A few months ago, a facility manager reached out after their CNC parts failed inspection.

The tolerance was fine, but the surface finish didn’t pass. Their drawing had no Ra value, just a rough description.

They didn’t know finishing had its own set of standards.

We’ve worked with dozens of businesses that didn’t realize surface finish is its own world, with its own measurements and language.

That’s where we step in to help.

In this article, I’ll walk you through the core surface finishing standards, how they’re used in engineering and manufacturing, and how to apply them properly, no guesswork required.

If your team has ever said “we thought the supplier would just know,” you’ll want to read this.

So let’s get into it!

1. What is Surface Finishing?

Let’s be honest. How a part looks and feels matters more than most people think.

When something’s been freshly machined, the raw edges and unfinished texture don’t just look rough—they perform that way too. That’s where surface finishing steps in.

Surface finishing is what gives a part its final feel, fit, and function. It’s that last pass before something’s truly ready for use.

Here’s what it really means:

- The Final Touch: Surface finishing changes how a part looks and behaves. It can smooth it out, toughen it up, or just make it look more polished and professional.

- Different Techniques, Different Goals: Some finishes remove material—like grinding or sanding. Others add something—like a powder coat, plating, or paint. And sometimes, it’s about treating what’s already there, like with polishing or passivation.

- More Than Just Looks: Sure, it makes things look better. But it also protects parts from rust, improves how they fit together, and even boosts durability over time.

- Every Industry Counts: Whether you’re building aerospace parts, medical tools, or industrial machinery—surface finishing isn’t optional. It’s what takes your work from “functional” to “flawless.”

Surface finishing isn’t just a pretty face. It’s protection, performance, and presentation all in one.

When it’s done right, it shows.

2. Purpose of Surface Finishing Standards

Here’s the truth: Without standards, surface finishing becomes a guessing game. And guessing doesn’t work in quality control.

Standards give your spec sheets teeth.

They help you communicate intent with clarity and hold both internal and external teams accountable.

Aligning Expectations from the Start

One of the biggest benefits I’ve seen firsthand is how standards keep everyone aligned from day one. Whether you’re working with in-house machinists or an overseas supplier, surface finish specs become the common reference point. This prevents misunderstandings that can delay production or compromise product performance.

It’s about setting expectations before the first part is even made.

Protecting Functional and Aesthetic Goals

Surface finish isn’t just about how something looks—it can affect how parts slide, seal, or resist corrosion. That’s why standards are so crucial for both performance and presentation.

I’ve seen polished parts that looked perfect but failed miserably in field testing because they didn’t meet the functional spec. With clear standards, you ensure your product works as good as it looks.

3. Key Surface Finishing Standards Bodies

You’ve probably seen acronyms like ISO, ASME, or ASTM pop up on specs, but who sets the rules?

Let’s look at the major players.

- ISO (International Organization for Standardization): ISO develops globally recognized standards. ISO 1302 is a go-to for surface texture symbols and rules used in technical drawings.

- ASME (American Society of Mechanical Engineers): ASME standards are common in North America. Their Y14.36M standard defines surface texture symbols used in engineering drawings.

- ASTM (American Society for Testing and Materials): ASTM covers material testing, including surface roughness and coating specifications.

- SAE (Society of Automotive Engineers): SAE standards often show up in automotive and aerospace specs, especially for coatings and corrosion protection.

- DIN (Deutsches Institut für Normung): These German standards are widely used across Europe and in global manufacturing partnerships.

Depending on your industry and region, one body may carry more weight than others. But aligning with any of these helps streamline supplier communication and quality audits.

4. Common Types of Surface Finishes and Their Classifications

I’ll admit, when I first started working with surface finishes, it all sounded like alphabet soup: Ra, RMS, blasted, passivated.

It took hands-on experience to really understand how different finishes work and where they fit.

