One day, a shop owner told me his aluminum parts were turning dull and cloudy before he could even coat them. He was losing time and money, and nothing seemed to work.

He asked if there was a better way to fix it before it cost him another job.

I knew exactly what he needed.

As someone who runs a professional sandblasting service, I get called in when surface prep goes wrong.

With years of hands-on experience helping businesses get clean, coating-ready surfaces, I’ve seen how the right sandblasting approach can completely change outcomes.

It’s not just about cleaning—it’s about setting your process up for success.

In this article, I’ll explain what sandblasting is, how it works, and why it matters.

If you’re dealing with rust, paint that won’t stick, or metal that just won’t look right, this guide will help you fix it the right way.

So, let’s dive in!

1. What Is Sandblasting?

Sandblasting is when you shoot abrasive material—like sand, glass beads, or even walnut shells—at a surface using high-pressure air or water.

Sounds intense, right?

It definitely can be. But with the right setup, it’s not just about brute force—it’s about precision.

Whether you’re stripping rust off a steel beam, prepping metal for powder coating, or cleaning old concrete, sandblasting shows up as the go-to tool for pros who need fast, clean results.

Here’s why people rely on it:

- Tough on Grime: Rust, paint, weld slag—it doesn’t stand a chance.

- Great for Prep: Clean surfaces bond better with paint, coatings, and finishes.

- Surprisingly Versatile: Dial in the right pressure and media, and you can go gentle or aggressive.

If you’re in manufacturing, repair, or even heavy-duty cleaning, you’ve probably seen it in action. But knowing when to use it, and how to do it safely, can save you from costly mistakes or messy finishes.

2. Advantages of Sandblasting

At first glance, sandblasting might seem like a harsh or messy option.

But once you actually try it, you’ll see it’s one of the most reliable and precise surface prep tools out there. It’s not just about blasting things clean.

It’s about giving surfaces the right texture to hold up better after painting, coating, or repairing.

It Saves You a Lot of Time

Be honest. Scraping rust by hand or grinding away old paint takes forever. If you’re up against a tight deadline or a big job, sandblasting can seriously speed things up.

It covers large areas fast and does it evenly, so you don’t waste time going back to fix missed spots. Less time working means more time moving forward, and that’s always a good trade.

It Gets Surfaces Truly Ready

Prepping a surface before painting or coating isn’t just a formality—it’s the key to getting results that last.

Sandblasting gives just the right amount of roughness so your coating sticks better and holds up longer. Whether you’re working with powder coat, epoxy, or traditional paint, you’ll notice fewer issues like peeling or flaking down the line. Good prep makes everything else easier.

It Works on All Kinds of Materials

You don’t need a separate tool for every surface you work with. One of the best things about sandblasting is how easy it is to adjust. Change the abrasive, tweak the pressure, and you’re good to go—from tough metal to delicate surfaces like glass.

It’s flexible, reliable, and fits into almost any kind of shop setup.

It Cuts Out the Harsh Chemicals

If you’re trying to create a safer workspace or cut back on chemical use, sandblasting is a solid choice. You can strip away paint, grease, or rust without needing any toxic cleaners.

That means fewer fumes, fewer safety worries, and a much easier time staying compliant with health and safety standards. You get a cleaner result with less risk to you or your crew.

3. Common Types of Sandblasting Methods

Sandblasting isn’t a one-size-fits-all kind of deal. If you’ve ever stood in front of a grimy metal part wondering what’s the best way to clean it up, you already know there’s more than one route to take.

The good news? Once you get the hang of the different methods, it’s actually pretty easy to pick the right one for the job.

Dry Sandblasting

This is the one most people imagine right away. You’ve got abrasive particles flying through high-pressure air, hitting the surface like a mini sandstorm. It’s powerful, fast, and absolutely eats through rust, paint, or anything stubborn.

I reach for this when I’m working outside or in a big open shop where dust clouds aren’t a big deal.

Just make sure your PPE game is strong, because it gets messy quick. When you need raw force, this method delivers.

