Back when I worked in product development, I hit a wall trying to figure out why a supplier kept delaying our parts.

Turns out, I didn’t understand the die casting process at all, and that was the real bottleneck.

That mistake taught me to pay more attention to manufacturing details.

Today, I write with that same mindset: help businesses understand what’s really happening behind the scenes. You can trust this guide to walk you through each die casting step with just the info you need.

This article is practical, visual, and built to answer the exact questions you’re likely asking right now. No jargon, no fluff, just the process, clearly explained.

Not all production problems start on the shop floor. Sometimes, they start with what we don’t know.

Let’s get started!

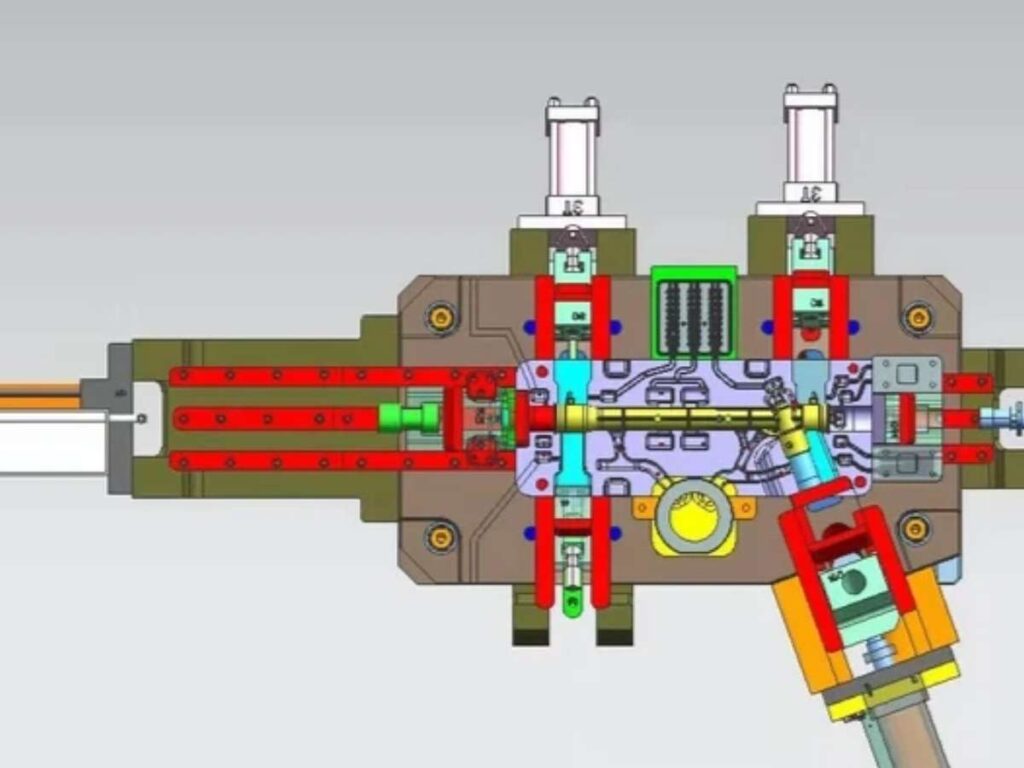

Step #1: Mold Design and Tooling

This is where the entire die casting journey really begins, and it’s more than just sketching shapes on a screen. I’ve seen firsthand how a well-planned mold can keep a whole production line running smooth—and how a rushed one can cause non-stop delays.

- Create A Detailed Part Model: Begin by developing a complete 3D model of the part using CAD software. This will serve as the foundation for the die design and needs to include all critical features and tolerances.

- Design The Die Layout: Use the part model to create the layout for the mold, including cavities, runners, gates, vents, and overflow areas. Think through how the metal will flow and fill each section to avoid short shots or air pockets.

- Incorporate Draft Angles And Fillets: Add draft angles to the vertical surfaces and rounded edges where needed to allow for smooth part ejection. This helps prevent sticking and reduces the risk of damage to both the part and the mold.

- Run Flow And Fill Simulations: Before any steel is cut, simulate the molten metal’s path through the mold using software. These simulations help catch design flaws early, such as turbulence, cold shuts, or uneven filling.

- Machine The Mold Components: Cut the die blocks using CNC or EDM processes based on the final approved design. This includes shaping the cavity, core, slides, and any inserts to match the part geometry precisely.

- Install Cooling And Venting Features: Add channels to manage temperature and place vents where trapped gases may accumulate. This step improves both cycle time and part quality by controlling heat and airflow inside the mold.

Step #2: Preparing the Die Casting Machine

I’ve always looked at this step as setting the stage before the real work begins. If something’s off here: misaligned die, poor temperature control, bad timing—it’s going to show up later in the parts. That’s why I like to go through setup with a clear checklist to avoid surprises down the line.

