I remember getting a call from a client—frustrated and worried. Their freshly coated parts were already peeling just days after installation. It wasn’t the material. It wasn’t the environment.

The problem?

Their previous supplier skipped crucial prep work. And because of that, they lost an important customer.

Situations like that don’t just hurt your products. They hurt your business name.

I work with manufacturers who can’t afford failures like this—fabricators, OEMs, and suppliers counting on powder coating to hold up under pressure.

I’ve seen firsthand how small oversights in the process lead to big consequences.

That’s why I take the time to help businesses—especially small to mid-sized shops—understand what goes into a strong, lasting powder coat.

In this article, I’ll show you the full process we use every day in our shop, from degreasing to curing, so you know what to look for—and what to avoid.

Let’s start!

Step #1: Surface Cleaning and Pre-Treatment

Before you even think about spraying powder, you need to make sure your metal is spotless.

This isn’t just about looking clean—it’s about eliminating every possible barrier to adhesion. I’ve seen powder coatings that looked great on day one but started peeling after just a week.

The culprit? Skipping or rushing the surface prep.

The surface must be free of oils, rust, scale, and even microscopic residues. And it’s not just about cleaning—it’s about giving the powder something to grip. T

Here’s what the process typically looks like:

- Degreasing: You start with a solvent or alkaline cleaner to strip the part of any oils, machining fluids, or fingerprints. This step is non-negotiable—if there’s any grease left, the powder won’t stick.

- Blasting: Once degreased, the part is mechanically blasted with sand, shot, or glass beads. At MachMaster, this step is carefully controlled to remove rust, old paint, and mill scale while creating just the right surface profile for optimal powder adhesion.

- Chemical Pretreatment: After blasting, a phosphate or chromate solution is applied. This adds a thin, reactive layer that boosts both corrosion resistance and coating adhesion. It’s especially critical for outdoor or high-performance applications where durability matters.

- Rinse and Dry: Finally, the part must be rinsed to neutralize any residual chemicals, then dried completely—either with forced air or in a dry-off oven. Moisture is a silent killer in powder coating.

These steps may sound routine, but they’re the backbone of a professional-grade powder coat.

I once worked with a shop that thought they could cut time by combining rinse and dry in a single chamber. It seemed clever—until 200 parts showed up with blotchy, uneven finishes.

Surface prep isn’t where you experiment. It’s where you lock in the quality that the rest of the job will build on.

Step #2: Rinsing and Thorough Drying

Once the surface has been cleaned, the next critical phase is rinsing and drying.

This stage ensures that nothing—no detergent, no rust inhibitor, no trace minerals—is left behind to interfere with coating adhesion. Even microscopic residue or trapped moisture can cause major defects once the part enters the oven.

That’s why this step is all about control: controlling cleanliness, chemistry, and moisture.

The rinsing phase typically includes multiple stages. Each one plays a distinct role in getting the part clean and chemically balanced:

- Initial Water Rinse: Flushes away detergent and loose contaminants from degreasing or blasting.

- Chemical or Neutralizing Rinse: Applies phosphate or passivation for corrosion resistance, or balances acidic residues.

- Deionized Water Rinse: Eliminates any remaining mineral content and prevents spotting during drying.

Once rinsing is complete, drying takes over. The goal here is to remove all moisture, visible or not, from both the surface and internal cavities:

- Drip-Off Transfer Zone

- Drying with Heated Air

- Dry-Off Oven

Moisture may not look dangerous, but it can wreck an entire batch if ignored. I once saw a batch of powder-coated frames ruined because a single weld joint held water.

Once that part hit the curing oven, the steam caused bubbling and pinholes all over the finish.

Thorough rinsing and drying may seem like background work, but it’s the backbone of coating quality. If you want powder to stick evenly and last for years, this step is where that success begins.

Step #3: Masking and Fixturing the Parts

Before coating can begin, you need to protect the areas that should stay bare. Threaded holes, electrical grounding points, tight-fit assemblies—these all need to be masked.

