I’ve seen parts come off a CNC machine that look flawless, until they don’t fit. That’s what happens when you assume “machined” means “precise.”

That’s when I realized: not all CNC machining is created equal. Precision is a different game.

After working with manufacturers and engineering teams for years, I’ve learned what to look for and what to avoid. I wrote this with one goal: to help you make better, faster prototyping decisions.

This guide breaks down what precision machining really is, how it connects to CNC prototypes, and what it means for your business. If you’re trying to get this right the first time, this article will help.

If your tolerances are too loose, your profits might be too.

Let’s get into it!

1. What Is Precision Machining?

Precision machining uses computer-guided equipment like CNC mills, lathes, and EDM machines to shape raw materials into finished parts that meet strict tolerances. Unlike general machining, where “close enough” might cut it, here, every cut, bore, or thread needs to be exact. Think of it like architectural design at a microscopic level.

This process is behind almost everything that requires tight engineering standards, from aerospace brackets and surgical tools to automotive transmission components. And in today’s fast-paced industries, precision isn’t a luxury. It’s the baseline.

2. Benefits of Precision Machining

When I first started working with custom parts suppliers, I didn’t realize how much time and money could be saved by getting things right the first time. Precision machining changed the game for our operations. It made everything smoother, from sourcing to final assembly.

Consistent Part Quality Across Every Batch

Precision machining removes the guesswork from part production. Whether you’re ordering 5 units or 5,000, every piece meets the same high standard. That kind of consistency builds trust across your supply chain, especially when your end customers expect flawless results. It also reduces the need for manual checks and post-processing, which saves time on your floor.

Reduced Waste and Better Material Utilization

Scrapped parts are a silent budget killer, especially when you’re working with expensive metals. With precise cuts and optimized tool paths, material waste drops significantly. That means more usable components from every sheet, billet, or rod. Over time, that adds up to real savings, not just on materials but also on machining hours.

Faster Prototyping and Scalable Production

I’ve seen projects go from digital design to real-world parts in just a few days, thanks to CNC precision. Once your prototype is validated, scaling to full production is seamless. The same files, machines, and processes can be reused with almost no extra prep. That speed gives your business the flexibility to test, pivot, and launch faster than competitors.

Better Fit, Performance, and Reliability

When every cut, hole, and groove is made to spec, parts just work better. Assemblies fit tighter, moving components glide smoother, and you get fewer malfunctions in the field. That kind of performance translates into longer equipment life and lower maintenance costs. And for your customers, it shows you care about every last detail.

Freedom to Design Complex, High-Function Components

The beauty of precision machining is that it doesn’t limit creativity, it unlocks it. Engineers can design intricate parts that would be impossible or too costly to cast or mold. Whether it’s internal channels, sharp corners, or tight curves, the machines can handle it. That means your products can be more compact, efficient, and innovative without compromise.

3. Core Principles of Precision Machining

Back when I first started reviewing machined parts, I assumed the machines did all the work. But it didn’t take long to realize that precision isn’t just about equipment. If you’re relying on these parts to perform under pressure, you want to know the principles behind their accuracy.

- Tight Tolerances: Precision machining revolves around holding tolerances down to thousandths of an inch or smaller. These tolerances ensure that parts fit, move, and function exactly as intended.

- Repeatability: It’s not enough to get one part right. A shop must produce thousands of identical parts without variation to be considered truly precise.

- Proper Tool Selection and Calibration: Using the right cutting tool and keeping it sharp is essential for achieving clean edges and consistent dimensions. Tools must also be regularly calibrated to maintain accuracy throughout production.

- Machine Stability and Maintenance: Even the most advanced machine loses accuracy if it’s not maintained. Stability and regular servicing help prevent vibration, tool deflection, and unexpected variation.

- Digital Workflow Integration: From CAD design to CAM programming, precision machining depends on a seamless flow of digital data. This integration reduces manual errors and speeds up the transition from design to production.

