I’ve worked on dozens of production runs. CNC, injection molding, vacuum forming. You name it.

But die casting? That one caught me off guard.

We chose it for a part that needed strength and consistency. And while the final result looked great, the process didn’t go the way we planned. We ran into porosity. Then redesigns. Then delays.

That experience taught me that die casting isn’t just about what you gain but also about what you give up.

If you’re here, you’re probably weighing the pros and cons yourself. This article lays them out in simple terms. I’ll explain what die casting can do, what it can’t, and how to know if it fits your project.

Let’s start!

1. What Is Die Casting?

I used to think die casting was just another fancy term manufacturers threw around. Until I actually worked on a project that used it.

That’s when I saw what it could do and where it could trip you up.

If you’re trying to figure out if die casting is right for your product, the first step is understanding what it actually is. Let’s break it down in plain language.

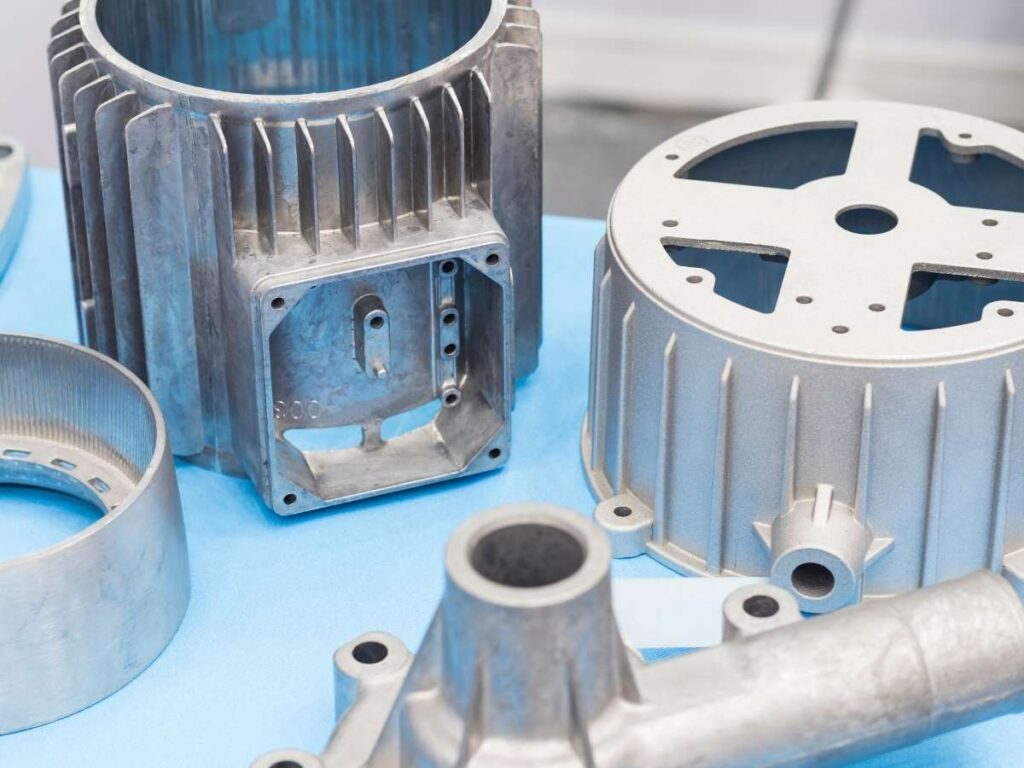

Die casting is a process where molten metal is injected into a mold under high pressure.

Think of it like making a waffle. You pour batter into the iron, close it, and let the shape form. Die casting is similar, but instead of batter, you’re using liquid metal. And instead of heat alone, pressure is a big part of the process.

The molds are made of hardened steel and designed to be used again and again. That makes die casting great for making lots of the same part. Fast and with consistent results.

It’s especially helpful when you need:

- Tight dimensions

- Smooth surfaces

- High repeatability

Sounds simple, right? But knowing what it’s used for can give you a better sense of whether it fits your own project.

Typical Use Cases

Die casting is common in industries that need high-volume metal parts. You’ll see it used in:

- Car parts like engine blocks and transmission cases

- Consumer gadgets like phone or tablet frames

- Industrial equipment housings or brackets

If you’re making anything that needs strong, precise, and repeatable metal parts, die casting might be worth exploring.

Common Materials Used

Most die casting is done with non-ferrous metals. That means metals without iron.

The three most common ones are:

- Aluminum: Lightweight and strong

- Zinc: Durable and easy to cast

- Magnesium: Lightest of all, used in electronics

But here’s the catch, die casting doesn’t work with steel or iron. So if your part needs to handle extreme wear or heat, another process might be better.

Die casting has a lot going for it. But before you decide if it fits your needs, you need to know where it shines and where it doesn’t.

