I’ve had customers come to me with great designs—strong materials, smart builds—but the surface didn’t hold up.

Why?

Because no one explained surface treatments to them.

As a manufacturer, we handle different surface finishes daily. From anodizing to powder coating, we’ve seen what works, what fails, and what saves money in the long run.

If you’re unsure what surface treatment your part needs, this article is for you.

I’ll walk you through 10 of the most common types, explain how they work, and help you match the right one to your application.

By the end, you’ll be able to ask the right questions and avoid costly mistakes.

So let’s get started!

Quick Comparison Chart

Before we get into the details of each surface treatment, here’s a quick side-by-side look of each surface treatment types. This table gives you a fast way to compare what each option offers and where it works best.

| Surface Treatment | What It Does | Best For | Benefits | Key Limitations |

| Anodizing | Electrochemically thickens oxide layer on aluminum/titanium | Aerospace, electronics, architecture | Corrosion resistance, hardness, color options | Only works on non-ferrous metals |

| Powder Coating | Sprayed dry powder, heat-cured | High-volume, high-wear parts | Durable, uniform, no VOCs | Requires heat cure, tight prep needed |

| Electroplating | Metal coating via electric current | Functional/decorative metal finishes | Wear resistance, conductivity, shiny appearance | Involves chemicals, inconsistent on shapes |

| Electropolishing | Electrochemically removes material for smooth finish | Precision or sterile-use parts | Smooth, clean, corrosion-resistant | Limited to certain alloys, reduces thickness |

| Passivation | Acid bath removes iron on stainless steel | Stainless parts in moist/oxidizing environments | Corrosion resistance, non-dimensional | Needs clean surface, limited to some grades |

| Black Oxide | Forms magnetite layer on steel | Tools, hardware, non-reflective parts | Matte look, light rust protection | Needs sealant, cosmetic use only |

| Painting (Industrial) | Liquid coating, air- or oven-dried | Structural parts, large assemblies | Custom color, UV & chemical protection | Less durable, VOCs, long dry times |

| Galvanizing | Zinc coating by dip or electroplating | Outdoor steel structures | Long-term rust protection, sacrificial layer | Thick coating, rough finish |

| Nitriding | Diffuses nitrogen into steel for hard surface | Gears, molds, shafts | Very hard surface, low distortion | Alloy limits, long cycle time |

| Chem. Conversion Coating | Converts aluminum/magnesium surface to protective layer | Parts needing paint, like enclosures or castings | Paint adhesion, corrosion protection | Limited wear resistance, chemical limits |

Now that you’ve seen the big picture, let’s take a closer look at each surface treatment one by one.

1. Anodizing

Anodizing is a surface treatment that changes the outer layer of a metal, usually aluminum, by creating a hard and protective oxide coating. It doesn’t just sit on top like paint. It grows from the metal itself.

This process makes the surface stronger, more resistant to corrosion, and can even add color.

You’ve probably touched an anodized surface without even knowing it. Think about the colored metal parts on kitchenware, phones, or bike frames. That smooth, matte finish? That’s anodizing at work.

How It Works:

Anodizing is done using electricity and acid. It’s an electrochemical process. The metal part goes into an acid bath. Then it’s connected to a power source.

Electricity passes through the acid and causes the metal surface to react. This builds up a layer of aluminum oxide.

That new layer becomes part of the metal. It won’t peel or flake off.

After that, the part can be dyed if color is needed. Then it’s sealed to close up the pores and protect the finish.

Key Benefits:

Anodizing is pretty awesome. Here’s why:

- Helps stop rust and corrosion

- Makes the surface harder and tougher

- Adds color without using paint

- Won’t chip or flake off

- Still keeps the part the same size (important for fitting pieces together!)

- Easy to wipe clean

It’s a strong and neat finish that works especially well indoors.

Where It’s Commonly Used:

Anodizing works best on aluminum. You’ll see it used in:

- Electronics: Phone casings, laptops, and camera bodies

- Architecture: Window frames, railings, and curtain walls

- Consumer goods: Cookware, sports gear, flashlights

- Transportation: Aircraft parts, bike frames, car trim pieces

Limitations to Consider:

Anodizing is helpful, but it doesn’t work for everything. Here’s what to keep in mind:

- Works best on aluminum, not steel or iron.

- If it’s colored and sits in the sun a lot, the color might fade over time.

