I once had a product prototype flop, simply because it was uncomfortable to hold. Everything else was right, but the material choice made it feel cheap.

That failure pushed me to find better ways to combine design with user comfort. That’s when I came across overmolding.

I’ve been researching and reviewing overmolding applications ever since, especially for manufacturers who care about quality without sacrificing speed or cost. If that’s you, you’re in the right place.

This article explains what overmolding is, how it works, and why it matters in real-world production. I’ll also break down its benefits, use cases, and what to watch out for when using it in your own designs.

Not every manufacturing method gives you better grip, insulation, and durability in one go. Overmolding does.

Let’s dive in.

1. What Is Overmolding?

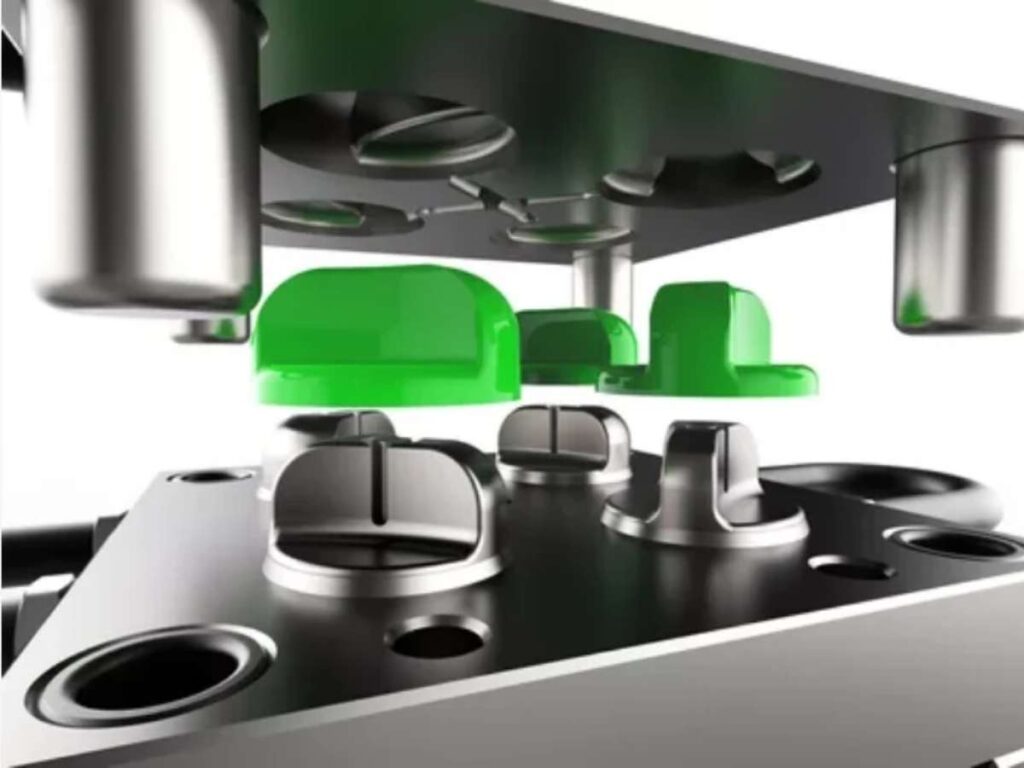

So, what exactly is overmolding? In the simplest terms, overmolding is a two-step injection molding process. First, a base component, usually rigid plastic or metal, is formed. Then, a second layer of material, typically softer, is molded over specific parts of the first one. The result? A single, unified piece that blends functionality and comfort.

For manufacturers and design engineers, this process opens doors to products that feel premium, function better, and even last longer. Whether you’re in tools, electronics, or automotive parts, overmolding isn’t just a trend, it’s a strategic move.

2. How the Overmolding Process Works

The first time I watched an overmolding cycle on the factory floor, I was fascinated. Two materials fused into one solid part, and yet the process looked surprisingly smooth. But behind that clean result is a carefully planned workflow that balances heat, pressure, and timing. If you’re considering this for your own product line, it’s helpful to understand what really happens during each step.

