I pulled an old machine base from storage. Rust everywhere. Oil stains. I thought about scrubbing it down—but that would’ve taken days.

Instead, I called in a sandblaster.

One hour later, the surface was bare, clean, and ready for primer. That job taught me how fast and powerful sandblasting really is. Now, it’s my go-to for surface prep.

In this article, I’ll explain how sandblasting works, when to use it, and what to expect. Whether you’re a designer, buyer, or just working on a personal project this guide is for you.

You’ll leave with a clear understanding of how sandblasting can clean, prep, or finish your metal parts so you can move forward with confidence.

So let’s start!

1. What Is Sandblasting?

Sandblasting is a way to clean or shape a metal surface using fast-moving particles.

Think of it as pressure washing but instead of water, it uses tiny bits of sand or other grit. These bits hit the metal hard. That force helps remove rust, old paint, grease, or anything stuck on the surface.

You might also hear it called abrasive blasting. Some people even use different materials like glass beads or walnut shells instead of sand. The idea stays the same: clean and prepare the surface using pressure and grit.

Sandblasting helps you:

- Strip off rust, paint, or oil

- Make the surface rough for better coating or welding

- Clean up used or dirty metal parts

- Shape or smooth the metal before using it

It works well on steel, aluminum, iron, and more.

I once had a batch of brackets that came in coated with grime and mill scale. I tried wiping them down. No luck. I tried grinding—too slow. Then I sent them for blasting. They came back clean, roughened just right, and ready to weld. That job taught me something simple: blasting isn’t just about looks—it’s about getting metal ready for real work.

If you’ve ever had paint peel too fast or welds fail early, surface prep might be the missing step. That’s where sandblasting makes a real difference.

2. How Sandblasting Works

Sandblasting might sound technical, but the process is pretty simple once you see it in action. Let’s break it down below:

Key Parts of the System:

- Abrasive media: sand, glass beads, steel grit, or other grit

- Blasting equipment: a cabinet (closed system) or a portable setup

- Air compressor or blast wheel: this powers the system

- Nozzle or blast gun: where the grit shoots out

- Safety gear: gloves, face shield, and a proper mask are a must

Basic Steps:

- Step#1 Inspect the metal. Check for grease, oil, or loose dirt

- Step#2 Pick the right media. Some grit is soft. Others are rough

- Step#3 Set the pressure. Lower for thin parts, higher for tough rust

- Step#4 Start blasting. Move the nozzle across the surface evenly

- Step#5 Clean the part again. Blow off dust or wipe it down

- Step#6 Inspect the result. It should look clean and feel slightly rough

There are 2 main types of sandblasting:

- Dry blasting: common for metal. It’s fast but dusty

- Wet blasting: uses water and grit. Softer on the surface and makes less dust

You can also choose between:

- Cabinet systems: great for small parts or repeat jobs

- Portable systems: good for large items or work done on-site

One time, we had to blast an old metal sign outside the shop. It was too big for a cabinet, so we used a portable blaster. With the right grit and steady movement, we stripped years of grime in under 30 minutes.

That’s the power of sandblasting fast, clean, and ready for what comes next.

3. Pros and Cons of Sandblasting Metal

Sandblasting is a powerful way to clean and prepare metal. But like any tool, it has ups and downs.

If you’ve ever had paint that didn’t stick or rust that kept coming back this process can help. It gives you a clean surface and a rough texture that holds coatings better. But it’s not perfect for every job.

Let’s look at both sides.

Pros

- Strong Cleaning Performance: Sandblasting does what wire brushes and chemicals often can’t. It gets deep into corners, curves, and rough spots. Rust, old paint, oil, and mill scale are gone in minutes. Even thick buildup comes off fast.

- Improves Coating Adhesion: After blasting, the surface isn’t just clean—it’s also rough enough for paint, primer, or powder coat to grip. This helps coatings last longer without peeling or flaking. It’s a key step before painting or coating any metal part.

- Works on Many Metals and Shapes: Sandblasting isn’t just for one kind of job. It works on steel, aluminum, iron, and more. You can clean flat parts, pipes, brackets, or even complex shapes with holes and curves.

