I remember the first time I looked for a zinc die casting supplier in China.

I had a CAD file, a small budget, and big hopes. But I didn’t know who to trust. Every factory claimed to be the best. Every site looked the same. I felt overwhelmed.

If you’re in that spot right now, I get it.

You’re not just looking for a supplier. You’re looking for someone who won’t disappear after payment. Someone who gets your product and gets it right.

Over the past few years, I’ve worked with multiple manufacturers in China. Some were helpful. Some missed deadlines. One even ghosted me after taking the deposit.

But I’ve also found partners who were fast, honest, and detailed.

That’s what this guide is about.

In this article, you’ll find 7 of the most reliable zinc die casting manufacturers in China. You’ll get a quick overview of who they are, what they do best, and what to look out for.

My goal is simple: help you avoid costly mistakes. And give you a list you can actually work from.

Let’s dive in!

Quick Comparison Chart

Here’s a detailed comparison table of the Top 7 Zinc Die Casting Manufacturers in China. This table gives you a quick look at how each company operates and what kind of buyer they best serve. It’s designed to help you compare their offerings at a glance without digging through each profile.

| Manufacturer | Key Focus Areas | Best For | Order Volume Flexibility | R&D Capabilities | Quality Approach |

| MachMaster | Zinc/aluminum die casting, CNC machining, full-service | Business owners needing reliable production and support | Small to large | Strong in-house team; uses CAD/CAM & simulations | ISO certified; in-process checks; final testing |

| Sunrise Metal | One-stop die casting, precision CNC, mold design | Supply chain managers needing full-cycle support | Medium to high | Full R&D lab; mold flow analysis; prototyping | ISO & IATF certified; CMM inspections; customer feedback |

| Ruitai Mould | Rapid prototyping, small-batch production | Product designers or startups needing fast samples | Low to medium | Agile R&D; CAD/CAM support; flexible design changes | ISO certified; spot checks; quick problem response |

| STK Die Casting | Zinc-only die casting, OEM work, tooling | Buyers with repeat orders of stable parts | Medium to high | Process-focused R&D; simple but efficient tools | ISO system; automated casting; thorough reporting |

| ECO Die Casting | Zinc/aluminum/magnesium parts, polished finishes | Medium to large brands needing volume and finish quality | Medium to large | In-house innovation; simulation tools; scalable | ISO & TS certified; statistical quality control |

| Yaheng Tech | Low-volume casting, prototyping, mold flexibility | Startups, personal buyers, R&D teams | Very low to medium | Modular tooling; quick test loops; CAD guidance | Manual/tool-based QA; photo proof; fast revisions |

| Eesson | Zinc casting for electronics and appliances | OEMs in electronics needing clean finishes and consistency | Medium to high | Stable design refinement; in-house mold making | ISO-compliant; visual checks; batch-level QA |

Each of these manufacturers offers strengths suited to different project types. Use this table to quickly narrow down who might be the right match based on your needs. Whether it’s speed, volume, or finish, there’s a fit here for you.

1. MachMaster

Headquarters: 202 Tianfeng Road, Xiamen, Fujian, China

Phone/Email: info@machcncmaster.com | +86-592-5782276

When I first launched my factory, finding the right supplier was hard. I needed someone who could meet tight deadlines, keep quality high, and actually respond when things went wrong. That’s how I found MachMaster.

MachMaster is based in Xiamen and has been around since 2002. They focus on die casting and CNC machining. They don’t just take orders, they work with you through the process. That made all the difference for me.

If you’re looking for a steady partner, they’re worth a look.

Key Products

MachMaster makes:

- Zinc die-cast parts

- Aluminum die-cast parts

- CNC machined components

- Tooling and mold making

These parts go into electronics, automotive, and home appliances. They can also handle special finishes like powder coating or polishing.

Research & Development (R&D)

R&D means “Research and Development.” It’s how companies come up with new ideas and improve products.