Let’s break it down into practical categories so you’re not just throwing terms around, you actually know what they mean:

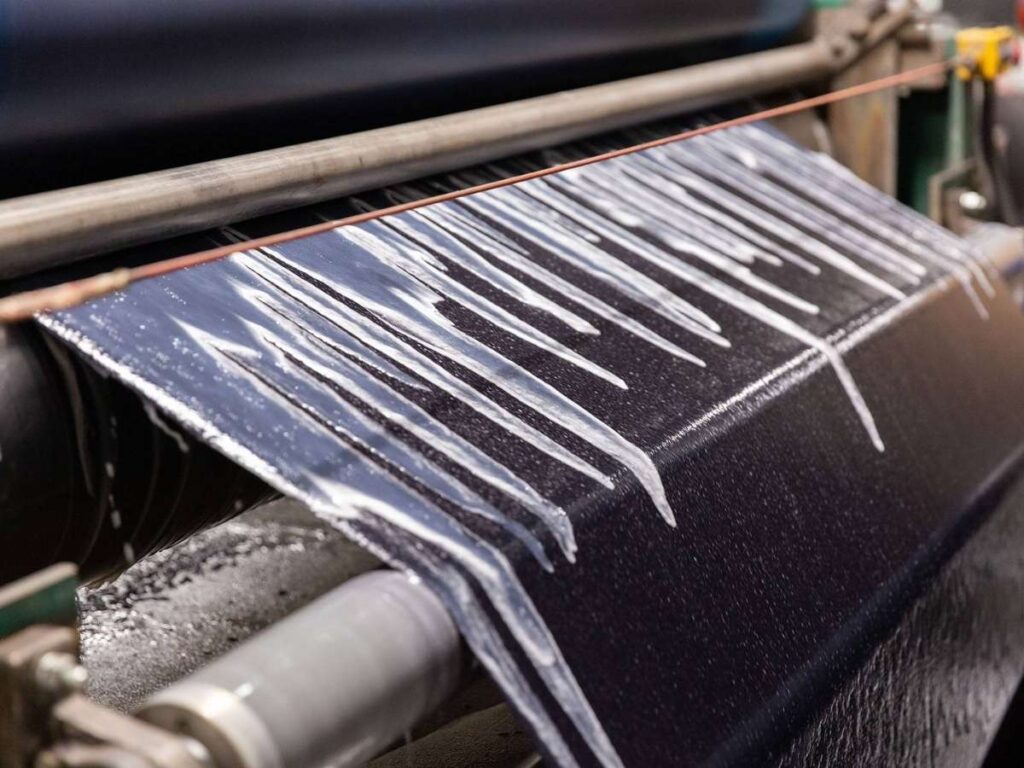

Mechanical Finishing

Mechanical finishes are created by physically altering the surface—grinding, sanding, polishing, or blasting it into shape. These methods are often used to improve appearance or meet dimensional tolerances.

For example, polishing can give stainless steel a mirror finish, while bead blasting adds a uniform matte texture. These processes are common in parts that are visible to the end user or need smooth operation in motion assemblies.

Chemical Finishing

-If you’ve ever seen a shiny stainless part that resists rust like a champ, chances are it’s been chemically finished. These finishes rely on chemical reactions to clean, protect, or alter the surface.

At MachMaster, processes like passivation and anodizing are routinely used to enhance durability while maintaining tight dimensional tolerances.

Passivation is a go-to for stainless steel, while anodizing is a favorite for aluminum. Chemical treatments are great for improving corrosion resistance without adding extra thickness.

Electrochemical Finishing

This group includes electroplating, electropolishing, and anodizing—finishes that use electricity to control the reaction. I’ve seen electropolished medical instruments that are so smooth, bacteria can’t even stick.

These finishes offer a balance of function and beauty, especially in industries where cleanliness or conductivity matters.

They’re more controlled than mechanical methods, but require specialized equipment.

Coated Finishing

Coated finishes involve adding a layer, whether it’s paint, powder, or plating, on top of the base material.

These are often chosen for color, wear protection, or weather resistance.

Powder coating is especially popular because it’s tough and eco-friendly, while chrome plating adds durability with a polished look. The big thing to remember? The coating has to stick, so pre-finish surface prep is everything.

