I still remember the first time one of my plastic prototypes cracked straight out of the mold.

I had spent weeks designing it. But the supplier didn’t explain their process clearly. I didn’t know what went wrong—was it the material? The mold? The casting method?

If you’re building a product or sourcing parts, setbacks like this waste time and money. I’ve been there.

Over time, I figured out what mold casting really is—and why it matters.

In this article, I’ll explain everything in simple terms. You’ll learn what mold casting means, the different types, when to use it, and how it applies to your work.

By the end, you’ll have the tools to make better decisions and avoid common mistakes.

So let’s start!

1. What Is Mold Casting?

When I first got into manufacturing, I thought mold casting was a complicated process used only by big factories. But after working on real projects, I realized how common and useful it is.

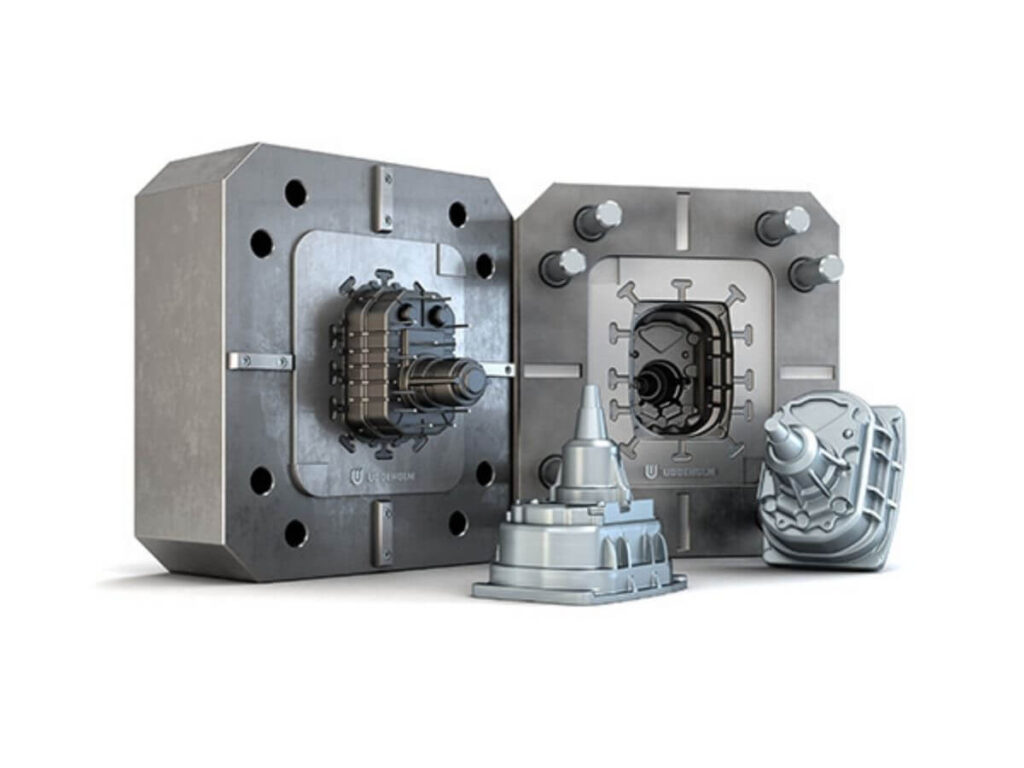

Mold casting is a process where you pour a liquid material into a hollow shape (called a mold). Once it cools and hardens, you get your finished part. Simple as that.

But there’s more to it than just pouring and waiting. If you need one part, you can machine it or 3D print it. If you need 100 or 10,000, mold casting makes more sense.

Here’s why people use it:

- Fast production

- Repeatable quality

- Consistent shape from the same mold

- Great for prototypes and large runs

I used to think mold casting was just for metal. But that’s not the case. You can use:

- Metal: aluminum, zinc, brass

- Plastic: ABS, nylon, polypropylene

- Resin: for figurines, jewelry, custom parts

- Ceramic: for high heat or electrical uses

Each material cools and flows differently, so the choice depends on the job.

You’ve likely used cast parts without realizing it. Common examples include:

- Cars: engine blocks, brackets

- Planes: lightweight metal parts

- Medical devices: plastic housings

- Electronics: casings, connectors

- Home goods: faucets, knobs, toys

Once I noticed how often it’s used, I started seeing it everywhere.