MachMaster has its own in-house R&D team. That means they don’t rely on outsiders to test new designs. They use:

- CAD (Computer-Aided Design) software to plan products

- CAM (Computer-Aided Manufacturing) for production planning

- Simulation tools to check if a design will work before making it

They also run tests on new items before going into full production. That helps you catch issues early.

If your design needs to change, they can adapt fast.

Quality Control & Assurance

MachMaster takes quality seriously. Every step is tracked. Here’s what they do:

- Source raw materials from trusted suppliers

- Follow ISO 9001:2015 standards (this is a global quality guideline)

- Use in-process checks and final inspections

- Encourage feedback and fix problems quickly

They also use measuring tools like CMM (Coordinate Measuring Machines) to make sure parts meet your drawings.

Final Verdict

MachMaster is a strong fit for business owners who need reliable zinc die-cast parts. If you’ve had bad luck with slow replies or poor quality before, you’ll notice the difference right away. I did.

They’re especially helpful if you need support with design or testing. You won’t have to go it alone. And they handle both small and large orders well.

2. Sunrise Metal

Headquarters: Kunshan, Jiangsu Province, China

Phone/Email: sales@sunrise-metal.com | +86-512-5792-7206

Sunrise Metal has been offering die casting services since 2003. They’re based in Kunshan, a city known for manufacturing. Sunrise handles everything from mold design to final finishing. Their setup supports both small and large volume orders.

They also have in-house CNC machines and testing labs. This helps them keep things fast and accurate. Sunrise is known for its one-stop service model. That means fewer handoffs and less confusion for you.

Key Products

- Zinc and aluminum die-cast parts

- Precision CNC-machined components

- Rapid prototypes

- Die cast tooling and molds

They serve medical, telecom, and industrial customers. If you work in these sectors, they’ll likely understand your needs.

Research & Development (R&D)

Sunrise runs its own R&D center. Their team handles:

- Product development

- Mold design with flow simulation

- Testing new parts before full production

- Continuous improvement through internal trials

They also update their processes often. That helps them meet changing product demands.

Quality Control & Assurance

Sunrise holds ISO 9001 and IATF 16949 certifications. These are industry standards for quality. Here’s what else they do:

- Raw material tracking

- In-process checks using 3D scanning tools

- Final inspection before shipment

- Quick resolution of client feedback

They test every batch to catch problems early. This saves time and reduces waste.

Final Verdict

I once worked with a buyer who needed telecom parts fast. We tried Sunrise. They managed everything on time, even during a national holiday rush.

Sunrise is great if you need structure and clear steps. But because they follow strict processes, it may take longer to make changes mid-project. Still, if you want stability and follow-through, they’re a solid choice.

