I used to think die casting was overkill.

Too expensive. Too specialized.

Then I saw what it did for our lighting housings.

Stronger parts. Less machining. Faster turnaround.

And suddenly, I was asking, “Where else can we use this?”

If you’re asking the same thing—or wondering which industries are using die casting and why—you’re in the right place.

This article will walk you through 8 major industries benefiting from die cast components. I’ll show you what kinds of parts they use, and how those choices impact design, cost, and performance.

Whether you’re sourcing parts, designing a product, or making supply chain decisions—this will help you evaluate if die casting has a role in your space.

So let’s get started!

Quick Guide

Let’s start with a simple breakdown. Below is a quick list of industries where die casting plays a critical role—just a glimpse before we go deeper.

| Industry | How Die Casting Helps | Common Components |

| Automotive | Reduces weight, boosts output volume | Engine blocks, brake calipers |

| Aerospace | Delivers lightweight, precision parts | Sensor housings, mounting brackets |

| Electronics | Manages heat and EMI, supports miniaturization | Heat sinks, device enclosures |

| Medical Devices | Ensures precision and hygiene compliance | Monitor housings, imaging arm brackets |

| Telecommunications | Strengthens outdoor durability, blocks signal interference | Antenna plates, signal booster frames |

| Industrial Machinery | Combines strength and fit accuracy | Gearbox housings, pump covers |

| Consumer Appliances | Adds visual quality and function | Coffee machine housings, mixer frames |

| Lighting | Supports heat dissipation and bold designs | LED housings, decorative frames |

Let’s now take a closer look at how each of these industries truly benefits from die casting.

1. Automotive Industry

If you’re in the automotive business, you know how tight timelines and high volumes can push every part of production.

I still remember one project for an electric vehicle where switching to die casting saved the entire launch. We moved from machined parts to cast components, and suddenly everything clicked—faster delivery, tighter fit, and better performance under heat and pressure.

Why Die Casting Works for You

- Lightweight Advantage: Using aluminum die casting helps you reduce vehicle weight without sacrificing strength. That means better fuel economy—or longer range for EVs.

- Precise Dimensions: With die casting, you get tight tolerances from the start, cutting down on secondary machining and assembly issues.

- High Output Speed: Once you’ve got the tooling set up, die casting produces parts at a pace that keeps up with your production targets.

- Heat Resistance: If your parts sit near motors or engines, die-cast metals can handle the heat and keep performing.

