I was standing on the shop floor, watching sparks fly from the plasma cutter. At first, it looked fine. But once the job was done, I knew we’d made the wrong call.

The edges came out jagged. The sheet bent in the wrong spots. And the customer? Not impressed.

If you’ve ever had a project go sideways—parts scrapped, budgets wrecked, or deadlines missed—I get it. I’ve been there too.

Over the years, I’ve worked with different machines, cutting teams, and real-world jobs. I’ve seen which tools deliver clean results—and which ones leave a mess.

This article will help you figure out what actually works.

You’ll learn:

- The main types of sheet metal cutting

- Which machines and tools are used

- How to choose the best method based on your material, design, or budget

If you’re trying to avoid waste, fix delays, or just do the job right the first time, you’re in the right place.

Let’s walk through sheet metal cutting in a way that actually makes sense—and saves you trouble down the line.

So let’s get started!

1. What Is Sheet Metal Cutting?

Sheet metal cutting is how you turn a plain sheet of metal into a real part.

It might sound simple. Just cut the metal, right? But I’ve learned the hard way—it’s not always that easy.

I once had a job where we rushed through the cutting step. The parts came out the wrong size. Holes didn’t line up. We had to redo the whole thing. That one mistake threw off the entire project.

At MachMaster, we’ve seen how cutting affects everything: fit, finish, and function. Whether you’re making a machine bracket, a medical panel, or a custom enclosure—how you cut the sheet matters.

So what does sheet metal cutting actually involve?

- Slicing large metal sheets into smaller pieces

- Creating holes, slots, or curves

- Preparing parts for bending, welding, or assembly

You’ll deal with different materials like steel, aluminum, and copper. Each one cuts differently.

And the thickness? That’s called gauge. A lower number means a thicker sheet.

If your cut is off, the whole part can fail. That’s why this first step deserves your full attention.

2. Benefits of Sheet Metal Cutting

If you’ve ever messed up a cut or had parts that didn’t fit, you’re not alone. I’ve had projects where the cuts were just a little off—and it threw everything out of place. Wasted time. Wasted material. And a whole lot of stress.

That’s why good sheet metal cutting is such a big deal. When the cut is clean and accurate, the rest of the job goes smoother.

Here are some real benefits I’ve seen again and again:

Enables Complex Part Production

Not all parts are simple. Maybe you need slots, vents, or detailed corners. I had a job once with tiny cutouts—over 30 in one piece. We thought it would take forever.

But with the right cutting method, it was fast and spot-on.

Sheet metal cutting can handle:

- Curved shapes

- Fine lines

- Decorative features

So you don’t have to avoid tricky designs.

Fast Turnaround for Prototypes and Mass Production

Ever been in a rush?

One time we had a last-minute prototype request. Thanks to CNC cutting, we uploaded the file and got parts the same day.

Cutting methods like this help you:

- Test ideas quickly

- Deliver parts faster

- Keep big orders moving

High Repeatability and Accuracy

Need every part to match?

Some tools, like laser or waterjet cutters, keep sizes tight—within ±0.1 mm. That’s super useful when you’re making parts that need to line up or fit together.

I’ve had to rework whole batches over small size changes. It’s not worth it. A clean cut from the start saves trouble.

Cost-Effectiveness at Scale

Cutting isn’t just about speed. It can help your budget too.

With good planning, you can:

- Fit more parts on one sheet

- Use less material

- Finish more pieces per hour

All that adds up—especially on larger runs.

Compatible With Many Sheet Materials

No need to stick to one type of metal.

You can cut:

- Aluminum

- Steel

- Copper

- Brass

- Even coated sheets

Each one reacts a little differently, but there’s a method that works for them.

Clean Edges and Minimal Finishing (Depending on Method)

Here’s something I really appreciate: less cleanup.

Some cutting methods—like laser or waterjet—leave smooth edges. That means:

- Less sanding

- Less grinding

- Fewer finishing steps

One project I worked on came off the table ready to install. No extra work. That kind of time-saver makes a big difference.

So yeah—sheet metal cutting does more than just shape your part. It helps you build faster, cleaner, and with less waste. And if you’ve ever had to redo a job because of one bad cut, you know how valuable that really is.

3. Types of Sheet Metal Cutting Methods

Not all cutting methods are the same. I’ve made the mistake of picking the wrong one for a job—and ended up with warped edges and missed deadlines.

If you want clean results and fewer surprises, it helps to know your options.