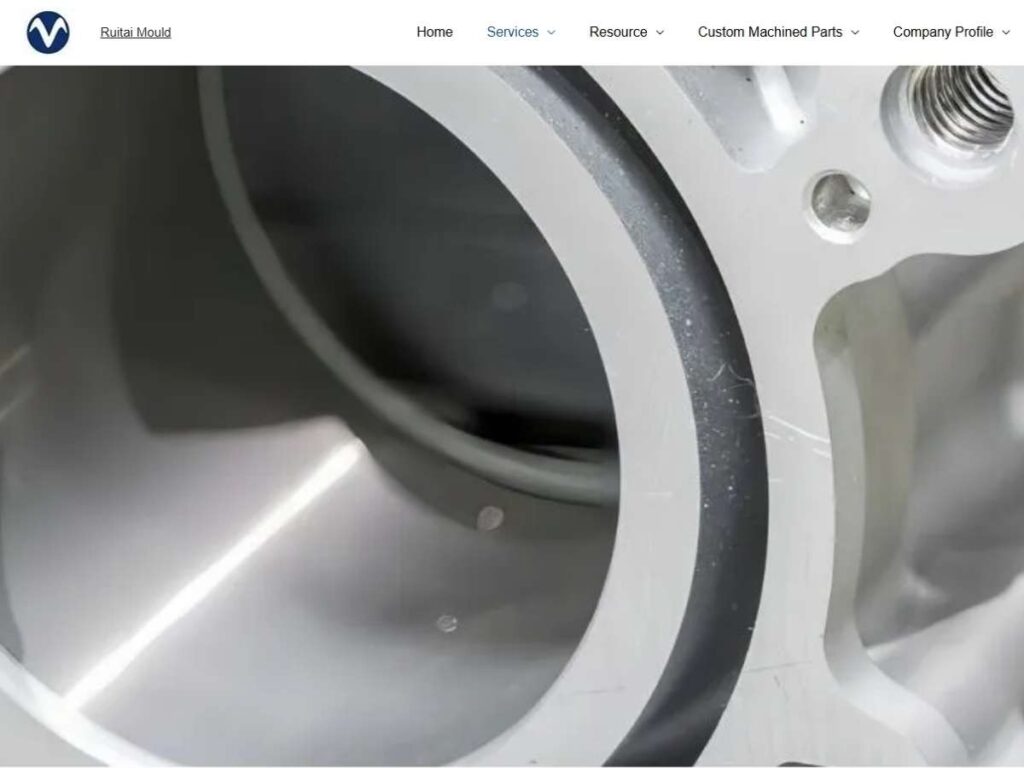

3. Ruitai Mould

Headquarters: Dongguan, Guangdong Province, China

Phone/Email: info@rtprototype.com | +86-769-8161-6930

Ruitai Mould focuses on speed. They specialize in rapid prototyping and small batch production. That means they’re a fit for companies needing samples or short runs.

Their factory is in Dongguan, a city known for fast-paced manufacturing. They offer zinc die casting, CNC machining, and vacuum casting.

When I was still testing out a new product design, Ruitai helped me get working parts in just five days. That speed helped me pitch to a buyer sooner.

Key Products

- Zinc die-cast prototypes

- CNC-machined parts

- Silicone molds

- Low-volume production tools

They support startups and growing brands that need fast turnaround.

Research & Development (R&D)

Ruitai uses an in-house team for:

- CAD modeling

- Mold flow simulation

- Quick testing of prototypes

- Adapting designs based on test feedback

They’re good at tweaking products after the first trial. That’s useful if your designs are still evolving.

Quality Control & Assurance

Even though they move fast, quality is still a focus:

- ISO 9001-certified processes

- Material checks before casting

- Use of CMM tools for measurements

- Spot-checking during each batch

Their QA staff works closely with engineers. This keeps everyone aligned with your needs.

Final Verdict

Ruitai is a good match if you’re developing a new product or need samples fast. Their biggest strength is speed.

But, if you’re looking for high-volume output, you might outgrow their setup. I’d recommend them to designers, engineers, and buyers who need flexibility and low minimum orders.

4. STK Die Casting

Headquarters: Ningbo, Zhejiang Province, China

Phone/Email: sales@zamakdiecasting.com | +86-574-8806-2750

STK has been in business since 2000. They’re based in Ningbo, a hub for export manufacturing. STK focuses only on zinc die casting, which makes their processes more refined.

They produce parts for lighting, tools, and home hardware. They also support OEM (original equipment manufacturing) work, which means they can make products under your brand.

I remember seeing a batch of bathroom hardware parts they made. Clean finish, zero burrs (sharp leftover edges), and no extra polishing needed.

Key Products

- Zinc die-cast components

- Home and kitchen hardware

- Lighting accessories

- Custom tooling for new molds

They mainly serve buyers in home goods, retail, and electrical parts.

Research & Development (R&D)

STK keeps their R&D simple but effective:

- Uses CAD/CAM software for design

- Tests new molds before mass runs

- Focuses on refining casting efficiency

- Keeps designs easy to repeat at scale

They’re not focused on trendy features but more on solid and consistent output.