Where You’ll Use It

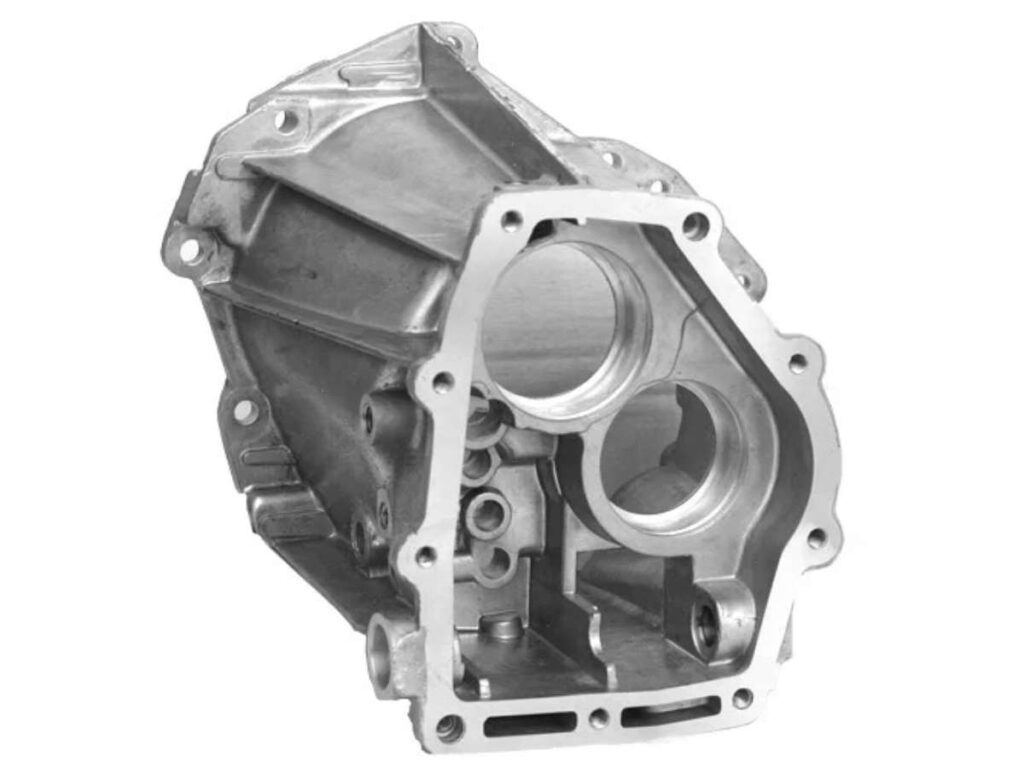

- Transmission housings: Complex geometry, strong under torque, and no compromise on fit.

- Engine blocks and covers: Die casting keeps them light but strong enough to handle combustion and vibration.

- Alloy wheels and hub assemblies: Balance, appearance, and durability all in one.

- Brake calipers and brackets: Get the alignment and strength you need for consistent braking.

- Motor enclosures for EVs: Protect your electronics and manage heat efficiently with cast aluminum designs.

Die casting helps you deliver faster, build lighter, and meet modern automotive demands. If you need a reliable service provider, choose MachMaster. They helped teams like yours take their automotive parts from design to delivery with speed and confidence.

2. Aerospace Industry

One of my most challenging—but rewarding—projects involved avionics casing for a lightweight aircraft. We opted for magnesium die casting, and it exceeded expectations. The part passed mechanical testing, dropped assembly time, and helped the aircraft meet strict weight limits.

Since then, I’ve seen aerospace engineers turn to die casting when both performance and precision matter.

Why Die Casting Works for You

- Weight Savings: Whether you’re using aluminum or magnesium, die casting gives you the strength-to-weight ratio your aerospace designs demand.

- High Repeatability: You need reliable parts for flight-critical applications. Die casting helps you hit those tight tolerances consistently.

- Complex Geometry in One Go: You can cast ribs, channels, or brackets all in one shot—saving you time on machining and assembly.

- Durability Under Harsh Conditions: With the right finish, your cast parts resist corrosion, moisture, and heat—perfect for high-altitude or external use.

Where You’ll Use It

- Seat Frame Connectors: You get strong, lightweight components without needing added reinforcement.

- Sensor Housings: You can protect sensitive flight sensors with compact, sealed casings.

- Instrument Brackets: You’ll reduce vibration and keep your readings accurate with rigid, cast supports.

- Gearbox Covers: You can protect gears and seal in fluids while keeping weight to a minimum.

- Electronic Control Enclosures: You can fit avionics into tight, rugged housings built to handle flight stress.

Working on aerospace projects taught me to respect precision more than ever. There’s very little room for error when something’s going into the sky.

I’ve watched die casting play a quiet but powerful role in building reliable, flight-ready parts. It continues to be a valuable choice for aircraft manufacturers that need strength without added weight.

3. Electronics Industry

If you’re building compact and powerful electronics, you’ve probably faced challenges with heat, space, and signal interference. I’ve worked with clients just like you who needed parts that do more than just hold components—they had to manage thermal loads, resist interference, and look good on the shelf.

Why Die Casting Works for You

- Thermal Control: You get better heat conduction than with plastics. That helps your devices stay cool and last longer.

- Signal Protection: Cast metal shields your electronics from electromagnetic interference (EMI). This is key for wireless and high-speed systems.

- Precision Builds: You can produce small, intricate shapes with tight tolerances. That’s a big win for your compact assemblies.

- Attractive Finish: You can powder-coat, plate, or polish your parts. This gives your devices a professional, durable exterior.

Where You’ll Use It

- Power Supply Housings: You protect internal components and manage airflow. Metal cases often double as heat sinks.

