You’ve heard the term “metal injection molding,” but the details are fuzzy.

Is it like plastic molding? Is it cost-effective? Can it really handle complex parts?

I had those same questions. Years ago, I was leading a product development project that hit a wall. Our part needed precision, strength, and scalability. None of the traditional methods fit.

That’s when someone mentioned MIM.

At the time, it sounded like a buzzword. But after testing, redesigning, and sitting through supplier walkthroughs, I saw its real potential.

Now, I want to walk you through it—with none of the fluff or confusion.

This article will give you:

- A clear picture of how MIM works

- The pros and limitations

- And how to decide if it’s right for your next move

If you’re designing, sourcing, or simply exploring options—this guide will give you a solid foundation.

Let’s get started!

1. What is Metal Injection Molding?

Have you ever needed a small metal part that was just too complex to machine?

You’re not alone. One of my first clients in electronics needed tiny stainless steel parts with fine detail. CNC couldn’t get it right. Casting was messy. That’s when we turned to metal injection molding, or MIM.

So, what is it?

Metal injection molding is a manufacturing process. It combines two things—plastic injection molding and powder metallurgy. Think of it like making a plastic toy, but instead of plastic, you’re molding metal powder.

It’s used when parts are:

- Very small

- Too detailed for machining

- Needed in high volumes

If your current method is too slow, expensive, or wasteful, MIM might be worth looking into.

I use it when my clients need quality parts—fast.

And if you’re still asking, “Is this right for my project?”—keep reading.

I’ll walk you through it.

2. How Metal Injection Molding Works?

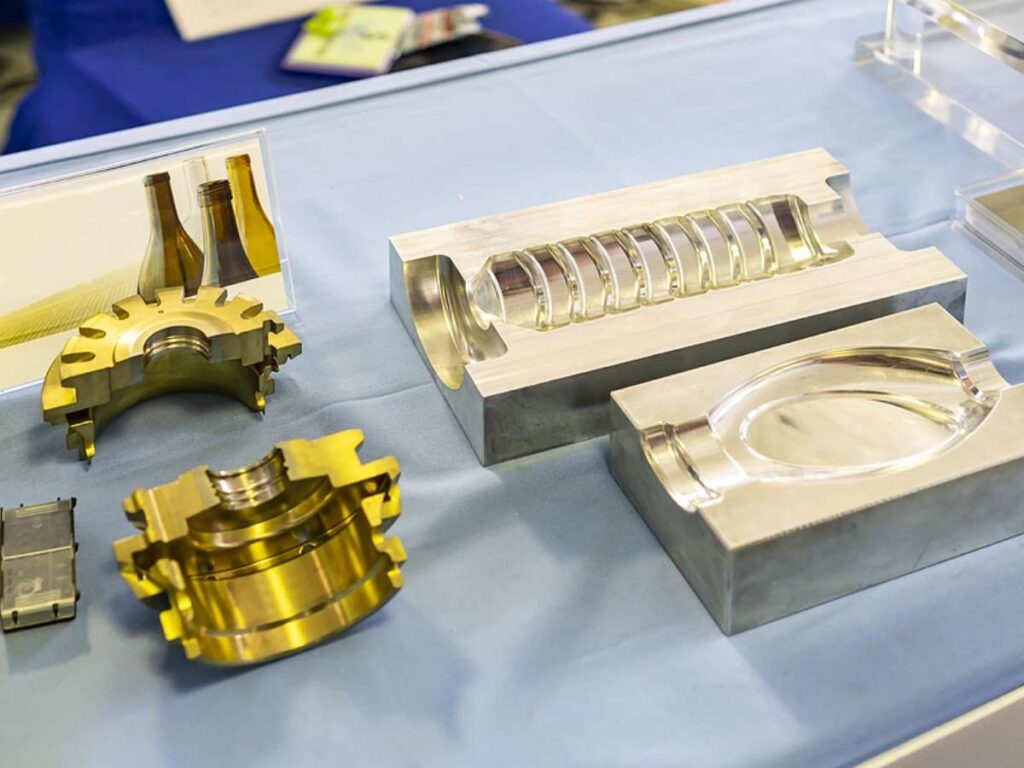

Metal injection molding (MIM) works by combining metal powders with a plastic binder to shape small, complex parts that would be hard or costly to machine.