- The surface has to be smooth first—scratches or dents will still show.

- It won’t protect well from strong chemicals or really rough wear.

So if you have a shiny aluminum part and want to make it tougher or give it color, anodizing could be a smart choice.

But if it’s steel or something that’ll go through harsh conditions, you might need a different surface treatment.

Need help deciding? MachMaster doesn’t just anodize—we offer a range of finishing services to match the right treatment to your material and use case. From trial runs to full production, we support you at every step. Contact us now for more information!

2. Powder Coating

Ever wonder how some metal things stay looking new for years? Like a bright red bike, a smooth gym machine, or a metal fence that doesn’t rust?

That’s probably powder coating doing its job.

Powder coating is kind of like painting—but stronger and cleaner. Instead of using wet paint, it uses dry powder that sticks to the surface using static electricity (like how socks stick in the dryer!). Then it gets baked in a super-hot oven until the powder melts into a smooth, tough shell.

How It Works:

Powder coating starts with a clean metal part. Any dirt, grease, or rust has to be removed first. Then the powder is sprayed on using a special gun. This gun gives the powder an electric charge.

That charge makes the powder cling to the surface.

Once coated, the part goes into an oven. It’s baked at high heat—usually around 350°F to 400°F. The powder melts, flows, and hardens into a strong shell.

After cooling, the finish is fully cured.

No drying time. No peeling. It’s ready to use right away.

Key Benefits:

Powder coating is known for:

- Strong resistance to scratching and chipping

- Bold color options in gloss, matte, or textured finishes

- No solvents or wet chemicals

- Great protection for outdoor or heavy-use parts

- Even coverage without runs or drips

I once had a client use it on gym equipment. Years later? It still looked almost new—even with sweaty hands and daily workouts.

Where It’s Commonly Used:

Powder coating is popular across many industries. You’ll find it in:

- Automotive and motorcycle parts: Frames, wheels, bumpers, and engine covers

- Appliances: Washers, dryers, refrigerators, and microwave housings

- Fitness machines: Gym frames, weight racks, and benches

- Outdoor furniture: Chairs, tables, and metal fencing

- Storage and racks: Toolboxes, shelves, and commercial racks

Limitations to Consider:

Even a good finish has limits.

- It doesn’t work on most plastics or rubber

- Large parts need big ovens—not every shop can handle that

- Touch-ups are hard. You usually have to redo the whole part

- Surface prep matters. Dirt or oil can ruin the coating

So, is powder coating right for you?

If your part is metal, can take heat, and needs to look great for a long time—yes, it’s a solid option. But if you’re working with plastic, rubber, or something really big, you might want to try another method.

Still deciding what’s best? At MachMaster, we help you choose the right finish for your part—and deliver it too. With precision production, in-house coating, and ISO 9001 quality, your project’s in safe hands.

3. Electroplating

I’ve had people bring me parts that looked dull and worn—and ask if there was a way to give them new life. That’s when I talk about electroplating.

Electroplating is a surface treatment that adds a thin layer of metal on top of another metal. It’s mostly used to improve how a part looks or to help it resist rust and wear. The final result is smooth, shiny, and often looks more expensive than it really is.

The main part is usually made from a lower-cost metal. The coating, though, might be nickel, chrome, gold, or even silver.

It’s a great way to give everyday parts a cleaner look—and better performance.

How It Works:

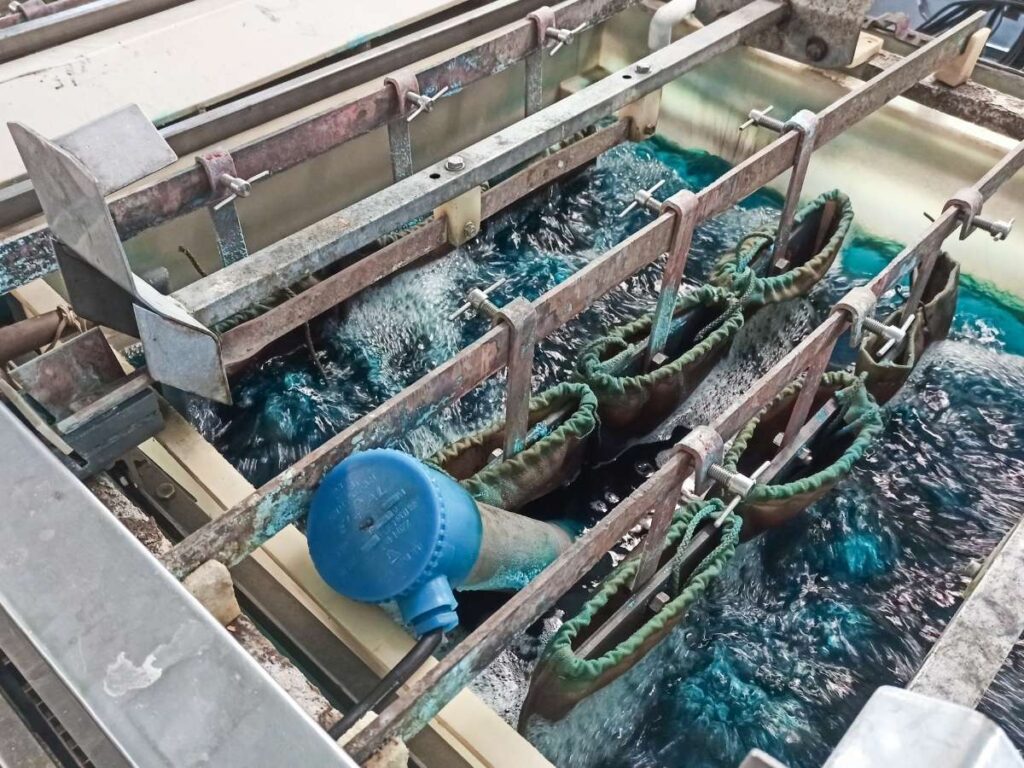

Electroplating uses electricity and a chemical bath to apply a thin metal layer to a part’s surface.

First, the part is cleaned to remove grease, rust, or dirt. Then it’s placed into a liquid solution called an electrolyte. A second metal, such as nickel or chrome, is added to the solution.

An electric current is passed through the setup, causing metal ions in the solution to bond to the surface of the part. The result is a thin, smooth, and even coating that looks polished and holds up well in many applications.

Key Benefits:

Electroplating offers several useful advantages:

- Protects against rust and corrosion

- Gives parts a shiny, polished appearance

- Reduces surface friction

- Increases surface hardness

- Makes low-cost metals look high-end

I had one customer who used it on plain steel fasteners. After plating them with nickel, they looked like high-end parts—and held up well in humid conditions.

Where It’s Commonly Used:

You’ll find electroplating in many industries:

- Jewelry and accessories: Gold, silver, or rhodium finishes

- Automotive parts: Door handles, trim, badges

- Electronics: Circuit connectors and pins

- Tools and hardware: Wrenches, screws, and decorative bolts

Limitations to Consider:

Like any process, electroplating has its limits.

- It only works on materials that conduct electricity

- The metal layer is thin and can wear off with use

- Good surface prep is needed or the finish may peel

- Some plating solutions contain toxic materials

Looking for a shiny, protective layer that upgrades your part’s look? Electroplating could be the right call.

But if you need something more durable for heavy wear, electroplating is not for you.

4. Electropolishing

Sometimes, parts come off a machine rough, dull, or full of small surface flaws. Even when the shape is perfect, the finish just isn’t there.

That’s where electropolishing comes in.

Electropolishing is a surface treatment that smooths and brightens metal parts. It removes a thin layer from the surface using an electric current and a chemical bath. The result is a clean, shiny, and smooth finish.

You’ll often see it used on stainless steel parts that need to look sharp and resist rust—especially in food, medical, or lab settings.

How It Works:

Think of electropolishing like gently shaving off the rough top layer of metal.

First, the part is cleaned. Then it’s placed in a tank filled with acid. The part is hooked up to electricity, becoming the “positive” side. A second metal acts as the “negative” side.

Once the current flows, metal begins to dissolve from the surface. The high spots disappear faster than the low ones, which helps flatten and polish the entire part.

What you’re left with is a smoother, shinier version of the same part—without adding anything to it.

Key Benefits:

Electropolishing offers a range of improvements:

- Smoother surface with fewer flaws

- Better corrosion resistance

- Easier to clean

- Improved look—shiny, bright finish

- Can reduce friction in moving parts

I once worked with a client in the medical field who needed ultra-smooth stainless steel tubes. Electropolishing made the surfaces clean and easy to sterilize.