If you’re working on a product or sourcing parts, mold casting is something worth knowing. It’s reliable, flexible, and used across almost every industry.

2. How Mold Casting Works

The first time I watched a mold casting job from start to finish, I was surprised by how each step mattered. Skip one, and the part could fail.

If you’re new to this or planning to use mold casting for your parts, here’s a clear step-by-step view of the process:

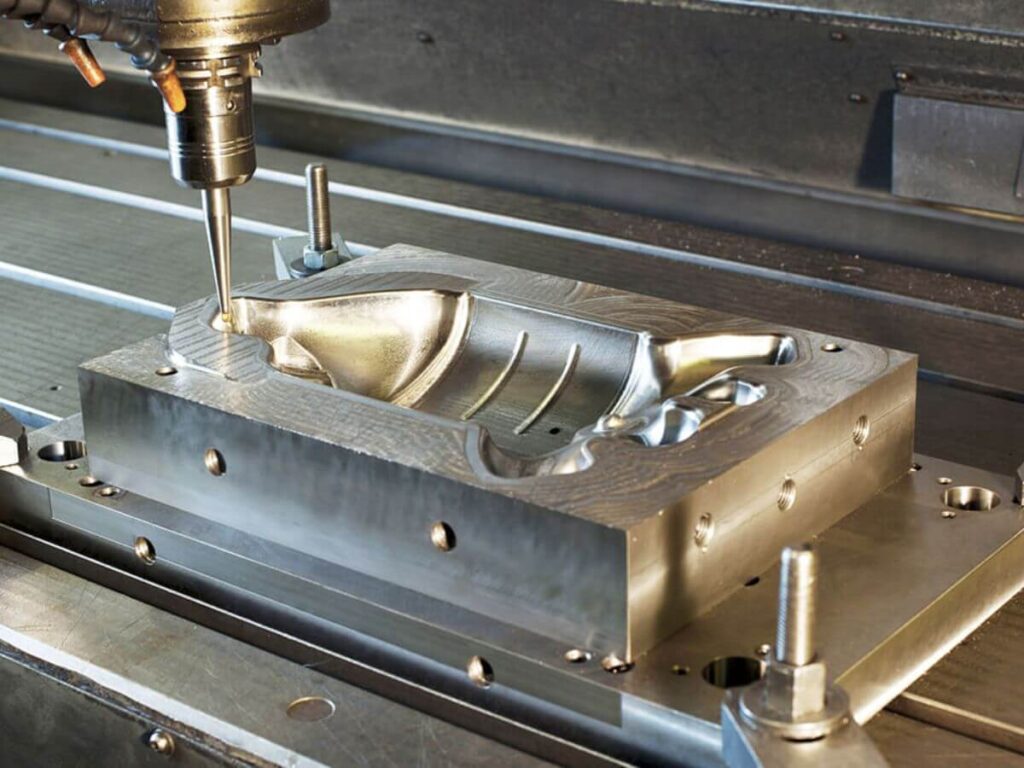

- Step# 1: Create a mold—either reusable (metal) or single-use (sand or ceramic).

- Step# 2: Heat the raw material (metal, plastic, resin, or ceramic) until it becomes liquid.

- Step# 3: Pour the liquid into the mold, making sure it fills every space.

- Step# 4: Let it cool and solidify. This can take minutes or hours, depending on the material.

- Step# 5: Remove the part—by opening the mold if it’s reusable, or breaking it if it’s not.

- Step# 6: Finish the part by trimming, machining, or polishing, depending on the design needs.

Casting setups range from simple to complex based on the part and material. You’ll commonly see mold materials like:

- Sand

- Ceramic

- Silicone

- Steel

- Aluminum

Basic equipment includes:

- Melting furnaces

- Pouring ladles

- Mold frames or boxes

At MachMaster, these tools often work alongside CNC machines, injection molding systems, and finishing stations. That makes it easier to match each part to the right method—without switching suppliers.

Before casting begins, a few design details need attention:

- Parting line: where the mold separates

- Draft angles: slight tapers to help remove the part

- Vent holes: let trapped air escape during pouring

- Shrinkage: all materials shrink as they cool, so molds must be slightly oversized

- Cooling time: affects production speed and quality

- Tolerances: the acceptable size variation, which must be discussed early

Once I learned to pay attention to these small details, my casting jobs ran smoother—and my rework pile got a lot smaller.