Everything starts with a mix of fine metal powder and plastic. This mix is soft enough to be injected into a mold, just like plastic parts. Once shaped, the plastic is removed, and the part is heated until the metal particles fuse together into a solid, dense piece.

MIM is known for:

- Handling very complex shapes

- Making tiny, detailed parts with tight tolerances

- Reducing material waste and cost compared to traditional machining

It can be used with many metals, like stainless steel, titanium, and special alloys.

In short, metal injection molding shapes metal like plastic first, then turns it into solid metal—giving you precise, high-quality parts without heavy machining.

3. Advantages of Metal Injection Molding

When a client asks, “Why would I use MIM instead of CNC or casting?”—I get it.

You want something that works, fits your design, and doesn’t break the budget. That’s why I often recommend metal injection molding when the part is small, complex, or needed in large quantities.

Here’s what makes MIM stand out:

Handles Complex Designs

If your part has:

- Thin walls

- Small features

- Internal shapes or curves

MIM handles it—all in one shot.

No multi-axis setups. No tricky add-ons.

We’ve seen projects that saved weeks just by switching to this process.

Lower Cost

Yes, there’s a mold cost upfront. But once that’s covered?

The per-part price drops fast.

If you’re making:

- 500 parts a month

- Or 5,000 parts over the quarter

MIM usually ends up cheaper than other options.

In many cases, we’ve seen a 30–50% cost drop just by switching to volume production.

Strong, Functional Metal Parts

Some folks ask about strength.

MIM parts are sintered, which means they’re dense, solid, and built to perform.

We’ve used MIM for parts in:

- Medical devices

- Defense components

- High-use industrial tools

They hold up under pressure—literally.

Minimal Post-Processing

CNC and casting often need rework.

Polishing. Cleaning. Trimming.

All of that adds time and cost.

MIM parts?

They come out near-net shape—meaning they’re almost final straight from the mold.

Many of our clients move directly to assembly, no touch-ups needed.

And if you’re not sure? Talk to MachMaster, they will help you decide based on what you’re making and what really matters about function, cost, and delivery.

4. Materials Used in Metal Injection Molding

Not sure which metal fits your part?

Here are the materials we most often use for MIM and how they help in real projects:

Stainless Steel

Stainless steel is a corrosion-resistant and durable material. It’s ideal for clean, strong parts that must hold up in tough environments.

Common uses:

- Medical parts like surgical tools or device housings

- Food and beverage components that must stay clean

- Consumer products like watch cases and belt clips

I’ve seen stainless steel work especially well in parts that need both durability and cosmetic finish—like handles, buttons, or structural fasteners.

Tool Steel

Tool steel is a hard metal that stands up to pressure, wear, and repeated use. It’s built for parts that do work—cutting, clamping, shaping, or holding.

Common uses:

- Cutting tools and inserts

- Press-fit parts in machines

- High-strength dies and locking systems

Tool steel delivers long-lasting performance where cheaper metals would wear out. If your application involves repeated stress, this material works well in the long run.

Titanium Alloys

Titanium is a high-strength metal with excellent corrosion resistance and low weight. It’s trusted in industries where every gram and every detail matters.

Common uses:

- Medical implants like brackets or frames

- Aerospace parts where weight savings matter

- Sporting goods with strict strength-to-weight needs

Titanium is tough to machine—but easy to mold with MIM. If you need a light, high-performing part with a clean finish, titanium offers real value.

Low-Alloy Steels

Low-alloy steels mix carbon steel with small amounts of other elements for added strength. They cost less than stainless steel but still hold up well in many applications.

