Before working with us, a client had failed an aerospace inspection, not because of machining errors, but because their previous partner neglected surface finishing.

It costs them more than just time.

They weren’t alone.

It’s a common gap when teams focus only on tolerances and materials.

We help businesses close that gap with industrial-grade surface finishing services. From anodizing to polishing and everything in between.

In this guide, you’ll learn exactly what surface finishing is, which methods to consider, and how to apply them to meet both visual and functional standards.

Let’s begin!

1. What Does Surface Finishing Mean?

When we talk about surface finishing, we’re not just adding shine or smoothing out edges. We’re talking about the final layer of trust—the part your client actually touches, sees, or tests.

It’s the difference between “good enough” and “done right.”

Surface finishing includes all those extra steps that make your parts not only look better but work better, last longer, and perform safely under pressure.

And here’s the thing: it’s not just for show.

- Reduces Friction and Wear: A well-finished part slides, glides, or rotates more easily—less heat, less damage.

- Improves Corrosion Resistance: From coatings to chemical treatments, it keeps rust and pitting from creeping in.

- Boosts Functionality: Some finishes help paint stick better, others prep the part for bonding, sealing, or welding.

Skipping this step might seem like a time-saver at first. But in my experience, that shortcut usually leads to headaches down the line: returns, complaints, or sudden failures in the field.

Think of it as laying a foundation. If the surface isn’t clean, consistent, or properly prepped, every process that follows can fall flat.

2. Benefits of High-Quality Surface Finishing

Surface finishing doesn’t just clean things up. I’ve seen well-made components fail just because the surface wasn’t finished right.

It’s one of those behind-the-scenes details that makes a bigger impact than most people realize.

Protection Against Corrosion and Wear

When a part is left bare, it’s vulnerable to everything around it. Moisture, chemicals, even air can cause damage over time.

A solid finish creates a shield that keeps those threats out, especially in harsher environments.

I’ve watched a basic anti-corrosion treatment make the difference between a smooth installation and a full recall. That kind of protection doesn’t just preserve materials—it protects your reputation, too.

Improved Functionality and Durability

Surface quality directly affects how a part moves, fits, or holds up under stress. A smoother finish reduces drag, minimizes wear, and supports long-term use without breakdowns.

In one case, switching to a tighter surface spec extended our bearing life by almost 40%.

It’s these quiet gains that keep machines running and clients from picking up the phone with problems.

Enhanced Visual and Tactile Appeal

Even the best design can feel off if the finish isn’t right. I’ve seen people trust a part more just because it felt clean and consistent in their hands.

It’s not about fancy polishing, it’s about delivering something that looks intentional, not rushed. When something looks finished, people believe the work behind it is solid.

Compatibility With Other Processes

Downstream tasks like painting, bonding, or coating rely on the surface being just right. Too rough or too smooth, and suddenly you’re facing peel-offs, adhesion failures, or costly rework.

I’ve been in meetings where the blame game started, and every finger pointed back to the finish.

Getting it right upfront avoids surprises later on.

3. Types of Surface Finishing Processes

Choosing the right surface finishing method is about function, fit, and performance.

Each process serves a specific purpose, and knowing the difference can save you from wasted time, extra costs, or a product that doesn’t hold up.

Here’s a breakdown of the most commonly used finishing types and where they shine.

Mechanical Finishing

Mechanical finishing is all about physically altering the surface, usually by grinding, sanding, polishing, or blasting.

This method smooths out imperfections, removes burrs, or preps the material for further treatment.

I’ve seen teams rely on this for parts that need clean edges and a professional feel without adding chemicals or coatings. It’s fast, effective, and works well when appearance and texture matter just as much as precision.

Chemical Finishing

Chemical processes change the surface using reactions. Think about acid cleaning, passivation, or chemical etching.

These are often used to remove contaminants, improve corrosion resistance, or create a uniform surface before painting or bonding.

In one project, switching to passivation instantly reduced our stainless-steel returns due to rust. It’s a go-to choice when cleanliness and protection are critical.

Electrochemical Finishing

This category includes methods like electroplating and anodizing, where electricity drives the process.

Electroplating deposits a thin metal layer onto the part, while anodizing thickens the oxide layer on materials like aluminum for added durability.