Textured or Patterned Finishing

Sometimes, you don’t want a smooth surface. You want grip, adhesion, or a particular visual style. That’s where textured finishes like knurling, shot peening, or etching come into play.

I’ve worked with teams who needed specific textures just so adhesives would bond properly.

These finishes are functional, not just decorative, and they’re often overlooked until something fails.

5. Essential Surface Finish Measurement Standards

When I first had to verify Ra values, I didn’t even know there were other roughness parameters that mattered just as much, until a supplier pointed out the spec mismatch.

Here’s a comprehensive table outlining the most commonly used surface finish parameters, what they mean, how they’re measured, and where they’re typically applied:

| Parameter / Standard | What It Measures | Common Units | Measurement Tool | Typical Applications |

| Ra (Roughness Average) | Average height of surface peaks and valleys over a sampling length | µm or µin | Contact profilometer, optical profilometer | General machining, cosmetic surfaces |

| Rz (Ten-Point Height) | Average height difference between 5 highest peaks and 5 deepest valleys | µm or µin | Profilometer | Functional sealing surfaces, automotive parts |

| Rt (Total Height) | Distance from highest peak to lowest valley in a single measurement trace | µm or µin | Stylus profilometer | Critical wear surfaces, precision tools |

| Rq (Root Mean Square Roughness) | RMS value of height deviations from the mean line | µm or µin | Stylus or optical profilometer | Aerospace and medical components |

| ISO 4287 / ISO 4288 | Defines profile parameters (Ra, Rz, etc.) and sampling rules | N/A | Based on parameter used | European engineering standards |

| ASME B46.1 | US standard for surface roughness and texture symbols | N/A | Used with engineering drawings | North American manufacturing and QC |

| Replica Tape | Creates a physical impression of surface profile | Mil or µm | Optical reader or micrometer | Field inspection of welds, coatings, shot peening |

| Visual Comparator Standards | Side-by-side comparison with pre-defined surface textures | N/A | Optical comparator plate | Quick checks during fabrication or inspection |

| 3D Optical Scanners | High-resolution, non-contact surface mapping | Microns (µm) | Laser or white light interferometry | Complex geometries, fragile or soft materials |