Where It’s Commonly Used:

Electropolishing is common in industries that need high-purity or easy-to-clean parts:

- Medical devices: Surgical tools, implants, tubing

- Food and beverage: Processing equipment and valves

- Pharmaceutical: Stainless steel tanks and fittings

- Aerospace: Hydraulic components and fasteners

Limitations to Consider:

Every surface treatment has trade-offs, and electropolishing is no different.

- Only works on metals that conduct electricity

- Best results come from stainless steel and similar alloys

- Doesn’t fix deep scratches or dents

- Needs careful setup to avoid over-polishing

Want a smooth, bright surface without coatings or paint? Electropolishing might be what your part needs.

But if you’re dealing with rough or damaged material, this process won’t fill gaps—it only removes.

5. Passivation

Sometimes, stainless steel doesn’t stay shiny like you thought it would. Even though it’s supposed to fight off rust, little spots can still show up. This happens a lot after cutting, welding, or just touching it with bare hands.

That’s why passivation is helpful.

Passivation is like a deep clean for stainless steel. It washes away tiny bits of iron and dirt that can cause rust later. After cleaning, a thin layer forms on the metal. You can’t see it, but it helps protect the surface from air and water.

If you use stainless steel parts and want them to last longer and stay cleaner, it’s a smart process to know about.

How It Works:

Passivation doesn’t add anything to the surface. Instead, it removes tiny iron particles that don’t belong. First, the part is cleaned to get rid of oil or dirt. Then it’s soaked in a nitric or citric acid solution. The acid reacts with the surface and dissolves any free iron left behind after machining.

After that, the part is rinsed and dried. This leaves behind a clean, passive layer that resists rust. The surface doesn’t change in color or feel, but it becomes more stable and lasts longer in the right conditions.

Key Benefits:

You might not see a change—but you’ll notice the results later:

- Helps stainless steel resist rust

- No paint, coatings, or layers

- Keeps parts clean for longer

- Great for food, medical, and lab gear

- Extends part life without changing appearance

One client had stainless fasteners in a food line that kept showing rust. After passivation? No rust—months later, they still looked brand new.

Where It’s Commonly Used:

Passivation is often used when stainless steel needs to stay clean, smooth, and rust-free:

- Medical and surgical instruments: Scalpels, clamps, and implantable devices

- Food processing machines: Mixers, tanks, and piping systems

- Pharmaceutical equipment: Stainless steel reactors, cleanroom parts

- Aircraft parts and fasteners: Screws, clips, and hydraulic fittings

- Cleanroom and lab hardware: Trays, trolleys, and test racks

Limitations to Consider:

Passivation works well for many stainless steel parts, but it’s not the answer for everything.

- Only works well on stainless steel and related alloys

- Doesn’t fix surface damage or roughness

- The finish looks the same before and after

- Requires clean handling and thorough rinsing to be effective

Need to protect stainless parts without changing how they look or feel? Passivation is a smart, low-impact solution.

But if you’re trying to hide flaws or change the surface finish, you’ll need a different process.

6. Black Oxide

If you’ve ever held a matte black screw or tool that didn’t glare under light, there’s a good chance it was treated with black oxide.

Black oxide is a chemical surface treatment that gives metal parts a dark, smooth finish. It doesn’t add a thick layer or change the part’s size. Instead, it reacts with the surface to form a thin, black layer that helps resist rust and reduce glare.

The finish looks sharp, but it’s not just for style. It also adds light protection and helps oil stick to the surface, which improves lubrication.

How It Works:

The process starts by cleaning the part to remove any dirt, oil, or rust. Then the metal is placed in a hot alkaline solution, usually heated to around 285°F. This causes a chemical reaction on the surface of the metal, forming a thin layer of black iron oxide.

After the black layer forms, the part is rinsed and dipped in oil or wax. This final step helps seal the finish and adds light corrosion resistance. The end result is a dark, smooth surface that becomes part of the metal itself. It won’t flake, peel, or change the size of your part.

Key Benefits:

Black oxide offers several simple but useful advantages:

- Reduces glare on shiny metal parts

- Adds light corrosion resistance when paired with oil or wax

- Keeps part dimensions unchanged

- Improves appearance and surface uniformity

- Helps retain lubricants in moving parts

I worked with a toolmaker who used black oxide on wrenches. The dark finish helped reduce glare under bright lights and made the tools easier to grip.

