I remember one of my first big projects. A client needed 200 precision parts. Fast.

I found a supplier. They promised tight tolerances, quick turnaround, low cost. It looked perfect.

But when the parts arrived? Holes were off. Edges were rough. None of them fit.

That’s when I realized I didn’t really understand CNC machining. And without that knowledge, I couldn’t ask the right questions or catch red flags early.

If you’re here, maybe you’re in the same boat. Maybe you’re sourcing parts. Or just trying to figure out if CNC machining is right for your design, your budget, or your product.

In this article, I’ll explain what CNC machining is in plain language. I’ll share what it does well, what to watch for, and whether it’s the right process for your needs.

By the end, you’ll know enough to make smart decisions without wasting time, money, or material.

So let’s get started!

1. What Is CNC Machining?

When I first heard the term “CNC machining,” I had no idea what it meant. I thought it was just another fancy factory term. But after working with suppliers and watching parts get made, it clicked. CNC isn’t just a buzzword it’s how a lot of the things around you are made.

CNC stands for Computer Numerical Control.

Sounds complicated, right? But it’s actually simple.

Instead of using hands to guide tools, CNC uses a computer program to:

- Tell the machine exactly what to do

- Control the movement of cutting tools using code

- Shape materials like metal, plastic, wood, or foam with precision

No cranking handles. No eyeballing measurements.

Just software and motors do the work.

CNC machining changed how products get made.

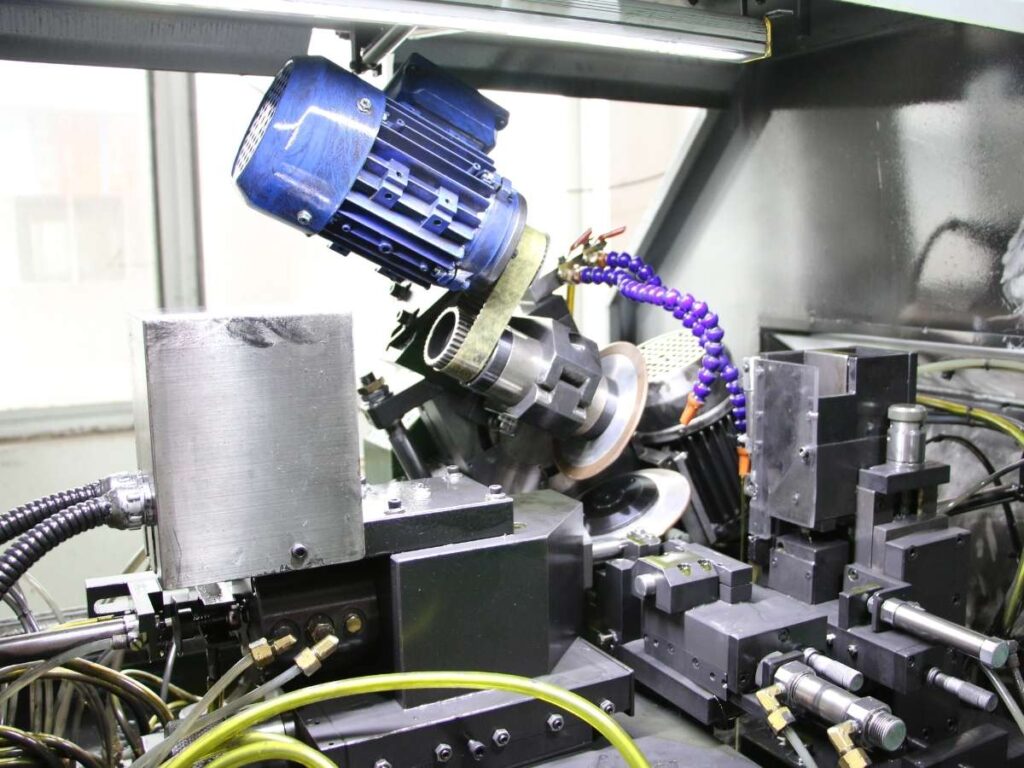

At MachMaster, we offer CNC solutions for everything from simple brackets to complex components. We’ve seen how powerful this process can be when it’s done right.

