I remember sitting in a team meeting when someone asked, “Can we use die casting for this part?”

Everyone nodded like they knew exactly what that meant.

I just sat there, quietly.

Honestly? I had no clue what die casting really was.

If you’ve ever been in that spot—nodding along but unsure—you’re not alone.

Over the years, I’ve worked closely with engineers, factory owners, and sourcing teams. I’ve seen how much smoother things go when people actually understand the basics.

In this article, I’ll walk you through what die casting is, how it works, what parts are involved, and where it’s used.

Whether you’re building a product, buying parts, or just learning—you’ll get what you came for.

By the end, you won’t just guess when someone brings up die casting. You’ll know what to say—and why it matters.

Let’s dive in!

1. What is Die Casting?

If you’re working with high-volume metal parts that need strength, consistency, and speed—die casting is a method worth knowing inside out.

I can tell you that die casting is one of the most reliable ways to produce complex metal components at scale—with minimal post-processing and excellent repeatability.

Key Characteristics of Die Casting

- Speed: Once mold (die) is made, thousands of identical parts can be produced quickly—ideal for high-volume runs.

- Precision: This process supports tight tolerances and detailed geometries, giving accurate results across every piece.

- Surface Finish: Die-cast parts come out smooth enough to skip polishing, saving extra time and cost.

- Strength: The parts are durable and wear-resistant, making them suitable for real-world use straight out of the mold.

Because of these benefits, die casting is widely used in automotive, electronics, power tools, and consumer products—where performance, finish, and speed all matter.

Why It Matters

If you’re choosing a manufacturing method, it’s not just about cost—it’s about how well the part performs long-term. Die casting gives you a reliable way to make strong, precise components at scale.

2. How Does Die Casting Work?

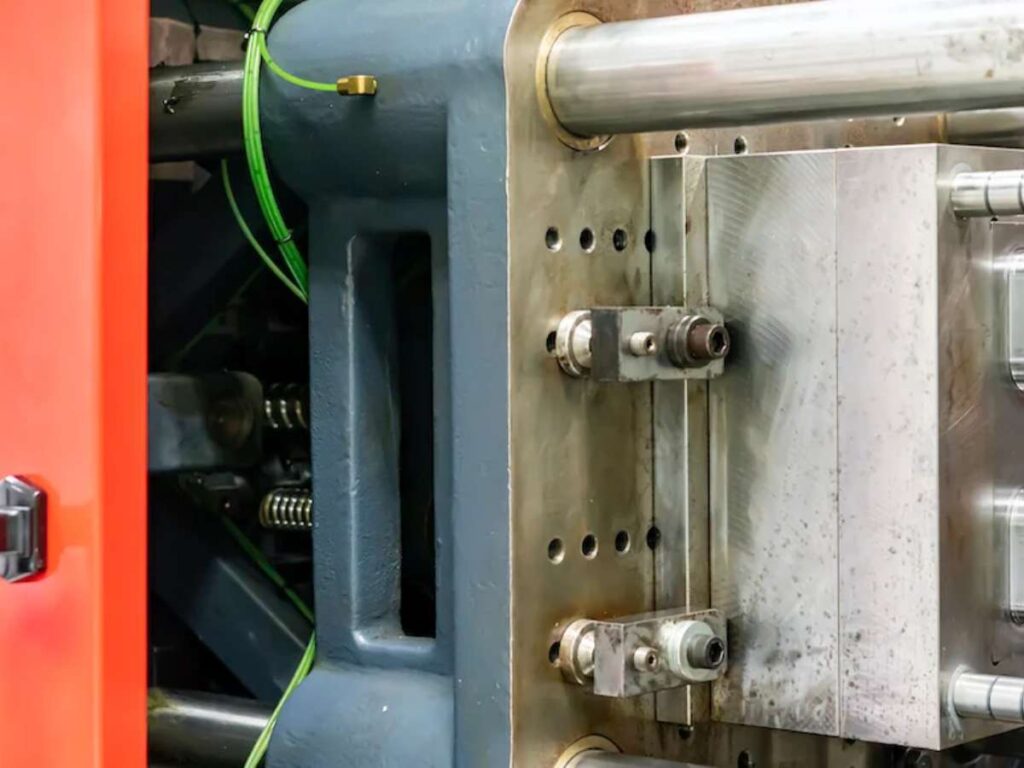

Die casting is a high-pressure method for making precise metal parts—fast, repeatable, and cost-effective at scale.