If they get coated, you’re looking at rework, thread chasing, or worse—scrapping the part entirely. Masking isn’t the most exciting part of the process, but it’s one of the most important for fit, function, and finish.

The process starts with a close look at drawings or customer specs. Any area that needs to stay clean must be clearly identified and protected. From there, masking and fixturing move hand-in-hand:

- Identify Areas to Be Masked: Operators review blueprints or 3D models to find surfaces that need to remain uncoated—typically threaded inserts, bearing seats, or ground contact points.

- Apply High-Temp Masking Materials: Flat surfaces or edges get heat-resistant tape, while holes, threads, and cavities are plugged or capped using high-temp silicone pieces.

- Fixture for Positioning and Coating Access: Parts are mounted on custom racks that support weight and maintain proper spacing.

Once everything is masked and fixtured, a final check is essential. Loose tape or poorly inserted plugs can shift during spraying or fall out entirely in the oven.

I’ve seen it happen—an operator missed one threaded insert on a high-volume batch. It got coated, cured, and couldn’t be salvaged. That mistake held up an entire assembly line waiting on rework.

Since then, we always double-check every plug and piece of tape before moving forward.

Masking and fixturing might not get much attention, but they’re what keep everything downstream running smooth. Skipping or rushing this step is how a good finish turns into a costly problem.

Step #4: Grounding the Workpiece

Grounding isn’t just a box to check—it’s the backbone of the entire powder coating process.

Without a solid ground, the electrostatic charge won’t build, the powder won’t cling, and your coverage will be patchy at best.

A proper ground doesn’t just help transfer powder—it reduces waste, ensures uniform coating, and keeps rework to a minimum.

The setup starts by ensuring bare metal contact. Any spot where the part touches the fixture needs to be completely free of coatings or debris. From there, the grounding steps look like this:

- Establish Contact with Bare Metal: Each part is clipped, hung, or clamped in a way that guarantees direct contact between clean metal surfaces.

- Confirm Electrical Continuity: Operators or sensors use meters to verify that the circuit from the part to the grounding point is complete. At MachMaster, this check is standard procedure, since even slight resistance in the connection can weaken the electrostatic field and reduce powder attraction.

- Stabilize Fixture Connections: Fixtures are tightened down to prevent wiggling or vibration during spraying. If the connection shifts mid-process, the ground could break—and powder won’t stick where it should.

- Isolate Non-Conductive Materials: Plastic inserts, rubber bushings, or non-metal surfaces are masked or separated to prevent static loss. This keeps the electric field focused on the metal surface that actually needs coating.

You’d be surprised how often this step gets overlooked.

I once saw a batch come out with powder only on one side—turns out, the ground clamp was loose, and the part never built up a proper charge.

It looked like a spray gun problem, but it was really a grounding issue hiding in plain sight.

A reliable ground might seem like a small detail, but it’s what makes the entire electrostatic process possible. Get it wrong, and you’ll waste time, powder, and parts. Get it right, and everything flows from there.

Step #5: Applying the Powder Coating

This is the moment when preparation turns into product. Powder application is where technique meets technology. Everything from the way the gun is set up to how the operator moves their hand affects the final result.

The goal? Full, even coverage at the right thickness, with no waste or rework.

It starts with getting the equipment and grounding set up properly:

- Load the Powder Into the Hopper: Powder coating material is poured into a fluidized hopper that keeps it aerated for smooth flow into the spray gun.

- Connect and Verify Grounding: Before spraying begins, the operator checks the ground path between the part and the booth system. Without that electrostatic link, the powder won’t cling, and you’ll get patchy or uneven coating.

Once the part is grounded and the powder is flowing, application technique takes over:

- Adjust Gun Settings and Start Spraying: Spray guns are dialed in for voltage, flow rate, and air pressure based on the part’s geometry. The operator then applies the powder in even, overlapping strokes to build a smooth coat.