- Smartphone Midframes: You add structure and heat dissipation in one part. Cast frames support slim but strong builds.

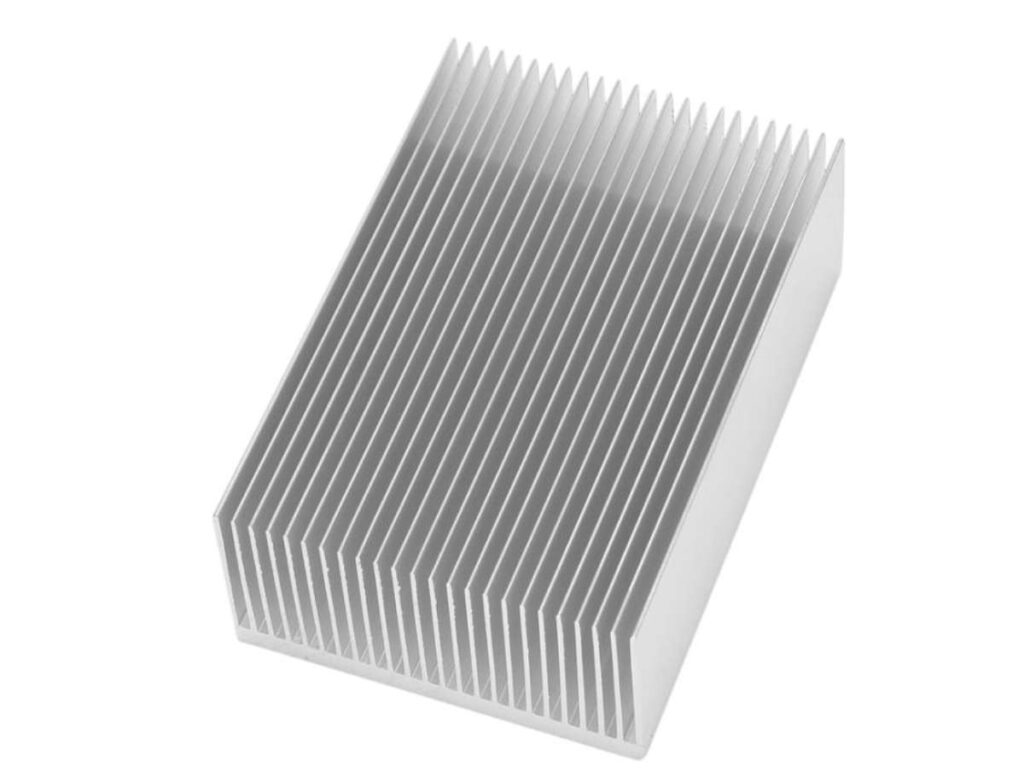

- Heat Sinks for Graphics or Processors: You draw heat away from critical chips. Complex fin shapes improve cooling efficiency.

- Cable and Plug Connectors: You build small, accurate parts that hold up. Die casting delivers consistent results across batches.

- Game Console Structural Parts: You shield internals from drops and stress. A solid housing also gives your product a premium feel.

In electronics, performance, heat management, and compactness must all come together in one design. Die casting helps engineers meet these needs efficiently, combining structure and function in one precise process. It’s a go-to solution for housings and frames across devices used in homes, offices, and industrial parts.

4. Medical Device Industry

One startup I worked with was building a portable imaging device. Their initial housing was 3D printed plastic, and it broke during testing. We transitioned to aluminum die casting and the results were immediate: improved strength, a cleaner finish, and regulatory approval without redesign.

Why Die Casting Works for You

- Clean Material Options: Some die cast alloys are safe for contact with skin or fluids. This supports hygiene and safety in patient environments.

- Accurate Builds: Medical tools must work reliably every time. Die casting allows for parts with precision that matches surgical standards.

- Stable Results: Whether you’re producing 100 or 10,000 units, you get consistent quality. That helps you meet strict inspections with less stress.

- Low Weight: Lighter devices are easier to handle. This benefits both patients and healthcare providers using portable tools.