Quality Control & Assurance

- Follows ISO 9001 quality system

- Material testing for every incoming batch

- Visual and dimensional checks at each stage

- Maintains low defect rates through automated casting machines

Their inspection reports are detailed. You’ll know exactly what’s going on.

Final Verdict

STK is a fit for buyers who care about stability and don’t need much hand-holding.

They’re great for repeat orders and simple products. One downside is that they aren’t built for rush jobs or custom feature development. But if you want steady output and clear pricing, they’ll serve you well.

5. ECO Die Casting

Headquarters: Dongguan, Guangdong Province, China

Phone/Email: sales@ecodiecasting.com | +86-769-8793-1718

ECO Die Casting has been in the industry since 1996. Located in Dongguan, they serve multiple sectors like automotive, lighting, and home electronics. What sets them apart is their balance between volume production and custom orders.

They offer aluminum, magnesium, and zinc casting, but zinc is a big part of their portfolio. They’re flexible with orders and offer surface finishes in-house.

Key Products

- Zinc die-cast parts

- Tooling for die casting molds

- Machined components

- Surface-treated products (painting, polishing)

They serve brands that need both technical parts and good-looking finishes.

Research & Development (R&D)

ECO runs their own R&D division. They offer:

- Product design support

- Testing of casting flows and cooling times

- Design for manufacturing (DFM) checks

- Prototype testing

They use tools like MoldFlow to catch issues early. If you’re scaling from prototype to production, this helps avoid costly delays.

Quality Control & Assurance

- ISO 9001 and TS 16949 certified

- Spectrometers for metal composition testing

- In-line inspections

- End-of-line visual and measurement checks

- Customer complaint tracking system

They also do spot audits and use statistical control to reduce variation in large orders.

Final Verdict

I remember needing parts for a lighting fixture with tight screw threads. ECO delivered them without needing post-processing.

ECO is a smart pick if you care about both looks and function. They’re reliable for volume work and steady on timelines. If your project needs heavy design input, though, they might not be as collaborative in the early stages. But for solid delivery and clean finishes, they perform well.

6. Yaheng Tech

Headquarters: Shenzhen, Guangdong Province, China

Phone/Email: info@yahengtech.com | +86-755-2302-5595

Yaheng Tech focuses on low-volume and prototype zinc die casting. Based in Shenzhen, they support early-stage product development and short production runs. Their service is ideal for personal buyers, startups, and R&D teams.

One of the first projects I saw from them was a batch of custom drone frames. Each piece had complex shapes and smooth edges, without needing polishing. That showed me they really understand precision, even at low volumes.

Key Products

- Zinc die-cast prototypes

- Small-batch production parts

- Mold making for short-run tools

- Technical consulting for prototyping

They’re ideal for clients who are still finalizing product specs.

Research & Development (R&D)

- In-house engineers for quick feedback loops

- Modular tooling options to cut costs

- Testing on a per-piece basis before larger orders

- CAD support for early design stages

They prioritize flexibility and speed rather than deep innovation.

Quality Control & Assurance

- Batch-level QC reports

- Quick revisions based on customer feedback

- Manual and tool-based measurements

- Spot testing and pre-shipment photos

They’ll work closely with you to make sure you’re happy before shipping.

Final Verdict

Yaheng is a strong choice if you’re still in development and need someone who can move fast. They’re good with tight timelines and quick mold changes.

If you’re looking for a long-term, large-scale supplier, this may not be the best fit. But for short runs and early-stage needs, Yaheng is one of the most responsive suppliers I’ve worked with.

