Most people don’t think about what is overmold until they hold something like a drill, a toothbrush, or even a car wheel that feels soft but tough at the same time. I didn’t either.

Years ago, I picked up a tool at a factory and wondered why it felt so good in my hand. I found out it was because of overmolding. That small moment got me hooked.

Since then, I’ve spent 15 years inside factories, talking to suppliers, and sometimes losing money on mistakes. Those lessons taught me the real story behind how things are made.

That’s why you can trust me to give you the simple, honest truth.

You’re here because you want to know what is overmold, maybe for a new product, a bulk order, or even a personal project.

This guide is for you. I’ll show you what overmolding means, how it works step by step, and where it’s used. By the end, you’ll see how overmolding might help you solve problems or make smarter choices for your next idea.

So let’s get started!

1. What is Overmold?

Have you ever held a tool product with a soft rubber grip wrapped around a hard plastic handle?

That’s overmolding.

Overmold is a process where two materials are molded together to make one finished part.

Usually, one material is rigid (like plastic), and the other is softer (like rubber or silicone).

I use it all the time in parts like:

- Power tool handles

- Toothbrush grips

- Seals and gaskets

- Medical device housings

So why does overmolding matter to you?

Because it:

- Reduces the need for adhesives

- Makes parts more durable

- Improves appearance and function

If you’re designing or sourcing multi-material parts, overmolding might be the better option.

It’s not just about looks—it’s about bonding two parts into one solid piece.

2. How Overmold Works

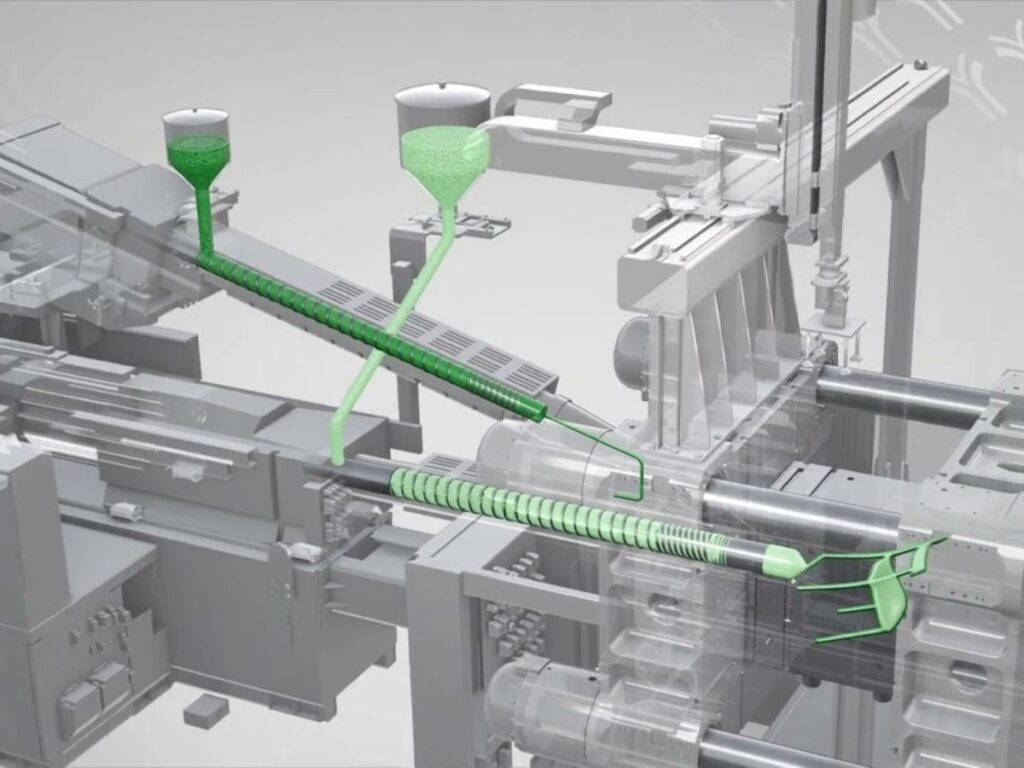

So how does overmolding really work?

Let’s break it down.