Each method has its strengths, weaknesses, and best-use situations.

Here are the 5 most common sheet metal cutting methods—and where they fit in real jobs.

Laser Cutting

A focused laser beam melts or burns through the metal. It follows the shape of your file with high precision.

Best for: Thin to medium metals, detailed shapes

Pros:

- Very accurate

- Cuts logos, vents, slots, and fine outlines

- Clean edges and minimal finishing

Cons:

- Doesn’t work well on shiny metals like aluminum or copper without a special laser

We cut aluminum panels for electronics. The laser left perfect edges—no filing needed.

Plasma Cutting

This method uses superheated gas to blow through the metal. It’s fast and powerful.

Best for: Thick sheets, budget-friendly jobs

Pros:

- Fast cutting

- Works well on steel and thick materials

- Handles painted or rusty surfaces

Cons:

- Rough edges

- Needs grinding or sanding after cutting

I used plasma to cut steel brackets. It was quick, but we spent time cleaning the edges.

Waterjet Cutting

Cut metal using high-pressure water mixed with sand-like grit. No heat is involved, which keeps the material stable.

Best for: Thick or heat-sensitive materials

Pros:

- No heat distortion or burn marks

- Great for thick metal

- Can handle detailed or curved shapes

Cons:

- Slower than laser or plasma

- Costs more per part

We used a waterjet for stainless steel parts that needed a perfect finish. Slower, but flawless.

Shearing (Mechanical Cutting)

Uses a sharp blade to cut straight lines through flat sheet metal. Like industrial scissors.

Best for: Simple, straight cuts

Pros:

- Fast

- Great for cutting sheets to size

- Low cost

Cons:

- Can’t cut curves or shapes

- Limited to trimming

I trimmed copper sheets for bending jobs using a shear. Fast and clean when you just need straight lines.

Punching (Turret or CNC)

A punch tool presses through the sheet to create holes, slots, or patterns. CNC punching is guided by a design file.

Best for: Repeat holes, vents, or cutouts

Pros:

- Fast after setup

- Good for high volumes

- Works well for patterns like grids

Cons:

- Can distort thin metal

- Needs special tools for each shape

We used CNC punching to cut dozens of vents into stainless panels. It was quick and reliable, but we had to watch for slight bending in thin sheets.

Each cutting method has its place. Before starting, think about what you’re making, how fast you need it, and how clean the final part needs to be.

That one choice—laser, plasma, waterjet, shearing, or punching—can make your job go a lot smoother. Trust me, I’ve learned that lesson more than once.

4. Common Tolerances and Surface Finish Expectations

If you’ve ever had a part that almost fit—but not quite—you already know how important tolerances are.

That tiny gap or rough edge can ruin the whole building.

I’ve learned this the hard way.

Sometimes the part looks great at first, but once you start assembly, problems show up.

Cutting method plays a big role in how precise the part is—and how clean the surface looks. Some methods are great for tight fits.

Others might need some extra cleanup before the part is truly ready. Here’s how different methods stack up, so you can pick what works best for your part.

Typical Tolerances by Method

Every cutting method has its own level of accuracy. If you’re building parts that must fit tightly—like enclosures or brackets—it helps to know what kind of precision to expect.

Here’s a general guide based on my own experience:

- Laser cutting: ±0.05 mm

- Waterjet cutting: ±0.1 mm

- Punching: ±0.2 mm

- Plasma cutting: ±0.3 mm

If you’re making something for electronics or medical use, laser or waterjet is a better fit. But if you’re cutting steel for a heavy-duty frame, plasma might be just fine.

Surface Finish Levels

Surface finish affects how your part looks and how it behaves during assembly. Some methods leave clean, burr-free edges. Others leave dross (melted metal on the edge) or burrs (sharp metal bits). Those need to be removed before painting or assembly.

Here’s what I’ve seen:

- Laser: Usually clean. May need light deburring.

- Waterjet: Very smooth, no heat marks.

- Plasma: Can leave rough edges and dross.

- Punching: Often leaves burrs, especially on thicker sheets.

If your part will be painted, anodized, or powder-coated, a clean surface makes a big difference. Any sharp edges or leftover slag can mess with the final look—or cause coating to peel.

Some finishes look fine as-is. Others need post-processing like grinding, polishing, or deburring. At MachMaster, we often add this extra step when the job calls for it.

5. Applications Across Industries

Sheet metal cutting isn’t one-size-fits-all.