Cons

- Can Damage Thin Parts If Misused: If you blast thin sheet metal with too much pressure or stay in one spot too long—it can bend, warp, or even tear. You need to test your settings first and go gently on delicate pieces.

- Creates Dust (Requires PPE and Containment): Dry blasting sends grit and dust everywhere. That dust isn’t safe to breathe. You’ll need gloves, a mask, eye protection, and good airflow. If you’re inside, use a cabinet or blast room to keep it contained.

- Surface Texture May Not Be Uniform Without Control: If your movement is too fast or uneven, some areas may look smooth while others are rough. A steady hand and even distance help keep the texture consistent. If not, coatings may look uneven later.

I once blasted a batch of aluminum plates for a coating job. I used too much pressure and didn’t test first. The edges curled a little, and the coating didn’t hold right. That mistake taught me to always adjust the pressure and test on a scrap first.

Sandblasting works well but only if you use it with care.

4. Types of Abrasive Media for Metal Sandblasting

The abrasive you choose matters. It affects how the surface looks, how clean it gets, and how much material gets removed.

Some media are rough. Some are gentle. Some you can reuse. Others break down fast.

If you pick the wrong one, you could damage your part—or not clean it well enough.

Here’s a breakdown of common blasting media and how they work.

Aluminum Oxide

This is one of the most common options.

- Very aggressive

- Cuts through rust, scale, and old paint fast

- Great for hard metals

- Can be reused several times

If you need strong cleaning and don’t mind a rough surface, this works well.

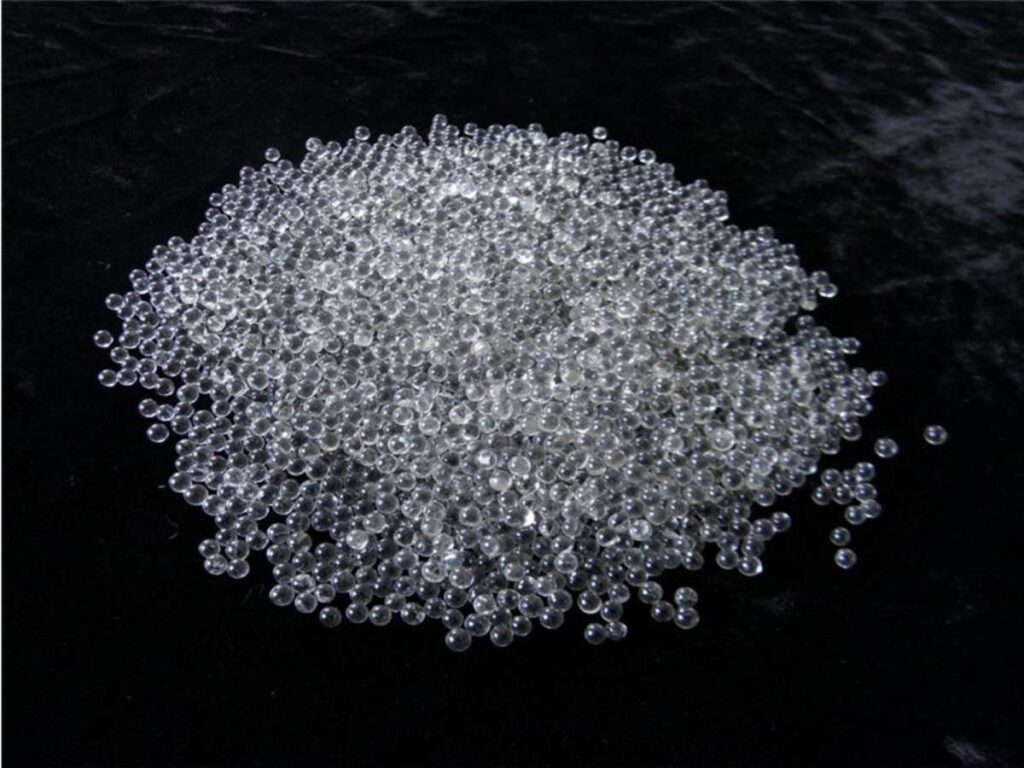

Glass Beads

Glass beads give a softer finish.

