I used to always pick aluminum or steel for most parts.

They felt like the “safe” choice. Strong. Common. Easy.

Zinc? I didn’t give it much thought.

That changed during a project where we needed small parts that had to be strong—but still cheap to make.

A supplier suggested die cast zinc. At first, I wasn’t sure.

But I started asking questions, testing samples, and learning what made it work.

Since then, I’ve seen zinc used in all kinds of products—handles, housings, gears. And I’ve seen what happens when it’s used the wrong way too.

In this article, I’ll explain what die cast zinc is in simple terms. You’ll learn how it’s made, where it works best, and what to keep in mind.

By the end, you’ll have a clear idea of whether it makes sense for your part or project.

So let’s get started!

1. What Is Die Cast Zinc?

I used to think zinc was just a cheap filler metal.

Back then, I didn’t give it much thought. But one project changed that.

We needed small parts that were strong, smooth, and easy to produce. A supplier suggested die cast zinc. I was skeptical at first—but after testing it, I started to see its value.

So, what is die cast zinc?

It’s when melted zinc is injected into a steel mold to make a part. This process is called die casting. Once the metal cools, the mold opens, and out comes a finished part—fast and ready to use.

You’ll find die cast zinc in things like:

- Door handles

- Car interiors

- Phone charger shells

- Electrical boxes

- Zippers and latches

Zinc may not sound exciting, but once I saw how well it worked in real products, I changed my mind.

It’s not the answer for everything. But in the right place, it makes a big difference.

Next, I’ll show you why so many manufacturers choose it—and when you should too.

2. Advantages of Using Zinc for Die Casting

When I first came across zinc parts, I didn’t think much of them.

But after working on a few projects that used zinc, I saw how well it performed—and how much time and cost it saved.

If you’re trying to decide whether zinc is a smart choice, here are the main benefits I’ve seen over and over again.

Excellent Dimensional Accuracy

Zinc fills molds better than many other metals.

That means the final part comes out with very accurate measurements—even on tiny details.

This helps when your parts need to:

- Fit together tightly

- Have sharp corners or clean edges

- Keep the same shape, even in high volumes

I’ve used it in gear parts and tiny brackets where precision really mattered.

Superior Surface Finish

Zinc castings often come out smooth and clean.

No deep scratches. No rough edges.

That means:

- Less polishing

- Less machining

- Faster assembly

Sometimes, the part is ready to use right out of the mold. That’s a huge time saver.

Long Tool Life and Cost Efficiency

Zinc melts at a lower temperature than aluminum.

Lower heat means less wear on the mold, which makes it last longer.

In one project, the zinc mold kept going strong after hundreds of thousands of parts.

This can save you:

- Money on tooling

- Time replacing worn-out molds

- Headaches during production runs

High Strength and Durability

Don’t let the soft raw material fool you.

Once cast, zinc becomes tough.

It works great for:

- Door handles

- Lock parts

- Hinges and hardware

These are parts that take regular hits and still hold up.

Fast Cycle Times

This is a big deal in manufacturing. Zinc cools fast.

That means parts come out of the mold quickly—and you can cast more parts per day.

If you need:

- High volume

- Short lead times

- Consistent results

Zinc can help you meet those goals without slowing down.

Zinc surprised me. It might surprise you too.

If you’re after speed, strength, and clean results, it’s worth a closer look.

3. Key Properties of Die Cast Zinc

Zinc die casting isn’t just about cost savings—it’s also about performance. Over the years, I’ve seen how zinc offers reliable results in both everyday parts and high-volume production.

Here are the key technical properties that make it stand out:

- Density: Around 6.6 g/cm³, giving each part a solid, durable feel without making it too heavy.

- Melting Range: Between 380–390°C, which lowers energy use and reduces stress on casting tools.

- Tensile Strength: Up to 410 MPa (depending on the alloy), making it strong enough for parts that need to hold up under force.

- Impact Resistance: High toughness helps zinc parts absorb shock and resist cracking under pressure or vibration.

- Thermal & Electrical Conductivity: Zinc can carry heat and electricity well, making it suitable for components in power systems or thermal transfer setups.