Common uses:

- Automotive parts that need to be strong and affordable

- Structural components inside industrial equipment

- Mechanical locks and medium-load fittings

This is a practical, budget-friendly option. It’s a smart pick for internal or hidden parts that don’t need corrosion resistance.

By matching the right metal to your part’s function, budget, and environment, MIM becomes a reliable way to get high-performance results without overcomplicating production.

5. Applications of Metal Injection Molding

Most of my projects don’t come to us asking for “MIM.” They come with a part that’s too complex to machine or too expensive to cast.

That’s where metal injection molding steps in. Here’s where MIM is already solving problems and where it might work for you too:

Medical Devices

MIM is widely used for surgical instruments, dental braces, implant components, and precision fittings.

- Why it works: Small parts, high strength, and smooth finishes are essential.

- What to consider: Biocompatibility, sterilization, and material certification often apply.

If you’re in the medical field, and your parts need precision, safety, and volume—MIM is worth a closer look.

Consumer Electronics

MIM is often used for phone buttons, laptop hinges, camera brackets, and wearable frames.

- Why it works: It produces sleek metal parts with tight tolerances in small form factors.

- What to consider: Aesthetic appearance, surface finish, and strength-to-size ratio.

If your product combines function and visual appeal in a tight space, MIM can help you deliver both.

Automotive

Common parts include gears, turbocharger vanes, connectors, locking mechanisms, and internal supports.

- Why it works: High-volume production, repeat accuracy, and complex geometry all benefit from MIM.

- What to consider: Strength, wear resistance, and cost efficiency at scale.

If you’re working on a high-quantity automotive part with fine detail, MIM often cuts cost and lead time.

Industrial Equipment

MIM is used for tooling components, clamps, housings, and mechanical linkages.

- Why it works: You can shape wear-resistant metals without full CNC machining.

- What to consider: Load, vibration, and cycle life.

If your operation uses custom tool parts or mechanical pieces that need to last, MIM can simplify your supply chain.

No matter what industry you’re in, if your metal parts are small, detailed, and produced in volume—MIM could be a better fit.

6. Metal Injection Molding vs. Other Metal Manufacturing Methods

Metal injection molding isn’t always your only option. You’ll often compare it with CNC machining, die casting, or metal 3D printing.

Looking at them side by side helps you decide where metal injection molding fits best—and when another method might serve your needs more efficiently. Here are the comparison:

| Feature | Metal Injection Molding | CNC Machining | Die Casting | Metal 3D Printing |

| Best For | Small, complex parts in high volume | Low-volume or simple parts | Medium to large parts with simple geometry | Prototypes or custom designs with internal features |

| Design Complexity | Excellent for internal threads, thin walls, and fine detail | Limited by tool access and setup | Good for simple shapes and generous wall thickness | Excellent for internal channels and freeform geometry |

| Material Waste | Minimal (most of the feedstock becomes part) | High (metal is cut away) | Moderate | Depends on part and support structures |

| Surface Finish | Smooth, often no finishing needed | Excellent with finishing | Moderate, may need post-machining | Often rough, finishing required |

| Tolerances | Tight and repeatable | Extremely tight; good for precision parts | Moderate | Moderate; depends on printer and post-processing |

| Production Speed | Fast after tooling | Fast for simple parts | Very fast once set up | Slow for high volumes |

| Upfront Tooling Cost | High | None | Moderate to high | None |

| Volume Suitability | High-volume runs | Low to medium volume | Medium to high volume | Low volume, prototyping |

| Material Options | Ferrous metals like stainless, tool steel, titanium | Wide range, including exotic alloys | Mostly non-ferrous like aluminum and zinc | Growing selection, still limited |

| Post-Processing Needs | Minimal to moderate | Often required | Often required | Almost always required |

No single method fits all.

Metal injection molding works best when fine detail, strength, and production volume all matter. It’s a powerful tool in the right situation—and comparing it directly helps make a clearer, smarter decision.

7. Challenges and Solutions of Metal Injection Molding

Metal injection molding has a lot to offer, but no process is perfect.