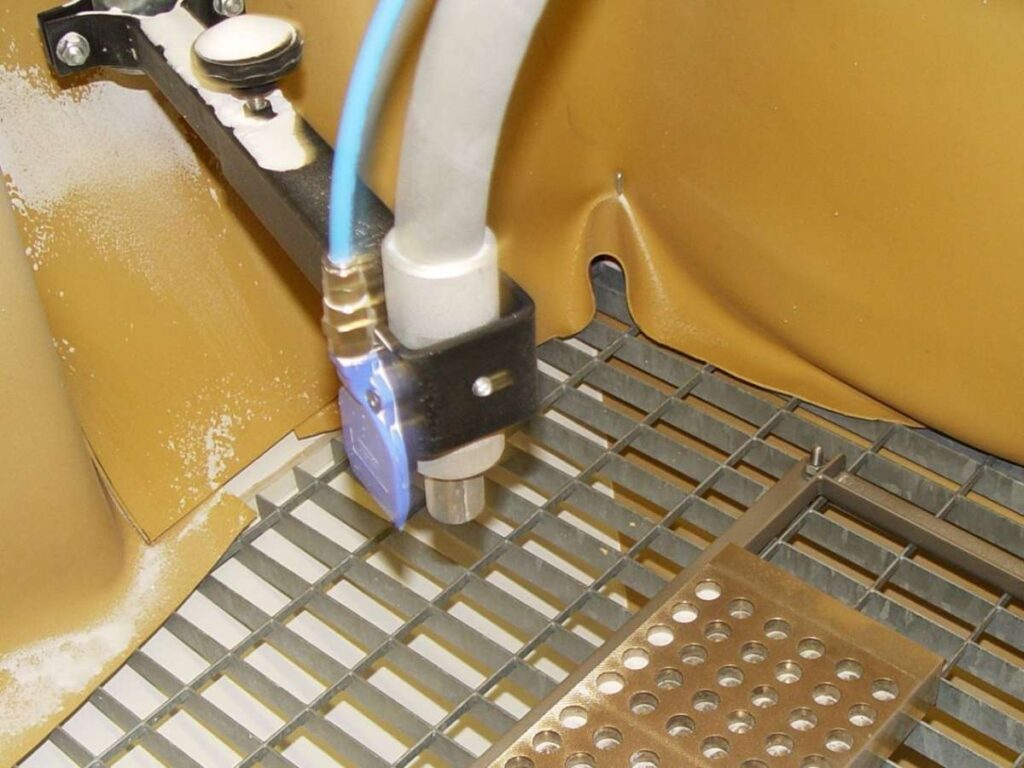

Wet Sandblasting (aka Dustless Blasting)

Add water to the equation, and suddenly the whole process feels more controlled. Wet blasting keeps dust to a minimum, which makes a big difference when working indoors or around other equipment.

It’s especially useful for delicate surfaces where you want to avoid the harsher impact of dry media.

This method is often used for parts that require a cleaner environment or a gentler touch during prep. For tight spaces or more sensitive applications, it’s a smart tradeoff.

Soda Blasting

Here’s where things get interesting. Instead of sand, you’re using good ol’ baking soda—yes, the same stuff from your kitchen. I like this method when I’m cleaning something fragile, like soft aluminum or painted wood

I don’t want to damage. It’s gentle but still gets the job done, especially when you’re dealing with soot, grime, or smoke-damaged surfaces.

Plus, cleanup is easy since the soda just rinses away with water.

Bead Blasting

If you ever need a surface to look polished without cutting too deep, bead blasting is your friend. It uses tiny glass beads to clean without being too harsh, which makes it perfect for things like stainless steel parts or components that need a uniform finish.

I’ve used it when appearances matter as much as performance—think food-grade or medical equipment. The finish is smooth, matte, and super consistent.

Vacuum or Enclosed Blasting

Sometimes, you just can’t make a mess. That’s when vacuum blasting comes in. This setup sucks up the abrasive and debris as soon as it hits the surface, keeping things tidy and safe.

It’s not the fastest option out there, but it’s a must-have when you’re working in sensitive areas like cleanrooms, tight industrial spaces, or anywhere dust could cause real problems.

It’s slower, yes, but also smarter when precision and cleanliness are top priorities.

4. Types of Abrasive Media Used

The blasting method matters, but so does what you’re blasting with. Your media choice can change everything: speed, finish, safety, and even cost. Here are the most common ones, and what they’re best suited for.