- Focus on Hard-to-Reach Areas: For deep recesses or blind spots, the operator may circle back with a second pass or reposition the gun to improve coverage. Complex parts sometimes require a second operator for complete results.

Even with the best prep and equipment, this step still relies heavily on operator awareness. Powder builds fast, so consistency and control are key.

I remember one project where the operator forgot to recalibrate after switching to a larger part. The gun pressure was too high, and the powder blew past the edges without sticking.

The result? Spotty coverage that didn’t show up until after curing—and a full batch that had to be stripped and redone.

When done right, powder application is smooth, efficient, and almost effortless. But if you rush or skip the details, those mistakes bake in permanently.

Step #6: Heat Curing in the Oven

Once the powder is applied, it’s not a finished product until it’s cured. This step transforms powder into a

Powder coating doesn’t become a functional finish until it’s cured. This stage turns loose powder into a solid, continuous film that’s bonded to the metal surface.

It might look finished after spraying, but without proper heat and time, that coating will crack, peel, or stay soft.

Here’s how the curing process works in practice:

- Preheat the Oven to the Target Temperature: The oven is brought to a stable setting—typically between 350°F and 400°F—based on the powder manufacturer’s data sheet. Consistent oven temperature ensures every part gets equal heat exposure.

- Load the Parts onto the Rack or Conveyor: Parts are transferred into the oven using hooks or racks, with care taken to prevent any contact between parts or surrounding surfaces. Even a slight bump can leave an imprint in the final finish.

- Monitor Metal Temperature, Not Just the Air: Infrared sensors or thermocouples are used to measure when the metal itself reaches the required curing temperature. Since powder doesn’t begin to flow until the part gets hot, tracking only air temp can lead to inconsistent results.

- Hold for the Correct Dwell Time: Once the part hits curing temperature, it must stay there for a specified period—usually 10 to 20 minutes. This allows the powder to melt, flow out, and chemically cross-link into a hard, protective shell.

I remember one job where a batch of cast aluminum parts came out looking flawless—but failed durability testing within a week.

The issue? They hadn’t held the curing temp long enough. The powder had melted but never fully bonded. We had to strip and recoat the entire order.

Curing is the final test of everything that came before it. Get it right, and you lock in strength, appearance, and performance all at once.

Step #7: Controlled Cooling Process

Just because a part comes out of the oven doesn’t mean it’s ready for handling. Cooling may seem passive, but it’s a critical step in locking in the integrity of the finish. Rush it, and you risk distortion, scuffing, or even subtle defects that show up later.

The goal is to let the part return to room temperature slowly and evenly—no shortcuts, no fan blasts, and definitely no hands-on contact while it’s still hot.

Here’s how the cooling process is typically managed:

- Transfer the Part to a Designated Cooling Zone: Once the curing cycle is complete, parts are moved from the oven to a clean, enclosed area.

- Allow Natural Air Cooling to Take Place: Parts are cooled by ambient airflow rather than forced fans. This slower cooling process helps prevent warping, especially on large or thin-walled components that might deform under rapid temperature change.

- Avoid Premature Handling: Operators are trained not to touch or move the part until it’s completely cool to the touch. Grabbing too soon can leave fingerprints, dents, or pressure marks in finishes that are still setting.

- Maintain Part Spacing During Cool-Down: Fixtures are designed to keep parts separated during cooling, allowing air to circulate around each one. This reduces the chance of coated surfaces sticking together or getting abraded from contact.

While it’s tempting to speed things up here—especially in high-volume shops—this is a step where patience pays off.

Cooling too quickly or handling too soon can undo everything you worked for in prep, spraying, and curing.

Letting the part cool completely ensures the finish cures stress-free and looks exactly how it should.

Step #8: Final Inspection and Quality Control

Even the best-looking finish can hide a flaw if you don’t check thoroughly.

That’s why inspection isn’t optional—it’s the last line of defense between the production floor and your customer. Final quality control ensures the coating meets visual, mechanical, and performance standards.

When done right, it catches minor issues before they become warranty claims or rejected shipments.