At MachMaster, these techniques are used when both performance and visual consistency matter—especially for parts requiring corrosion resistance and tight aesthetic standards.

I’ve used anodizing when clients needed both performance and a polished, color-matched finish. These methods give you surface protection that’s built to last and look good doing it.

Coating and Painting

Sometimes, the final step is about adding rather than removing.

Coatings, like powder coating, paint, or Teflon, give surfaces both function and flair. They can add color, resist abrasion, reduce friction, or prevent corrosion.

It’s a popular choice when the finish has to match a brand look or perform under demanding conditions.

Heat Treatments

While not always grouped under “finishing,” heat-based processes like case hardening or tempering change the surface structure for added strength or resistance.

These are ideal when parts face mechanical stress, high friction, or sudden impacts. I’ve worked with teams that used hardening just to meet a client’s durability spec without changing the part design.

It’s a behind-the-scenes method that seriously boosts performance.

4. Common Materials That Undergo Surface Finishing

Not all materials react the same way to surface finishing, and picking the wrong process for the wrong material can cost you more than just time.

I’ve seen solid designs get ruined because the base material wasn’t properly considered during finishing.

Here are the most commonly used materials and why surface finishing matters for each one:

- Aluminum: Lightweight and corrosion-prone, aluminum often needs anodizing, polishing, or powder coating to enhance durability and appearance. It takes well to color finishes and is popular in aerospace, electronics, and consumer products.

- Steel: From mild steel to stainless, this material benefits from processes like electroplating, passivation, and grinding. Without a proper finish, steel can rust quickly, so protection is key.

- Brass and Copper: These metals are often finished for decorative reasons, but also to prevent tarnishing and improve conductivity. Plating and clear coating are commonly used to maintain their warm appearance over time.

- Zinc and Zinc-Alloy Castings: Affordable and easy to mold, these materials usually require plating or chromating to resist corrosion. I’ve worked with parts where even a simple zinc coating extended the product’s life dramatically.

- Plastics: While they don’t rust, plastics still benefit from surface treatments like texturing, painting, or UV coatings. These help improve grip, aesthetics, or resistance to sunlight and wear.

- Titanium: Strong and corrosion-resistant on its own, titanium is often bead-blasted or anodized to refine its finish and improve fatigue resistance. It’s a favorite in high-end medical or aerospace parts that demand strength without extra weight.

- Magnesium: Very lightweight but prone to corrosion, magnesium components typically receive conversion coatings or specialized platings. I’ve seen poor finishing on magnesium lead to premature failure, so it’s not one to skip over.

- Glass and Ceramics: While not metals, these materials also undergo surface treatments like glazing, polishing, or etching for clarity, strength, or decorative appeal. It’s all about surface control—especially in optics or lab environments.

5. Surface Finish Measurements and Standards

Understanding surface finish isn’t just about feeling a part, it’s about knowing how to measure and specify what’s acceptable.

Whether you’re machining, plating, or coating, these metrics help everyone speak the same language across design, production, and quality control.

| Term | Meaning | Unit of Measure | Typical Range | Common Applications |

| Ra (Roughness Average) | The average deviation of surface peaks and valleys from the mean line | Micrometers (µm) | 0.1 – 6.3 µm | General machining, metal fabrication |

| Rz (Mean Roughness Depth) | Average difference between the highest peak and lowest valley in five sample lengths | Micrometers (µm) | 1 – 20 µm | Automotive, injection molds, die casting |

| Rt (Total Height) | Distance between the highest peak and the deepest valley in the evaluation length | Micrometers (µm) | 5 – 50 µm | Surface profiling, deep analysis |

| Sa (3D Surface Roughness) | 3D equivalent of Ra, showing average surface height over an area | Micrometers (µm) | 0.01 – 2.5 µm | Aerospace, medical components |

| Surface Texture | General term that includes roughness, waviness, and lay pattern | N/A | N/A | Across all industries—specifications vary |

| Grit Size | Abrasive rating based on particle size (used in sanding/polishing) | Grit (e.g., 80, 240) | 60 – 600 (common range) | Metal finishing, wood, and plastic polishing |

| ISO 1302 | International standard for specifying surface texture on drawings | Symbolic/Qualitative | Ra and symbol-based | Global manufacturing drawings and blueprints |

| ASME B46.1 | U.S. standard covering definitions and measurement methods for surface texture | Symbolic + Numeric | Various—based on Ra, Rz, etc. | Precision parts, regulated industries |

6. Industries That Rely on Surface Finishing

Surface finishing plays a key role across industries where performance, appearance, and durability matter. I’ve seen how even a small change in surface treatment can make or break a product depending on where and how it’s used.