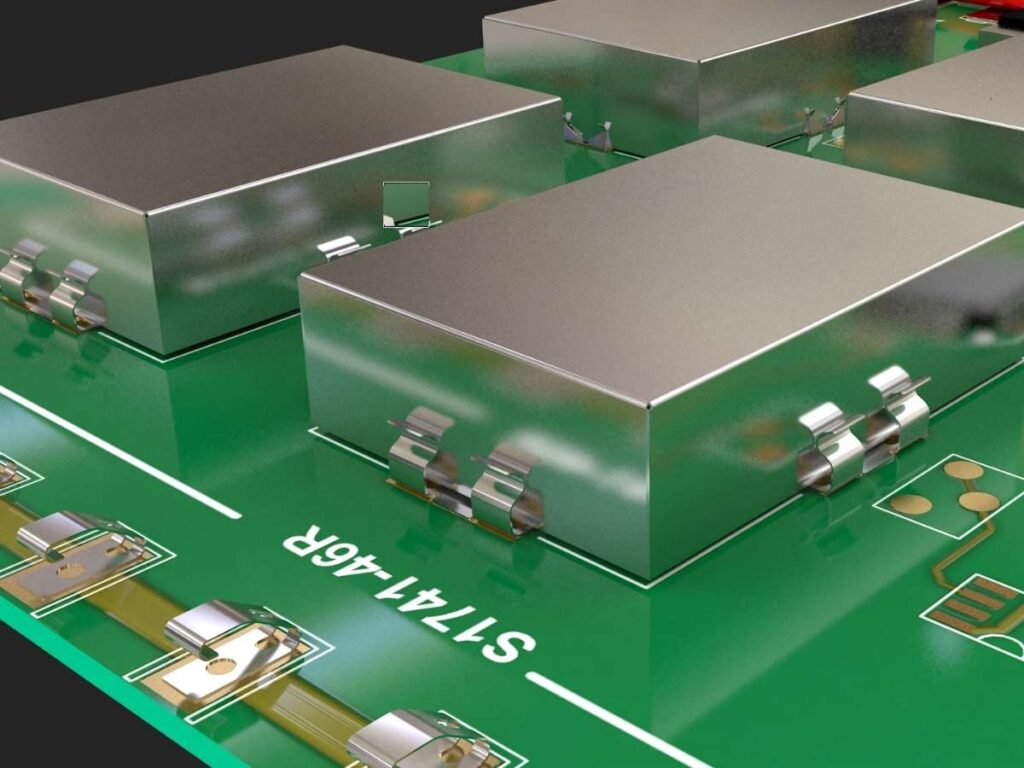

- EMI Shielding: Zinc alloys help block electromagnetic interference, which is critical in housings for electronics and sensitive devices.

- Dimensional Stability: Parts stay consistent over time and under load, which helps maintain fit and function in mechanical assemblies.

These properties explain why zinc remains a dependable choice in many industries.

Whether you’re building a bracket, a housing, or a decorative piece, zinc gives you performance you can count on—without overcomplicating your production.

4. Zinc Alloys Used in Die Casting

When I first started sourcing zinc parts, I thought zinc was just… zinc. But I quickly learned that not all zinc alloys are the same. Choosing the right one depends on your part’s job—how strong it needs to be, how much wear it will take, and how detailed the shape is.

Here’s a breakdown of the most common zinc alloys used in die casting, along with when you might want to use each one

Zamak Series

The Zamak series is the most common group of zinc alloys used in die casting. The name comes from the main elements in the mix: Zinc, Aluminum, Magnesium, and Copper.

At MachMaster, we work with Zamak alloys daily because they offer a balance of strength, precision, and finish that suits many industries. Here’s how each type fits different needs:

- Zamak 3: This is the go-to alloy for most general applications. It offers good strength, surface finish, and dimensional stability. If you’re not sure where to start, Zamak 3 is a safe and common choice.

- Zamak 5: It’s similar to Zamak 3 but has a bit more copper, which gives it higher strength and hardness. It’s better for parts that take on more stress or need a tougher build—like brackets or small mechanical housings.

- Zamak 2: This one has even more copper than Zamak 5. It’s known for excellent wear resistance. I’ve seen it used in gears, cams, and other moving parts that experience friction.

- Zamak 7: This alloy flows better into detailed mold shapes, which helps reduce porosity and improves finish. It’s ideal if your part has thin walls, sharp edges, or a lot of fine detail.