Where It’s Commonly Used:

You’ll often find black oxide on parts that need to look good and hold up to wear:

- Hand tools: Wrenches, sockets, and screwdrivers

- Fasteners: Screws, bolts, and washers

- Firearms and tactical gear: Barrels, sights, and mounts

- Machinery parts: Shafts, gears, and bushings

- Cutting tools: Drills and taps

Limitations to Consider:

Black oxide does a good job in the right setting. But it’s not perfect for every part or environment.

Here are a few things to think about:

- It only works on ferrous metals like steel and iron

- The rust protection is light, unless you add oil or wax

- It doesn’t hold up well in wet or outdoor areas

- The finish can wear off over time, especially with heavy use

- It won’t protect against deep scratches or rough handling

I’ve used black oxide on parts that stayed inside and out of harm’s way—it held up just fine.

But when I needed something for outdoor tools or parts that took a beating, I had to switch to a tougher finish. You might want to do the same.

7. Painting (Industrial Coating)

You might think paint is just for walls or school projects—but it’s used a lot in factories too.

I’ve seen it sprayed on metal frames, control boxes, and even machine parts. Why? Because it protects things and makes them look better.

This isn’t the kind of paint you’d use at home. Industrial paint is made to fight off rust, sun, rain, and scratches. And yes, you can still pick colors or make them shiny if you want.

How It Works:

Industrial painting starts with surface prep. The part is cleaned, sometimes sanded or blasted, to remove any grease, dust, or rust. This step is key to helping the paint stick.

Then the paint is applied. It can be sprayed, brushed, or dipped, depending on the job. Some coatings are air-dried. Others need to be baked or cured with heat.

Once dry, the painted surface forms a barrier. This layer protects the metal or plastic underneath from damage caused by water, chemicals, or sun exposure.

Key Benefits:

Painting offers both protection and appearance. Here’s what it can do:

- Adds color and a finished look

- Protects against rust and corrosion

- Helps reduce UV damage and weathering

- Works on many materials, including metal and plastic

- Easy to repair or touch up when scratched

One of my clients owns a small business that sells outdoor gear. He paints steel frames using a strong enamel paint. It works really well—even when it rains, gets dusty, or sits outside in the hot sun all day.

Where It’s Commonly Used:

You’ll see industrial painting used in a wide range of products:

- Construction equipment: Loaders, cranes, and lift arms

- Appliances: Washers, dryers, and ovens

- Electrical enclosures: Boxes, panels, and cabinets

- Furniture: Desks, shelves, and storage frames

- Automotive parts: Body panels, bumpers, and undercarriages

Limitations to Consider:

Painting is a flexible option, but it’s not always the most durable.

- Paint can chip or peel over time

- Needs good prep for strong adhesion

- Drying and curing can slow production

- Not as durable as powder coating in harsh environments

Looking for an easy way to add color and surface protection? Industrial paint might be the right choice.

But if you need extreme durability or heavy-duty wear resistance, you may want to explore other coatings.

8. Galvanizing

If your part is going outside—like in the rain or near the ocean, it can start to rust fast. Plain steel can’t handle that kind of weather for long.

That’s why people use something called galvanizing.

Galvanizing is when you cover the steel with a layer of zinc. The zinc works like a raincoat. It blocks water and air from reaching steel. And even if the zinc gets scratched, it still protects the steel. The zinc rusts first—on purpose—so the steel doesn’t have to.

This is called sacrificial protection, and it really works.

If you want your metal to last a long time outside, galvanizing is one of the best ways to keep it safe.

How It Works:

First, the metal gets cleaned—no grease or dirt allowed. Then it goes into a big pot of melted zinc. It’s kind of like giving the part a hot bath.

When it comes out, it’s covered in a gray, bumpy layer of zinc. That layer sticks tight. Even if the surface gets scratched, the zinc keeps protecting the metal underneath from rust.

Sometimes, people use electricity instead of heat to add zinc, but the goal stays the same—keep the steel strong and stop rust from winning.

Key Benefits:

Galvanizing offers powerful protection in tough conditions:

- Long-lasting corrosion resistance

- Protects even if the surface gets scratched

- No need for frequent repainting or maintenance

- Good coverage, even on corners and edges

- Works well in outdoor, wet, or industrial settings

I once had a customer who needed fencing for a farm near the coast. Paint peeled within a year. Galvanized posts? Still solid and rust-free five years later.

