I used to think sheet metal fabrication just meant cutting flat sheets of metal. Simple, right?

Then one of my parts came back—and it didn’t fit. The bend was off. The holes weren’t lined up. And that’s when it hit me: I didn’t understand the process as well as I thought I did.

Since then, I’ve worked with fabrication shops on all kinds of projects.

I’ve helped fix design mistakes, cut costs, and make sure parts actually work the way they’re supposed to. I’ve seen how one small decision—like the wrong thickness or bend angle—can throw off a whole production run.

If you’ve ever felt unsure about what “sheet metal fabrication” really means, you’re in the right place.

Maybe you’re designing a part. Maybe you’re buying one. Or maybe you’re trying to find the right manufacturer.

This guide will walk you through the basics. You’ll learn what sheet metal fabrication is, how it works, and why it matters—whether you’re building something new or sourcing parts for a job.

By the end, you’ll understand the process clearly. No fluff. Just useful info that helps you make better decisions.

So let’s get started!

1. What Is Sheet Metal Fabrication?

I still remember holding my first bent metal part: cool, smooth, and exact. That’s what sheet metal fabrication feels like—turning flat sheets into useful parts like panels, brackets, or covers.

But it’s more than just cutting or bending. Fabrication means turning raw metal into finished parts through steps like:

- Cutting

- Bending

- Punching

- Welding

- Assembly

Each process on its own doesn’t build a part—but combined, they create real, working components. That’s how you get things like machine enclosures, custom panels, or mounting brackets.

Wondering what type of metal to use? Here’s a quick guide:

- Aluminum: Lightweight, resists rust. Great for panels.

- Stainless Steel: Durable and clean-looking. Used in medical, kitchen, and industrial parts.

- Galvanized Steel: Has a rust-resistant coating. Ideal for outdoor applications.

- Copper and Brass: Softer. Found in electronics and decor.

The metal you choose affects how the part looks, performs, and holds up.

You probably see sheet metal every day:

- Electrical boxes

- Computer cases

- Light fixtures

- Car trims

- Wall brackets

At MachMaster, we offer complete sheet metal fabrication services—from cutting and bending to welding and finishing. We take your drawings and turn them into real, working parts with precision and speed.

2. How the Sheet Metal Fabrication Process Works

When I first stepped into a fabrication shop, I expected noise and chaos. There were sparks, sure. But what surprised me most? Everything was organized. Each part followed a clear path—from idea to final shape.

Once you understand the steps, it’s easier to see if this process fits your product.

