A client sent over their part file. It looked fine. Tight tolerances. Clean geometry.

Then the die caster sent it back.

“Redesign needed. Won’t release properly.”

That’s when we realized we had designed blind.

Understanding how die casting works changes everything. It saves time. Saves cost. Saves relationships.

After working across dozens of projects, from tooling approvals to final QC, I’ve seen how powerful that knowledge can be.

This guide lays it all out. The process. The reasons. The steps. What to expect and what to avoid. It’s everything you need to move forward with confidence, and no surprises.

Let’s jump in!

1. What Is Die Casting

If you’ve ever held a sleek aluminum phone case or popped the hood of a car and admired the precision of an engine component, there’s a good chance you were looking at a die-cast part.

I remember the first time I walked into a die casting facility, it was loud, hot, and everything moved with urgency. What struck me wasn’t just the machinery, but the efficiency. The speed at which these machines could produce identical parts was unbelievable. As a product development lead at the time, I realized this wasn’t just about “how parts are made.” It was about how to manufacture scales without sacrificing quality.

Key Characteristics

- Uses non-ferrous metals That means no iron. Common materials include:

- Aluminum (lightweight, corrosion-resistant)

- Zinc (great for small, detailed parts)

- Magnesium (ultra-light, strong)

- High-pressure injection This isn’t your average pour-and-pray method. We’re talking 1,500 to 25,000 psi, pushing molten metal into a precision mold faster than you can blink.

- Net-shape or near-net-shape parts What comes out of the mold is almost ready to use, minimal machining needed. That’s a huge cost and time saver, especially in high-volume runs.

You might not always see it on the surface, but behind a smooth finish or tight-tolerance part, there’s often a die casting process that made it possible.

And if you’re designing or buying those parts, knowing how this process works gives you a major edge.

2. Advantages of Die Casting

When you’re weighing manufacturing options, it all comes down to trade-offs.

Speed vs. quality. Cost vs. consistency. Flexibility vs. precision.

Here’s the truth: if you’re producing high volumes of metal parts and you care about tight tolerances, clean finishes, and short cycle times, die casting isn’t just a good option, it’s often the best one.

Let me walk you through why:

Fast Production Speeds

Die casting is built for speed. Once the tooling is ready, you can pump out hundreds or thousands of parts per day, all with near-identical dimensions.

- Cycle times are measured in seconds, not minutes.

- Ideal for high-volume runs where time-to-market matters.

- Fewer delays, fewer bottlenecks, and fewer headaches on your end.

I once worked with a supplier who went from prototype to 25,000 finished parts in less than three weeks, because they already had die casting lines running and ready to go.

Excellent Dimensional Accuracy

You don’t want to chase tolerances with post-processing. With die casting, you often don’t have to.

- Typical tolerances: ±0.002″ to ±0.005″

- Net-shape or near-net-shape parts mean fewer machining steps

- Complex geometries are repeatable across every cycle

If you’re designing enclosures, mechanical parts, or structural components, this kind of repeatability is gold.

Superior Surface Finish

Here’s where die casting really pulls ahead from sand casting or other methods:

- Clean, smooth surfaces straight out of the mold

- Minimal finishing or polishing required

- Great for consumer-facing parts or painted finishes

You can go from casting to coating, or even direct assembly, with fewer prep steps in between.

Design Flexibility for Complex Parts

Tight corners. Thin walls. Sharp detail.

Die casting lets you do more with your geometry without paying a premium:

- Add ribs, bosses, and internal features with ease

- Uniform wall thicknesses improve structural integrity

- Design freedom without blowing out tooling or per-part cost

Just remember: good design for die casting still requires proper draft angles and flow considerations. But once you nail those, the possibilities open up fast.

3. Types of Die Casting Processes

Not all die casting is created equal.

The type of die casting process you choose can have a huge impact on part quality, production speed, and even long-term tooling cost.

The two main categories, hot chamber and cold chamber look similar on the surface. But once you’re on the factory floor, the differences are hard to miss. I learned that firsthand after approving a zinc tooling design… only to find out the same setup wouldn’t work for aluminum. That mistake cost us two months and a retooling fee I still don’t like to talk about.

So let’s break down how they work, and when to use each one:

Hot Chamber Die Casting

This is the faster, more integrated version of die casting, ideal when you’re working with metals that melt at lower temperatures, like zinc and magnesium.

How It Works:

- The metal is melted in a built-in furnace attached directly to the casting machine.

- A gooseneck mechanism pulls the molten metal into the injection chamber.

- From there, it’s injected into the die under pressure.