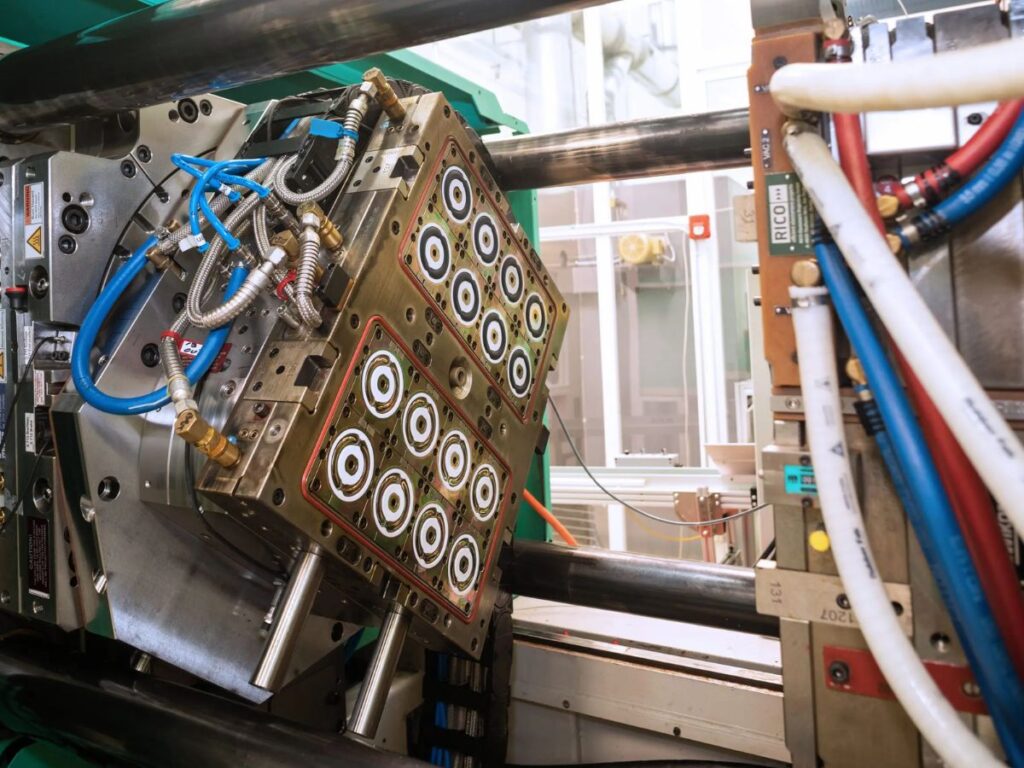

Overmolding is done in two main steps:

- Create the base part: This part is usually made of hard plastic like ABS or polycarbonate. It’s called the substrate.

- Mold a second material on top: A softer material—like TPE (thermoplastic elastomer)—is injected over or around the base part.

The two materials cool together.

They bond while they’re still hot, so the connection is strong.

We run this process all the time in our shop. I remember one project where the rubber layer had to be just soft enough to grip—but firm enough not to peel. It took three mold adjustments to get it right. That’s how precise overmolding needs to be.

There are two ways we usually do overmolding:

- Insert molding: Place the base part into the mold, then shoot the second material over it.

- Multi-shot molding: Both materials are molded in one machine, one after the other.

Which one’s better?

It depends on your design, volume, and budget.

Now that you know the steps, we’ll look at what materials actually work best in overmolding.

3. Common Materials Used in Overmold

If you’re considering overmolding for your next product, material selection is where things often go right—or wrong.

Here are the materials most often in production:

Thermoplastic Elastomers (TPE)

TPE, or thermoplastic elastomers, are plastics that offer rubber-like flexibility while being processed through standard injection molding.

Why does this matter to you?

- Provides a soft-touch surface ideal for grips, handles, and machine levers.

- Helps dampen vibration and absorb minor impacts, which can extend tool life.

- Available in a wide range of colors, supporting product branding or safety coding.

Many fabrication operations favor TPE when ergonomic comfort and a more controlled user interface are priorities. It’s a common choice for tool housings and industrial control surfaces.

Thermoplastic Polyurethane (TPU)

TPU is another thermoplastic, but it stands out for its high durability under tough conditions.

Why is TPU often selected in metal fabrication projects?

- Withstands abrasion and repeated surface contact better than most alternatives.

- Remains flexible in colder temperatures, preventing cracking in variable environments.