And once you understand how it works, it’s easier to see how CNC machining can fit your goals too.

2. Benefits of CNC Machining

When I first started working with CNC parts, I was blown away by how clean and exact they were. No rough edges. No odd shapes. Just perfect part after part.

That’s when I really saw the value of CNC machining.

Precision and Repeatability

If your parts need to be exact every time, CNC is the way to go.

- Machines follow computer instructions with incredible accuracy

- Tolerances can be as tight as ±0.01mm

- No guesswork or hand-measuring

That kind of precision is a must in industries like medical, aerospace, and electronics. I’ve seen tiny parts that look identical under a magnifying glass.

Once the program is loaded, the machine will make part #100 just like part #1.

Scalability

Whether you need one prototype or 10,000 production parts, CNC can handle it.

- Start with a small run to test your design

- Use the same setup to scale to full production

- No need to retool or rebuild the process

I’ve worked with product designers who started with a single piece and ended up ordering full batches without slowing down or starting over.

Material Versatility

CNC machines work with a wide range of materials.

Here are some common examples:

- Metals: aluminum, stainless steel, titanium

- Plastics: ABS, POM (also called Delrin)

- Others: wood, foam, acrylic

You can switch from metal to plastic by just changing the cutting tool or settings.

Same machine new job.

That kind of flexibility is hard to beat.

Less Human Error

Because the process is automated, there’s less chance of human error.

- No hand measurements

- No manual tool changes

- Fewer defects and rejects

CNC machines also don’t get tired. They can run all night with the same results.

I’ve seen shops with one operator running several machines at once all turning out clean, perfect parts.

Fast Turnaround

Need a quick prototype? CNC is fast.

- You can go from 3D model to finished part in days

- No need for hard tooling or custom molds

- Great for testing ideas before full production

It also helps shorten lead times on production orders.

That’s a big deal if you’re trying to hit a tight deadline.

Whether you’re launching a new product or replacing a broken part, CNC machining saves time, cuts mistakes, and gives you repeatable results right when you need them.

3. Types of CNC Machines

Not all CNC machines are the same. I didn’t realize this at first. I thought “CNC” just meant one type of machine that did everything. But over the years, I learned that each type of CNC machine has its own job and choosing the right one depends on what you need to do.

| Machine Type | What It Does | Best For | Materials | Precision |

| CNC Milling | Rotating tool removes material | 3D shapes, pockets, flat surfaces | Metals, plastics | ±0.01 mm |

| CNC Lathe | Spins the part, tool cuts along the edge | Round or tube-like parts | Metals, plastics | ±0.01 mm |

| CNC Router | Similar to milling, but for softer material | Woodwork, signs, mold models | Wood, foam, soft metals | ±0.1 mm |

| Laser Cutter | Uses a focused laser beam | Engraving, cutting thin sheets | Plastic, wood, metal sheets | ±0.05 mm |

| Plasma Cutter | Uses hot plasma stream | Fast cutting of metal sheets | Steel, aluminum, copper | ±0.5 mm |

| Waterjet Cutter | Uses high-pressure water (sometimes with grit) | Multi-material cutting with no heat | Metal, glass, stone, rubber | ±0.1 mm |

4. Key Components of a CNC System

When I first saw a CNC machine, it looked like one big block of metal and wires. But once I started asking questions and watching it work, I realized something: every CNC machine is made up of smaller parts that work together just like a team.

Controller

The controller is like the brain.

- It reads G-code, which is the machine’s instruction file

- It sends signals to motors, tools, and sensors

- It makes sure everything moves where it should—and how fast

Think of it like a traffic cop, directing all the action in real-time.

Spindle or Tool Head

This is the part that does the actual cutting.

- It spins, drills, mills, or engraves depending on the tool

- Some spindles run fast but light

- Others are slower but stronger (for cutting tough materials)

The tool you pick and how fast it spins depends on what material you’re working with.

Machine Bed and Workholding

This is the base of the machine.