Here’s what a solid QC routine includes:

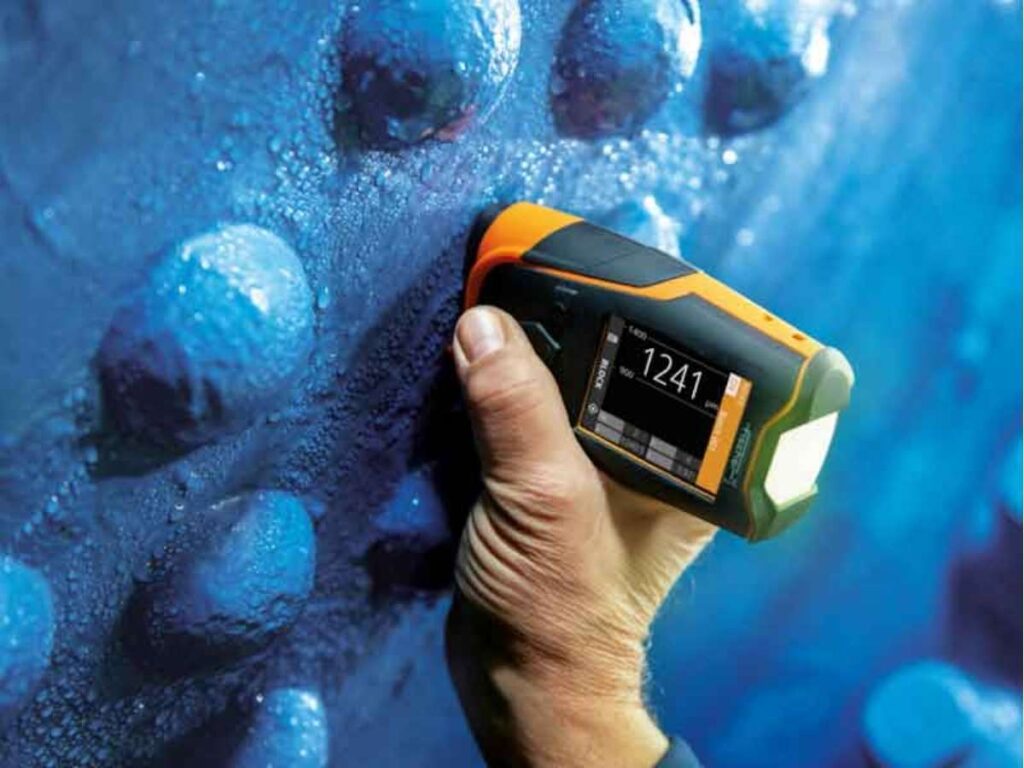

- Measure Coating Thickness: A dry film gauge is used to confirm the powder is within the specified range—typically between 1.5 to 3 mils, depending on application. This ensures durability while avoiding excess buildup that could cause chipping or dimensional interference.

- Test for Adhesion and Cure Quality: Sample parts may undergo cross-hatch or MEK solvent rub tests to confirm proper bonding and full cure. Failures in these tests often point to earlier issues like poor prep, grounding, or underbaking.

- Verify Color and Finish Consistency: Each batch is checked for color match using either visual comparison or digital color meters. This is crucial when parts will be installed side-by-side or must meet brand color requirements.

I once worked with a shop that skipped coating thickness checks for a rush job. The finish looked perfect—but when the customer tried to assemble the part, the excess powder caused fitment issues.

That small oversight ended up costing more in returns than the job was worth.

Quality control isn’t just about spotting problems—it’s about proving the process worked. And in powder coating, that’s what earns trust and repeat business.

Conclusion

Powder coating isn’t magic, it’s a smart, proven process. You’ve just seen it unfold, one step at a time.

From surface cleaning to quality control, you now understand the “how” and “why” behind each phase.

So what’s next for you? A better process. A cleaner finish. A smarter vendor.

Let MachMaster help you get there.

Contact us today to make your powder coating project hassle-free.

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.