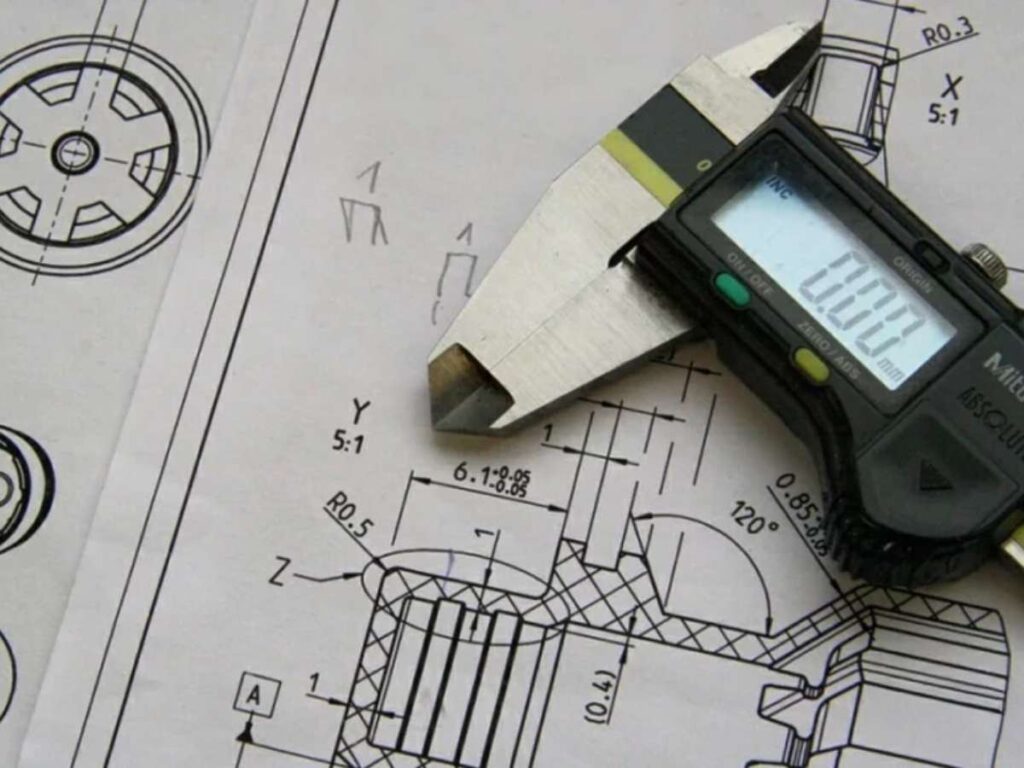

6. How to Specify Surface Finishing Standards in Technical Drawings

I’ve seen too many great designs fall apart in production simply because the finish wasn’t clearly called out on the drawing.

It’s not just about having a number, it’s about giving the right level of detail so no one’s left guessing.

- Always Include the Roughness Value: Start with a specific surface roughness value like Ra 1.6 µm or Ra 63 µin. This sets a measurable target that your machinist or supplier can follow and verify.

- Use the Correct Surface Finish Symbol: Include the standard symbol defined by ISO 1302 or ASME Y14.36M. These symbols help communicate finishing requirements visually and are essential when your drawings are shared across teams or borders.

- Call Out the Process if It Matters: If the finish requires a specific method, like anodizing, polishing, or bead blasting, state it clearly next to the symbol. This avoids the mistake of assuming that any method can achieve your finish when the application demands more.

- Define the Measurement Method: Indicate how the finish will be verified, whether it’s a contact profilometer, optical scan, or replica tape. Not all methods read the same, and setting this expectation keeps QC aligned with design intent.

- Specify the Surface Area or Zone: If the finish applies only to certain surfaces (like sealing faces or outer shells), highlight this with notes or section views. Don’t assume your supplier will know which surfaces matter most, spell it out.

7. Challenges in Achieving and Verifying Surface Finishing Standards

I’ve worked with suppliers who claimed they could meet a spec, only to find out later their measuring tools weren’t even calibrated.

Verifying surface finishes sounds simple, but there are plenty of places where things quietly go wrong.

Inconsistent Results from Manual Processes

Manual finishing methods like polishing or bead blasting can vary greatly between operators. Even if the same tools are used, pressure, angle, and technique can lead to different results.

I’ve seen two batches from the same supplier look noticeably different, just because a new technician took over.

This lack of repeatability becomes a real problem when specs are tight or cosmetic appearance matters.

Measurement Limitations and Calibration Errors

Not all profilometers or gauges are created equal, and that’s a serious issue when your tolerance is only a few microns.

Tools need to be regularly calibrated, and different devices can produce slightly different readings even on the same surface.

I’ve had teams accept a part using one tool, only for the customer to reject it using another. Without proper calibration and alignment on method, verifying surface finish becomes more guesswork than science.

Miscommunication Between Design and Production Teams

One of the most common issues I’ve seen isn’t technical, it’s communication.

Engineers will note a finish on a drawing but not specify how to achieve or verify it, and production fills in the gaps. That leads to mismatched expectations, especially when vendors interpret standards differently.

Clear documentation, shared reference samples, and aligned terminology can go a long way in avoiding these headaches.

8. 4 Best Practices for Compliance with Surface Finishing Standards

I’ve seen how just one unclear finish spec can slow down an entire production run, or worse, cause a product to fail inspection.

If you want to avoid surprises and keep your quality consistent, it pays to be proactive about how you manage surface finishing.

Start with Clear and Specific Documentation

Don’t leave finish requirements open to interpretation, spell out exactly what you want.

That means including roughness values, finish symbols, process notes, and verification methods right on the drawing.

I’ve seen parts delayed for days because someone assumed “smooth” meant polished, not Ra 0.8 µm. The more precise your documentation, the less room there is for costly mistakes.

Vet Supplier Capabilities Upfront

Before awarding the job, make sure your supplier actually has the tools and experience to meet your spec.