Key Benefits:

- Fast cycle times (typically faster than cold chamber)

- Less handling = lower risk of contamination

- Perfect for small, detailed parts where speed matters

Best For:

- Zinc die casting, especially in high-volume production

- Magnesium components like electronic housings

- Parts requiring tight tolerances and high repeatability

Cold Chamber Die Casting

This one’s built for tougher metals, like aluminum and brass, that melt at higher temperatures and would damage the internal parts of a hot chamber system.

How It Works:

- The metal is melted in a separate furnace.

- A measured amount of molten metal is ladled into the injection chamber.

- A hydraulic plunger then forces it into the die cavity at high pressure.

Key Benefits:

- Can handle high-melting-point alloys

- Better for large or structural parts

- Common in automotive and aerospace manufacturing

Best For:

- Aluminum die casting, including engine components and housings

- Brass or copper-based alloys in industrial products

- Larger parts with higher strength requirements

4. Common Materials Used in Die Casting

Choosing the right material for your die-cast part isn’t just about metal selection, it’s about performance, cost, appearance, and manufacturability.

Each alloy comes with its strengths and trade-offs. And if you’re working with tight deadlines, tough specs, or industry-specific standards, the wrong choice can stall your entire production run.

At MachMaster, we help clients every day navigate this decision, not just based on material data sheets, but on real-world application demands. Whether you need strength, weight reduction, or cosmetic perfection, the material you choose shapes everything.

Let’s walk through the most common metals used in die casting and what they’re best for:

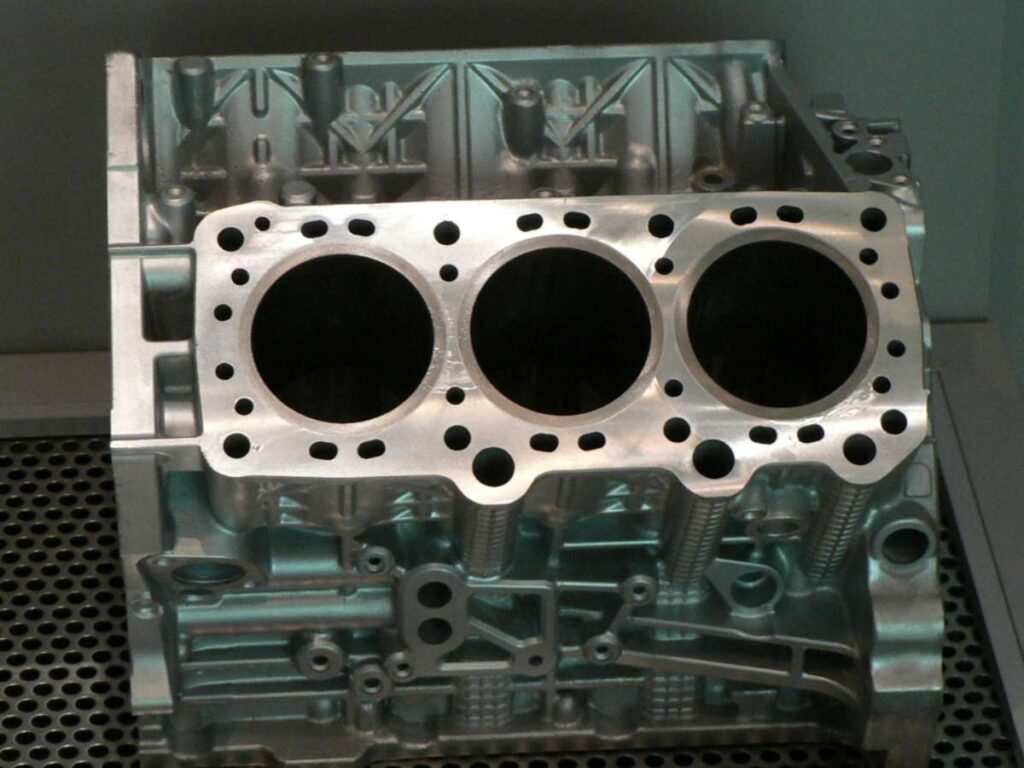

Aluminum Alloys

If you’re after lightweight strength, aluminum is often the top choice.

Why Use It:

- Excellent strength-to-weight ratio

- Naturally corrosion-resistant

- Good thermal and electrical conductivity

- Handles high operating temperatures

Common Grades:

- A380: Industry standard for general applications (electronics, housings)

- A360: Better corrosion resistance and pressure tightness

- ADC12 (Asia markets): Similar to A380, great for flow and castability

Ideal For:

- Automotive parts (engine blocks, transmission housings)

- Consumer electronics (frames, heatsinks)

- Industrial equipment (enclosures, brackets)

Zinc Alloys

Zinc is the go-to choice for small, complex, high-detail parts, especially where tight tolerances matter.