- Handles continuous bending or flexing without degrading.

One maintenance manager I know told me they switched to TPU for machine covers after too many early failures with cheaper materials. Less downtime, fewer headaches, that’s the real payoff.

Liquid Silicone Rubber (LSR)

LSR, short for liquid silicone rubber, begins as a liquid and cures into a flexible, stable rubber directly in the mold.

What makes LSR especially valuable?

- Performs reliably at high temperatures, maintaining its structure and flexibility.

- Resists a wide range of chemicals, which protects the underlying metal and simplifies maintenance.

- Commonly approved for food, pharmaceutical, or medical applications due to its hygienic properties.

I’ve heard more than one plant engineer say switching to LSR meant they could run parts longer between cleanings not because they wanted to stretch it, but because the surface just held up better.

Polypropylene (PP)

Polypropylene, or PP, is widely used as a practical, cost-conscious overmold material.

Where does PP typically make sense?

- Lightweight composition can help reduce total assembly weight.

- Naturally , many chemicals resist, making it useful for environments with exposure to oils or solvents.

- Offers a lower-cost option when the application doesn’t demand high-impact or soft-touch characteristics.

PP is often chosen for structural overmolds or covers where price control and chemical compatibility outweigh the need for flexibility or tactile softness.

I know sorting through these materials isn’t always straightforward figuring out what’s truly best for your overmolded parts can take some careful testing and real-world validation.

If you’re looking for hands-on support in narrowing down and proving the right material combinations, the team at MachMaster is ready to help. They understand the practical demands of production and can work with you to find solutions that hold up where it matters most.

4. Types of Overmold Techniques

Overmolding can be done using different techniques depending on the part design, material selection, and production requirements. This wasn’t always clear to me at the beginning, I used the same method on every job. Sometimes it worked, sometimes it didn’t.

Here are the most common methods you can choose from:

Multi-Shot Injection Molding

In this method, both materials are molded using one machine, often in one cycle. The machine injects the base material first, then rotates or shifts the mold to inject the second layer.

Multi-shot molding is ideal for:

- High-volume production

- Tight part tolerances

- Consistent bonding

We’ve helped clients scale from 1,000 units to 50,000 using this process. The parts come out cleaner and faster with fewer handling steps.

Your material, volume, and budget all matter—and getting it right early makes a big difference later.