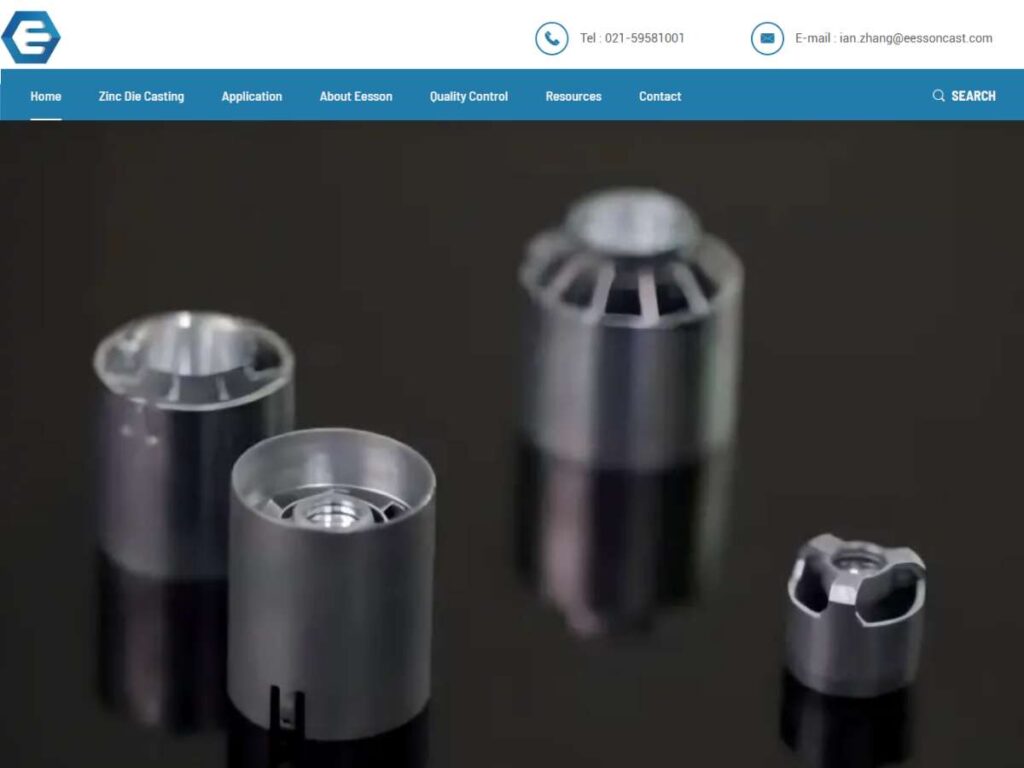

7. Eesson

Headquarters: Ningbo, Zhejiang Province, China

Phone/Email: eesson@eessoncast.com | +86-574-8836-1257

Eesson is based in Ningbo and started operations in 2008. They specialize in zinc die-cast parts used in electronics and home appliances. What makes them interesting is their blend of automation and attention to detail.

Their site shows rows of automatic casting machines, but they also hand-inspect parts for visual flaws. This dual approach helps keep volume high without giving up on cosmetic quality.

They work well with OEM clients, especially in electronics. I once recommended them to a colleague making casing parts for smart thermostats, he was happy with the uniform finish.

Key Products

- Zinc die-cast casings

- Electrical and electronic parts

- Cosmetic-grade hardware

- Custom packaging for fragile items

They support both functional and display-grade parts.

Research & Development (R&D)

- In-house team for tool design

- CAD/CAM modeling

- Design feedback loop based on mold performance

- In-house mold workshop for quick turnarounds

They focus on consistent repeatability in design.

Quality Control & Assurance

- Full compliance with ISO 9001

- In-line visual checks

- Sample-based measurement checks

- Post-packaging review process

They also track batch performance and share that data with you for your own QC system.

Final Verdict

Eesson works best for clients who want volume production with a solid surface finish. They’re reliable and fast. But they may not be ideal for constant product changes or unusual shapes, as their setup is built around consistency.

Still, if you’re in electronics or home goods, and need nice-looking parts, they’ll likely meet your standards.

Conclusion

You started with questions. Now you have answers.

We explored 7 trusted zinc die casting suppliers in China, who they are, what they offer, and how they work. If you’re tired of guesswork and want reliable results, this is your shortlist.

Remember that first story? That was me. Today, you’re ahead of where I began.

Machmaster makes sourcing smoother by connecting you with the right factory, faster.

Contact us today and get your project moving.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.