It starts with a custom steel mold, also called a die. Molten metal—like aluminum or zinc—is injected into that mold under high pressure. The metal quickly fills the shape, cools down, and hardens. Once solid, the mold opens and the part is released.

What you get is a part that’s:

- Dimensionally accurate

- Smooth on the surface

- Ready for finishing or light machining

For your team, here’s what matters:

- Design needs to be final before tooling starts

- Best for high volumes (hundreds to millions of parts)

- Works well for complex shapes with fine details

- Low cost per part after initial tooling

If your project needs metal parts that repeat consistently with minimal post-processing, die casting is worth considering.

It reduces assembly steps, speeds up lead time, and offers long-term savings—especially when part quality and volume matter.

At MachMaster, they can support your production goals with precision die casting, experienced engineering support, and flexible services—from tooling design to final finishing.

3. Advantages of Die Casting

After working on many types of projects, from custom components to ongoing supply runs, die casting has proven itself time and time again.

Here’s some of the advantages of die casting:

Fast Production Speed

Die casting uses a permanent steel mold to create parts in rapid cycles—often just a few seconds each.

That means:

- High daily output

- Shorter lead times

- Less manual labor required

If you are facing tight deadlines, this helps reduce lead times and maintain a steady supply for assembly lines, packaging, or delivery. The speed also helps reduce labor hours per unit, which lowers overall production costs.

High Dimensional Accuracy

Molten metal is injected under high pressure, which allows the material to fill every detail of the mold—no matter how small.

The result:

- Parts that closely match CAD specifications

- Tight tolerances without extra machining

- Better repeatability in every batch

This is especially useful when precision affects part performance or fit with other components.

Good Surface Finish

Die-cast parts typically come out of the mold with a smooth finish and sharp edges.

This makes it easier to:

- Use the part as-is with no additional processing

- Apply paint, powder coating, or plating

- Meet aesthetic or customer-facing requirements

When surface quality matters, die casting offers a clean starting point without extra prep.

Low Material Waste

Die casting forms each part using only the required volume of molten metal. Since it doesn’t involve cutting down solid stock, there’s far less waste.

Additional benefits include:

- Lower raw material usage

- Recyclable excess material (runners, flash)

- Cost savings over time, especially with aluminum and zinc

This efficiency becomes even more important when managing long-term production runs.

When output, accuracy, and efficiency matter most, die casting stands out as a proven method for consistent, large-scale metal production.

4. Types of Die Casting Processes

Die casting isn’t a one-size-fits-all process. The method you choose depends on the metal, part design, and production goals. I’ve learned—sometimes the hard way—that picking the right type from the beginning saves time, cost, and frustration later.

Here’s a breakdown of each type and when to use it:

Hot Chamber Die Casting

Ideal for low-melting-point metals like:

- Zinc

- Magnesium

- Some lead alloys

In this method, the injection system is placed directly in the molten metal bath, which allows for faster cycles and less downtime between shots.

You’ll like this method if you’re producing small-to-medium parts in high volumes—it cuts time and keeps your output steady.

Cold Chamber Die Casting

When your part calls for aluminum or other high-temp alloys, cold chamber is the way to go. The metal is melted separately and poured into the machine for injection.

While it’s a bit slower, it handles stronger metals—ideal if your part needs structural strength or durability under stress.

Vacuum Die Casting

This method removes air from the mold cavity before injecting the metal. It’s used when air pockets and porosity can’t be tolerated.