I’ve worked on projects in different industries, and each one needed something different. Some cared most about tight fits. Others needed strength or clean edges that looked sharp right out of the machine.

What really matters is what the part has to do. Is it visible? Does it need to handle stress? Will it fit into a precise assembly?

The cutting method you choose depends on those answers.

So, here’s how sheet metal cutting shows up across different industries—and why the method matters.

Electronics

If you’re building parts for electronics, chances are you’re working with thin aluminum.

Think of things like:

- Device enclosures

- Mounting plates

- Internal brackets

In these cases, accuracy matters. Even being off by half a millimeter can throw off a whole build.

Laser cutting is a great choice here. It gives you fine details and tight tolerances. For high-volume jobs with repeat holes or slots, punching can be faster and more cost-effective.

Medical Devices

Medical parts need to be clean, accurate, and safe. You don’t want heat marks or sharp edges that could fail under pressure.

Common materials include stainless steel and sometimes titanium. These are used for:

- Surgical tools

- Brackets and support frames

- Sterile covers

For these jobs, I usually go with a waterjet or laser. Waterjet is especially good because there’s no heat-affected zone, which keeps the metal properties intact.

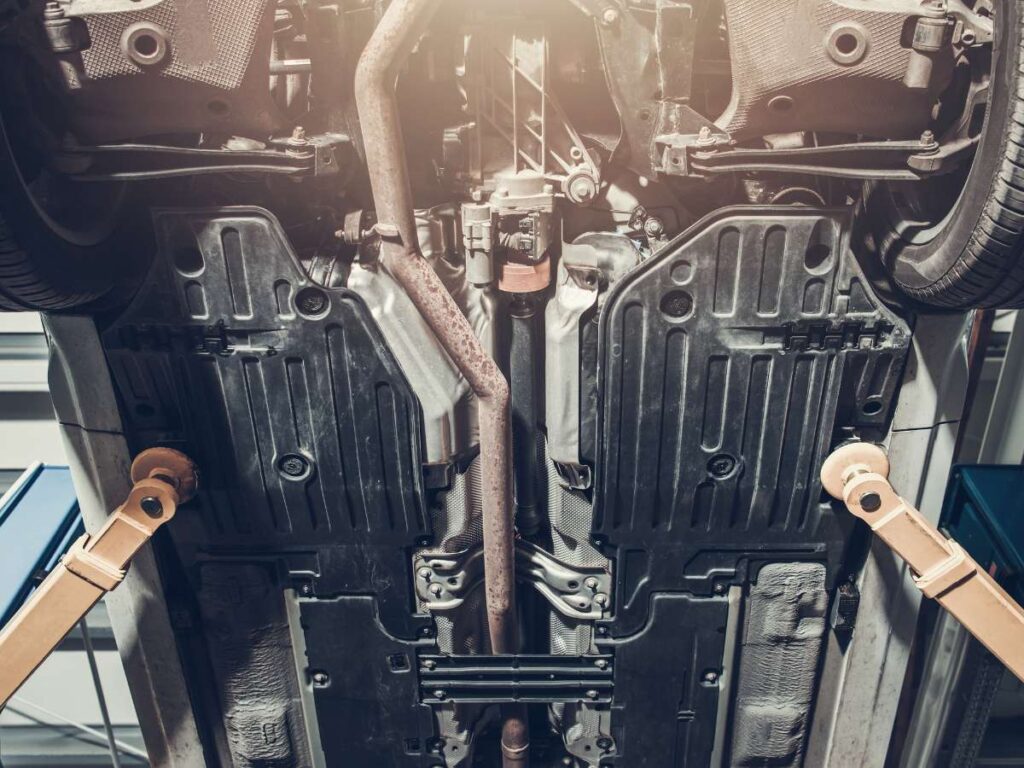

Automotive

Cars and trucks rely on strong parts that hold up under stress. That means cutting thicker steel, sometimes up to 6mm or more.

Common parts include:

- Chassis components

- Mounting brackets

- Protective covers

Plasma cutting is often used here. It’s fast, powerful, and works well on thick materials. If the job calls for cleaner cuts, laser is a solid backup.

Advertising & Signage

This is where looks really matter. Clean edges, smooth curves, and bold shapes make all the difference.

Typical jobs include:

- Storefront letters

- Company logos

- Decorative panels

Most signs are made from aluminum or steel. I usually recommend laser or waterjet cutting for these. Both give sharp, clean results with minimal edge cleanup.