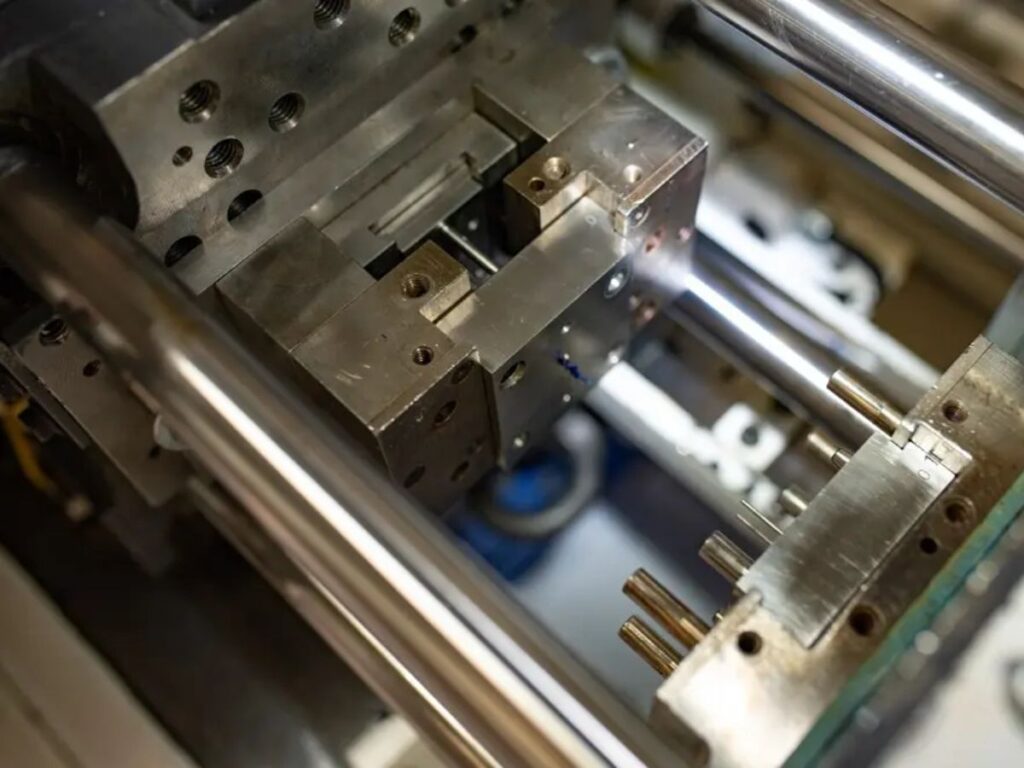

Insert Molding

This process starts by making the base part separately. Then we place it into a second mold, where the softer material is injected over it.

Insert molding works well for:

- Low to medium production volumes

- Simpler equipment setups

- Projects with limited budget

It’s reliable and flexible.

I’ve relied on this method when integrating threaded metal inserts into high-use parts, allowing mechanical fastening without secondary steps.

Co-Injection Molding

This technique injects two materials at the same time—one inside the other—through the same nozzle. Think of it like making a sandwich: one material becomes the core, and the other forms the outer shell.

Co-injection molding is useful when you need:

- A soft outer layer and strong inner core

- Barrier layers for chemical or moisture protection

- Cost savings by using recycled material inside

We usually see this in packaging or specialty industrial parts, not everyday grips or housings. If you’re considering co-injection, we’ll review if your material combo and volume make it a fit.

Each technique has its place. You just have to know which one fits your part and your goal and talk to your manufacturer.

5. Applications of Overmold in Different Industries

Overmolding is used across a wide range of industries. It often provides functional improvements, enhanced user experience, or long-term durability—all without adding complexity to assembly. Over time, this process has helped solve real production issues I’ve seen firsthand.

Below are several key industries where overmolding has played a valuable role.

Consumer Electronics

Devices today are touched, handled, and dropped more than ever. Overmolding improves the feel, grip, and durability of parts that go through constant daily use.

Common overmolded components:

- Phone cases

- Headphone bands and grips

- USB connectors and cable strain reliefs

Overmolding softens sharp transitions, adds flexibility where needed, and provides a clean, consumer-ready finish.

Medical Devices

In healthcare, cleanliness and ergonomics are critical. Overmolding helps eliminate seams that trap contaminants—and improves comfort during repeated use.

Typical use cases:

- Syringe plungers

- Surgical tool grips

- Sealed instrument buttons

You get smoother surfaces, fewer assembly points, and better tactile response for clinicians and technicians alike.

Automotive

Automotive parts deal with vibration, temperature swings, and constant human contact. Overmolding helps soften surfaces, insulate components, and extend part life.

Used for:

- Gear shift knobs

- Dashboard switches

- Interior handles and buttons

Adding a soft-touch layer not only improves grip—it helps dampen vibration and reduce noise, creating a better user experience without major redesign.

Industrial Equipment

In harsh environments, overmolding is all about sealing, protection, and performance.

You’ll often see it on:

- Control panel buttons

- Machine covers

- Tool casings and grips

It provides extra defense against:

- Dust and moisture

- Chemical splash

- Frequent washdowns

I’ve seen this make a big difference in factory settings where downtime is expensive. Overmolding helped keep electronics sealed—and running.

Whether it’s comfort, durability, or protection, overmolding adds value where it counts—making everyday products more reliable, safe, and user-friendly across industries.

6. Overmold vs. Other Molding Techniques

In many projects, you might ask: why not just glue or snap parts together instead of overmolding? It’s a smart question—especially when you’re weighing production cost, assembly time, or tooling investment.