Why Use It:

- Extremely fluid, fills thin walls and intricate features easily

- High dimensional stability and impact strength

- Longer die life than aluminum (great for high-volume runs)

- Lower melting point = lower energy costs and tool wear

Common Grades:

- Zamak 3: Most widely used zinc alloy

- Zamak 5: Higher strength, slightly less ductility

- ZA-8: Excellent for structural components

Ideal For:

- Connector housings

- Gear mechanisms

- Consumer hardware like latches, locks, and hinges

At MachMaster, we helped an industrial hardware client switch from CNC machining to zinc die casting for their locking handle sets. The change slashed part cost by 45%, without compromising strength or finish.

Magnesium Alloys

When weight is a priority, magnesium can’t be beat. It’s the lightest structural metal used in die casting.

Why Use It:

- Ultra-lightweight yet strong

- Excellent damping capacity (vibration absorption)

- High dimensional stability

- Good for parts needing EMI/RFI shielding (electronics)

Common Grade:

- AZ91D: Most commonly used magnesium alloy, great balance of strength, corrosion resistance, and castability

Ideal For:

- Laptop and tablet housings

- Automotive interior parts

- Portable devices

Other Specialty Alloys (Less Common)

While aluminum, zinc, and magnesium cover 95% of die casting needs, some niche applications call for:

- Brass/Bronze: For highly wear-resistant parts

- Copper-based alloys: Great electrical/thermal conductivity

- Lead-free options: For regulatory compliance (e.g., RoHS, REACH)

These materials are less common in high-pressure die casting but can be sourced or engineered when the application demands it.

5. The Step-by-Step Die Casting Process

Understanding how die casting works isn’t just about knowing where molten metal goes, it’s about seeing the entire system in motion.

From the first design sketch to the final part being ejected from the machine, every step affects your lead time, your cost, and your product quality.

At MachMaster, we walk our clients through this process every day, so they know what’s happening, what to expect, and how to make smarter decisions at each stage.

Let’s break it down:

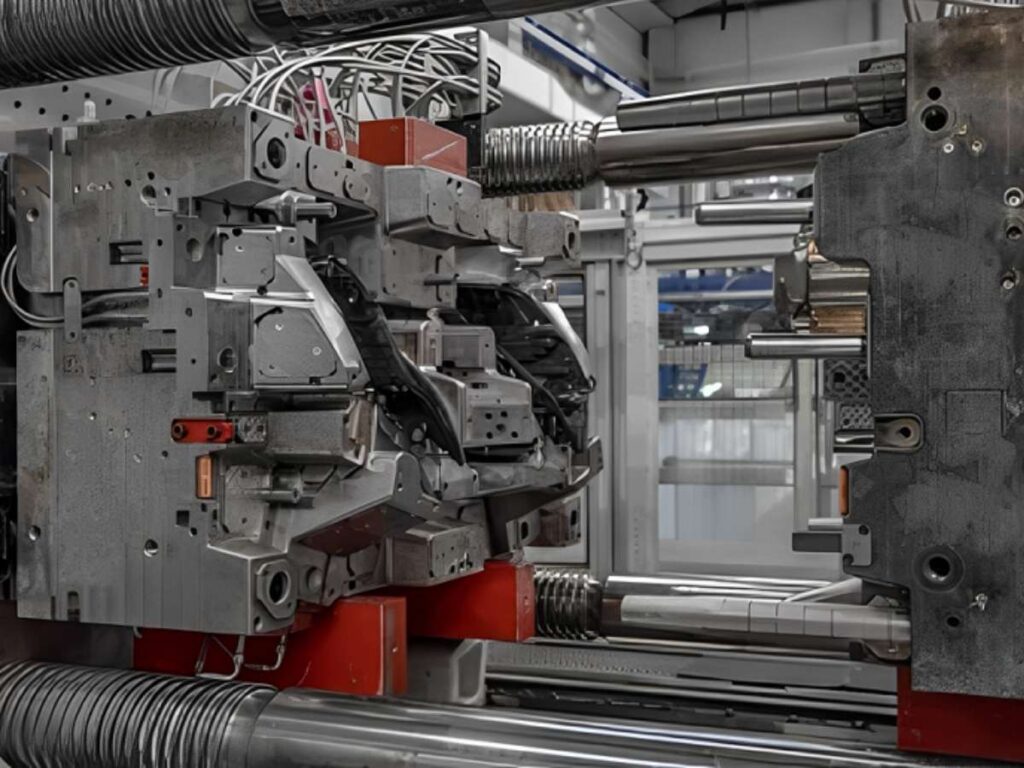

Step#1 Die (Mold) Design and Preparation

Everything starts with the die.