6. Challenges and Limitations of Sheet Metal Cutting

No cutting method is perfect. I’ve had jobs that looked great on paper, but the final parts told a different story.

If you’re in procurement or design, it helps to know where problems can show up. That way, you can spot issues early—before they cost you time or budget.

Here are some common challenges I’ve faced with sheet metal cutting. Knowing these can save you from extra work later.

Heat-Affected Zones (HAZ)

Laser and plasma cutting use heat to melt the metal. Sounds efficient, right? But on thin sheets, it can cause trouble.

You might see:

- Discoloration

- Warping

- Small bends around tight corners

This is called a heat-affected zone. It happens when the area near the cut gets hot and changes shape.

I once used plasma on a thin stainless panel. Looked fine at first—until it cooled. The whole piece curled slightly, and we had to toss it.

If your part needs a clean look or tight tolerance, heat-free methods like waterjet might be better.

Burrs and Secondary Processing

Some cutting methods leave behind burrs—tiny raised edges or rough spots.

They show up a lot with:

- Plasma cutting

- Mechanical shearing

- CNC punching

These burrs may need:

- Deburring

- Grinding

- Extra handling time

I’ve had to rush parts to a belt sander just to stay on schedule. It’s not ideal, especially for larger batches.

Warping and Material Movement

Thin metal sheets can move or shift while cutting. If they’re not clamped or supported properly, you might get:

- Misaligned cuts

- Uneven shapes

- Parts that don’t match the drawing

One time, a loose sheet lifted slightly during laser cutting. The beam missed its path by just a few millimeters. That tiny shift ruined the entire run.

Setup and Tooling Costs

Some methods need more than just a file and machine.

Punching or mechanical shearing may require:

- Custom dies

- Special tooling

- Setup time

That’s fine for big runs. But for small batches or prototypes, those costs add up quickly.

I once helped quote a job with five parts—but the die cost made it three times more expensive than laser cutting.

No method is completely hassle-free. But if you know what to expect, you can choose the one that gives you fewer surprises—and better results.

7. Tips When Choosing Sheet Metal Cutting Services

I learned the hard way that not all sheet metal cutting services give you the same results.

One job came back with jagged edges, missing holes, and delays that threw off my whole timeline. That experience changed how I pick cutting partners.

It’s not just about price. It’s about quality, fit, and whether the shop actually delivers what they promise.

Here are some things I always check—starting with the most important.

Match Cutting Method to Part Need

Not every part needs a perfect finish. But some absolutely do.

- Go with laser or waterjet for high-precision, cosmetic parts

- Choose plasma or shearing for structural components or rough cuts

We once sent a stainless faceplate to be plasma cut. The holes weren’t clean, and the edges looked burned. We had to switch to laser to get it right.

Request Cut Samples Before Placing Orders

This is especially helpful when:

- You’re working with a new supplier

- The parts will be painted or powder coated

- You’re using a material you haven’t worked with before

A simple sample can save a full production run from going off track.

Consider File Formats and DFM Rules

Send clear design files. Most cutting shops work with:

- DXF

- DWG

- STEP

Avoid tiny slots or sharp corners that might bend during cutting. Think about how the part will actually be made—not just how it looks in CAD.

Supplier’s Certifications & Equipment

Certifications matter. At MachMaster, we hold ISO 9001, and I’ve seen firsthand how following a proper system helps catch mistakes early.

You can also ask:

- Do they run in-house quality checks?

- What machines and software do they use?

- How do they inspect parts before shipment?

Even a quick chat about equipment can tell you a lot about their standards.

Lead Times and Minimum Orders

Ask questions early to avoid surprises later:

- What’s their usual lead time?

- Do they have a minimum order size?

- Can they help you save material by nesting parts efficiently?

- Do they keep your metal type in stock?

One time, we had a delay just because the supplier ran out of 3mm aluminum. If we’d asked ahead, we could’ve worked around it.

The more you know about your cutting partner, the smoother your projects will run. Good parts don’t happen by chance. They come from good planning—and asking the right questions before the first cut.

Conclusion

Sheet metal cutting isn’t just about slicing metal—it’s about shaping results. You now know the methods, the tolerances, and what to watch out for.

Whether you’re building something small or scaling big, the right choices begin here.

I’ve made the mistakes so you don’t have to. You’ve got the knowledge now.

So take the first step. Start smarter.

Need help? Contact us today. We’re here to support your next project.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.