3. Benefits of Mold Casting

When I started working on custom parts, I didn’t realize how much time and cost mold casting could actually save. I thought it was only for big factories. But I was wrong.

Whether you’re making hundreds of parts or just a few, mold casting offers real advantages—especially when you plan ahead.

If you’re working on a product design, or trying to keep your supply chain lean, mold casting gives you a strong edge.

Here’s why:

- Great for large-volume production: Once the mold is ready, you can use it over and over again with little change in output quality.

- Repeatable and consistent: Every part that comes out of the mold looks just like the last one. That’s hard to beat in high-precision work.

- Complex shapes made easy: You can cast parts with curves, holes, undercuts, and fine details—things that are tough with traditional machining.

- Minimal waste: Because you’re pouring just the right amount of material, there’s less scrap compared to cutting from a solid block.

- Freedom in design: You’re not locked into flat or simple shapes. If you can draw it, chances are mold casting can make it.

- Detailed textures: Want a textured grip or logo right on the part? That can be built into the mold—no need to finish it later.

- Combine features into one part: Instead of assembling multiple pieces, mold casting can build it all as one solid form.

- Lower cost over time: The upfront tooling cost can feel high, but if you’re making hundreds or thousands of parts, it pays off quickly.

- Simplifies your supply chain: You get fewer parts, fewer steps, and less room for error in assembly.

- Good for hobby projects or small batches: You can even use silicone molds or resin casting at home or in a small shop.

I’ve used mold casting for both mass production and personal prototypes.

In both cases, the payoff was worth it.

If your goal is to make better parts faster—without rework or delays—mold casting might be the right tool for you.

4. Different Types of Mold Casting

When I first got into mold casting, I thought every method worked the same. But that wasn’t true. Each type has its own strengths. Some are cheap and flexible. Others are better for speed or precision. Once I learned the difference, I stopped guessing—and started choosing smarter.

Sand Casting

- The first method I ever used—affordable and easy to set up.

- Works well for large metal parts.

- Surface finish can be rough, but good enough for testing ideas.

- Great for quick prototypes and small batches without high upfront costs.

- If you’re starting out or working with a limited budget, this is a smart choice.

Investment Casting

- Uses a wax model and ceramic mold for high accuracy.

- Produces smooth surfaces and fine details.

- I used it for parts that needed clean edges and tight tolerances.

- It takes more time, but the results are worth it.

- Ideal if you want a professional look and don’t mind longer lead times.

Die Casting

- The best method I found for making thousands of identical parts.

- Uses high pressure to inject molten metal into steel molds.

- Excellent for non-ferrous metals like aluminum and zinc.

- I relied on this for high-volume jobs where speed and consistency mattered.

- Choose this when you need scale, speed, and repeatable quality.

Permanent Mold Casting

- A middle-ground option between sand and die casting.

- Uses metal molds without pressure—better finish than sand, cheaper than die.

- I used it for medium batches of housings and brackets.

- Not suited for very complex parts, but dependable and clean.

- Makes sense when you need consistency but want to keep tooling costs down.

Resin or Plastic Mold Casting

- My go-to for personal projects and early prototypes.

- Doesn’t need large machines—just silicone molds and hand pouring.

- Ideal for plastic parts, small runs, or artistic designs.

- Quick to set up and low in cost.

- Great option if you’re a designer, artist, or small business testing new ideas.

5. Mold Casting vs Other Manufacturing Methods

Sometimes it’s hard to pick the right process. I’ve been there. You want something that fits your design, timeline, and budget—but not every method works the same.

Here’s a quick comparison table that shows how mold casting stacks up against other manufacturing methods based on real experience.