This is a custom steel mold designed to match the exact geometry of your part. It’s built in two halves, cover die (stationary) and ejector die (movable), that clamp together during each cycle.

Key Considerations:

- Draft angles to release the part cleanly

- Vents to release trapped air

- Cooling channels to control solidification

- Parting lines to avoid cosmetic or structural issues

Step#2 Melting the Metal

The selected metal, aluminum, zinc, or magnesium, is melted down in a furnace.

- For hot chamber machines, the metal is melted inside the machine itself (zinc, magnesium).

- For cold chamber machines, the metal is melted in a separate furnace (aluminum, brass), then ladled into the machine.

Why It Matters:

- Temperature control is critical, too hot, and you get flashing and shrinkage; too cold, and you risk incomplete fills.

- Cleanliness is key to avoiding inclusions or porosity.

Step#3 Injection Into the Die

This is the heart of the process.

The molten metal is forced into the die cavity at extremely high pressure, often between 1,500 to 25,000 psi, in just milliseconds.

Key Details:

- Pressure ensures the metal fills every corner of the mold.

- Vents release air to prevent defects like cold shuts or blowholes.

- The die stays clamped shut under force to hold the shape.

On a zinc housing project we ran, increasing injection speed by just 10% eliminated a recurring short-fill defect. Small tweaks here have a big impact on quality.

Step#4 Holding and Solidification

Once the metal fills the cavity, it’s held under pressure as it cools and solidifies inside the mold.

Why This Step Is Critical:

- Prevents shrinkage and internal voids

- Ensures structural integrity and tight tolerances

- Cooling systems in the die regulate solidification time

Cycle time at this stage depends on part size, material, and thermal design of the die.

Step#5 Mold Opening and Part Ejection

After the part has solidified, the die opens. Ejector pins in the movable half push the part out. This is fully automated in most high-volume production lines.

Tips:

- Ejection must be smooth to prevent deformation or surface marks

- Well-designed dies ensure minimal sticking or resistance

Step#6 Trimming and Post-Processing

Most die cast parts come out with a bit of extra metal called flash, as well as sprues and runners. These are trimmed or machined off, usually with mechanical presses or automated cutters.

Optional Secondary Processes:

- Deburring

- Shot blasting

- Surface coatings (powder coating, anodizing, plating)

- CNC machining for tighter tolerances or functional features

6. Applications of Die Cast Parts

When it comes to real-world use, die casting shows up everywhere, and for good reason.

If you need precise, durable, scalable metal parts at high volumes, die casting delivers in ways that few other methods can. From under the hood to inside your laptop, die-cast components are often the unsung heroes of modern product design.

Let’s take a closer look at where die cast parts make the biggest impact:

Automotive Industry

Die casting plays a major role in modern vehicle production, thanks to its ability to produce complex parts quickly while maintaining high structural performance.

Common Applications:

- Transmission cases

- Engine blocks and covers

- Brackets and structural supports

- Airbag housings and steering components

- Electric vehicle battery housings and motor mounts

Consumer Electronics

Precision, aesthetics, and repeatability, this is where die casting shines in electronics manufacturing.

Common Applications:

- Laptop and tablet frames

- Smartphone enclosures

- Heat sinks and internal brackets

- Game console casings

- Smart device housings

Zinc and magnesium are especially popular here due to their ability to form thin walls and fine details while keeping the final product lightweight.

We’ve worked with product teams developing handheld medical devices that needed rigidity and elegance. Die-cast magnesium gave them exactly that, at volume and without compromising the feel in-hand.

Industrial Equipment

In factories, construction sites, and warehouses, die-cast parts are used to protect, support, and connect.

Common Applications:

- Gear housings and motor covers

- Pneumatic and hydraulic valve bodies

- Sensor enclosures

- Mounting brackets and structural supports

Die casting allows for parts that are tough, corrosion-resistant, and highly repeatable, especially important for mission-critical or load-bearing components.

Power Tools and Appliances

Whether it’s a handheld drill or a coffee machine, die cast parts are essential to consumer and commercial hardware.

Common Applications:

- Tool bodies and handles

- Motor housings

- Heat shields

- Control knobs and bezels

Zinc and aluminum are the go-to materials here, offering durability without adding weight, plus the ability to be painted or plated for a sleek final look.

7. Die Casting vs. Other Manufacturing Methods

Choosing the right manufacturing method can make or break your project, literally and financially.

While die casting offers incredible advantages for high-volume metal production, it’s not always the only (or best) option. Depending on your part size, volume, design complexity, or material requirements, you might be weighing several alternatives.

