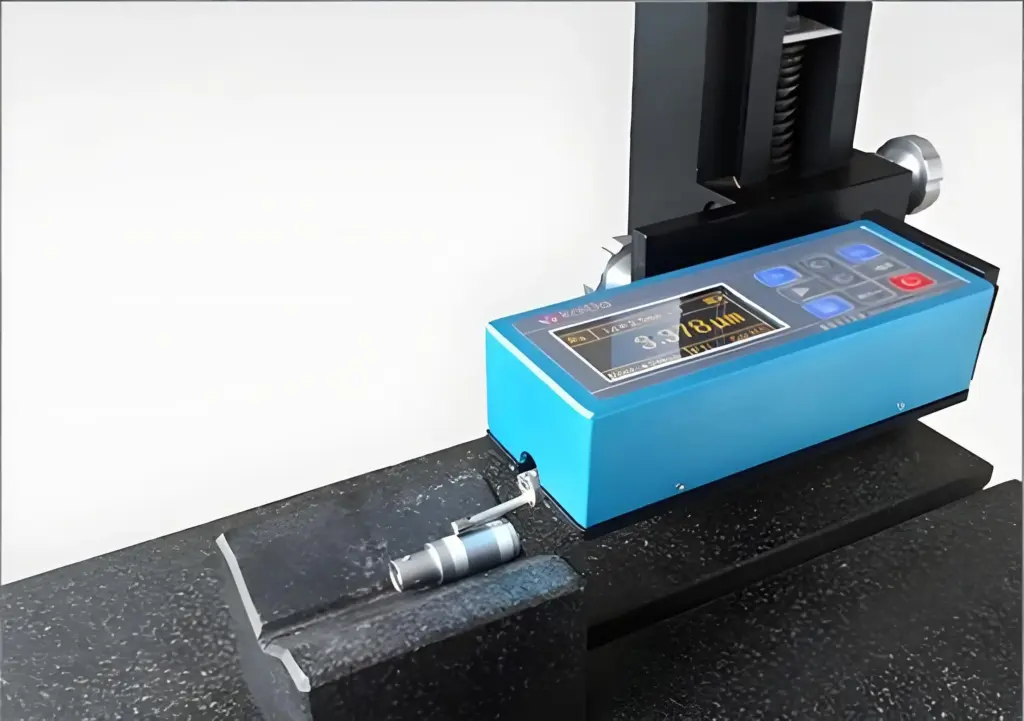

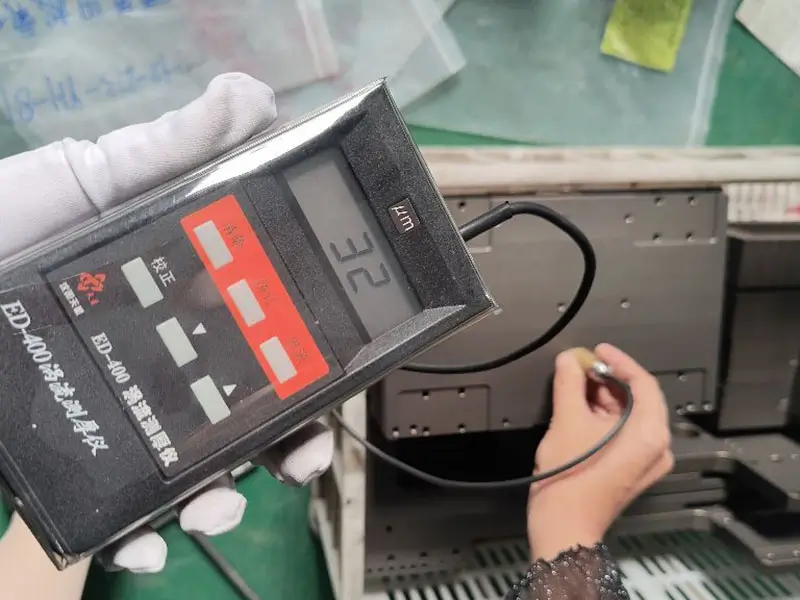

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Turning Designs into Precision Reality

See how MachMaster brings innovation to life through expert manufacturing.

Why Customers Choose MachMaster

Clear results, responsive service, reliable delivery—see why so many choose to work with us.

Trusted by Top Brands Worldwide

Answers to What Clients Ask Most

We operate under a strict zero-defect quality management system, covering raw material inspection, real-time production monitoring, and multi-dimensional finished product testing. ISO 9001 certified, we also support third-party inspection reports for complete quality assurance.

Customer satisfaction is our priority. If you are not satisfied within 7 days of receiving the goods, we offer rework, replacement, or full refund options based on your feedback.

Yes! Thanks to our intelligent production system and flexible scheduling, our delivery times are shortened by more than 30% compared to the industry average. For emergency orders, lead time can be compressed to 60% of the normal schedule.

We highly value customer confidentiality. We are willing to sign a Non-Disclosure Agreement (NDA) before you submit any drawings or sensitive information.

Absolutely. We provide a detailed production schedule and send weekly reports, including photos and videos showing real machining progress.

MachMaster offers one-stop custom manufacturing solutions covering CNC machining, plastic injection molding, sheet metal fabrication, and surface treatments such as anodizing and electroplating.

Costs are determined by factors like material selection, machining time, labor complexity, tool wear, and shipping. We always provide detailed quotations for full transparency.

Yes. We offer free DFM (Design for Manufacturability) analysis to help optimize your designs, improve machinability, and lower your production costs.