That’s exactly what we’ll get into next.

2. Pros of Die Casting

If you’ve ever needed hundreds or even thousands of metal parts that look and function exactly the same, die casting probably came up as an option. But why do so many manufacturers rely on it?

Let’s walk through what it actually does well.

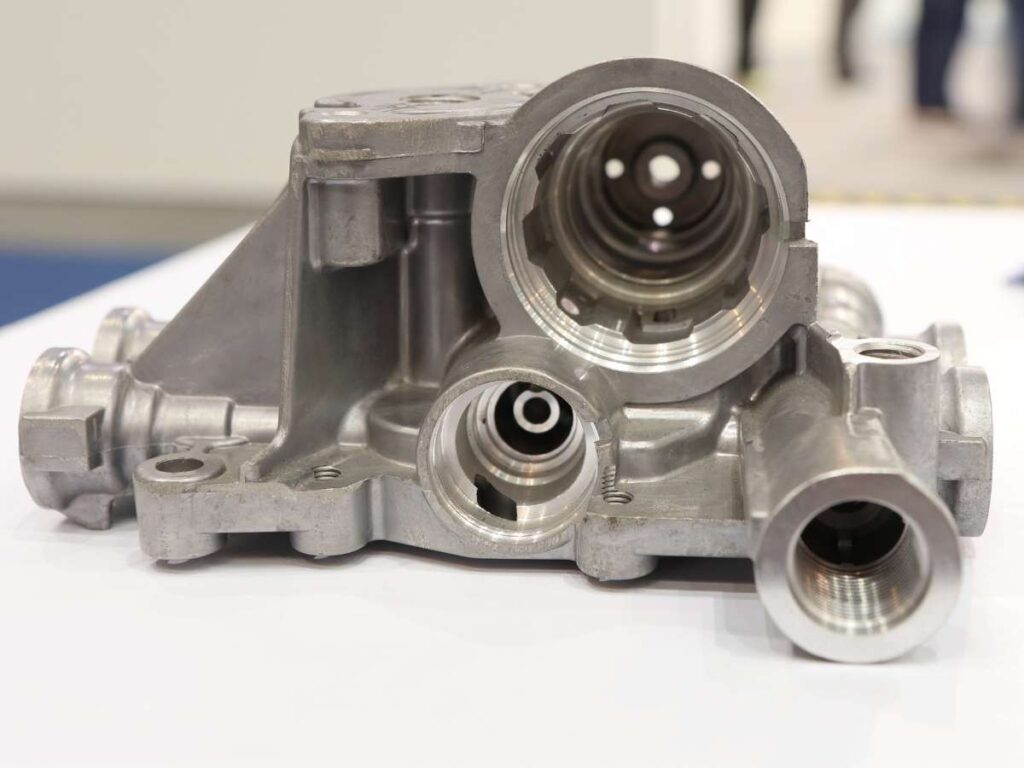

High Precision and Dimensional Stability

One of the biggest strengths of die casting is precision.

You can hit tolerances as tight as ±0.1mm. That’s small enough for parts that need to fit or move together with little room for error.

And because the molds don’t change shape easily, you’ll get the same dimensions every time. That means:

- Less rework

- Fewer bad parts

- And often, no need for extra machining

When we used it for a bracket with detailed holes and edges, the part came out ready to use—no extra steps needed.

Excellent Surface Finish

Another perk?

Parts usually come out with smooth surfaces.

You don’t have to spend time grinding or polishing unless you want a special look. This can save money if you’re producing at scale.

Rapid Production After Tooling

Once the die is built, things move fast.

Each part can be cast in seconds. That short cycle time adds up, especially in large batches.

It’s a big reason companies use die casting to keep up with demand.

Cost-Effective for High Volumes

If you only need 20 parts, die casting won’t save you much.

But if you need 2,000 or 20,000?

The price per part drops quickly. Over time, the upfront cost of tooling pays for itself.

Material Efficiency

Unlike CNC machining, which cuts material away, die casting fills a mold with just the right amount.

This means:

- Less metal wasted

- Scrap can be melted and reused

- Better use of raw materials

It’s especially efficient with aluminum and zinc.

Strong and Lightweight Parts

Die casting gives you parts that are both strong and light.

Aluminum, in particular, hits that sweet spot. We used it on a housing that had to look clean but hold its shape under pressure.

It did both.

Closing Thoughts

So, is die casting perfect?

No process is but if you need precision, speed, and consistency especially at higher volumes, it could be a smart move.

Next, we’ll look at the downsides so you get the full picture before making your call.

3. Cons of Die Casting

Die casting has its strengths. But it’s not the right fit for every project.

I’ve worked on jobs where die casting seemed perfect—until the costs started adding up, or the design didn’t quite work with the mold. That’s when I learned: the downsides matter just as much as the benefits.

Let’s take a closer look at what might hold you back.