Best for:

- Structural parts in automotive or aerospace

- Components requiring welding or surface coating

- When internal quality and appearance both matter

By reducing trapped gases, the process produces cleaner, denser parts—with improved mechanical performance.

Squeeze Casting

Think of this as a mix of die casting and forging. Molten metal is poured in, then squeezed under pressure to increase density.

If you’re making parts that can’t afford to fail—like heavy-duty tools or impact-loaded housings—this is a solid choice.

Choosing the right die casting method upfront means fewer defects, better part performance, and smoother production from start to finish.

5. Materials Used in Die Casting

I’ve worked on projects where the wrong material choice led to cracks, delays, and frustrated teams. But when do you match the right alloy to the job? The whole process runs smoother, from mold to assembly.

Below are the most common die casting materials, along with how they fit into real-world applications:

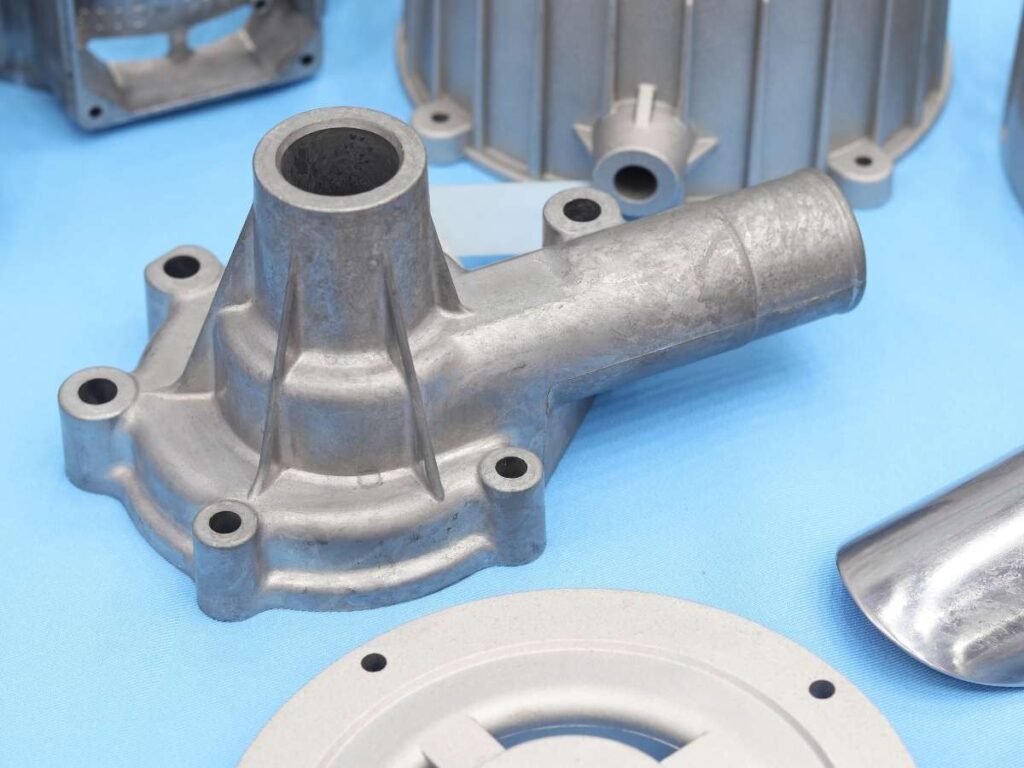

Aluminum Alloys

Aluminum is one of the most widely used metals in die casting for a reason.

Why it’s popular:

- Lightweight and corrosion-resistant

- Strong for its weight

- Performs well under heat

Where it fits:

- Automotive housings

- Power tool bodies

- Electronic enclosures

- Engine parts and heat-prone applications

Since aluminum melts at a higher temperature, it requires cold chamber die casting. But for structural parts that need both strength and lightness, aluminum is a go-to choice.

