One of the first things I hear from new clients is, “I wish I’d found you sooner.”

One customer even came to me after wasting $15,000 on tooling that couldn’t produce a single usable part — warped pieces, missed deadlines, and zero accountability.

They didn’t realize how complex injection molding really is, until it cost them.

That’s exactly where I help. I guide businesses through the entire process — from part design to material selection to final production — so they avoid surprises and scale with confidence.

In this article, I’ll break down what injection molding is, how it works, when it’s the right choice, and what your business needs to consider before diving in.

Whether you’re new to manufacturing or just looking to improve your process, this guide will answer your key questions.

So, let’s get started!

1. What Is Injection Molding?

Let’s say you need to make a thousand (or a million) identical plastic parts. That’s where injection molding comes in. It’s fast, repeatable, and crazy precise.

Here’s the gist: melted plastic gets injected into a mold. It cools down. It pops out. Done.

This process isn’t just efficient, it’s a workhorse. Whether you’re making car bumpers, medical devices, or the plastic shell on your favorite gadget, chances are injection molding had a role.

Here’s why it matters:

- Consistent Results: Every piece looks just like the last one. No surprises.

- Speed + Scale: Once it’s set up, it churns out parts like a machine (because it is).

- Fits Nearly Any Industry: Auto, healthcare, consumer goods—you name it.

If you’ve ever wondered how plastic parts look so clean and exact?

This is it. And knowing how it works could give your business an edge when you’re ready to scale smart.

2. How the Injection Molding Process Works

If you’ve ever baked cookies, you already understand the basics of injection molding, except instead of dough and cookie cutters, you’re working with molten plastic and precision-engineered molds. The idea is simple, but the execution?

It’s all about fine-tuned control and smart design.

Step#1 Clamping

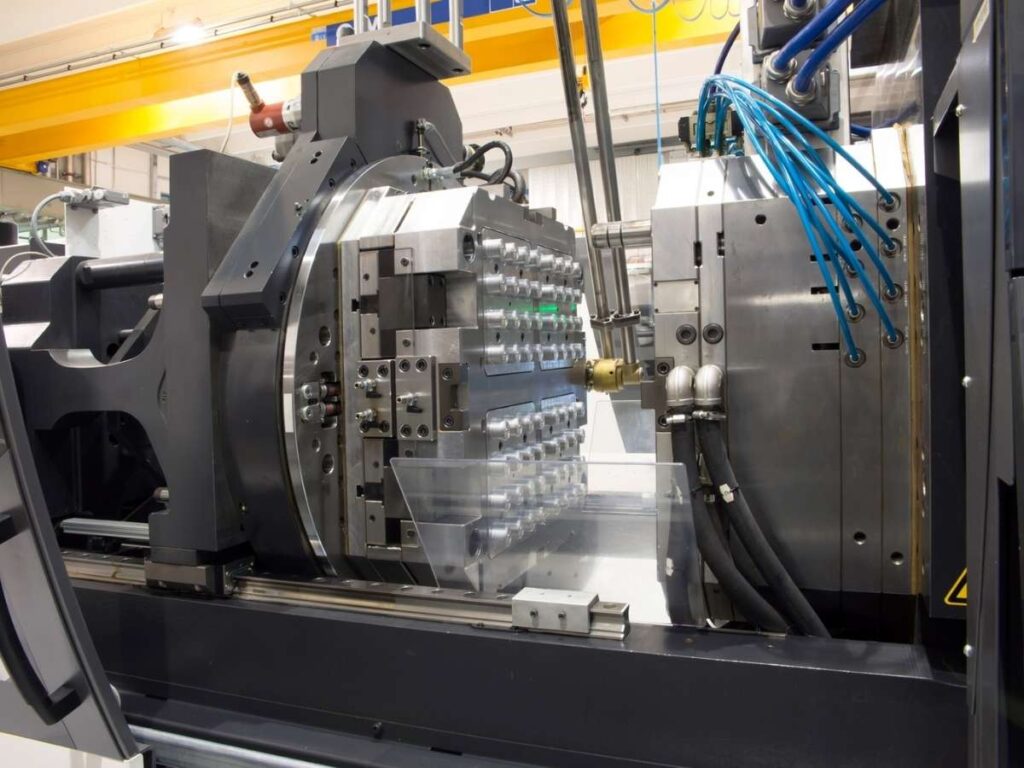

The process begins with clamping the two halves of the mold together. These molds are usually made of hardened steel or aluminum and have been custom-machined to the shape of your part.

A clamping unit locks the mold tightly so that no plastic leaks out during injection. The force needed depends on the size and complexity of your part.

A weak clamp can cause defects like flash or uneven surfaces.

Step#2 Injection

With the mold sealed, plastic pellets are fed into a heated barrel where they melt down into a thick, flowing liquid.