ZA Alloys (Zinc-Aluminum)

The ZA series contains more aluminum than the Zamak group. This boosts strength and makes it a good pick for structural or high-load parts.

- ZA-8: Great for pressure-tight parts. It offers higher strength and toughness than the Zamak alloys and can be cast using conventional hot-chamber equipment.

- ZA-12: Balanced for strength and castability. It works well for medium-duty structural parts like pump housings or industrial components.

- ZA-27: The strongest of the group. If your part needs maximum strength, wear resistance, and stiffness, this is the one to look at—but it can be harder to cast due to higher temperature needs.

5. The Die Casting Process

The first time I watched a die casting machine in action, I was surprised by how fast and smooth the whole process was. In just seconds, raw metal turned into a finished part. If you’re curious about how zinc parts are made, here’s a simple breakdown of the steps involved.

Step# 1: Die Design and Setup

Everything starts with the mold—also called a die. It’s made from hardened steel and shaped exactly like the part you need. If your part has fine details or thin walls, the die needs to be designed to match every curve and edge. This setup takes time up front, but once it’s ready, the rest moves quickly.

Step# 2: Melting the Zinc Alloy

Zinc alloy is melted in a chamber, usually at around 400°C. Since zinc has a relatively low melting point, this step is fast and energy-efficient compared to other metals like aluminum.

Step# 3: High-Pressure Injection

Once the zinc is fully melted, it’s pushed into the steel mold using high pressure. This fills the cavity completely, even in tight corners or thin areas. The pressure is key—it helps make sure the part comes out accurate and smooth.

Step# 4: Cooling and Solidifying

After injection, the metal cools quickly inside the die. This is one reason zinc is great for high-volume production—the cooling time is short, so you get more parts per hour.

Step# 5: Part Ejection

Once the metal solidifies, the die opens, and the part is ejected. At this stage, the part already has its basic shape and size. There’s usually no need for major machining.

Step# 6: Trimming and Surface Treatment

Excess material, called flash, is trimmed off. After that, the part can be coated, painted, or polished—depending on your final use. Zinc’s natural surface finish makes this step easier and cleaner.

Die casting is fast, repeatable, and perfect for making detailed parts at scale. If your product needs clean edges, tight fits, and high output, this process might be exactly what you’re looking for.

6. Common Applications of Die Cast Zinc

One thing I’ve learned from working with product teams and buyers is this: zinc shows up in more places than most people realize. It’s used not just for its strength, but for how well it handles detail, wear, and high-volume production.

If you’re trying to decide whether zinc die casting fits your project, here’s how it’s being used across different industries.

Automotive

Zinc is everywhere in the auto world. You’ll find it in:

- Lock housings that need strength and security

- Door handles that feel solid in your hand

- Mounting brackets that stay in place under vibration

Zinc’s strength, finish, and dimensional stability make it a good match for car interiors and mechanical linkages.

Electronics

If you’ve ever opened up a piece of tech, you’ve probably seen zinc—whether you realized it or not. It’s used in:

- Connectors where small size and durability matter

- EMI shields that block signal interference

- Device housings that protect circuit boards inside

Zinc’s electrical conductivity and shielding ability make it ideal for sensitive components.

Consumer Goods

Zinc is a common choice for household and everyday hardware. Some examples include:

- Cabinet hinges that open and close smoothly

- Knobs and pulls that feel high-quality

- Small hardware parts that need to last over time

It’s a favorite in this space because of its clean finish and reliable strength.

Tools and Equipment

For hand tools and industrial gear, zinc delivers where it counts. You’ll see it in:

- Levers that take repeated force

- Gear housings that protect moving parts

The material holds up well under repeated use without adding too much weight.

Lighting and Furniture Hardware

Designers often choose zinc for its decorative and practical value. It’s used in:

- Lamp bases that need balance and detail

- Drawer handles with clean lines and smooth finishes

- Adjustable joints that stay in place under stress

Zinc gives you both function and form.

Whether you’re building for strength, style, or both—die cast zinc gives you flexibility, durability, and finish across a wide range of industries.