Over the years, I’ve seen many companies face the same roadblocks—some minor, some costly. Here are the most common challenges and how to solve it:

High Upfront Tooling Costs

The mold for MIM isn’t cheap. That’s because it’s custom-built to your part’s design. It’s a fixed cost, and it only makes sense when you’re producing in volume.

What you can do:

- Ask for a volume-based cost breakdown

- Run the numbers on per-part savings over time

- Consider batch orders or part consolidation to boost value

If you’re doing short runs or one-time jobs, MIM may not be the right fit—so speak to your supplier early.

Part Shrinkage During Sintering

All MIM parts shrink during sintering—usually around 15%. That affects final dimensions and tolerances.

What you can do:

- Share critical dimensions with your supplier

- Confirm whether secondary machining is needed for tight fits

- Avoid last-minute design changes once molds are made

Always discuss tolerances upfront so your parts fit the first time, not after rework.

Limited Size Range

MIM works best for small, intricate parts—usually under 100 grams.

Larger parts become less cost-effective and harder to mold accurately.

What you can do:

- Break large parts into smaller, moldable sections

- Ask your supplier if hybrid production (MIM + machining) makes sense

- Review design changes that reduce bulk without affecting performance

If your part is palm-sized or smaller, MIM is likely a good fit—but always double-check with your supplier.

Long Lead Time for First Orders

Building the mold and validating the first batch takes time.

It’s not a quick-turn solution like 3D printing or soft tooling.

What you can do:

- Plan your timeline with a buffer for tooling

- Use prototypes for design validation before committing to MIM

- Ask for schedule estimates with realistic milestones

If you’re facing tight deadlines, bring that up early so your supplier can help manage the process.

MIM can absolutely work—but it needs the right setup.

8. Tips To Consider When Choosing Metal Injection Molding Services

Choosing the right metal injection molding supplier can make or break your production outcome. A strong partner will help avoid costly mistakes and keep your timeline on track.

Here are several tips to keep in mind before committing to a supplier.

Tip#1 Check Material Compatibility

Not all suppliers work with every type of metal. If your project involves specialty alloys like titanium or cobalt-chrome, verify that the supplier has real experience molding with those materials.

Ask them to provide samples or references for similar jobs. The right partner should already know how different metals behave during debinding and sintering. This helps avoid unnecessary trial and error down the line.

Tip#2 Look for Relevant Certifications

Start with ISO 9001—it’s the baseline for quality control. But also check if they meet specific industry standards like ISO 13485 for medical or AS9100 for aerospace.

Certifications signal that the supplier follows a consistent process and documents everything properly. This is key when you need traceability or are working in regulated sectors.

Tip#3 Request Sample Parts

It’s easy to make promises in a sales email—but physical samples tell the real story. Ask to see molded parts, ideally ones made from similar materials or with comparable features.

Pay attention to surface finish, dimensional consistency, and detail sharpness. At MachMaster, they don’t just talk quality—they show it. Actually, they offer sample parts so you can assess real results before committing.

Tip#4 Ask About Design for Manufacturability (DFM) Support

DFM reviews let you fix issues before they become expensive mistakes. Sharp edges, thin walls, and awkward geometries are common problems.

A supplier that offers real feedback rather than just quoting and tooling is worth keeping.

Conclusion

You’ve now seen what metal injection molding is, how it works, and why it’s worth considering.

From process breakdowns to design tips and real challenges, this article gave you the full picture.

It started with a question and maybe a bit of frustration. But it ends with clarity, confidence, and a path to better part production.

Need help evaluating your part or next step?

MachMaster is here to support your decision.

Contact us today and let’s move forward, together!

Explore More of Our Resources

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Injection Molding Fundamentals:

- What Is Injection Molding?

- What Is Jetting in Injection Molding?

- What Is Gate in Injection Molding?

- What Is Undercut in Injection Molding?

- What Is Cavity in Injection Molding?

Materials & Mold Systems:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.