Where You’ll Use It

- Diagnostic Equipment Frames: Support sensitive sensors and lenses. Castings ensure rigidity without being bulky.

- Brackets for Imaging Arms: Hold and move high-tech equipment with precision. Durable parts reduce misalignment.

- Wheelchair and Bed Components: Withstand load and movement over time. Cast pieces offer smoother profiles for comfort and cleaning.

- Outer Casings for Monitors: Protect internal circuits in mobile and bedside displays. Lightweight but sturdy.

- Structural Pieces in Lab Equipment: You support precise machine movement. Die casting helps you build repeatable, aligned systems.

Precision matters in every industry, but in medicine, lives are involved. Choosing the right material can ease production and improve patient care. I’ve seen the benefits of using die casting where failure isn’t an option. It gives engineers one less thing to worry about, so they can focus on outcomes.

5. Telecommunications Industry

Telecommunications infrastructure often depends on enclosures and brackets that function in harsh outdoor environments.

Die casting provides the durability, design flexibility, and thermal management needed to build long-lasting telecom components. It’s commonly used for outdoor enclosures, antenna mounts, and weather-resistant housing.

Why Die Casting Works for You

- Signal Shielding: Cast metal helps block interference from outside signals. This is critical for data clarity in antennas and routers.

- Temperature Tolerance: Aluminum die cast parts stay stable in heat and cold. They prevent cracking and warping in outdoor conditions.

- Mechanical Strength: Enclosures must resist wind and accidental impact. Die casting delivers strong, impact-resistant shells.

- Integrated Design: Features like mounts, seals, and wire passages can be molded directly. This reduces complexity and speeds up installation.

Where You’ll Use It

- Antenna Backplates: Secure antenna hardware with minimal movement. Prevent stress from wind or vibration.

- Router and Modem Enclosures: Protect sensitive electronics indoors or outdoors. Shield against both interference and physical damage.

- Signal Booster Frames: Hold amplifiers and brackets in place. Strong enough to mount on walls or poles.

- Satellite Housing Units: Must stay sealed in harsh environments. Die casting provides form, function, and protection.

- Wall-Mounted System Supports: Anchor heavy gear. Cast designs resist flexing and fatigue.

Telecom parts can’t afford failure—not when uptime matters. With die casting, you’ll get rugged, EMI-resistant, temperature-stable parts that perform day in and day out.

6. Industrial Machinery Industry

I still remember walking through a factory floor during a project review. A senior technician pointed at a newly installed motor bracket and said, “This one part saved us hours every week.” That part was die cast. It replaced five different welded pieces, and the change was immediate.

Why Die Casting Works for You

- Heavy-Duty Strength: You need parts that can take a beating—nonstop motion, pressure, and wear. Die-cast metals handle those stresses and keep your production line running strong.

- Reliable Sizing: With die casting, every part comes out consistent. That means fewer surprises during setup and less need for post-machining. Your machines run smoother because parts just fit.

- One-Piece Forms: Instead of bolting or welding five pieces together, you can design a single casting that does the job. Fewer joints, fewer weak spots, and a faster, cleaner assembly.

- Fast Supply: When something breaks or needs an upgrade, downtime costs you. Die casting supports high-volume runs, so you get parts quickly and keep your operation moving.

Where You’ll Use It

- Brackets and Tool Holders: These support your cutting tools or guides and must stay rigid under load. When you use die-cast versions, you reduce tool misalignment and keep your setups consistent.

- Covers for Industrial Pumps: These protect your pump’s internals from debris, fluid splash, or accidental impact. Precision casting gives you tight seals and reliable long-term use.

- Housing for Gearboxes: Your gearboxes need stable housing to handle moving parts, heat, and lubricant. A die-cast housing helps maintain alignment and cuts down on vibrations for smoother operation.

- Mounting Plates for Motors: These hold your motor to the frame or base. A proper fit helps prevent shifts that throw your machine off balance.

- Valve Body Components: You need these to manage fluid or gas flow through pipe systems. Die casting gives you smooth internal paths and strong pressure resistance—essential for performance and safety.