- Aluminum Oxide: This is a tough, angular abrasive that works well on hard metals and heavy coatings. It cuts fast and deep, making it great for surface prep before coating or welding. Aluminum oxide is reusable too, which helps lower your per-job media cost.

- Glass Beads: Glass beads offer a softer touch while still delivering a clean, smooth finish. They’re non-toxic, recyclable, and leave behind very little residue. You’ll find them used in parts cleaning, cosmetic finishing, or anywhere a satin-like surface is preferred.

- Steel Grit and Steel Shot: These are the heavy hitters. Steel grit cuts hard and fast, perfect for big jobs like prepping bridge components or ship hulls. Steel shot, being rounder, is better for peening and smoothing rather than cutting.

- Soda (Sodium Bicarbonate): As mentioned earlier, soda is great when you need low abrasion and high cleanliness. It’s safe for softer surfaces and won’t embed particles like some harder abrasives.

- Crushed Walnut Shells: Natural and biodegradable, walnut shells are perfect for cleaning without cutting or scratching. They’re used a lot in aerospace and automotive maintenance to clean engines or electronics without causing damage.

5. Key Applications of Sandblasting

You’ll find sandblasting in more places than you might expect. From prepping heavy equipment to cleaning delicate surfaces, it’s a process that crosses industries, and gets results fast.

Rust and Paint Removal

This is one of the most common uses for sandblasting, and it’s easy to see why. Rust and old paint can be stubborn, especially on outdoor structures or older machinery. Sandblasting strips these layers clean in a fraction of the time other methods would take.

You get a bare, ready-to-coat surface without excessive grinding or scraping. It’s especially helpful when time and consistency matter, like in fleet maintenance or metal fabrication.

Surface Preparation Before Coating

Proper adhesion doesn’t happen by accident, it starts with surface prep. Sandblasting roughens the substrate just enough to give paint, powder coat, or sealant something to grip.

This leads to better durability and reduces the risk of peeling or bubbling later. It also ensures that coatings wear evenly, which means fewer touch-ups or rework. For long-term performance, surface prep is where it all begins.

Cleaning and Etching Concrete

If you’ve ever seen a polished concrete floor with exposed aggregate, chances are sandblasting helped make it happen. It’s used to remove grime, expose textures, or prep floors for sealants and coatings. Unlike acid etching, it gives you more control and fewer environmental concerns.

Plus, it can improve slip resistance or give walkways a more finished look. Whether you’re in construction or maintenance, this method adds value.

Restoration of Buildings and Surfaces

Older buildings often have layers of grime, paint, or weather damage that need careful cleaning. Sandblasting helps reveal original textures without damaging underlying material when done correctly.

It’s used in everything from brick restoration to vintage signage cleanup. In many cases, it’s the only thing that can bring worn surfaces back to life.

A great choice when visual impact and preservation are both priorities.

Industrial Equipment Maintenance

Machinery tends to build up grease, rust, or residue over time—especially in high-heat or high-humidity settings.

At MachMaster, sandblasting gives maintenance teams a way to keep equipment clean, functional, and safe. It also allows for faster inspections by exposing flaws or damage that might be hidden under surface buildup. In repair shops or factories, it’s part of the regular workflow.

6. Potential Risks and Safety Considerations

As useful as sandblasting is, it’s not risk-free. Understanding what can go wrong—and how to prevent it—will save you a lot of trouble down the line.

- Dust Exposure and Respiratory Risk: One of the biggest hazards in dry sandblasting is airborne dust. If you’re using media like silica sand, this can lead to serious conditions like silicosis. That’s why modern operations either avoid silica altogether or require tight PPE protocols.

- Damage to the Surface: Using the wrong abrasive or too much pressure can cause surface damage, especially on softer materials. That’s why testing on a small patch first is always a good move.

- Flying Debris and Injuries: Sandblasting shoots material at high speeds, and anything in its path. That’s why face shields, gloves, and full-body suits are standard in professional setups. It’s not just about looking tough, it’s about staying safe.

- Noise and Equipment Wear: Sandblasting is really loud. Prolonged exposure without hearing protection can lead to hearing loss. And because the process is so abrasive, your gear takes a beating too. Hoses, nozzles, and blast cabinets need regular inspection and replacement.