- A strong, rigid bed helps the machine cut more precisely

- If it shakes or shifts, your parts will be off

You’ll also need workholding tools like:

- Vises

- Clamps

- Vacuum tables (for lighter materials)

These keep your part locked in place while the machine does its job.

Even the best machine can’t cut well if the part is moving around.

Drive System (Motors and Guides)

This is what moves the machine.

- Stepper motors move in steps

- Servo motors are faster and have better feedback

- Linear rails or ball screws guide each axis smoothly

The drive system controls where the tool goes and how accurately it gets there.

Software

You’ll need two types of software:

- CAD (Computer-Aided Design): You use this to design your part

- CAM (Computer-Aided Manufacturing): This turns your design into G-code

You don’t have to be an expert to get started.

Many programs are user-friendly and some are even free.

When you understand each part of a CNC system, it’s easier to troubleshoot problems, talk to your supplier, or choose the right setup for your job.

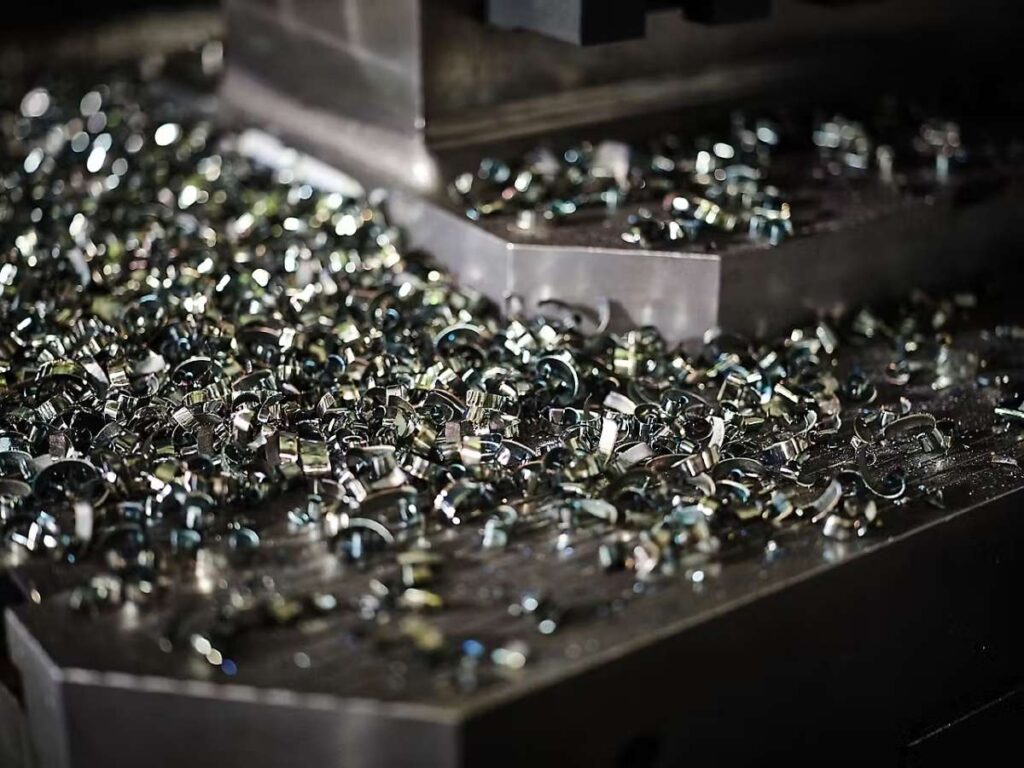

5. CNC Machining Processes

CNC machining includes several processes. Each one does something different. Some are better for shaping curves. Others are better for drilling holes or cutting fine details.

Milling

- A rotating cutting tool moves across a block of material

- The material stays in place while the tool removes what’s not needed

- Great for parts with 3D shapes, pockets, and channels

Milling is commonly used to make brackets, housings, and other parts with flat faces and slots.

Turning

- The material spins while the cutting tool shapes it from the outside

- The tool cuts along the part’s diameter

- Best for making round or cylindrical parts like shafts, rings, and pins

This process is fast and efficient for parts that need smooth, circular surfaces.