- Secure The Mold Onto The Platens: Start by mounting the two halves of the mold to the machine’s platens using clamps or bolts. Make sure the alignment pins are seated correctly so the die closes evenly without gaps.

- Connect All Cooling And Hydraulic Lines: Attach the cooling lines to the mold’s internal channels to help manage temperature during cycles. Then connect any hydraulic or pneumatic lines that control moving parts like slides or cores.

- Insert The Shot Sleeve And Attach The Plunger: Slide the shot sleeve into place on the injection system and install the plunger. Check that everything moves freely and lines up with the mold’s gating system.

- Preheat The Mold Gradually: Turn on the heaters or bring in an external heat source to slowly raise the die temperature. This helps reduce wear from thermal shock and makes sure the first few shots flow correctly.

- Calibrate The Machine Settings: Input the proper values for clamp force, injection pressure, fill speed, and hold time. Once everything is set, run a few dry cycles without metal to confirm that the machine and mold are synced up and ready to go.

Step #3: Melting the Metal

I’ve always found this part fascinating. Watching solid ingots turn into glowing liquid metal ready for casting never really gets old. But behind the glow and heat is a process that needs consistency, control, and a good bit of patience to get right every time.

- Choose The Right Metal Alloy: Start by selecting the metal alloy that fits your part’s performance needs: zinc, aluminum, and magnesium are the most common. Each one melts at a different temperature and has its own casting behavior.

- Load The Metal Into The Furnace: Place the raw metal ingots into the melting furnace, making sure it’s clean and free of moisture or contaminants. Over time, continue to top it up with fresh ingots to maintain volume during production.

- Heat The Metal To The Required Temperature: Use the furnace controls to bring the metal up to its specific melting point, typically between 370°C and 660°C depending on the alloy. Keep an eye on the temperature to avoid overheating, which can lead to oxidation or gas absorption.

- Skim Off Any Surface Slag: As the metal melts, impurities will float to the top in the form of dross or slag. Use a skimmer to remove this layer and keep the molten metal clean and ready for injection.

Step #4: Injecting the Molten Metal

I still remember the first time I watched the injection phase up close. It was fast, loud, and honestly a little intimidating. But once I understood what was happening behind the scenes, it became one of my favorite parts of the whole process.

- Transfer Molten Metal To The Shot Chamber: Use a ladle or automated system to pour the molten metal from the furnace into the shot sleeve. In a cold chamber machine, this step happens with each cycle, while in a hot chamber setup, it’s already inside the machine.

- Close The Die Completely: Make sure the die halves are clamped tightly together before each shot. This prevents flash and keeps the mold cavity sealed for high-pressure injection.

- Engage The Injection System: Activate the plunger or gooseneck to push the molten metal into the mold cavity at high speed. The goal is to fill every corner of the mold quickly before the metal starts to solidify.

- Apply Secondary Pressure (Hold Phase): After the cavity is filled, maintain pressure for a few seconds to pack the metal tightly and reduce porosity. This helps the metal settle into fine details and prevents internal shrinkage.

- Monitor Fill Time And Shot Speed: Track how long the cavity takes to fill and adjust injection speed if needed. If the shot is too fast, it can cause turbulence; too slow, and the metal may solidify before filling.

- Watch For Consistency Across Shots: Keep an eye on each cycle to make sure the injection phase stays stable. Inconsistent fills or incomplete parts are often signs that something needs to be recalibrated.

Step #5: Cooling and Solidification

I’ve always thought of this step as the quiet moment in the cycle, everything slows down while the part takes form. It’s not flashy, but it’s where the real transformation happens, turning molten metal into something solid and useful.

- Let The Metal Cool Inside The Mold: Once the cavity is filled, the metal begins to cool and contract within the die. It’s important to let this happen gradually to avoid creating stress inside the part.

- Hold The Die Closed During Solidification: Keep the mold tightly clamped while the metal solidifies. This maintains the part’s shape and prevents the cavity from opening too early under internal pressure.

- Monitor Cooling Time Based On Alloy And Part Size: Adjust the cooling duration based on the type of metal and the thickness of the casting. Thicker sections take longer, while thinner parts may be ready within seconds.

- Use Cooling Channels To Control Temperature: Built-in cooling lines circulate fluid around the mold to pull heat away from the metal. This helps achieve more consistent cycle times and improves overall part quality.

- Check For Hot Spots In The Mold: Some areas of the die retain heat longer and may delay solidification. These are often addressed with extra cooling or changes in die design for future runs.

Step #6: Ejection of the Casting

I used to think the casting just sort of “popped out” once it was solid. But after watching enough cycles, I realized this step needs just as much attention as injection or cooling, especially if you want clean parts and minimal scrap.

- Open The Mold After Cooling Is Complete: Once the metal has fully solidified, open the die using the machine’s control system. Timing matters here. Opening too early can warp the part, while waiting too long slows down your cycle.