Aerospace and Aviation

In aerospace, even the tiniest surface flaw can lead to serious problems under stress or altitude changes. Components often face extreme temperatures, pressure cycles, and constant vibration, so finishing processes like anodizing and precision polishing are non-negotiable.

I’ve worked with teams where surface spec issues delayed approvals for critical flight parts. In this industry, surface finishing isn’t just for longevity, it’s about flight safety.

Automotive and Heavy Equipment

Surface finishing in automotive isn’t just about glossy body panels, it’s deep in the engine, suspension, and transmission too.

Friction-reducing finishes keep parts running smoothly, while coatings protect components from heat, salt, and daily abuse.

When you’re building something meant to move fast, or haul weight, surface quality has a direct impact on performance and lifespan.

Medical Devices and Equipment

Cleanliness, precision, and safety are non-negotiables in medical manufacturing, and surface finish directly affects all three. Surgical tools and implants need ultra-smooth, contamination-free surfaces to prevent infection or rejection.

I’ve handled projects where even minor finish inconsistencies meant a batch had to be scrapped.

In this space, surface finishing isn’t an afterthought, it’s tightly linked to patient outcomes.

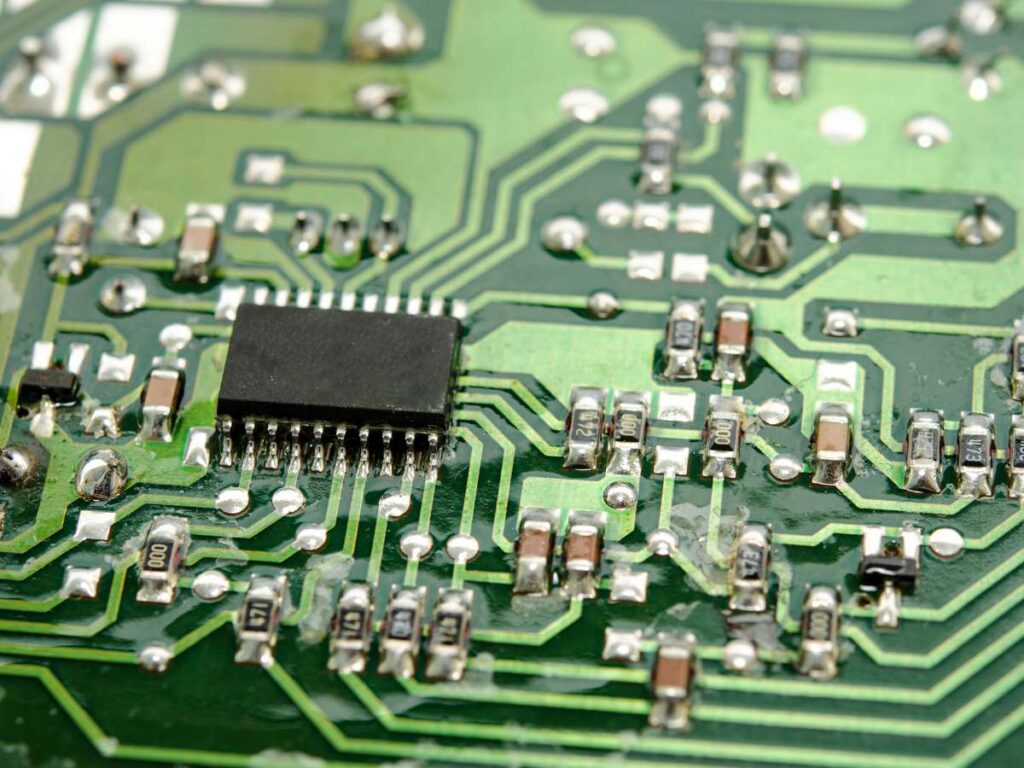

Electronics and High-Tech Manufacturing

Circuit boards, connectors, and enclosures all rely on surface finishing to manage conductivity, interference, and environmental protection.