- Less aggressive than aluminum oxide

- Good for cleaning without removing too much material

- Leaves a smoother, satin look

- Often used for polishing or cosmetic work

Works well on aluminum or stainless parts where appearance matters.

Silicon Carbide

One of the hardest media you can use.

- Very sharp and fast-cutting

- Great for tough surfaces or hard coatings

- Can cut quickly, even on thick build-up

- Not ideal for soft metals, it may be too harsh

Use with care. It’s powerful.

Steel Grit or Steel Shot

This is made for heavy-duty work.

- Used for cleaning thick rust or prepping structural steel

- Reusable many times

- Great for blast rooms or large jobs

- Not for delicate parts

This is industrial-level blasting. Strong and fast.

Walnut Shells or Corn Cob

Gentle and natural options.

- Good for soft metals like brass or aluminum

- Won’t scratch or damage the surface

- Useful when you want to clean without changing the part’s shape

- Breaks down faster, not as reusable

Best for light cleaning or restoration work.

I once had to clean some thin aluminum covers for a client. I used aluminum oxide on the first few. Big mistake. The surface turned dull and rough. Switched to glass beads and the difference was clear. Smooth finish, no damage.

The grit you pick shapes the result. Take your time and match it to the job.

5. Common Applications of Sandblasting Metal

Sandblasting isn’t just about cleaning—it’s about getting metal ready for real use. Whether you’re fixing, finishing, or fabricating, blasting plays a big role in how the part performs.

Here’s where it’s most useful.

Removing Rust and Paint

Old coatings and corrosion can be stubborn. Sandblasting strips them away fast.

It’s commonly used on:

- Structural steel beams

- Utility trailers

- Water tanks and fuel tanks

This gives you a clean surface to start fresh—no peeling, no hidden rust.

Prepping Before Coating

Before you paint, powder coat, or galvanize, the metal needs to be clean and rough enough to hold the finish.

Sandblasting helps by:

- Creating a textured surface

- Removing oils, scale, and old finishes

- Improving coating grip so it doesn’t flake or chip

This step is key to getting long-lasting results.

Restoring Old Parts

Old machines, car parts, or tools often look too far gone. But a solid blast can bring them back.

Common uses include:

- Antique engine parts

- Farm tools

- Metal signs or shop equipment

It removes years of dirt and damage, revealing solid metal underneath.

Texturing or Profiling Surfaces

Some coatings need a “bite” to stay in place. Sandblasting creates that grip.

This is helpful when using:

- High-performance paints

- Epoxy coatings

- Industrial adhesives

It’s not just clean—it’s surface-ready.

Used Across Many Industries

You’ll find sandblasting used in:

- Automotive: frames, wheels, engine parts

- Aerospace: prep for coatings or inspection

- Marine: ship hulls, docks, and tanks

- Oil & Gas: pipelines, rigs, and large vessels

I remember restoring a rusted-out trailer frame in our yard. It looked beyond repair. But after sandblasting? Clean metal. Solid bones. We primed and painted it that same week—and it’s still holding strong today.

At MachMaster, we offer both. As a technology-driven precision manufacturing company, we handle in-house sandblasting as part of our full-service production—from CNC machining to surface treatment. For high-volume or advanced finishes, we also partner with trusted vendors that meet our strict ISO 9001 standards.

No matter what you’re working on, sandblasting helps bring metal back to life and get it ready for what’s next.

6. In-House Sandblasting vs Outsourcing

If you’re working with metal often, you’ve probably wondered should I do the blasting myself, or send it out?

Both options have pros and cons. One gives you control. The other saves time and setup. The right choice depends on your budget, space, and how often you need it.

Here’s a side-by-side look to help you decide:

| Factor | In-House Sandblasting | Outsourcing Sandblasting |

| Cost | High upfront cost (equipment, space, safety) | Pay per job—no setup or maintenance fees |

| Time Control | Immediate use, no waiting | May involve wait times or scheduling delays |

| Skill Needed | Requires trained staff and safety training | Handled by professionals |

| Consistency | Quality may vary if staff is inexperienced | Usually more consistent finish |

| Maintenance | You handle cleanup, filter changes, etc. | No maintenance on your end |

| Best For | Frequent jobs, tight timelines, full control | One-off projects or jobs with complex needs |

Here’s the truth you don’t have to choose just one. Some shops do both. You can blast small parts in-house and outsource the rest. It all depends on your workflow, team, and what your parts really need.