Ask how they measure finish, whether they calibrate their tools, and if they’ve handled similar parts before. I once caught a potential issue early when a shop admitted they couldn’t verify Ra below 1.6 µm—something MachMaster routinely checks as part of their surface validation process.

A little upfront vetting saves a lot of downstream repair work.

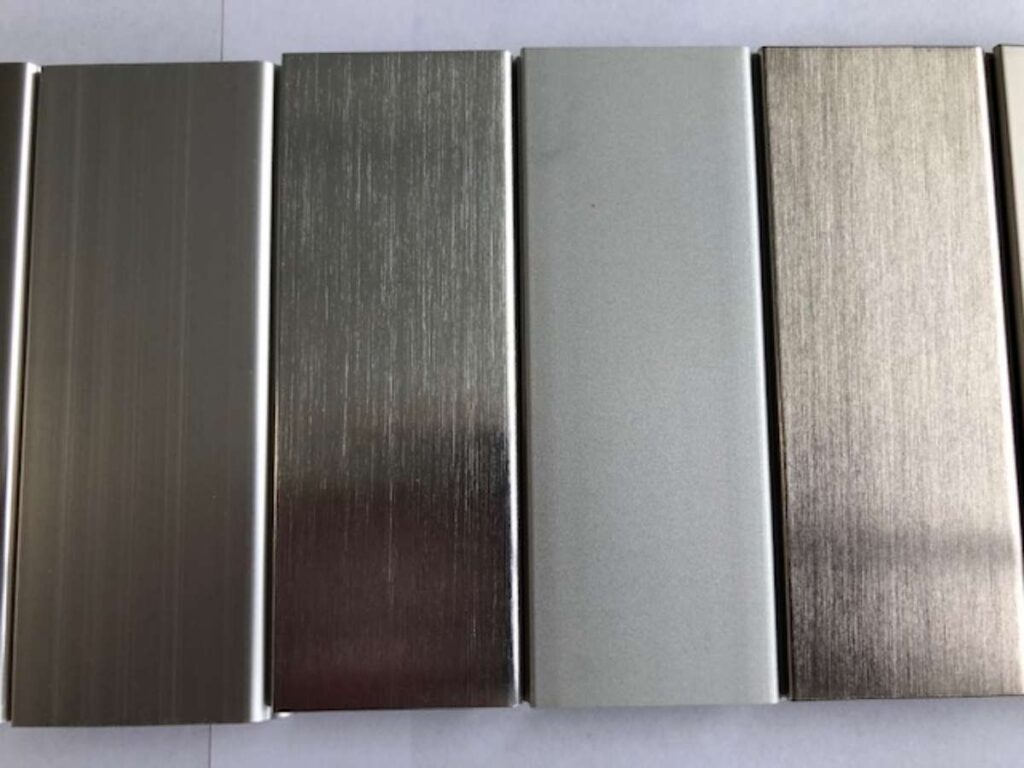

Use Controlled Samples or Finish Plates

If you’re working with a new supplier or a custom finish, send a reference sample or require one back. These finish plates can be physical guides that both parties agree on, removing any ambiguity.

I’ve had cases where visual differences nearly derailed a project, until both sides compared it to the approved sample. It’s a simple, effective way to align expectations.

Train Your Internal Teams on Surface Standards

It’s not enough for the quality team to know what Ra or Rz means: engineering, procurement, and production all need to speak the same language.

When everyone understands how surface specs impact function and fit, fewer things slip through the cracks. I’ve seen massive improvements in quality just from holding short internal sessions on finish callouts.

A trained team leads to fewer missteps, faster resolutions, and better results overall.

Conclusion

That early lesson I shared still sticks with me. When specs are vague, quality suffers.

But now, you’ve got the clarity I didn’t have.

This guide gave you the essentials: the types, the standards, the symbols, and the pitfalls. You know what good looks like and how to make it repeatable.

So take the first step. Rethink how you verify your parts.

Contact MachMaster today. Your partner for CNC machining, and surface finishing.

Recommended Reads for You

If you need more options, take a look at our full range of products. You might find just what you need:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.