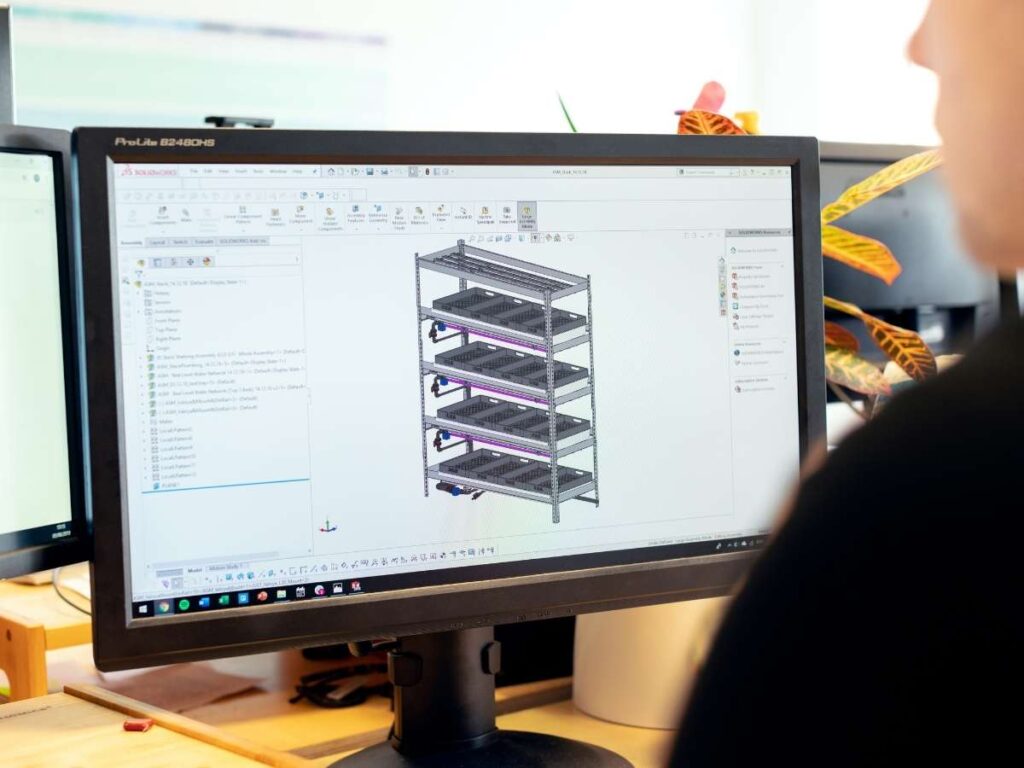

Step #1: Design and CAD Modeling

It all starts with a drawing. Most parts begin as a 3D model using CAD software. This shows the size, shape, and where to place bends or holes. A clear CAD file removes the guesswork. Without it, I’ve seen projects fall apart.

Step #2: Cutting

This is where flat metal gets its shape. There are a few ways to cut:

- Laser cutters: Clean, detailed edges

- Plasma cutters: Fast, good for thick metal

- Waterjet cutters: Cold cutting with high-pressure water and grit

The method depends on your metal type, thickness, and accuracy needs.

Step #3: Forming or Bending

The cut piece gets bent into shape. Two tools help here:

- Press brakes: Bend along a straight line

- Rollers: Curve the sheet into round shapes or tubes

Good bends add strength without adding weight.

Step #4: Joining

Once the part is shaped, it’s time to join it. You can:

- Weld it: Melt the metal edges together

- Rivet it: Pin the pieces when welding isn’t a fit

- Bolt or screw it: For parts that need to come apart later

Some projects use more than one method. It depends on what the part needs to do.

Step #5: Finishing

This protects the part and helps it look better:

- Powder coating: Dry paint baked on

- Anodizing: Color and corrosion resistance for aluminum

- Plating: Thin layers of metal like chrome or zinc

I’ve seen bare metal rust fast. A good finish makes a big difference.

You don’t need to know every machine—but it helps to know what they do.

- Laser cutters shape metal with light

- CNC punch presses make holes or slots

- Press brakes handle bending

- Welders fuse parts into one

These tools work fast, repeat shapes, and keep things accurate. That matters when you’re making more than one part.

Once you understand how the steps fit together, it stops feeling like magic. It’s just the right tools, in the right order.

3. Advantages and Disadvantages of Sheet Metal Fabrication

I’ve worked on projects where sheet metal was the perfect fit. Fast, clean, affordable. But I’ve also seen cases where it caused delays, headaches, and high costs—just because it wasn’t the right choice for that job.

Understanding both the pros and cons helps you figure out if this process makes sense for what you’re building.

Advantages

Sheet metal fabrication has some clear advantages. That’s why it’s used in so many industries.

- Strong but lightweight: You get a solid part without the bulk. Great when you need something that holds up without adding extra weight. I’ve seen this make a big difference in portable products.

- Works for small runs or mass production: You can make just a few parts—or thousands. Once the design is ready, it’s easy to scale.

- Lots of material and finish choices: Want something that won’t rust? Need a specific color? Prefer aluminum or stainless steel? You have options.

- Easy to tweak or redesign: I’ve had clients make a quick change to a hole or bend mid-project. That’s much harder to do with casting or machining.

This flexibility saves time and stress—especially during product development.

Disadvantages

But it’s not perfect for everything.

Here are a few things to think about:

- Can get expensive for tricky shapes or small batches: If your design has lots of bends, welds, or tiny details, the cost can rise fast—especially if you’re only making a few parts.

- Takes time to set up: Machines need to be programmed. Tools need to be loaded. That setup takes time, which may not work if you’re in a rush.

- Not great for very thick parts or odd 3D shapes: Sheet metal starts flat. That works well for many designs—but not all. If your part is thick or highly sculpted, you may need another process like casting or machining.

I’ve learned to ask early: “Does this really need to be sheet metal?” If the answer’s yes, it usually makes things easier. If it’s no, knowing that early saves time and money.

You can do the same—now that you know the trade-offs.