Step#1 Creating the Substrate

Every overmolding job starts with the substrate, which is just a fancy word for the base part. This is typically molded using a standard injection molding machine with a rigid plastic like ABS, polycarbonate, or even a metal insert. Once molded and cooled, this base is removed from the first mold and prepped for the second stage. At this point, it’s not a finished product, but it’s the foundation for everything that comes next.

Step#2 Preparing for Overmolding

Now the molded substrate is placed into a second mold designed specifically for the overmolding stage. This mold has precise cavities where the second material will flow around or over the base. Proper alignment is critical here because a slight shift can cause material overflow or weak adhesion. Most experienced molders use automated or robotic placement to keep things accurate and consistent.

Step#3 Injecting the Overmold Material

With the substrate secured in place, it’s time to inject the second material. This could be a soft thermoplastic elastomer, silicone, or any other flexible polymer, depending on your product needs. The material flows into the new mold under high pressure and heat, bonding to the first part either chemically or mechanically. If done right, the bond is seamless, and the two materials act as one finished unit.

Step#4 Cooling and Final Ejection

Once the second material fills the mold, the entire piece must cool before removal. Cooling time depends on the material, thickness, and design complexity. Afterward, the complete part is ejected and inspected for quality, including bond strength and surface finish. What you get is a final product that looks unified and performs like a single component, even though it was built in two layers.

3. Benefits of Overmolding

When you’re building a product that needs to work hard and feel right in someone’s hand, small design choices start to matter more than you expect. That’s where overmolding quietly earns its place. It doesn’t scream for attention, but it solves problems that come up again and again.

Feels Better to the End User

There’s a big difference between something that works and something that feels good to use. Overmolding lets you add soft-touch surfaces or textured zones exactly where people grip, push, or hold. It turns a basic part into one that’s more comfortable, more intuitive, and less fatiguing to handle. And when a product feels better, it gets used more—and trusted more.

Helps Your Product Last Longer

Wear and tear happens. Tools get dropped, parts get knocked around, and materials get pushed beyond their limits. Overmolding adds a protective layer that cushions impact, resists scratching, and helps seal out moisture and dust. That one change can cut down on damage, extend product life, and lower your return rate over time.

Makes a Stronger, More Unified Part

Instead of fastening or gluing separate components together, overmolding joins them during the molding process. The result is a cleaner, tighter bond that’s built to stay in place, even under pressure, heat, or heavy use. You’re not just sticking parts together—you’re making them one. That leads to fewer failures and a better-built product overall.

Raises the Bar Visually

People notice when something looks dialed in. Overmolding lets you build in contrast, color, and texture that instantly sets your product apart. You can even mold your logo right into the surface, giving it a subtle but lasting branding touch. All of this happens during the molding cycle, so there’s no need to bolt on style after the fact.

Simplifies the Manufacturing Process

With overmolding, you skip extra steps like secondary bonding or assembling multiple parts. That cuts down your production time and reduces the chances of something going wrong on the line. It also means fewer parts to stock, track, or troubleshoot. When your process is smoother, scaling up feels less like a risk and more like a plan.

4. Common Materials Used in Overmolding

Now let’s talk shop. Choosing the right combination of materials is half the battle in overmolding. Whether you’re working with plastics, metals, or medical-grade parts, getting the material pairing right is what makes the whole process work.

Substrate Materials (The Base Layer)

- ABS (Acrylonitrile Butadiene Styrene): This is a popular rigid plastic with good impact strength and dimensional stability. It’s a go-to for consumer products, tool housings, and enclosures.

- Polycarbonate (PC): Known for being both strong and transparent, PC is a solid choice when durability and visibility are both on the list. It’s especially common in electronic casings and industrial panels.

- Nylon (PA): Nylon brings high mechanical strength and chemical resistance, making it ideal for structural parts. It’s widely used in automotive components and hand tools.