A screw mechanism injects this molten plastic into the mold cavity under high pressure. The timing, pressure, and temperature need to be carefully controlled to avoid issues like short shots (when the mold isn’t fully filled) or air bubbles.

This phase moves fast, but it’s precision-driven every step of the way.

Step#3 Cooling

Once the mold is full, the plastic begins to cool and solidify.

Cooling is engineered into the mold design with internal channels that circulate water or other coolants to pull heat away evenly.

Uneven cooling can cause warping, shrinkage, or stress in the part. Cooling time is often the longest step in the cycle, but rushing it can ruin your results.

Step#4 Ejection

After the part has solidified, the mold opens and the part is pushed out using ejector pins. These pins must be positioned carefully so they don’t damage or deform the part during removal.

In high-volume operations, robotic arms often catch and transfer parts automatically. If your part has thin walls or delicate features, poor ejection planning can lead to costly rework or breakage.

Step#5 Trimming and Post-Processing

In some cases, excess plastic—called flash or sprue—needs to be trimmed off.

This can be done manually or by machine. Depending on the finish quality you’re aiming for, parts might also be polished, painted, or go through secondary processes like drilling or ultrasonic welding.

A well-designed mold reduces or eliminates most of this, saving you time and money.

3. Benefits of Injection Molding

When businesses think about scaling product manufacturing, injection molding is often the first method that comes to mind, and for good reason.

If you’re aiming for repeatable success at high volumes, here’s what makes injection molding such a smart choice.

Consistent Quality and Repeatability

Once your mold is dialed in, every part produced will come out nearly identical. That kind of reliability is essential when working with tight tolerances or safety-critical components.

At MachMaster, this consistency is built into every production run—whether it’s 5,000 or 500,000 parts, quality doesn’t fluctuate.

This reduces inspection time and waste, which adds up to serious cost savings over time. Your customers get a dependable product, and that helps build trust in your brand.

High Production Speed

Injection molding cycles can run as short as a few seconds. This rapid pace makes it ideal for businesses that need to deliver high volumes quickly.

With the right automation setup, you can run machines around the clock with minimal human input. That kind of output allows you to hit tight deadlines or respond to market surges with ease.

The faster your turnaround, the more competitive you become.

Material and Design Versatility

Injection molding supports a wide range of plastic resins, each with its own characteristics.

You can choose materials that are heat-resistant, flexible, transparent, or even electrically conductive. It also supports intricate part designs, including complex geometries, undercuts, and thin walls.

This flexibility gives you more room to innovate while still keeping production feasible.

Reduced Waste and Environmental Benefits

Compared to machining or casting, injection molding generates significantly less waste. Any excess material from runners or sprues can often be reground and reused, depending on the material.

This not only saves money but also supports sustainability goals. In a world where environmental responsibility matters more to customers and regulators, this efficiency can give your business a reputational edge.

4. Types of Injection Molding

Injection molding isn’t a one-size-fits-all process. Depending on what your part needs, whether it’s strength, softness, or two materials in one, you’ll need the right molding technique.

Understanding your options here can save you time and money, especially when prototyping or scaling production.

Thermoplastic Injection Molding

This is the standard process most people think of when they hear “injection molding.” It uses thermoplastic resins like ABS, polypropylene, or polycarbonate.

These materials can be melted and re-melted without major degradation, which makes them highly recyclable. Thermoplastic molding is ideal for parts that need durability, finish, and speed.

Overmolding

Overmolding combines two or more materials into a single part. For example, you might mold a soft rubber grip over a hard plastic handle.

This is perfect for products that require both strength and comfort, like power tools or toothbrushes.

At MachMaster, overmolding is often used to streamline multi-material designs while improving grip, durability, and visual appeal. It eliminates the need for adhesives or screws and simplifies assembly. Functionally, it boosts both aesthetics and user experience in one go.

Insert Molding

This method involves placing a metal or non-plastic component into the mold before the plastic is injected around it.

Think of items like electrical connectors or threaded inserts. Insert molding strengthens the bond between materials while reducing the number of post-molding steps. It’s especially valuable for products that combine electronics with durable outer shells.

You save time, reduce assembly, and improve structural reliability.

Liquid Silicone Rubber (LSR) Molding

LSR molding is your go-to when flexibility, heat resistance, or biocompatibility is needed. It’s widely used in healthcare, baby products, and kitchen tools. Unlike thermoplastics, LSR cures through a chemical process while in the mold, not by cooling.

That allows it to withstand more extreme conditions without breaking down. It’s not cheap, but for critical or flexible parts, it’s hard to beat.

5. Materials Used in Injection Molding

The material you choose doesn’t just shape your product, it defines its strength, flexibility, durability, and even how your customers experience it. Different applications require different plastics, and understanding the pros and cons of each can help you avoid costly missteps in production.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a versatile thermoplastic known for its toughness, impact resistance, and decent heat tolerance. Its smooth surface finish makes it easy to paint or glue, offering more flexibility in post-processing.