Whether it’s gold-plated contacts or anti-static coatings, the right finish ensures devices stay reliable and safe. One misstep in finishing can short a system or kill signal clarity, especially in sensitive electronics.

When high precision and long-term stability are the goal, finishing is part of the equation from the start.

7. Surface Finishing Challenges and Limitations

Even though surface finishing brings a lot of value, it’s not always a smooth ride. There are technical limits, practical trade-offs, and cost considerations that need to be weighed carefully, especially when scaling up or working with tight specs.

Material Compatibility Issues

Not every finishing method works on every material, and choosing the wrong combination can lead to damage or poor results. I’ve seen teams try to rush a job by using a standard finish on a specialty alloy, only to end up with peeling or pitting.

Some metals react badly to certain chemicals, while others may not bond well with specific coatings. Getting this right means understanding the behavior of your material before committing to a finish.

Inconsistency Across Batches

Even with automation, finishes can vary slightly from one batch to the next due to environmental changes, operator technique, or equipment wear. That can cause problems when clients expect perfect visual uniformity or precision specs across every unit.

I’ve had projects where two batches looked just different enough to raise flags during final inspection. Keeping tight controls in place and verifying each run becomes essential, especially when appearance is part of the deliverable.

Added Cost and Time

Surface finishing is valuable, but it doesn’t come free. It adds time to production and can significantly increase per-unit costs depending on the method used.

Sometimes, a budget-friendly coating just doesn’t hold up, and cutting corners ends up costing more in returns or rework.

Balancing performance, cost, and turnaround is one of the trickiest parts of getting finishing right, especially when timelines are tight.

8. 3 Factors to Consider When Choosing a Surface Finishing Service

When you’re choosing a surface finishing provider, it’s not just about price or location. The technical side matters more than most realize, especially when precision, durability, or compliance is on the line.

These are the factors that can make or break the final result:

Surface Finish Tolerances and Process Control

One of the first things to check is whether the service can meet your required surface roughness values, like Ra or Rz, within tight tolerances.

Not all providers can guarantee consistent surface texture across complex geometries or mixed material parts.

Ask how they measure finish quality, whether it’s contact profilometers, non-contact scanning, or 3D surface mapping. If their process control isn’t repeatable, you may end up with variation from batch to batch, especially on high-precision parts.

Pre and Post-Finishing Treatment Capabilities

Surface finishing doesn’t start or stop at the coating or polish. It often includes prep steps like degreasing, pickling, bead blasting, or masking, and post-steps like curing, sealing, or dimensional checks.

MachMaster offers full pre- and post-finishing support to make sure each stage—from surface prep to final inspection, is tightly controlled.

The quality of these stages directly affects how well the finish performs.

I’ve seen coatings fail just because the surface wasn’t cleaned properly beforehand. A good service should offer a complete process flow, not just the finishing step in isolation.

Material-Specific Expertise and Compatibility Testing

Every material reacts differently to finishing methods, and not every shop is equipped to adjust for that. A coating that works well on aluminum may blister or peel on magnesium if the prep isn’t right.

Ask if the provider offers compatibility testing, adhesion checks, or salt spray testing for corrosion resistance.

Providers with real-world experience across a range of materials will be much better at preventing finish-related failures before they happen.

Conclusion

Turns out, the surface wasn’t an afterthought—it was the deciding factor. That client passed their next inspection, no surprises, no stress.

If your parts are built to perform, they should look the part too.

Surface finishing closes the loop—and we’re here to help you get it right.

Ready to move past basic specs and deliver truly finished work?

Contact MachMaster today. Where the finish is part of the standard.

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Industry & Standards:

- 8 Industries That Rely on Surface Finishing

- A Quick Guide to Surface Finishing Standards

- Surface Finish Tolerances: What You Must Know

Types of Treatments & Finishes:

- 10 Different Types of Surface Treatments

- Common Metal Finish Types & Their Uses

- 9 Different Types of Finishes for Metal

- Top 8 Surface Finishes Examples

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.