The table below shows the comparison between overmolding and other techniques:

| Feature | Overmolding | Coating | Double-Shot Molding | Insert Molding |

| Material Bonding | Strong mechanical bond between layers | Surface-level adhesion | Very strong bond using a dual-barrel machine | Strong bond, especially for combining metal and plastic |

| Assembly Complexity | Integrated into molding process | Easy post-process application | Fully automated process | Semi-automated or manual depending on setup |

| Durability | High durability under stress and frequent use | May chip, scratch, or peel | High consistency and durability | High durability with added structural support |

| Cost Consideration | Higher upfront tooling, lower long-term part cost | Low cost for basic cosmetic finishes | High tooling and equipment investment | Medium tooling cost; cost-effective for mixed materials |

| Application Suitability | Grips, seals, handheld components | Cosmetic enhancements, basic wear protection | Mass-produced consumer goods | Connectors, embedded parts, metal-plastic interfaces |

| Design Flexibility | Moderate; depends on substrate geometry and material flow | Very high; can be applied to varied shapes | Limited; constrained by dual-shot mold setup | Moderate; constrained by insert shape and mold access |

| Bonding Time | Fast; integrated into one molding cycle | Instant or short drying time | Immediate bonding during same molding cycle | Requires placement step before molding |

| Production Speed | Efficient once setup is done | Very fast application | High-speed production for large volumes | Moderate; depends on complexity of inserts and mold design |

By comparing overmolding with other options, you can choose the method that best fits your part’s function, durability, and production goals.

7. Limitations and Challenges with Overmold

Overmolding brings many advantages, but like any manufacturing method, it also presents challenges.

Here are some lists of limitations and challenges with overmold:

Higher Tooling Costs

Overmolding requires molds that support both the substrate (the base part) and the overmold material. These are:

- More complex than standard single-shot molds

- Often built in two stages or with dual-cavity tooling

- More expensive to produce and maintain

If you’re working on a low-volume product, that upfront tooling investment may outweigh the long-term benefits.

Material Compatibility Issues

Not all materials bond well. Just because two polymers mold cleanly doesn’t mean they’ll chemically or mechanically adhere.

You’ll need to consider:

- Thermal expansion differences

- Shrink rate mismatches

- Adhesion properties (especially if using TPE, TPU, or nylon)

Always ask your supplier to run bonding tests early. Visual checks might pass—but functional failure can happen under stress, heat, or time.

Process Complexity

Overmolding isn’t plug-and-play. It demands:

- Tight timing between shots

- Consistent temperature control

- Proper alignment between materials

Without good process control, you may see:

- Warping

- Surface defects

- Incomplete fills or flashing

Expect some back-and-forth during setup. Most projects take a few iterations to dial in pressure, shot size, and cooling time.

Design Limitations

The overmolded material needs to flow cleanly around your base part—and that’s where geometry matters.

Difficult features include:

- Thin walls

- Sharp internal corners

- Deep undercuts

These can block flow or cause uneven bonding.

Sometimes, the solution is simple:

- Add a radius

- Widen a wall

- Simplify an edge

I’ve seen excellent product ideas fail until we softened a few design features. Once flow improved, everything clicked.

Understanding these challenges early—before tooling begins—helps to design smarter, avoid bonding failures, and get better results from overmolding.

8. Tips To Consdider When Choosing Overmold Services

Choosing the right overmold service isn’t always straightforward. You might have a great design, but without the right supplier or setup, things can go wrong fast.

These are the tips I will recommend for you follow with every project:

Tip#1 Verify Material Compatibility

Not every material combination works. Some resins don’t bond, while others fail under stress or heat. Your supplier should help you choose both the substrate and the overmold material based on compatibility, performance, and cost.

If they can’t explain the pros and cons of TPE, TPU, silicone, or your chosen base resin, that’s a concern.

Tip#2 Scalable Production Options

Some manufacturers can prototype but can’t scale. Others do volume well but won’t take on small runs. You want a service partner who can grow with your needs—whether you’re starting with 100 parts or ramping to 100,000.

Ask if they support low-volume trials, bridge tooling, or full-scale production. That flexibility can save time and cost as your project moves from testing to launch.

Tip#3 Check Supplier Experience

Not every molding supplier is good at overmolding. You need someone who understands part geometry, flow, bonding, and tool design.

At MachMaster, overmolding isn’t just a capability, it’s a core strength. Their team brings real-world insight from dozens of successful projects, helping clients catch hidden flaws before production begins.

Conclusion

So now you know what overmold is, how it’s done, and where it changes products.

It’s that clever trick that made me love how a simple tool felt in my hand years ago.

Whether it’s durability, comfort, or function—you’ve got a better option now.

Is overmolding right for your product? You already have the clues.

Still unsure? We’re here to walk you through it.

Contact Machmaster today and let’s make your product stronger, smarter, and built to last!

More Guides and Tips to Explore

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.