One client that sticks out came to me completely stressed.

They needed 10,000 precision brackets fast, and their small team just couldn’t keep up. Every batch had slight differences, and it was starting to cost them.

They asked if stamping could help. I told them, “Honestly, this is exactly what stamping is built for.”

I run a stamping shop, and over the years, I’ve helped a lot of businesses hit tight deadlines without blowing their budget.

I do this kind of work all the time—progressive stamping, deep draw, you name it. If you’re trying to make a high number of parts quickly and consistently, stamping is one of the most efficient ways to get there.

And we’ve got the tools and the experience to make it work for you.

In this article, I’ll break down what stamping is, how it works, and where it fits best in real-world manufacturing.

If you’re trying to improve part quality, cut costs, or just stop worrying about whether your parts will arrive on time—this will help.

So, let’s get into it!

1. What Is Stamping?

There’s something incredibly satisfying about watching a stamping press in motion.

The rhythm, the force, the precision—it’s all engineered to perfection. Sheet metal feeds in, and almost instantly, you’ve got a finished part shaped exactly to spec.

Stamping is a metalworking process where flat sheet metal is formed into specific shapes using a die and press. It’s like precision origami, but with steel and speed instead of paper and patience.

Here’s why stamping continues to be a go-to for smart manufacturers:

- High-Speed Output: Stamping delivers rapid production without sacrificing quality. Perfect when you need thousands of identical parts in a short timeframe.

- Consistent Accuracy: The process is built for repeatability. Every press stroke produces parts that match your specifications down to the last millimeter.

- Scalable Cost Efficiency: Once tooling is set, per-unit costs drop significantly—especially for high-volume production runs.

- Complex Geometries Made Simple: Stamping handles multi-feature parts easily. Bends, holes, flanges—it’s all built into the die design.

- Streamlined Downstream Processes: Stamped parts often come off the press ready for assembly or surface treatment, cutting down on post-processing time.

If you’re making strategic decisions about part sourcing, production methods, or supplier capabilities, stamping should absolutely be on your radar.

It’s not just efficient, it’s built for scale, reliability, and real-world performance.

2. Benefits of Stamping

If there’s one process I trust when the pressure is on, it’s stamping.

I’ve worked with clients who needed tens of thousands of parts yesterday, and stamping is how we made it happen without compromising on quality or budget.

High-Speed Output

Once the die is dialed in, a stamping press becomes a powerhouse. We’re talking thousands of parts per hour, all running like clockwork with minimal operator intervention.

That kind of speed makes a serious difference when you’re chasing tight deadlines or scaling up to meet a sudden demand spike.

For businesses trying to stay agile in a competitive market, stamping delivers the momentum you need to move fast without skipping steps.

Consistent Quality

There’s a certain confidence that comes with knowing your parts will be exactly the same, every time. Stamping gives us that. Because each stroke of the press follows a pre-set path, there’s almost no variation—just clean, predictable results.

That level of consistency is one reason businesses turn to partners like MachMaster, where tooling precision and process control are dialed in from the start.

When you’re building parts that need to fit, seal, or align perfectly, that reliability pays off in fewer rejects, fewer returns, and happier customers.

Scalable Cost Efficiency

Let’s be honest, the upfront investment in dies can feel steep at first. But once they’re in place, your per-part cost drops quickly as volume increases.

I’ve seen clients double their order size and still stay well within budget because stamping scales so efficiently. It is a smart move for any business planning long-term growth.

You get predictability, cost control, and more flexibility to reinvest where it matters.

Cleaner, Lower-Waste Production

One of the things I really value about stamping is how clean it runs. The precision we achieve with a well-designed die leads to minimal scrap.

That is good for your raw material costs and your environmental impact. If you are aiming for leaner operations with less waste and better use of resources, stamping is an excellent choice.

3. Types of Stamping Operations

One of the things that impressed me most about stamping early on was how many different operations can be done under the same umbrella.

Each method serves a specific purpose, and the right combination can lead to incredible production results.

- Blanking: Blanking is the process of cutting out flat pieces from sheet metal, like cutting cookies from dough. These blanks often go through further shaping or forming, but sometimes, the blank itself is the finished part.

- Punching: Punching is all about creating holes or slots in a sheet. It’s done by forcing a punch through the material into a die, cutting out precise sections. You’ve probably seen this in action on things like electrical boxes or mounting plates.

- Bending: Bending reshapes the metal along a straight axis to create angles or flanges. It’s used everywhere from brackets to enclosures and support frames. The trick is managing the spring-back, especially with stronger materials like stainless steel.