- Metal (Aluminum, Steel): When maximum rigidity is non-negotiable, metal substrates are the answer. You’ll often see these in medical instruments, power tools, or anything that needs a solid core.

Overmold Materials (The Outer Layer)

- TPE (Thermoplastic Elastomer): Flexible, soft, and great for grip, TPE is the most widely used overmold material. It’s ideal for anything that gets handled frequently, like tool grips and device housings.

- TPU (Thermoplastic Polyurethane): This is a tougher, more wear-resistant option that holds up well against abrasions and oils. It works best in rugged environments and is commonly used for protective casings.

- Silicone: Silicone is biocompatible, soft to the touch, and resistant to extreme temperatures. It’s a top pick for medical devices and products that require skin contact.

- Liquid Silicone Rubber (LSR): LSR flows easily into tight molds and cures quickly, which makes it ideal for small or intricate parts. It’s widely used in wearables, baby products, and soft-touch electronic buttons.

5. Industries That Commonly Use Overmolding

Overmolding shows up in more industries than most people realize. That’s because it quietly solves problems like grip, protection, and usability without adding extra complexity. Below are just a few industries that rely on it heavily, and for good reason.

Power Tools and Handheld Equipment

In the tool industry, performance means nothing if the product slips out of someone’s hand. Overmolding adds grip zones and shock-absorbing layers that make daily use safer and more comfortable. These parts also tend to last longer because the outer layer handles the abuse first. For drills, saws, and utility knives, overmolding turns good tools into dependable ones.

Medical and Healthcare Devices

Medical equipment needs to be safe, sterile, and comfortable for both patients and providers. Overmolding helps meet all of those needs by combining hard internal parts with soft outer layers. Silicone and LSR are often used here since they’re biocompatible and easy to clean. Whether it’s a surgical handle or a wearable monitor, overmolding plays a big role in both function and safety.

Automotive and Transportation

Overmolding is commonly used in vehicle interiors and electrical systems. From dashboard knobs to wire harness connectors, it helps improve grip, reduce vibration, and create water-resistant seals. Manufacturers also use it to consolidate parts, which saves space and lowers weight. That’s a win for production efficiency and long-term reliability.