7. Zinc Die Casting vs. Other Metal Casting Methods

If you’re deciding between zinc and other materials, it helps to look at the trade-offs side by side. I’ve had these conversations with buyers and designers many times—and a simple chart like this can save hours of back and forth.

| Feature | Zinc | Aluminum | Magnesium | Plastic (Injection Molded) |

| Surface Finish | Very smooth; often needs little post-processing | Moderate; may need extra finishing | Moderate; may need polishing | Smooth, but depends on mold quality |

| Tolerances | Very tight; great for precision parts | Good, but not as tight as zinc | Fair; more shrinkage than zinc | Fair; tolerances vary by plastic type |

| Strength | High strength and impact resistance | Good for structural parts, especially larger ones | Strong but more brittle than zinc | Low to moderate; weaker under stress |

| Weight | Heavier | Lighter than zinc | Lightest of all metals | Very light |

| Durability | Excellent for wear and daily use | Good under load | Brittle under impact | Wears faster over time |

| Heat Resistance | Performs well under heat | Good for moderate heat | Moderate; lower heat resistance | Poor; melts or deforms under heat |

| Cost | Moderate | Moderate | High | Low |

| Best For | Small, detailed, durable parts | Large, structural parts with less fine detail | Lightweight parts where cost is less of a concern | Cost-sensitive, low-strength parts |

8. 6 Factors to Consider When Choosing Die Cast Zinc Services

Choosing the right die casting partner isn’t just about who gives you the lowest quote.

I’ve learned this the hard way. I’ve worked with vendors who looked great on paper—but missed deadlines, didn’t catch design issues, or couldn’t meet our surface finish needs.

The best results always came from suppliers who asked good questions, gave useful feedback, and stayed honest.

If you’re sourcing die cast zinc parts, here are the most important things to look for.

Tooling Cost and MOQ

The mold—or tooling—is one of your biggest upfront costs. Some suppliers charge more, but the quality and lifespan of that tooling can make or break a project.

Ask how much it costs, how long it lasts, and how quickly they can make it.

Also check the minimum order quantity (MOQ).

Some shops won’t start unless you commit to a large batch. If you’re in early development or just need samples, low MOQ options help you move forward without overspending.

Alloy Selection Support

Zinc comes in several alloy types, like Zamak 3, Zamak 5, and ZA-8. Each one has different traits:

- Zamak 3: good for general use

- Zamak 5: slightly stronger, better for structural parts

- ZA-8: high hardness and wear resistance

If you’re not sure which one to use, a knowledgeable vendor will walk you through it. I’ve had parts perform much better just by switching alloys based on a supplier’s advice.

DFM (Design for Manufacturability) Help

DFM means the vendor checks your design to make sure it’s easy to cast. This can save you:

- Time in production

- Money on rework

- Headaches from defects later

One time, a supplier pointed out a sharp internal corner in our design that would wear the mold too fast. A small tweak made the mold last twice as long.

Finishing Options

Zinc can look and feel completely different depending on the finish. Ask what finishing services they offer, such as:

- Polishing

- Powder coating

- Chrome or nickel plating

The right finish doesn’t just improve appearance. It can also protect the part from wear, corrosion, or scratches.

Certifications

Certifications tell you how seriously a supplier takes quality. Some buyers overlook this, but I’ve found certified vendors to be more organized and reliable.

At MachMaster, we’re ISO 9001 certified. That means we follow strict quality processes.

We also meet RoHS standards, which help keep materials safe and eco-friendly—especially important if you’re building electronics or exporting to Europe.

Lead Times and Delivery Terms

Always ask two things: how long will it take, and what happens if they’re late? A two-week delay may not sound like much—until your whole product line is waiting on it.

A good vendor will give you realistic delivery timelines and update you if anything changes.

Sustainability or Recycling Policies

Zinc is recyclable, which is a plus. Some suppliers collect leftover zinc and reuse it, helping cut waste and lower costs. Others have processes to reduce scrap, energy use, or emissions.

If you care about sustainability—or work with clients who do—ask about their recycling policies.

In the end, the right die cast zinc partner isn’t just a factory. It’s someone who helps you build smarter, avoid problems, and meet your goals. Ask the right questions early, and you’ll thank yourself later.

Conclusion

We’ve covered what die cast zinc is, why it’s used, how it’s made, and when it makes sense.

You’ve got the facts, examples, and tools to move forward.

So what’s next? It’s time to take that idea or design and turn it into something real.

Are you ready to build something that lasts?

Contact us today—let’s make sure your next project starts strong and ends better.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.