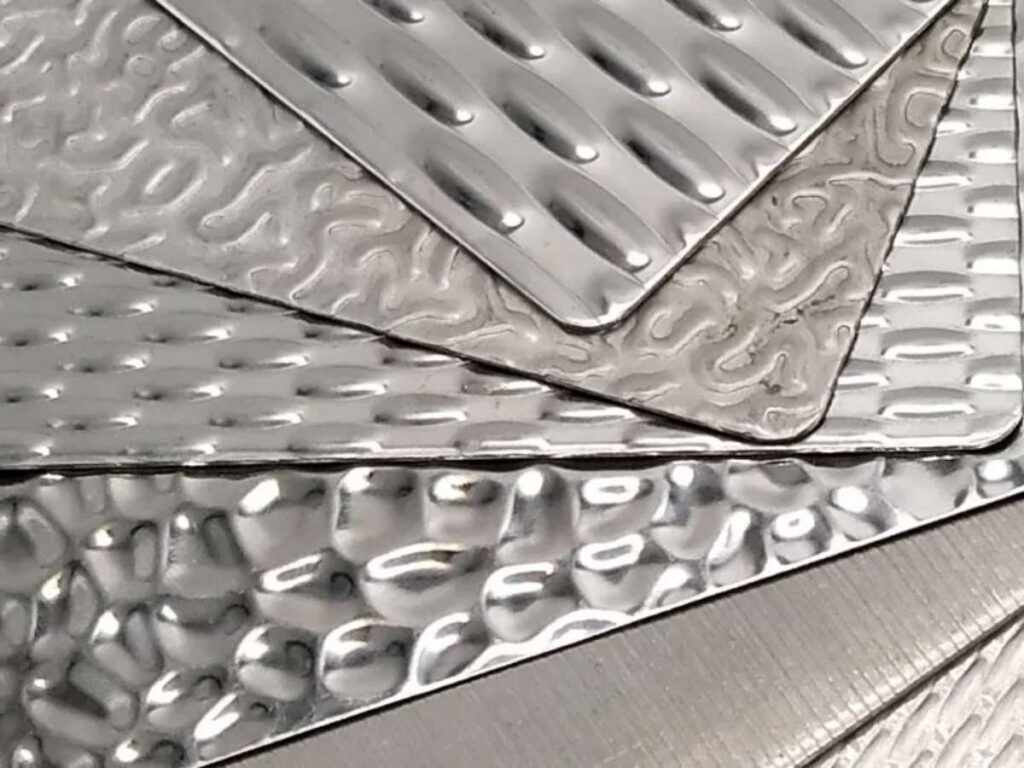

- Embossing: Embossing adds raised or recessed features to the surface, which can serve both functional and aesthetic purposes. I’ve seen it used to add logos, product codes, or textures to improve grip. Because the metal isn’t cut or removed, strength is preserved.

- Deep Drawing: Deep drawing involves stretching the metal into a new shape, often a cylindrical or box-like form, without breaking it. It requires careful control to avoid tearing, but when done right, it produces strong, seamless parts.

4. Materials Used in Stamping

I’ve had countless conversations with customers who came in set on one material, only to walk away with a completely different choice after we looked at their project needs.

I’ve seen the right material cut costs, reduce lead times, and improve quality—while the wrong one caused delays and frustration.

Mild Steel

Mild steel is a true staple in our world. It’s affordable, easy to shape, and incredibly versatile. I’ve used it for everything from furniture brackets to automotive structural parts. It may not have the flashiest specs, but when you need something that bends clean, welds easily, and stays within budget, mild steel is hard to beat.

For high-volume, general-purpose parts, this is often where I start the conversation.

Stainless Steel

If your part is going to live in a harsh environment—think moisture, chemicals, heat—stainless is the way to go. It’s tougher to form, and yes, it can be harder on your tooling, but the payoff is durability that lasts.

I’ve worked with stainless in projects for medical devices, kitchen hardware, marine fittings—you name it. Once it’s stamped and finished, you end up with a part that feels premium and takes a beating without breaking down.

Aluminum

When clients come to me asking for lightweight and corrosion-resistant, I immediately think aluminum.

It runs smooth in the press, doesn’t wear out your dies as quickly, and is a favorite in industries like aerospace, consumer electronics, and lighting.

That said, I always caution about scratching or distortion during handling. With the right prep and care, aluminum gives you clean results and fast cycle times. It’s also one of the fastest metals to cool, which helps during post-processing.

Copper and Brass

These two metals are the go-to when conductivity or aesthetic finish is a priority. I’ve stamped copper terminals for electrical clients that outperformed machined parts at a lower cost.

Brass is another one that machines and stamps beautifully, especially for decorative or functional fittings.

Both materials are more expensive, so I usually recommend them when their unique properties really matter—whether it’s electrical conductivity, ease of forming, or that polished look you can’t get from other metals.

5. Industries That Rely on Stamping

Once you see how many parts are made through stamping, you start spotting them everywhere.

It’s like a silent partner across industries, helping businesses meet their production and cost goals. Whether you’re making cars, devices, or medical tools, stamping probably plays a role.

Automotive

From chassis brackets to airbag housings, stamped parts are all over vehicles. Automakers love the speed and repeatability stamping provides.

I’ve worked with suppliers who produce millions of identical parts each month, all within spec.

It’s one of the few processes that can meet both the volume and precision demands of the auto industry. Without stamping, assembly lines would grind to a halt.

Electronics

Think of connectors, brackets, EMI shields. Many of these are stamped by the millions. Because these parts are small and often require complex shapes, precision is key.