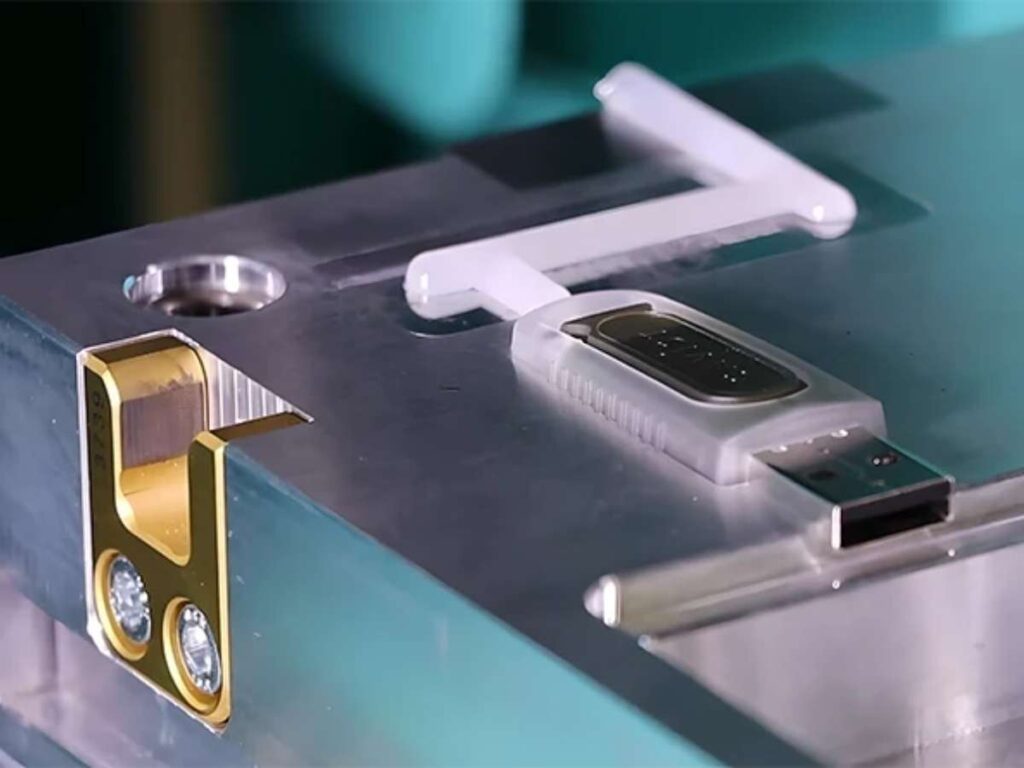

Consumer Electronics and Wearables

When people carry something around all day, it needs to feel right and hold up over time. Overmolding helps electronics stay durable without sacrificing style or comfort. You’ll find it in remote controls, gaming gear, headphones, and fitness trackers. It’s the reason a sleek product can also be tough and easy to handle.

6. Challenges and Limitations of Overmolding

Overmolding comes with a lot of upsides, but it’s not perfect for every situation. Like any process, it has its own set of challenges that are worth considering before jumping in. Knowing what to expect upfront can save time, cost, and a few production headaches.

- Higher Tooling and Setup Costs: Overmolding typically requires two sets of molds and more complex tooling, which can raise the upfront investment. For low-volume production, that cost might be hard to justify.

- Material Compatibility Issues: Not all materials bond well together, which can lead to weak spots or delamination over time. Picking the wrong combo can ruin the integrity of the final part.

- Longer Cycle Times: Since it’s a multi-step process, overmolding can slow down your production line compared to single-shot molding. Cooling and alignment also take more time between stages.

- Design Constraints: Overmolded parts need very specific design features for bonding and flow, so your flexibility can be limited. It’s not something you can easily retrofit onto an existing product.

- Difficult Repairs or Replacements: Once two materials are fused together, it’s tough to separate or replace one without damaging the other. That can be a downside if your product needs to be serviceable or modular.

7. 4 Tips to Consider When Choosing an Overmolding Service

Choosing the right overmolding partner isn’t just about who offers the best price or fastest lead time. These tips can help you make a decision that supports your goals and your product’s long-term success.

Prioritize Material Compatibility Knowledge

A good overmolding service should guide you through which substrate and overmold materials pair well—and which ones don’t. This isn’t guesswork; the wrong combo can result in peeling, warping, or poor adhesion. Look for a team that can explain chemical versus mechanical bonding and knows how to test it. If they can’t speak confidently about material behavior, it’s a red flag.

Ask About Tooling and In-House Capabilities

Tooling plays a huge role in overmolding success, especially when tolerances are tight. Make sure the provider can design and produce both the base and overmold tools, or has proven partners who can. In-house tooling usually means faster changes and better process control. It also reduces the risk of miscommunication between multiple vendors.

Look for Industry Experience That Matches Yours

Different industries have different requirements, and not every shop can pivot from automotive to medical, or vice versa. You’ll want a provider who understands your compliance standards, performance expectations, and quality benchmarks. Ask about previous projects similar to yours and what challenges they helped solve. Familiarity with your sector can save you time and costly trial runs.

Confirm Quality Testing and Prototyping Options

Before you commit to full-scale production, it’s important to see how your parts perform under stress. A reliable overmolding partner should offer prototyping runs, adhesion testing, and detailed inspections. This allows you to catch flaws early, tweak designs, and get clear on what your end product will feel like. A solid testing phase builds trust and ensures consistency from the first unit to the thousandth.

Conclusion

Great products don’t just happen. They’re designed with intention, right down to the smallest touchpoint.

Overmolding helps you do exactly that. It improves comfort, extends life, and brings real-world strength into every part.

So what’s stopping you from upgrading your next design?

Contact MachMaster today. Let’s build smarter.

More Guides and Tips to Explore

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.