7. Common Problems and How to Avoid Them

Sandblasting can save you time and give great results but only if it’s done right.

When something goes wrong, it’s often from pressure, technique, or the setup. The good news? Most mistakes are easy to avoid once you know what to watch for.

Here are some of the most common problems and how to fix them:

Warping or Over-Blasting Metal

Thin metal bends fast if blasted too hard or too long. Once it warps, it’s hard to fix.

To avoid this:

- Use lower air pressure

- Choose softer media like glass beads or walnut shell

- Keep the nozzle moving so heat and pressure don’t build up in one spot

Don’t rush. Gentle passes get better results.

Inconsistent Finish or Pitting

Sometimes the surface looks patchy. Or worse, there are small pits or dents. That usually means the blasting wasn’t even.

To avoid this:

- Keep a steady angle and distance, don’t wave the nozzle around

- Use clean, sifted media dirty grit clogs and cuts unevenly

- Check for moisture in your air lines wet media clumps and makes a mess

An uneven finish can ruin a paint job. Take time to set it up right.

Media Clogging or Dust Build-Up

Dust and clogged media are common problems, especially in humid areas or older setups.

To avoid this:

- Use a dry air source, add an air dryer or desiccant if needed

- Clean nozzles often grit buildup cuts flow and power

- Empty blast cabinet filters clogged filters slow everything down

Clean equipment works better and lasts longer.

We once had a job delay because the nozzle kept clogging. Spent hours swapping out parts only to find the problem was moisture in the air line. A $20 air dryer fixed it for good.

Mistakes happen, but they don’t have to happen twice. With the right setup and a few habits, you’ll keep your blasting jobs smooth and stress-free.

8. How to Choose a Sandblasting Supplier

Not all sandblasting shops are the same. Some just clean parts. Others prep them for high-performance coatings or tight-tolerance assembly.

If you’re sourcing a supplier, the small details matter. You want someone who does more than just blast—you want someone who understands why the surface finish matters.

Here’s a checklist to help you choose the right one:

Checklist for Procurement & Sourcing Teams

Before picking a supplier, ask yourself:

- What abrasive media do they use? Different jobs need different grit. Aluminum oxide is rough. Glass beads are smooth. They should be able to match your part’s needs.

- Can they hit your Ra or finish spec? Some coatings need a rougher surface. Others don’t. A good shop should know how to blast to a target roughness.

- Do they test parts after blasting? Ask if they include adhesion or surface inspections. It’s a good sign they take quality seriously.

- Can they do masking for selective blasting? If some areas shouldn’t be blasted, they should be able to cover them. Tape, plugs, or custom masks—ask what they offer.

How to Ask the Right Questions

These simple questions can save you from problems later:

- “What’s your process for cleaning after blasting?” Leftover grit or dust can mess up coating or welding.

- “Can you hit a specific surface roughness?” This tells you if they understand finish specs and can deliver.

- “What are your lead times for a 100-piece batch?” Helps you plan production and avoid delays.

We once worked with a shop that did great blasting but didn’t mask holes on a machined part. The result? Grit got inside threads and bearings. We had to rework the batch.

That’s why attention to detail matters especially for companies like MachMaster, where precision comes first. As a custom manufacturer handling everything from CNC machining to surface treatment, we rely on blast shops that can meet strict Ra values and follow tight quality standards.

If your parts need to meet tough specs, don’t settle for “good enough.” Ask better questions. Choose partners who treat surface prep like it matters because it does.

Conclusion

ou’ve got the knowledge. You know what sandblasting does, what tools you need, and how to avoid costly mistakes.

Whether it’s your first project or your fiftieth start with clean, prepped metal. It’s the one thing I wish I hadn’t skipped.

Now’s the time. Don’t wait for coatings to peel or parts to fail.

Contact MachMaster today if you’re looking for a trusted production partner who understands how prep impacts precision.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.