4. Design Considerations for Sheet Metal Parts

Designing for sheet metal isn’t hard—but it’s not the same as working with plastic or 3D printing. I’ve seen great ideas fail simply because the design didn’t match what the machines could actually do.

A few small choices can save time, cut costs, and make sure your part works right the first time.

Key Design Rules for Manufacturability

These are the basics I always go back to:

- Minimum bend radius = material thickness: If your sheet is 1 mm thick, your bend radius should be 1 mm or more. Tighter bends may crack the metal.

- Avoid super tight tolerances: Sheet metal moves a bit when bent or cut. If you call for exact fits, it could lead to delays or rejected parts.

- Add relief cuts near bends: These are small notches that stop the metal from tearing during bending. I’ve seen parts fail simply because this was skipped.

When in doubt, ask your fabricator what works best. They’ve seen it all.

Cost-Saving Design Tips

Simple designs are usually cheaper—and easier to make.

Here’s what helps:

- Stick to standard hole sizes: If your holes match common drill or punch sizes, you save on custom tooling.

- Reduce part complexity: Fewer bends, welds, or small cutouts = faster production.

- Use rounded internal corners: Sharp corners are harder to cut cleanly. A small radius makes machining and cutting easier.

One project I worked on saved hundreds just by rounding off three tight corners and changing two hole sizes.

Software and File Formats for Designers

You don’t need fancy software—but using the right tools helps.

Popular design programs include:

- SolidWorks: Great for mechanical assemblies.

- AutoCAD: Good for 2D layouts.

- Fusion 360: Cloud-based and user-friendly.

When it’s time to send files, stick with:

- DXF: Great for 2D cutting profiles.

- STEP: Good for full 3D models.

- DWG: Works well with AutoCAD.

Getting your files right means fewer delays, clearer quotes, and better results. I always double-check the format before sending it off. You should too.

Good design doesn’t need to be fancy—it just needs to work with the process.

5. Sheet Metal Fabrication vs Other Methods

| Criteria | Sheet Metal Fabrication | CNC Machining | Injection Molding |

| Best For | Enclosures, brackets, panels, frames | Solid parts with high precision and detailed 3D shapes | High-volume production of complex plastic parts |

| Material Used | Metal sheets (aluminum, steel, copper, etc.) | Solid metal blocks (aluminum, steel, etc.) | Thermoplastics (ABS, polycarbonate, etc.) |

| Setup Cost | Low to moderate | Moderate to high | High (due to mold creation) |

| Per-Unit Cost | Low for medium/high volumes | High, especially for large or flat parts | Very low at high volume |

| Design Flexibility | Easy to modify or revise | Moderate—revisions can be time-consuming | Low—difficult and expensive to change after mold is made |

| Lead Time | Fast for prototypes and short runs | Slower, especially for large parts | Long upfront (tooling), fast after production begins |

| Strength & Durability | Strong yet lightweight (good structural balance) | Very strong (solid material) | Moderate (depends on plastic type) |

| Ideal Geometry | Flat or folded shapes | Complex 3D shapes with deep features | Highly detailed and organic shapes |

| Production Volume | Best for low to medium volumes | Small to medium volumes | Best for high-volume (1,000+ units) |

| Common Use Cases | Mounting brackets, control boxes, panels | Engine parts, tool components, custom hardware | Phone cases, plastic housings, consumer electronics |

| Recommended When | You need speed, flexibility, and strength for flat or bent metal parts | You need tight tolerances or deep 3D features | You’re producing high volume and can invest in tooling upfront |

6. Common Mistakes to Avoid in Sheet Metal Fabrication

I’ve seen good designs fail—not because the idea was bad, but because of small mistakes that crept in early.

The good news? Most of these are easy to avoid if you know what to look for.

Design-Related Mistakes

These errors often show up on the drawing—long before the part hits the shop floor.

- Ignoring bend allowances: When metal bends, it stretches. If you don’t account for that, holes or features may end up in the wrong place. I’ve seen parts misalign just because this was skipped.

- Over-specifying tolerances: It’s tempting to ask for super tight tolerances everywhere. But the tighter the spec, the harder—and more expensive—it is to make. Only call for tight tolerances where it matters.