Where It’s Commonly Used:

You’ll see galvanized parts almost everywhere outdoors:

- Fences and gates: Posts, mesh, and hardware

- Utility poles: Street signs and guardrails

- Building frames: Roofing supports and brackets

- HVAC parts: Ducting and outdoor units

- Automotive frames: Truck beds and underbodies

Limitations to Consider:

Galvanizing offers strong protection, but it doesn’t suit every situation.

- Only works on steel or iron

- The surface looks dull or rough—not for cosmetic parts

- Can’t apply over small internal surfaces or threads easily

- Adds weight and may affect tight tolerances

Do you need something that keeps metal from rusting for a long time? Galvanizing could be the right pick for you.

But if you care more about how it looks or showing off small details, you might want to go with a different finish.

9. Nitriding

Sometimes, you don’t care if a part looks shiny or cool. You just want it to be strong. Really strong.

That’s where something called nitriding helps.

Nitriding is a heating process that makes steel harder on the outside. It works by putting nitrogen into the surface of the metal. This creates a tough outer layer that fights off wear, heat, and cracking.

And here’s the cool part—nothing is added on top. The metal itself changes and becomes tougher.

If you need a part that moves a lot or carries heavy weight—and you want it to last—nitriding might be just what you need.

How It Works

Nitriding is done in a special furnace. The part is first cleaned and placed inside. Then the furnace is filled with a nitrogen-rich gas, like ammonia. The temperature is kept lower than other heat treatments—usually around 950°F.

As the part sits in the furnace, nitrogen atoms soak into the surface. This reaction creates a hard outer layer while leaving the core of the part strong and flexible.

There are a few types of nitriding, including gas, salt bath, and plasma. Each one has slightly different equipment, but they all use the same basic idea: nitrogen plus heat equals hardness.

Key Benefits

Nitriding offers serious performance for tough jobs:

- Increases surface hardness

- Boosts wear and fatigue resistance

- Adds protection without adding thickness

- Maintains tight tolerances

- No need for quenching or extra machining

One time, I worked with a small shop that made gears for food machines. After they used nitriding on the gears, those things kept running every single day—and even after months, they still looked like new. I was really impressed.

Where It’s Commonly Used

Here are some places where nitriding really makes a difference:

- Automotive: Camshafts, crankshafts, valve parts

- Manufacturing: Gears, shafts, and precision dies

- Hydraulics: Piston rods and cylinders

- Aerospace: Fasteners, actuators, and landing gear

- Tooling: Injection molds and stamping tools

Limitations to Consider

Nitriding is great for surface hardness, but it’s not a universal solution.

- Only works on certain types of steel

- Not suitable for soft metals like aluminum or copper

- Surface color may change to gray or dull

- Not ideal if a shiny or decorative finish is required

Need your part to last longer, even with lots of pressure and wear? Nitriding might be what you’re looking for—it helps make metal parts tougher and stronger.

But if you’re using softer metals or want your part to look shiny and bright, this might not be the best choice. There are other ways that could work better for you.

10. Chemical Conversion Coating

Not every part needs fancy paint or a shiny finish. Sometimes, you just want basic protection that works.

That’s where chemical conversion coating helps.

It’s a quick surface treatment that gives metal a thin, protective layer. Instead of covering the metal, it changes the top layer through a chemical reaction. This makes the surface a little tougher and helps paint stick better if you add it later.

If you work with aluminum, you might hear people call it alodine or chromate coating. Same idea—just different names depending on the metal and formula.

This method is often used during prep. But it also works as a light-duty finish when appearance doesn’t matter much.