High Initial Tooling Cost

Before you can make a single part, you need a tool: the steel mold that shapes your product.

That mold isn’t cheap.

Depending on the size and complexity, it can cost thousands—or even tens of thousands. If you’re only making a small batch, you may never recover that cost.

We once spent $15,000 on tooling for a short run. In the end, the project changed directions, and most of the mold sat unused. That hurt.

Limited to Non-Ferrous Metals

Die casting works with non-ferrous metals. That means metals without iron.

Common ones include:

- Aluminum

- Zinc

- Magnesium

But if you need steel or iron? Die casting won’t work.

That’s a deal breaker for heavy-duty parts or high-heat applications.

Not Ideal for Low Volumes

Thinking of making 100 parts? Die casting probably isn’t your best option.

Better choices for small runs include:

- CNC machining

- Sand casting

- 3D printing

Die casting usually starts to make financial sense around 1,000 to 5,000 units.

Design Restrictions

Some shapes just don’t cast well.

You’ll need to follow certain rules:

- Keep wall thickness even

- Avoid sharp internal corners

- Undercuts? You’ll need extra mold parts, which adds time and cost

Your design has to work with the process—not against it.

Risk of Porosity

Porosity is what happens when tiny gas bubbles get trapped inside the part.

You might not see them, but they can weaken your product.

To fix this, you may need vacuum casting or extra machining. More steps. More cost.

Long Lead Times for Tooling

Tooling doesn’t happen overnight.

It often takes several weeks to design, build, and test the mold. That can delay your launch.

If you’re working on a tight timeline, this might be a problem.

Closing Thoughts

Every process has trade-offs. Die casting can be powerful, but it comes with real limits.

The key is knowing those limits up front, so you don’t lose time or money down the road.

4. Comparing Die Casting with Other Processes

Choosing a process can feel overwhelming. This table will help you quickly see how die casting stacks up against CNC machining, injection molding, and 3D printing. Use this table as a quick reference:

| Process | When It’s Better Than Die Casting | When Die Casting Is Better |

| CNC Machining | Better for low volumes or prototypes Easier to modify designs Handles deep pockets or sharp corners | Lower cost per part at high volumes Faster for large batch production Less waste once tooling is done |

| Injection Molding (for plastics) | Best for plastic parts Lightweight and flexible applications | Needed when part must be metal Stronger and more durable Better for structural or heat-resistant parts |

| 3D Printing | Fast setup with no tooling Great for short runs or testing designs | More durable for real-world use Cleaner surface finish Faster at scale |

Still unsure? Ask yourself:

- How many parts do I need?

- How soon do I need them?

- What material and strength do they require?

The answers will point you in the right direction.

Next, let’s break it down by buyer type so you can see whether die casting makes sense for you.

5. Is Die Casting Worth the Investment?

Now that you know the pros, cons, and how die casting compares to other processes, there’s still one question left: Is it worth it for you?

The answer depends on who you are and what you’re trying to build. Let’s look at it from different points of view.

For Business Owners

If you’re producing at scale, die casting can save money in the long run. Once the tooling is paid off, your per-part cost drops fast.

But don’t just look at price.

You’ll want a supplier who’s ISO-certified and can handle your volume without missing deadlines. Ask about past experience. Look for real production capacity—not just a nice website.

And before committing? Always request a small test run. It might cost extra up front, but it’s worth it to catch problems early.

If you’re still looking for a reliable supplier, MachMaster might be a good fit. We’re ISO 9001 certified and support both small batch trials and large-scale runs with precision manufacturing that meets ±0.01mm tolerances.

For Product Designers

Start talking to suppliers while you’re still in the design phase.

They can help with DFM: Design for Manufacturing. This is where you tweak your part to work better with the die casting process.

Pay special attention to:

- Wall thickness

- Draft angles (to help parts release from the mold)

- Parting lines (where the mold separates)

Making smart changes early can save weeks later.

For Procurement Professionals

Your job is all about the details.

Ask about:

- Tooling cost and timeline

- Minimum order quantities

- Shipping and logistics plans

Look for suppliers with strong quality control systems. Bonus if they have backup tooling in case something goes wrong.

For Personal Buyers

Die casting is usually overkill unless you’re scaling up.

If you’re making 20 parts or testing a new idea, CNC or urethane casting is faster and cheaper.

Conclusion

Die casting isn’t perfect.

But if you’re producing parts at scale and your design fits the process, it might be exactly what you need.

We’ve covered:

- What die casting is

- Where it works best

- Where it doesn’t

- And how to decide based on your role

So… what’s your next move?

Whether you’re a designer, business owner, buyer, or builder, this is your moment to decide.

Need help figuring it out?

Contact us today. Let’s work through it together.

More Guides and Tips to Explore

Not quite what you’re looking for? Explore our wider product range for more choices:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.