Drilling and Tapping

- Drilling makes clean, round holes

- Tapping adds threads inside those holes so screws or bolts can fit

- Counterboring creates a flat-bottomed hole to seat a screw head

If your part needs fasteners or precise alignment holes, this process is essential.

EDM (Electrical Discharge Machining)

- Uses tiny electrical sparks to cut through metal

- There’s no direct contact, so it works well on hard or delicate materials

- Ideal for cutting sharp corners, thin walls, or detailed features

EDM is often used for mold parts, medical components, and small tooling that needs fine detail.

6. Challenges and Limitations of CNC Machining

CNC machining is powerful. But like any tool, it has limits. Knowing these early helps you plan better and avoid surprises down the road.

Setup and Programming Time

Before cutting begins, there’s prep work.

- A custom program (G-code) has to be created for your part

- The machine setup tools, speeds, fixtures takes time too

For large batches, this setup cost spreads out. But for very small runs, it might feel like a lot up front.

Some online CNC platforms help with this. They use pre-configured machines and fast quoting tools to cut down on wait times.

Geometry Constraints

Not every shape is simple to cut.

- Undercuts (shapes hidden beneath another layer) can’t be reached with basic tools

- Deep cavities may need special tools or multi-axis machines

You can work around these limits:

- Use 5-axis CNC machines for complex shapes

- Break up your design into multiple parts

- Add secondary operations like EDM for fine features

It just depends on how exact your part needs to be.

Material Waste

CNC is a subtractive process.That means it removes material from a solid block.

And yes, that creates waste.

In comparison, additive processes like 3D printing build parts layer by layer with less scrap. Still, CNC often gives you stronger, smoother parts. And some shops recycle leftover metal, so not all material is lost.

Learning Curve

There’s a skill to running a CNC machine well.

- You need someone who understands CAM software

- Operators must know how to read tolerances and run toolpaths

- Mistakes in setup or code can lead to scrap parts

But support is available. Many manufacturers offer help with programming.

Some even let you send in your design files and handle the setup for you.

7. 5 Tips for Choosing the Right CNC Machining Service

Finding a CNC service that fits your needs isn’t always easy. Some shops say they can do it all but when the parts show up, you realize they didn’t have the right tools or experience. I’ve been there. That’s why it helps to ask a few key questions before you commit.

#1 Material and Process Compatibility

First, check if the service works with your material. Not every shop cuts titanium or knows how to machine nylon. Some focus on metals, others on plastics. You’ll also want to know if they offer the process you need like milling, turning, or EDM. If they can’t do the full job in-house, you may face delays or extra cost.

#2 Tolerances and Capabilities

Look for a shop that can consistently hold tight tolerances ±0.01mm is a common benchmark for precision work. If your part has special features or critical dimensions, ask if they’ve handled similar jobs before. At MachMaster, we offer quality reports and sample parts to show what we can deliver upfront. It’s a simple way to build trust and avoid surprises later.

#3 Certifications

If you’re in medical, aerospace, or other regulated industries, certifications matter. A shop with ISO 9001 or ISO 13485 has systems in place to track quality. Even if you don’t need these certifications, it’s a good sign when a supplier has them. It means they care about doing things right.

#4 Batch Flexibility

Think about how many parts you need. Some CNC shops are great at low-volume prototyping. Others handle large production runs. If you’re starting small but plan to scale up, ask if they can grow with you. It’s easier to build a long-term relationship with a shop that can do both.

#5 DFM Support

Some shops offer design feedback before production. This is called Design for Manufacturability, or DFM. It’s a real bonus. A quick review might reveal a small tweak like changing a sharp corner or adjusting a hole size that makes your part easier (and cheaper) to machine. Good suppliers will help you spot these changes early.

Conlcusion

You started this article looking for clarity.

Now, you understand what CNC machining is, how it works, and when to use it.

We covered the key machines, the benefits, the limits, and how to choose the right supplier.

You’ve got everything you need to take the next step with confidence.

I’ve made the mistakes and learned the lessons so you don’t have to.

If you’re ready to turn an idea into a part or need a supplier, you can trust MachMaster is here to help.