- Activate The Ejector Pins Or Plate: Use the built-in ejector system to push the casting out of the mold cavity. These pins are usually behind the part and apply even pressure to prevent bending or damage.

- Remove The Casting Carefully From The Die Area: Once the part is ejected, take it out manually or with an automated arm. Make sure it clears the mold area completely before the next cycle begins.

- Inspect For Sticking Or Drag Marks: Check if the part stuck to the mold or shows signs of rough ejection. If that happens often, it might be time to clean the mold surface or adjust ejector timing and position.

Step #7: Trimming and Removal of Flash

I remember being surprised at how much cleanup a freshly ejected casting needs. Even with a well-made die, there’s always a bit of excess metal that needs to be trimmed away before the part can be considered finished.

- Transfer The Casting To The Trimming Station: Move the part from the press to a dedicated trimming area, either manually or using a conveyor. It’s best to do this quickly while the part is still slightly warm and easier to handle.

- Position The Part In The Trim Die Or Fixture: Place the casting into a trim die, jig, or fixture that holds it securely for cutting. This setup helps guide the blades and prevents shifting during the process.

- Shear Off Excess Metal From The Gates And Runners: Use a press or mechanical trimmer to cut away the thicker feed system sections attached to the casting. These areas are where the metal entered the mold and are no longer needed.

- Remove Flash From Parting Lines And Vents: Cut or grind off the thin layer of metal that forms where the mold halves meet. Flash might look minor, but leaving it on can interfere with assembly or product performance.

- Check For Sharp Edges Or Burrs: Feel along the trimmed surfaces and edges to make sure they’re smooth. If needed, use a deburring tool or grinder to finish off any leftover roughness.

- Sort Out Scrap For Recycling: Collect the trimmed-off metal and separate it for remelting. Most die casting shops reuse this material in the next batch, which helps reduce waste and save on raw costs.

Step #8: Surface Finishing and Treatment

I’ve always thought this is where castings go from rough to refined. After all the heat, pressure, and trimming, it’s the surface finishing step that makes the part truly look ready for business, whether it’s going into an engine block or a product housing.

- Clean The Casting To Remove Residue: Start by washing off any leftover lubricant, metal dust, or debris from earlier steps. This can be done with a parts washer, ultrasonic cleaner, or simple air blast depending on the part size and volume.

- Apply Shot Blasting Or Sandblasting: Run the casting through a blasting machine to smooth out the surface and remove any remaining flash or oxidation. This step also improves paint and coating adhesion down the line.

- Grind Or Polish Key Surfaces: If the part has functional surfaces like mating edges or sealing faces, use a grinder or polishing tool to fine-tune those areas. This helps meet dimensional specs and surface finish requirements.

- Add Protective Coatings If Needed: Depending on the final use, apply a powder coat, anodizing layer, or chemical conversion coating. These treatments help protect the part from corrosion and wear in demanding environments.

- Mask Off Sensitive Areas Before Coating: For parts with threaded holes or precision fits, use caps or tape to block those features before spraying or dipping. This keeps tolerances intact and saves time during assembly.

- Apply Custom Textures Or Branding: Some parts require cosmetic finishes or logo markings for branding purposes. This can be done through engraving, pad printing, or specialized coating techniques.

- Cure Or Dry The Coating Before Handling: Let the part sit in a controlled oven or drying area until the finish sets. This prevents smudges, scratches, or chemical reactions from happening after the coating is applied.

Step #9: Inspection and Quality Control

I’ve learned that even the best-run casting line needs a strong quality check at the end. It’s easy to assume the part came out fine just because the machine ran smoothly, but a quick inspection often reveals what the numbers don’t show.

- Perform A Visual Check For Surface Defects: Start by looking over each part for obvious flaws like cracks, porosity, flash, or incomplete fills. Surface appearance can give early clues about deeper internal issues.

- Measure Critical Dimensions With Gauges Or CMM: Use calipers, gauges, or a coordinate measuring machine to check key dimensions against the part drawing. Focus on tight-tolerance features that affect fit, function, or assembly.

- Check For Internal Defects With X-Ray Or Dye Penetrant: For parts where internal integrity matters, run non-destructive tests like X-ray scans or dye penetrant inspections. These help identify hidden voids, cracks, or shrinkage.

- Verify Coating Thickness And Adhesion: If the part has a finish, use tools like micrometers or test strips to measure coating thickness. Adhesion tests confirm that the finish will hold up under handling and real-world use.

- Record Inspection Results And Sort Parts: Log the measurements and test results into a quality control system for traceability. Good parts move on to packaging, while non-conforming ones are flagged for review or rework.

Conclusion

Now you’ve seen what it takes to get there. From mold design to final inspection, every step plays a part.

This guide gives you the full picture.

Ready to move from knowledge to action? It starts with one decision.

Contact MachMaster today to turn your ideas into real, precision-made parts.

More Guides and Tips to Explore

Not quite what you’re looking for? Explore our wider product range for more choices:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.