- Quality Control and Inspection: Every part must be verified using precise measurement tools like CMMs, gauges, and scanners. This step catches issues early and maintains accountability across batches.

- Operator Skill and Attention to Detail: No matter how automated the process is, skilled machinists still make a difference. Their experience helps identify small adjustments that improve quality and efficiency.

4. Materials Suitable for Precision Machining

One of the things I’ve always admired about precision machining is its range. The process isn’t limited to just one type of material. Depending on the application, almost anything solid can be machined to spec. What matters most is choosing the right material for the job and making sure it performs the way you need it to.

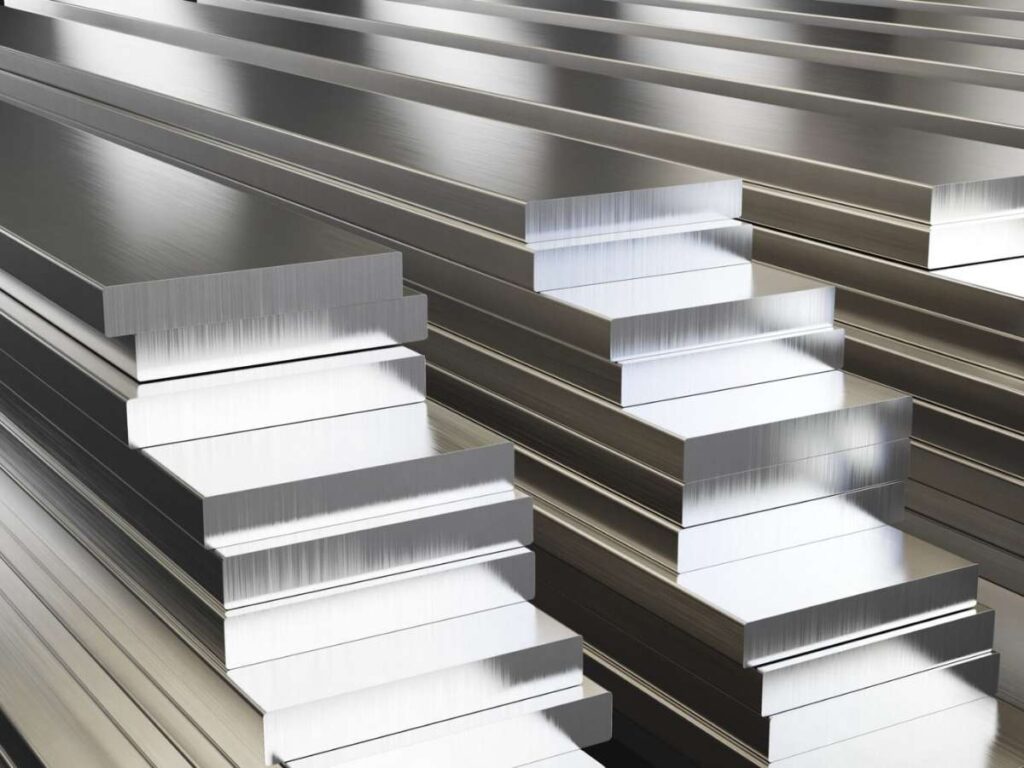

Metals

- Aluminum: This metal is lightweight and easy to machine, making it a favorite for industries like aerospace and electronics. Its strength-to-weight ratio and resistance to corrosion make it incredibly versatile.

- Steel (and stainless): Steel offers durability and strength, perfect for high-load or structural applications. Stainless versions add corrosion resistance, making them ideal for automotive, medical, and marine uses.

- Titanium: Titanium is both strong and lightweight, which makes it popular in demanding industries like aerospace and healthcare. However, it is more challenging to machine due to its toughness and low thermal conductivity.

- Brass and Copper: These metals are commonly used in electrical and plumbing applications because of their excellent conductivity. They’re also easy to machine and have natural resistance to corrosion.

Plastics

- Delrin (Acetal): Delrin is known for its strength, stiffness, and low friction, making it perfect for precision gears and bushings. It holds tolerances well and performs consistently under load.