| Comparison Area | Mold Casting | CNC Machining | Injection Molding | 3D Printing |

| Best Use Case | Medium to high volumes with detailed shapes | One-off or short-run precision parts | High-volume plastic parts with fast output | Prototyping and complex designs |

| Material Type | Metal, plastic, resin, ceramic | Metal and plastic | Thermoplastics only | Plastics, resin, some metals (limited) |

| Surface Finish | Good (varies by method) | Very good | Excellent | Good (depends on printer type) |

| Production Speed | Moderate | Slow to moderate | Fast once mold is ready | Slow (best for small runs) |

| Setup Cost | Medium | Low to medium | High (tooling is expensive) | Very low |

| Per Part Cost | Low (in volume) | High (more material waste) | Very low (in large runs) | Medium (not ideal for scaling) |

| Design Complexity | High (great for curves, hollows, and detail) | Limited by tool access | Moderate (less flexible for geometry) | Very high (great for tight spaces or lattice shapes) |

| Tolerance Range | Moderate | Very tight | Moderate | Low to moderate |

| Strength | Strong, especially for metals | Strong, very durable | Strong, but only for plastic | Weaker than cast or machined parts |

| Volume Fit | Best for 100–100,000+ parts | Best for 1–100 parts | Best for 10,000+ parts | Best for 1–50 parts |

6. Challenges & Safety Considerations

Mold casting can be a smart way to make parts—but like any process, it comes with its own set of challenges. I’ve run into a few of them myself. And if you’re new to this, it helps to know what you’re getting into before starting a project.

Being prepared makes a big difference—especially if you’re working with suppliers or trying mold casting on your own.

The first thing you’ll notice is the upfront cost. Making a mold, especially for metals or plastics, takes time and money. I once waited nearly three weeks just to get a custom mold ready—and it wasn’t cheap.

Here are a few other hurdles you might face:

- Tooling costs can be high, especially for complex or long-life molds.

- Lead times can be long, depending on the material and design changes.

- Shrinkage and warping sometimes happen, especially with thin or detailed parts. I learned the hard way to always leave room for minor distortion.

It’s better to catch these issues early—before your parts go into production.

Safety Notes

If you’re doing any part of the casting yourself, safety should be your first concern.

You’re dealing with high heat, heavy tools, and sometimes toxic fumes. I’ve worked on small resin castings at home and still wear protective gear—even for simple jobs.

Don’t skip this part.

Here’s what you’ll need to stay safe:

- Heat-resistant gloves to protect your hands from hot molds and materials

- Face shields or goggles to guard against splashes

- Long sleeves and closed shoes to cover skin

- Good ventilation or a fume extractor, especially for plastic or resin casting

- Fire extinguisher nearby, just in case

- Keep your workspace clean and dry to avoid slips or fires

- Work in a well-lit area so you can see what you’re doing

- Never pour metal or resin near water, as it can cause dangerous steam explosions

If a project feels too risky, there’s nothing wrong with outsourcing it. I’ve done it myself for parts that needed more precision—or better tools than I had.

Safety isn’t just about rules. It’s about keeping your project on track, your parts intact, and yourself out of harm’s way.

7. How to Choose the Right Mold Casting Process

When I first got into mold casting, I didn’t know which process fit which job. I had to learn through trial—and sometimes expensive—error. But you don’t have to guess. If you look at the right factors and ask the right questions, you’ll avoid costly mistakes. Here’s how I decide which casting method to use based on real projects I’ve worked on.

#1 Casting Type

Think about how many parts you need, what material you’ll use, and how detailed your shape is. These things make a big difference. Tight tolerances and shiny finishes need different tools than rough or bulky parts. I always write down my project needs first. It makes it easier to match the job to the right casting type, instead of relying on supplier guesses.

#2 Right Supplier

I used to skip asking questions because I didn’t want to seem unsure. But once I started asking directly, my results improved fast. Ask what kind of mold they’ll use. Ask how many parts that mold can make. Ask if they’ve worked with your material before. These answers helped me avoid wasted time, blown budgets, and parts that didn’t meet the mark.

#3 DFM Consultation

Design for Manufacturability—or DFM—is something I once ignored. Big mistake. A supplier pointed out that one of my features couldn’t be cast cleanly. After a short DFM call, we changed it, saved money, and got better parts. If you’re unsure what process to pick, ask your supplier for a DFM check. At MachMaster, they offer support across casting, machining, and molding—so you can choose what works best for your part.

Conclusion

You came here to figure out mold casting.

Now you know what it is, where it fits, and how to use it wisely.

Whether you’re sourcing parts, building a prototype, or scaling production—you’ve got a clear path forward.

I’ve made mistakes so you don’t have to.

You’re ready now. Trust yourself. Start the process.

Contact us today to get started!

More Guides and Tips to Explore

Not quite what you’re looking for? Explore our wider product range for more choices:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.