Zinc Alloys

Zinc is known for fluidity and fine detail capture—it flows into every tiny section of the mold, even at lower pressure.

Why does it work:

- Great for small, detailed parts

- Excellent dimensional accuracy

- Long mold life = lower long-term costs

- Smooth as-cast finish

Common applications:

- Hinges, latches, and locks

- Electrical connectors

- Cosmetic hardware

Hot chamber die casting is typically used for zinc. It’s a good option if your parts need precision and aesthetics without high structural loads.

I’ve used zinc on small mechanical parts where the finish had to be clean and tolerances tight—no sanding or secondary ops needed.

Magnesium Alloys

Magnesium is the lightest structural metal used in die casting.

Why you’d choose it:

- Extremely lightweight

- Easy to machine

- Decent strength for its mass

- Good shock absorption

Great for:

- Handheld consumer products

- Automotive interior components

- Aerospace housings

- Electronics where every gram matters

It costs more than zinc or aluminum, so it’s best used where weight reduction is mission-critical.

I remember working on a handheld enclosure where switching to magnesium dropped the total weight by 25%—a huge improvement for end users.

Copper and Brass Alloys (Less Common)

These alloys aren’t used as often, but they serve a purpose when wear resistance or electrical conductivity is non-negotiable.

What to expect:

- Higher material cost

- Faster mold wear

- Excellent conductivity and strength

Best used in:

- Electrical terminals

- Plumbing hardware

- High-friction components

These materials are specialty choices—but when durability and current flow matter, they’re worth it.

6. Applications of Die Casting in Different Industries

Die casting is used in more industries than most people realize. From car parts to kitchen tools, its strength, speed, and surface finish make it a solid choice for many kinds of products.

Below are some of the industries that use die casting every day.

Automotive

This is by far one of the biggest users of die casting.

Common parts include:

- Transmission housings

- Engine blocks and covers

- Brackets and steering components

- Structural and trim parts

Aluminum is often the material of choice because it offers a high strength-to-weight ratio—essential in modern car design.

Die casting supports:

- Tight tolerances across high-volume runs

- Lightweighting for fuel efficiency

- Reduced machining and faster assembly

I’ve seen customers replace multi-part assemblies with a single die-cast bracket. That change saved both time and tooling costs in final assembly.