If you’re working with industrial machinery, die casting gives you the strength, precision, and consistency your parts demand. In environments where uptime counts, reliable components aren’t optional—they’re essential.

7. Consumer Appliances Industry

For the consumer appliance industry, quality, appearance, and function all play a role in product success. Die casting enables manufacturers to produce visually appealing, strong, and durable components that withstand daily use.

It supports both exterior casings and internal structural parts across a range of appliances, from coffee makers to washing machines. The method is well-suited for blending design with practicality in household items.

Why Die Casting Works for You

- Polished Look: Die cast parts offer a clean, refined surface that can be painted, polished, or textured. This gives home appliances a more professional and high-quality appearance.

- Tough Under Use: Kitchen environments involve heat, moisture, and frequent use. Die-cast components handle these conditions better than many molded plastics.

- Lower Unit Cost: Once the mold is created, thousands of parts can be produced at a low cost. This reduces the overall manufacturing expense and keeps retail prices competitive.

- Space-Saving Features: Design features like internal channels or support ribs can be integrated into a single part. That saves space and reduces the need for extra fasteners or sub-assemblies.

Where You’ll Use It

- Housing for Coffee Machines: These enclose heating elements and control units. Die casting keeps everything protected while supporting a sleek exterior look.

- Blender and Juicer Bases: These must hold motors securely while handling vibration. A solid, balanced base also contributes to quieter operation.

- Stand Mixer Frames: These anchor multiple moving parts like beaters and gears. Die casting provides long-lasting rigidity and easy cleaning.

- Internal Fan Blades: These circulate air to cool motors or internal electronics. Cast blades can be molded for balance and improved airflow.

- Iron and Steam Cleaner Plates: These transfer heat directly to surfaces. Flat, uniform castings allow for consistent heating and reduce hot spots.

For home appliances, die casting delivers the kind of durability and visual quality that end-users notice—and appreciate.

It’s one of the reasons products feel sturdy, last longer, and look good on store shelves and kitchen counters.

8. Lighting Industry

Lighting was where I first saw die casting make a real difference. I was working on a custom hotel lighting fixture. The design needed to be sleek, but the housing also had to handle heat, stay durable, and keep weight low.

We went with die casting. Years later, those fixtures are still in place—no corrosion, no failures. That project showed me just how well die casting balances strength, design, and longevity.

Why Die Casting Works for You

- Heat Flow Support: You get better thermal management for high-output LEDs. That means cooler operation, better light output, and longer lifespan.

- Tough Outdoors: Your cast parts hold up to sun, rain, and rough handling. That’s why they work so well in outdoor and industrial lighting.

- Custom Shape Design: You can mold sleek or complex shapes that look good and help function. Want vents or curves? You can build them right in.

- Secure Mounts: Your brackets and bases stay solid over time. Whether it’s a wall, ceiling, or pole, the fixture holds firm.

Where You’ll Use It

- LED Cooling Fins: These help pull heat away from the LEDs. You keep brightness high and avoid burnout.

- Decorative Lamp Frames: You control the look and feel of your fixture. Die casting gives you smooth lines and consistent form.

- Light Post and Ceiling Brackets: These take the weight and keep everything aligned. No droop. No shift.

- High Bay Light Housings: These need to be light but strong. Die-cast shells handle impact while staying easy to install.

- Enclosures for Smart Lighting Tech: These protect sensors, drivers, and modules. You get a compact, sealed fit that also looks clean.

Lighting manufacturers use die casting when performance has to meet appearance. It gives you design flexibility, solid construction, and reliability over time.

At MachMaster, they support lighting manufacturers with high-precision die cast components that meet modern lighting standards—engineered for quality, built for endurance, and delivered with speed.

Conclusion

Remember when I doubted die casting?

I thought it was overkill—until I saw the results myself.

Now, you know what industries benefit most. You’ve got a list.

You’ve got the why.

And maybe… the spark to try it yourself.

Don’t let cost fears or old processes slow you down.

You don’t need to commit to everything—just start the conversation.

Let’s figure it out together.

Start now. Contact us today.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

Want to learn more? Here are some articles filled with valuable tips and information to guide you further:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.