How It Works

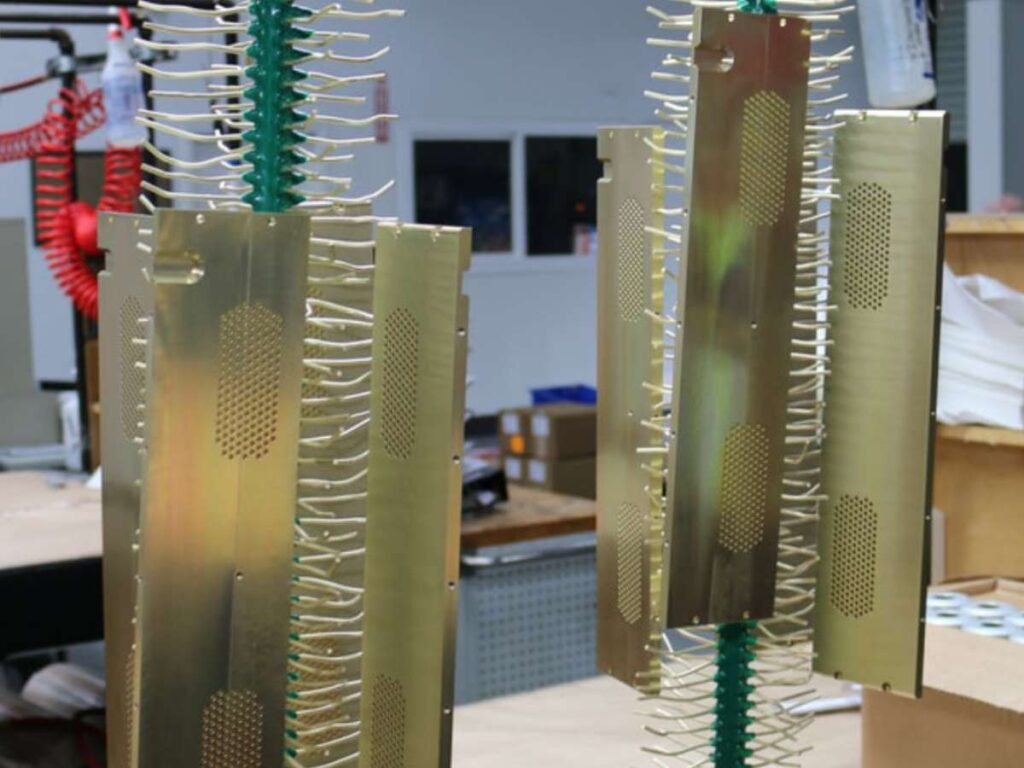

The process starts with cleaning the metal to remove any dirt, grease, or oxides. Then the part is dipped, sprayed, or brushed with a chemical solution. The solution reacts with the surface and creates a new layer of material that bonds to the metal.

Unlike paint or powder coating, nothing is added on top. The coating comes from the reaction itself. Once applied, the part is rinsed and dried.

The finish is very thin. It doesn’t change how the part looks much, but it gives it a dull, sometimes yellow or green tint depending on the formula.

Key Benefits

This process may be simple, but it brings a lot of value:

- Adds light corrosion protection

- Improves paint and primer adhesion

- Doesn’t affect part dimensions

- Can be used on aluminum, zinc, and magnesium

- Works well for electrical parts (it stays conductive)

I remember helping a client who made small metal boxes for wireless gadgets. They didn’t want the parts to rust, but they also couldn’t block any signals. This coating gave them just what they needed—clean protection without getting in the way

Where It’s Commonly Used

Chemical conversion coating is often used on lightweight or indoor parts that need basic corrosion resistance or better paint adhesion:

- Control panels: Aluminum switch plates and faceplates

- Communication devices: Signal boxes, housings, and brackets

- Medical carts and frames: Coated before powder coating or paint

- Office equipment: Printer housings, copier parts, and mounting plates

- Light-duty enclosures: Indoor boxes for wiring, power, or HVAC use

Limitations to Consider

Chemical conversion coating is useful in many cases, but it does have limits.

- Not strong enough for outdoor or high-wear parts

- Appearance may vary and look uneven

- Offers only basic corrosion protection

- Some formulas contain toxic chemicals

Looking for a fast, no-fuss way to prep your part or keep rust away indoors? This might be the right fit.

But if your part is going outside or needs to take a beating, you’ll want something stronger.

Conclusion

Picking a surface treatment doesn’t have to be a guessing game anymore.

You just went through 10 solid options—like anodizing and powder coating. Each one helps solve different problems and works best for certain jobs.

Think about parts you’ve used before that didn’t last long. Maybe the finish wore off too fast or didn’t look right. Now you’ve got the knowledge to do it better.

Keep this guide handy. Use it like a checklist. Share it with your team if they’re stuck too.

If you are still unsure what to choose for your project, reach out to us at Machmaster.

We’re here to help you pick the one that actually fits your job.

Recommended Reads for You

If you need more options, take a look at our full range of products. You might find just what you need:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.