- PTFE (Teflon): PTFE is chemically resistant and has a very low friction surface, which is great for seals, gaskets, and insulating parts. It’s also non-stick and performs well in harsh environments.

- Nylon and Polycarbonate: These plastics offer a solid mix of strength and light weight, often used in electronic housings and automotive components. They’re easy to machine and can handle moderate mechanical stress.

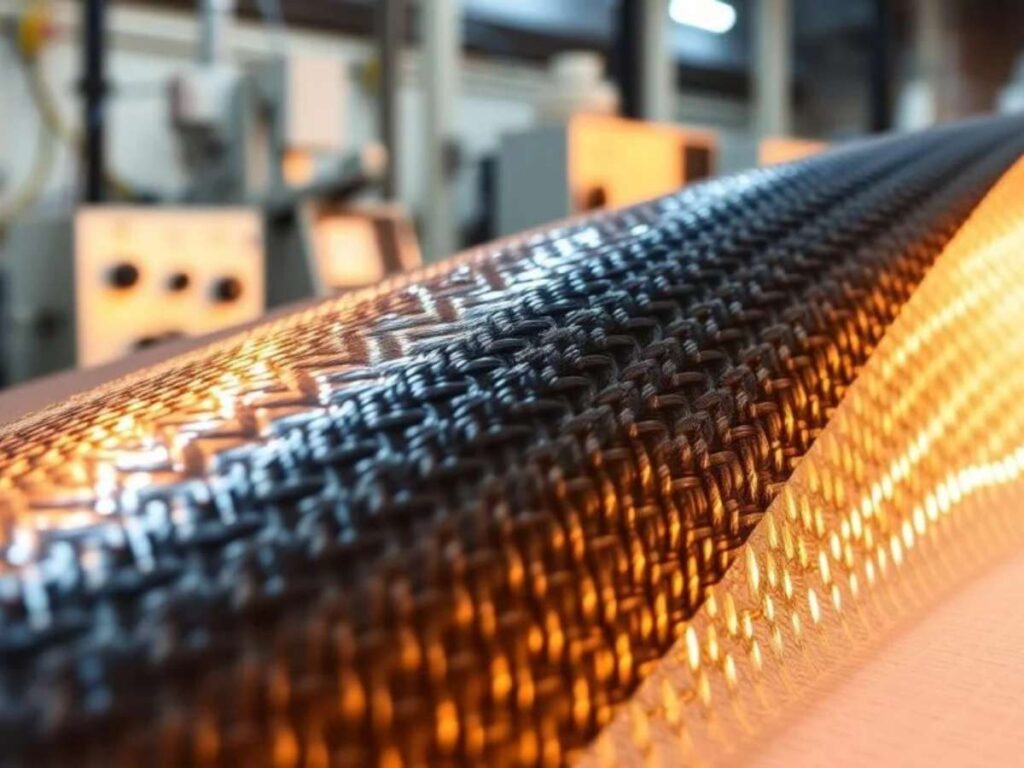

Exotics and Composites

- Carbon fiber composites, Inconel, and ceramics: These advanced materials can be machined to tight tolerances but require specialized tools and slower feeds. They’re typically used in aerospace, defense, or high-performance applications where strength and resistance to heat or chemicals are critical.

5. Applications of Precision Machining in Key Industries

The first time I walked through a production floor filled with aerospace components, I realized just how far-reaching precision machining really is. It’s not just about cutting metal with accuracy. Precision machining shows up in more places than most people think.

Aerospace and Defense

Precision machining is essential in aerospace where even the smallest flaw can put lives at risk. Aircraft parts like turbine blades, landing gear, and structural brackets must meet tight tolerances to ensure performance and safety. Defense applications also rely heavily on precision parts for weapons systems and communication equipment. In both cases, failure is not an option and reliability is everything.