- Designing parts that can’t be formed: Some designs just don’t bend well. Maybe the flange is too close to a hole, or the angle’s too sharp. If the part can’t be made with standard tools, it may not get made at all—or it’ll cost more.

Sourcing and Production Errors

Even with a good design, production can go wrong if sourcing isn’t handled carefully.

- Not checking supplier capabilities: Every shop is different. Some can laser cut but don’t do forming. Others handle high volume but not small batches. Always ask what they actually do in-house.

- Using the wrong material: I once saw a stainless steel part rust after a few weeks—because it was the wrong grade. Make sure the material matches the use case: strength, corrosion resistance, and finish.

- Forgetting finished details in the RFQ: If you want powder coating, plating, or anodizing, say so up front. I’ve seen parts quoted without finishing, then delayed because that step was added later.

Double-checking these areas can save you time, money, and frustration. Keep this list handy next time you design a part or reach out to a supplier. It’s helped me—and it’ll help you too.

7. How to Choose the Right Sheet Metal Fabrication Services

I’ve worked with dozens of fabrication shops over the years. Some made the process smooth from start to finish. Others? They caused delays, errors, or extra costs.

The difference usually came down to one thing—fit. Whether their services matched the project’s real needs.

So how do you pick the right one for your job?

Ask yourself these five key questions:

What Services Does the Shop Actually Offer?

Not all fabrication shops are built the same.

Some will cut and bend your parts—nothing more. Others can:

- Weld parts together

- Add inserts or hardware

- Handle powder coating, plating, or anodizing

- Package or lightly assemble your parts for shipping

Think about what you need beyond the first bend. Do they work with your material type? Can they hold the tolerance you need? Do they have machines that fit your part size?

One client brought us a design that another shop turned down—just because it needed tapping and finishing work. We took it from flat sheet to packaged product, and they never had to touch a thing.

Can They Meet Your Timeline?

How fast do you really need the part?

Some jobs are flexible. Others are on tight deadlines. That’s where lead time comes in.

One shop might promise a 5-day turnaround. Another? Three weeks.

- Ask upfront: What’s your current lead time for this type of part?

- If the quote doesn’t mention it, that’s a red flag.

Late parts can delay launches, stall production, and cost you more in the long run.

What’s the Quality of Their Work?

A good part isn’t just “cut and bent.” It looks right. Feels right. Functions right.

Don’t be afraid to ask for photos of past jobs—or better yet, physical samples. Look at:

- Edge smoothness

- Consistency across parts

- Alignment of holes and bends

- Surface finish

I once saw a set of brackets where half the holes didn’t line up. The shop said, “That’s within tolerance.” But try explaining that to your customer when it doesn’t assemble properly.

At MachMaster, we send real samples before large orders. It shows clients the care we put into every part—and gives them peace of mind before production begins.

Do They Handle Finishing In-House or Outsource It?

If you need coatings or plating, ask early:

- Do they apply finishes in-house?

- Or do they send parts to a partner shop?

This matters.

Outsourcing can mean longer lead times or extra costs. It also means you may have less control over quality.

Knowing this ahead of time helps you avoid last-minute surprises.

What’s Included in the Quote?

A quote isn’t just about the bottom-line number.

Look at the details:

- Material type

- Part quantity

- Surface finish

- Hole sizes, tolerances, bends

- Packaging (if needed)

A quote that looks cheap up front might leave out key steps. You don’t want to find that out mid-project.

We had a client show us a quote that looked like a great deal—until they realized it didn’t include finishing or hardware install. The final cost? Almost double.

Conclusion

Now that you know what sheet metal fabrication is, how it works, and when to use it, you’re ready to avoid the same headaches.

Whether you’re building one part or one hundred, now you understand how it’s done.

So—what will you create first?

You don’t have to figure it out alone.

Contact us today and turn your idea into a part you can hold.

Recommended Reads for You

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Sheet Metal Fundamentals & Uses:

- Sheet Metal Fabrication: What You Need to Know

- What Is Sheet Metal Used For?

- Sheet Metal Fabrication Process: Step-by-Step Guide

- Mastering Sheet Metal Fabrication in 8 Steps

Industry & Applications:

- Top 10 Industries Benefiting from Sheet Metal Fabrication

- Top 7 Industries Using Sheet Metal Manufacturing

- Sheet Metal Prototype: What You Must Know

Techniques & Processes:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.