Below is a side-by-side comparison of die casting vs. five other common manufacturing methods used for metal or similar applications:

| Feature / Method | Die Casting | Sand Casting | Investment Casting | CNC Machining | Injection Molding | 3D Printing (Metal) |

| Ideal Volume | High | Low to Medium | Low to Medium | Low to Medium | High | Low |

| Material Types | Non-ferrous metals (Al, Zn, Mg) | Ferrous & non-ferrous metals | Ferrous & non-ferrous metals | All metals, plastics | Thermoplastics | Metals (Al, Ti, SS) |

| Tooling Cost | High upfront, low per part | Low | Medium | None | High | Low |

| Lead Time | Medium (tooling + setup) | Short to medium | Long (complex mold-making) | Short | Medium to long | Short to medium |

| Dimensional Accuracy | High (±0.002″–0.005″) | Low to medium | Medium to high | Very high (tight tolerances) | High | Very high |

| Surface Finish | Smooth out of mold | Rough (requires finishing) | Smooth (requires minor finishing) | Depends on tooling/machining | Excellent | Smooth, depending on printer |

| Part Complexity | High (complex geometries possible) | Low to medium | High | Very high (but costly) | High | Very high |

| Material Waste | Low (recyclable scrap) | Medium | Medium | High (subtractive process) | Low | Low |

| Best Use Cases | Automotive, electronics, tools, enclosures | Large metal parts, low-run jobs | Aerospace, art castings, complex geometry | Precision parts, prototyping, low volumes | Plastic parts, enclosures, mass production | Prototyping, aerospace, medical |

Key Takeaways

Die Casting is your go-to for high-volume production of metal parts with tight tolerances and minimal finishing. Once tooling is built, it’s extremely cost-efficient per unit. Sand Casting is better for large parts or lower-volume needs, but it sacrifices precision and finish.

Investment Casting handles complex parts well, but it’s slower and more expensive per part.

8. Factors to Consider When Choosing Die Casting Services

Choosing a die casting partner isn’t just about machines and metal. It’s about trust, technical capability, and the ability to deliver consistent quality at scale.

We’ve seen projects get delayed, not because the product was poorly designed, but because the wrong partner was chosen. Either they weren’t equipped for the alloy, couldn’t hold tolerances, or simply didn’t have the production capacity to hit deadlines when it mattered most.

Here are the key factors you should be paying close attention to:

Tooling Capabilities and Engineering Support

The quality of your parts begins with the quality of the die. Ask whether your supplier offers in-house tooling or relies on third parties. A shop that controls tooling in-house often delivers faster lead times and tighter quality control.

But tooling isn’t just about machining steel, it’s about design collaboration. You want a partner who can review your CAD files, recommend changes for castability, and spot potential issues before you spend a cent on tooling.

If you’re sending designs overseas without strong DFM feedback, you’re taking a gamble. Look for a supplier who works with you, not just for you.

Material Expertise

Not every die caster is good with every alloy. Some specialize in zinc for small precision parts, others in aluminum for structural components. A few have cross-material experience that allows flexibility as your product line evolves.

Make sure the supplier not only offers your material of choice but also has experience producing similar parts with it. Alloy selection affects tool wear, surface finish, strength, and price, so it’s not a decision you want to make in a vacuum.

Production Volume and Capacity

Volume alignment is crucial. If your job is too small for a high-capacity supplier, it’ll likely get deprioritized. If it’s too big for a small shop, you’ll face delays, inconsistent batches, or scaling problems down the line.

Discuss your current volume, your forecast, and whether your supplier can scale with you. Ask about cycle times, press sizes, and shift schedules. The right partner won’t just have the machines, they’ll have the workflow discipline to keep your parts moving.

Quality Control and Certifications

It’s one thing to say a part is good. It’s another to prove it, every time.

You want a supplier that uses real inspection processes, dimensional checks, pressure tests, X-ray analysis for structural parts when needed. And if you’re serving regulated industries like automotive or medical, you’ll also need certifications like ISO 9001, IATF 16949, or others.

Conclusion

That part we redesigned?

It passed the next review with no issues. No delays. No extra cost.

That’s what knowing the die casting process can do for you.

We walked through each step, what happens, how it works, and why it matters. Now, you can design smarter, source better, and avoid costly surprises.

Machmaster helps businesses do this every day. From design checks to final parts, we’re here to guide you.

So, what’s the next part you want to get right?

Contact MachMaster today. Let’s make sure your next design is ready for production.

More Guides and Tips to Explore

Not quite what you’re looking for? Explore our wider product range for more choices:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.