- Polypropylene (PP): Polypropylene is one of the lightest and most chemically resistant plastics used in molding. It’s ideal for products like hinges, containers, and laboratory equipment. What makes PP stand out is its fatigue resistance. You can bend it repeatedly without it breaking.

- Polycarbonate (PC): Polycarbonate is extremely strong, transparent, and heat-resistant, making it a common choice for safety equipment, light lenses, and electronic components. It’s a more expensive material, but it offers top-tier performance in impact-sensitive environments.

- Nylon (Polyamide): Nylon is known for its excellent wear resistance, high strength, and ability to handle friction-heavy environments. It’s often used in mechanical parts like gears, bushings, and bearings.

- Thermoplastic Elastomers (TPE & TPU): These materials feel like rubber but process like plastic. They’re flexible, stretchable, and return to shape without tearing. You’ll find them in grips, seals, and wearable tech.

- Polyethylene (PE): Polyethylene is one of the most widely used plastics worldwide, largely due to its affordability and chemical resistance. It’s found in everything from packaging and containers to industrial tanks and tubing.

- PBT (Polybutylene Terephthalate): PBT is a type of polyester with excellent electrical insulation properties and high dimensional stability. It’s commonly used in automotive electrical systems, household appliances, and connectors.

6. Common Applications of Injection Molding

Once you start looking, you’ll notice that injection-molded parts are everywhere, from industrial control panels to disposable syringes. If your business deals with physical products, there’s a strong chance injection molding is already part of your supply chain, or should be.

Automotive Components

Injection molding plays a central role in automotive manufacturing, especially when it comes to interior and under-the-hood parts. Things like dashboards, air vents, cup holders, and sensor housings are all commonly molded.

These parts need to meet strict safety and performance standards while also being lightweight. By using engineered plastics, manufacturers can reduce vehicle weight and improve fuel efficiency. The method also supports high volumes with tight tolerances, which is a must in this industry.

Medical Devices and Equipment

The medical field requires components that are sterile, consistent, and often disposable—making injection molding a perfect fit. Products like syringe barrels, IV connectors, inhalers, and surgical tools are molded by the millions.

For higher-end devices, materials like LSR (Liquid Silicone Rubber) are used due to their biocompatibility and flexibility. Manufacturers favor molding in this space because of its repeatability and the ability to scale up without compromising quality. Regulatory compliance, especially with ISO 13485 standards, is also supported through validated mold processes.

Consumer Electronics

From smartphone casings to power tool housings, injection molding shapes the protective shells and ergonomic interfaces that consumers handle every day. These parts often need to be impact-resistant, lightweight, and visually polished.

The ability to integrate textures, branding, or multiple materials via overmolding makes injection molding especially attractive here. It’s also fast—critical for meeting tight product launch timelines in competitive markets. Whether you’re prototyping a gadget or running full-scale production, this method delivers.

8. Limitations and Challenges in the Injection Molding Process

Injection molding is powerful, but it’s not perfect. If your business is planning a high-volume product or entering new markets, understanding these challenges upfront can save you from expensive surprises down the line.

High Tooling and Setup Costs

One of the biggest hurdles in injection molding is upfront investment. Mold tooling can cost anywhere from a few thousand to hundreds of thousands of dollars depending on part complexity, material, and cavity count.

If you’re only planning to produce a few hundred units, the per-part cost can be prohibitively high. This makes the process best suited for high-volume production runs where the tooling cost can be amortized over thousands, or millions of parts.

Businesses need to be sure of their design and demand forecasts before committing to tooling.

Long Lead Times for Tooling

Designing and manufacturing the mold is not an overnight process. It typically takes several weeks to months, especially if revisions or prototype tooling are required. For companies in fast-moving industries, these lead times can delay product launches. There are options like soft tooling or aluminum molds to speed up the timeline, but they come with shorter life spans.

Design Constraints

While injection molding supports complex parts, there are still design rules that must be followed. Thin walls, deep undercuts, sharp corners, and inconsistent wall thicknesses can all lead to defects or tool wear. These limitations mean that engineers must think in terms of moldability from the start—often requiring a DFM (Design for Manufacturability) review.

Ignoring these constraints can result in expensive redesigns or tooling modifications.

Material Restrictions

Not every plastic resin is suitable for injection molding. Some materials degrade when heated or don’t flow well enough to fill a mold properly. Others, like high-performance polymers, require special machines and higher processing temperatures, which increases cost.

If your application demands unique chemical or mechanical properties, your material options might be limited.

Conclusion

You’ve made it this far. That means something.

You’re not just curious, you’re serious. Serious about building, scaling, improving. And now you’ve got the knowledge to take action.

Injection molding? It’s how smart businesses bring products to life.

Now it’s your turn.

Contact us today at MachMaster. We are here to walk with you, from idea to prototype to full-scale production.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.