7. Sandblasting vs Other Surface Treatments

When you’re choosing how to clean or prep a surface, the options can feel overwhelming. This chart breaks down how sandblasting compares to other common surface treatments so you can quickly see what fits your application best.

| Method | Best For | Pros | Cons | Common Use Cases |

| Sandblasting | Removing rust, paint, scale, and tough coatings; prepping metal/concrete | Fast and efficient over large areas. Excellent for aggressive removal. Produces a consistent finish. Adaptable to different materials with media choice. | Can be dusty (unless wet blasting). May damage soft materials if pressure or media is not chosen correctly. | Industrial equipment cleaning, structural steel prep, tank maintenance, concrete etching, paint stripping |

| Power Washing | Cleaning dirt, oil, or grime from surfaces like concrete or siding | No abrasives needed. Environmentally friendly with proper water handling. Easy to use for basic cleaning. | Doesn’t remove paint or rust. Not suitable for coating prep. Can lead to pooling or drainage issues indoors. | Driveways, sidewalks, walls, post-construction cleanup |

| Grinding / Wire Brushing | Small, focused areas where manual control is needed | Low-cost tools. Good for weld prep or detail work. No need for containment systems or special PPE. | Time-consuming and labor-intensive. Prone to uneven finishes. Hard to scale across large surfaces. | Weld cleaning, tight corners, small touch-ups on steel or iron |

| Chemical Stripping | Removing coatings from detailed or heat-sensitive surfaces | Non-abrasive. Effective on delicate substrates. Works well on wood or thin metals. | Slow process. Requires chemical handling training. Generates hazardous waste and fumes. | Furniture restoration, antique preservation, aircraft component cleaning |

| Laser Cleaning | Precision cleaning on valuable or sensitive materials | Extremely accurate. No dust or abrasion. Leaves base material unharmed. Low environmental impact. | High initial cost. Slower on large areas. Requires operator training. | Aerospace, electronics, historic monuments, mold removal on sensitive surfaces |

8. 4 Factors to Consider When Choosing a Sandblasting Service

If you’re outsourcing the job, picking the right provider matters. A good partner can deliver clean, consistent results—while a poor one can cost you time, money, and even damage your parts. These four factors can help you separate professionals from unprepared operators.

#1 Industry Experience

Blasting a metal part is one thing.

Blasting a heritage building or sensitive engine component is another. Look for a provider who has experience in your industry and understands your standards. The more relevant jobs they’ve done, the more likely they’ll know how to avoid common mistakes and deliver the finish you need.

MachMaster, for example, has handled everything from intricate aerospace components to large industrial assemblies—proof that experience really does translate into better results.

Don’t hesitate to ask for case studies or examples, they’re often happy to show off previous work.

#2 Media and Equipment Options

Not every job needs the same abrasive or blasting method. A vendor with multiple media types—like soda, grit, or glass beads—can customize the process to your surface. Ask if they can handle both dry and wet blasting or accommodate unusual materials.

The manufacturer’s flexibility in tools reflects a more knowledgeable and better-equipped team. Their up-to-date gear and a range of nozzles or blast cabinets often produce better, more consistent results.

#3 Safety Standards and Certifications

Ask about PPE, air quality systems, and cleanup procedures.

Are their staff trained and certified? Do they meet OSHA or local environmental standards?

A provider who invests in safety also tends to invest in quality, which protects both your team and your project. You want someone who treats safety as non-negotiable—not as a box to check.

#4 Scheduling and Turnaround Time

Can they deliver on your timeline without overbooking or rushing the job? Ask about their current workload and how they handle last-minute changes.

A reputable service will set realistic deadlines—and stick to them. Fast is good, but reliable is better when planning around production or inspections. If delays do happen, you want a partner who communicates early and offers solutions, not excuses.

Conclusion

I used to think sandblasting was just industrial noise, until I saw it turn failure into progress right in front of me.

You now know what makes it useful, how it compares to other treatments, and when it’s the best choice.

Where are you stuck in your process right now?

What could you move forward if your surfaces were production-ready?

Contact MachMaster today, and let’s get your parts prepped, coated, and ready for the next phase.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

Interested in more? Here are some additional articles with insights and tips to keep you informed:

- Why Sandblasting Comes Before Powder Coating?

- Sandblasting Metal: What You Need to Know

- What Is Sandblasting Used For?

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.