Stamping allows for high-speed production with low material waste. It’s also perfect for progressive die setups where multiple features can be formed in one pass. This makes it ideal for both consumer tech and industrial control systems.

Medical Devices

Medical equipment demands cleanliness, precision, and consistency.

I’ve worked with OEMs who rely on stamping for everything from surgical tools to diagnostic cartridges. Stainless steel stamping is common here due to hygiene requirements.

It’s also a process that scales well for disposable medical components. Safety and reliability are non-negotiable, and stamping delivers both.

6. Progressive Die vs. Single-Stage Stamping

Choosing between progressive die stamping and single-stage stamping comes down to more than just production speed.

This table breaks down the key differences to help you decide which method fits best with your business goals and production needs.

| Category | Progressive Die Stamping | Single-Stage Stamping |

| Process Overview | Metal strip moves through multiple die stations in one press to form the part in a single run. | Each operation (blanking, bending, piercing, etc.) is performed separately, often on different machines. |

| Best For | High-volume, high-consistency production with minimal manual intervention. | Low to medium volume, custom parts, or projects with frequent design changes. |

| Speed | Extremely fast once set up; ideal for mass production. | Slower due to multiple steps and handling. |

| Flexibility | Limited flexibility after tooling is made; changes are costly and time-consuming. | Very flexible; easier to make quick adjustments or changes to design. |

| Tooling Cost | High upfront cost due to complex, multi-stage tooling. | Lower initial investment; tools are simpler and cheaper to build. |

| Per-Part Cost | Very low per-part cost at scale due to high efficiency. | Higher per-part cost, especially in large runs. |

| Changeover Time | Longer setup time; not ideal for frequent production switches. | Shorter setup; easier to switch between part types or jobs. |

| Complexity of Parts | Excellent for complex parts that require multiple operations in one pass. | Better for simpler parts or when features need separate control. |

| Error Risk and Inspection | Fewer handling steps reduce chances of human error; in-line QC possible. | Higher risk of errors from manual transitions; more checkpoints needed. |

| Die Maintenance | More complex dies require skilled maintenance and longer downtime if issues occur. | Easier to maintain or replace single-purpose dies quickly. |

| Scalability | Easily scalable for long-term production needs. | Less efficient for scaling but great for initial runs or prototyping. |

7. 4 Factors to Consider When Choosing a Stamping Service

Choosing a stamping service is more than checking prices and lead times. It’s about finding a reliable partner who understands your materials, volumes, and goals.

Over the years, I’ve learned that getting this choice right can make or break a production schedule.

Tooling Capabilities

Always ask if the shop builds and maintains its own tooling in-house. In-house toolmaking speeds up revisions and reduces lead times. It also means they have tighter control over quality. If they outsource tooling, expect delays when changes or repairs are needed.

Tooling experience is one of the most overlooked, yet most critical, signs of a competent stamping vendor.

Don’t be afraid to request sample parts or even visit the facility. Seeing tooling quality upfront tells you a lot about what to expect.

Material Experience

Not every shop handles all materials equally. Some specialize in mild steel but struggle with high-tensile stainless or soft aluminum. I once sourced a stainless steel part from a shop that primarily did aluminum—they couldn’t hold the tolerances.

Make sure your vendor has experience with your material type and gauge. The wrong material handling process could lead to inconsistent edges, poor surface finishes, or even unusable parts.

Material-specific tooling and press tuning can make a huge difference. Getting this part wrong leads to rejections, delays, and unhappy customers.

Volume Capacity and Lead Time

Your ideal partner should scale with you. Whether you’re doing a pilot run or full-scale production, they should have the machines and manpower to meet deadlines. Ask about lead time guarantees and how they handle urgent or repeat orders. The last thing you want is a bottleneck in your supply chain.

Look at their press capacity, number of shifts, and backup equipment plans.

MachMaster, for example, runs high-volume operations with built-in redundancies to keep production moving even when demand spikes or unexpected issues come up.

Also, ask how quickly they can respond to unexpected changes. Can they accommodate a rush order? What happens if a die breaks mid-run? These questions help you avoid surprises down the line.

Quality Control Systems

ISO certification is a good starting point, but dig deeper. Do they use vision systems or manual inspection? What’s their defect rate? I’ve had projects saved by vendors with solid QC, and others derailed by shops that cut corners. Reliable inspection means fewer surprises and happier customers.

Some stamping shops invest in in-line monitoring systems that catch errors during the press cycle. Others rely entirely on human inspection at the end of the run. Ask about their process, and make sure it aligns with your product’s tolerance needs.

A good partner will be transparent about their inspection plan and give you confidence in every part they deliver.

Conclusion

I stood in that shop years ago, watching raw metal transform. Now, you’ve seen how it happens—and how it could change your process too.

Stamping is more than shaping metal. It’s about building faster, smarter, leaner. With the right service, you can scale with confidence and crush your deadlines.

Everything you need to start is already in front of you.

MachMaster’s ready when you are. Contact us today.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.