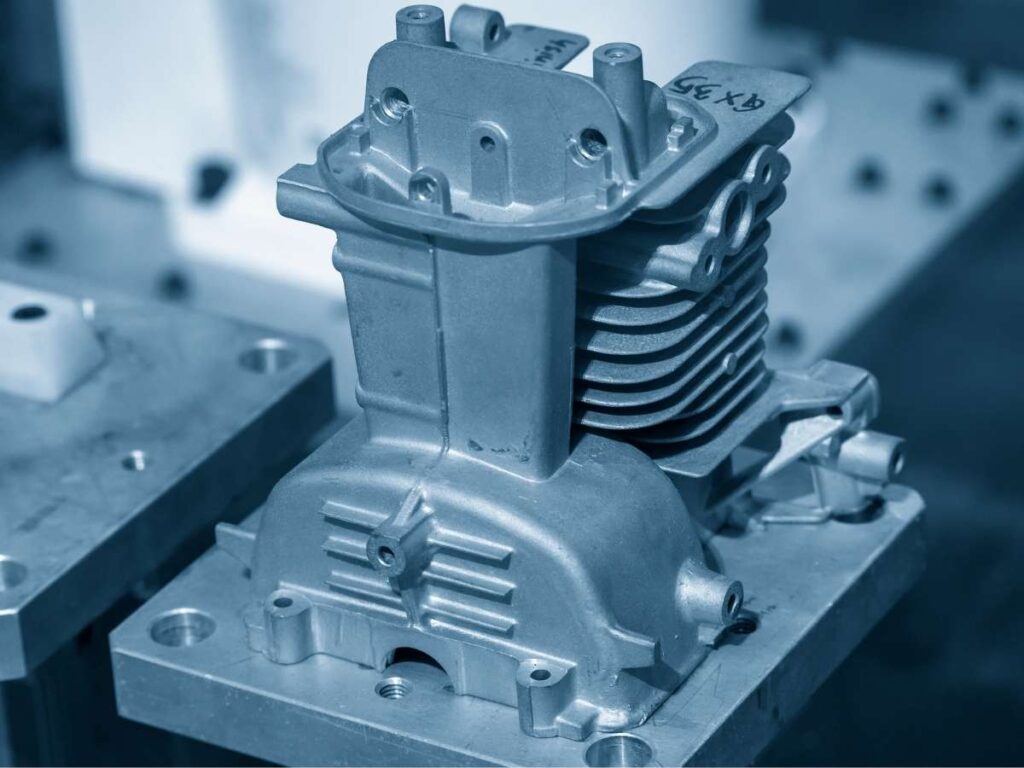

Industrial Equipment

From power tools to machinery frames, die casting supports:

- Housings and motor covers

- Heat sinks and gear cases

- Tool bodies and structural supports

It works well when you want to combine multiple features into one part—cutting down on fasteners, welding, and post-assembly labor.

Best fit for:

- Compressors

- Pumps

- Construction tools

- Factory equipment

We worked on a tool housing that used to be three welded steel pieces. Switching to die-cast aluminum cut production time by almost 40%.

Lighting and Fixtures

Die casting is ideal for products that need clean shapes, long life, and good heat dissipation.

You’ll find it in:

- LED enclosures

- Floodlight frames

- Lamp bases and wall mounts

Aluminum and zinc are popular here. They resist corrosion, handle outdoor environments, and look sharp right out of the mold.

No matter the industry, die casting offers a proven way to produce high-quality parts at scale—combining strength, precision, and efficiency in one process. It’s a smart choice when consistency, speed, and long-term durability all matter.

7. Die Casting vs Other Manufacturing Processes

Every manufacturing method has strengths—and trade-offs. I’ve had projects where the right decision came down to more than just speed or tooling cost.

Here’s a broader comparison to help evaluate die casting against other common methods.

| Category | Die Casting | Sand Casting | CNC Machining | Injection Molding |

| Part Volume | Best for high-volume runs | Suitable for small batches or large parts | Ideal for prototypes or low volume | Great for plastic parts in large quantities |

| Tooling Cost | High upfront mold cost | Low cost, easy to modify | No tooling needed, but higher cost per part | High mold cost, but low part cost later |

| Production Speed | Very fast after tooling is ready | Slower; longer cooling and setup time | Slow, especially for complex parts | Very fast once running |

| Material Waste | Low waste; metal can often be recycled | Moderate waste; sand not reusable for all molds | High waste from material removal | Low waste for plastics |

| Surface Finish | Smooth surface, minimal finishing needed | Rough finish, needs post-processing | Excellent finish, especially with polishing | Smooth finish, great for visible parts |

| Tolerances / Precision | Good tolerances, suitable for most commercial applications | Low precision | Very high precision possible | Good for plastic parts, less tight than metal |

| Strength & Durability | Strong, especially with aluminum or magnesium alloys | Lower strength; depends on material | High strength, based on metal type used | Not suitable for high-stress applications |

| Design Flexibility | Great for thin walls, complex shapes, and detailed features | Less flexible; large features easier than fine detail | Highly flexible, but limited by machining access | Very flexible for plastic forms |

| Best For | Automotive parts, consumer electronics, tools, hardware | Engine blocks, large housings, low-volume components | Precision parts, prototyping, low-volume or one-off jobs | Plastic housings, covers, toys, packaging |

Comparing die casting with other processes helps you choose the best fit—based on volume, material, part complexity, and total cost.