Medical and Healthcare

In the medical field, precision machining helps create surgical tools, orthopedic implants, and diagnostic equipment with extreme accuracy. The parts often need to be biocompatible and meet strict regulatory standards. A minor dimensional error could affect patient outcomes or render a tool unusable. That’s why precision is more than a nice-to-have—it’s a requirement.

Automotive and Electric Vehicles

Automotive manufacturers depend on precision machining to produce engine parts, brake components, and transmission gears. As the electric vehicle market grows, it also supports battery housings, motor shafts, and thermal management systems. These parts must perform under high stress and tight space constraints. Precision machining allows engineers to design smarter and pack more function into smaller spaces.

Industrial Equipment and Automation

Heavy equipment, robotics, and automated systems rely on precision parts to keep things running smoothly. Components like hydraulic blocks, actuators, and tool holders must align perfectly to maintain performance. Inconsistent tolerances can lead to system failures or increased maintenance downtime. With precision machining, businesses can count on consistency and long-term durability.

6. Challenges and Limitations in Precision Machining

I’ve worked with some great machining partners, but even the best setups come with their challenges. Knowing the limitations ahead of time can help your business make smarter decisions. It’s not about avoiding the risks, but managing them wisely.

High Costs and Investment Barriers

Precision machining equipment is expensive, and so is the labor to run it. From CNC machines to inspection tools, the initial investment can be a hurdle for smaller businesses. Even maintaining these machines and replacing worn-out tooling adds to the cost. That’s why many companies outsource rather than bring everything in-house.

Skilled Labor Shortage and Learning Curve

Operating precision machines takes more than just pressing buttons. Skilled machinists, programmers, and quality control staff are in high demand but short supply. Training someone to run a five-axis CNC or perform inspections with a CMM takes time and money. Without the right team, it’s easy to fall behind or produce inconsistent parts.

Material and Design Constraints

Not all materials are easy to machine, especially exotic metals or composites. Some require slower feeds, special tooling, or more frequent tool changes. On top of that, overly complex designs with extremely tight tolerances can slow production and raise costs. Engineers and machinists need to collaborate closely to balance functionality with manufacturability.

7 .How to Choose a Precision Machining Service Provider

I’ve reviewed a lot of machining quotes over the years, and I can tell you this: technical capability always beats a flashy website. So, it pays to dig into the technical side before you sign a PO.

#1 Machine Capability and Technology Stack

Start by looking at the shop’s equipment list. Do they have 3-axis, 5-axis, CNC turning, Swiss lathes, or EDM machines that match your part complexity? Newer machines with high spindle speeds, advanced controllers, and tool changers can deliver tighter tolerances with faster turnaround. Ask if they can handle your material type and feature geometry without excessive setups or workarounds.

#2 Tolerance, Surface Finish, and Dimensional Accuracy

Not all shops measure precision the same way, so always ask for their achievable tolerances and finishes. Can they routinely hold ±0.0005 inches or tighter across production runs? Surface finish capabilities also matter, especially for sealing surfaces, sliding parts, or cosmetic requirements. Make sure they inspect every batch and not just the first article.

#3 Inspection Equipment and Quality Control Processes

A true precision shop will have more than just calipers and micrometers. Look for CMMs, optical comparators, height gauges, and laser measurement systems on the floor. Ask about their calibration schedule, inspection documentation, and traceability standards. If they treat quality control like a final checkbox, that is a red flag.

#4 Programming and Workflow Efficiency

Behind every precise part is a well-optimized CAM program. Ask if they use advanced CAM software like Mastercam or Fusion 360, and how they simulate toolpaths before cutting. A shop that understands tool deflection, thermal expansion, and workholding dynamics will save you trouble in the long run. Bonus points if they provide design for manufacturability feedback to improve your drawings.

Conclusion

Precision machining caught my attention years ago, and it’s still the process I trust most.

After walking you through what it is, how it works, and where it fits, I hope it’s clear why it matters.

It’s time to build with confidence. Make parts that perform the way you planned.

Need support from a reliable precision partner?

Contact MachMaster today. We’re built to support your custom needs.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.