8. Challenges and Limitations in Die Casting

Die casting is fast, repeatable, and great for making thousands of precise metal parts. But like any manufacturing process, it has limits.

Here are the most common challenges I’ve come across, along with why they matter during real production:

High Initial Tooling Cost

Die casting requires a custom steel mold (called a die) for each part design. This die is machined with precision—and that makes it expensive.

If you’re planning a large run, the upfront cost spreads out over time. But for small batches, prototypes, or short product lifecycles, the tooling expense may not make sense.

I’ve had clients back out of die casting once they saw tooling quotes, especially when the order volume was under 500 units.

Limited to Non-Ferrous Metals

Die casting works with metals like aluminum, zinc, and magnesium—those with lower melting points. It doesn’t handle ferrous metals like stainless steel.

If your project demands high-temperature resistance or strong structural performance and requires steel, die casting won’t be the right fit. You might want to look at CNC machining, forging, or investment casting instead.

Porosity and Air Traps

Die casting shines with small to medium parts. But when you go too large or too thick:

- Tooling cost spikes

- Cycle times increase

- Cooling becomes inefficient

- Structural uniformity becomes harder to control

If your part is bulky or oversized, it might be better to:

- Break the design into smaller components

- Switch to sand casting or fabricated assemblies

- Reassess wall thicknesses for casting compatibility

Not every part is affected—but if you’re making something sealing fluids, gases, or handling pressure, porosity becomes a serious concern.

Part Size and Thickness Limits

Die casting machines are best suited for small to medium-sized parts. Very large components or thick walls aren’t practical because they need larger dies, more pressure, and longer cooling times—which slows everything down and drives up tooling costs.

If your part is bulky or oversized, sand casting or fabricated assemblies might work better. In one project, we had to divide a large base into smaller die-cast parts and weld them later. It worked, but required extra planning.

Die casting delivers speed and precision—but only when the project fits its strengths. Knowing its limitations upfront helps you avoid costly missteps, choose smarter alternatives when needed, and plan production with fewer surprises.

9. Factors to Consider When Considering Die Casting Services

Choosing a die casting service isn’t just about comparing quotes—it’s about finding a partner who can deliver what your project truly needs.

Before you commit, here are the most important factors to consider:

Production Volume and Scale

Die casting is designed for medium to high production runs.

Ask yourself:

- Can this supplier handle your current order size?

- Are they equipped to scale up for future batches?

- Do they offer both prototyping and long-term production?

Some shops focus only on low-volume or one-off jobs. That’s fine for development—but if you’re planning to grow, make sure they’re ready for it.

Tooling and Mold Capabilities

The die is the core of any casting project. If the tooling isn’t done right, the rest falls apart.

What to ask:

- Who builds the tooling—do they offer in-house mold making?

- Can they support your required tolerances and part complexity?

- What’s the estimated tooling lifespan, and how is maintenance handled?

Reliable tooling = consistent parts + fewer casting defects over time.

Material Expertise

Not every supplier is experienced with all materials. If your part requires aluminum, zinc, or magnesium, confirm they specialize in that alloy. Different metals need different machines and casting techniques. I’ve seen failed batches because a shop tried working with a material they weren’t familiar with.

At MachMaster, they focus specifically on non-ferrous alloys like aluminum and zinc. So their team understands how each alloy behaves in the mold and what’s needed to get consistent, defect-free results.

Conclusion

Now you now know what die casting is, how it works, and where it fits.

If you’ve got a part that needs to be precise, repeatable, and built to scale, die casting could be your answer.

Still not sure where to start?

Talk to MachMaster. We support businesses with die casting, CNC machining, and the kind of real-world help that gets things moving.

Contact us today and let’s make your idea real!

Check Out These Additional Resources

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Casting Fundamentals:

Die Casting Knowledge:

- Die Casting Process: Step by Step Guide

- How Does Die Casting Work

- What Are Standard Die Casting Tolerances?

Die Casting Insights:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.