I used to think CNC lathes were just about spinning metal and carving shapes.

How hard could it be?

Then I got my first quote for a project and I had no clue what I was looking at. Tooling fees, cycle times, threaded features I hadn’t planned for.

It hit me, I didn’t really understand how CNC lathe machining worked.

Maybe you’re in that spot right now. You’ve got a part in mind, a project, maybe even a supplier waiting for your file. But you’re stuck because you’re not sure what this process actually does or if it’s even the right one.

In this guide, I’ll walk you through the fundamentals. No fluff. Just the basics you need to make smart decisions faster. You’ll learn how it works, what it can do, and whether it fits your project.

Let’s begin!

1. What is CNC Lathe Machining?

When I first heard the term “CNC lathe,” I pictured a giant spinning machine, but I didn’t really know what it did. And I definitely didn’t know if I needed one. If that sounds familiar, don’t worry. You’re not alone.

Let’s break it down.

CNC stands for Computer Numerical Control. That means a computer controls the machine instead of a person turning knobs and handles.

Now let’s talk about the lathe. A lathe is a type of machine tool. It holds a piece of material—like metal or plastic and spins it fast. While the material spins, a cutting tool presses against it to remove parts you don’t need.

Think about sharpening a pencil with a knife. You hold the knife still and turn the pencil. That’s a lot like what a lathe does.

This process is great for making parts that are round and even all the way around. Common examples include:

- Shafts

- Bushings

- Bolts

- Threaded rods

Once you understand the basics, you’ll see there’s more than one way to shape the material. Some cuts happen on the outside. That’s called turning. Others happen on the inside. Those include boring, drilling, and threading.

So why does this matter to you?

If you’re trying to make precise, round parts, a CNC lathe might be exactly what you need.

Have you ever needed a part with clean threads or a smooth cylinder?

Chances are, it was made on a lathe.

2. How CNC Lathes Work

When I first saw a CNC lathe in action, I expected sparks, noise, and chaos.

Instead, I saw a quiet rhythm. Smooth movement. Clean cuts. It looked simple until I realized how much was happening behind the scenes.

If you’ve ever wondered how CNC lathes work, here’s a breakdown you can follow, even if you’ve never touched a machine before.

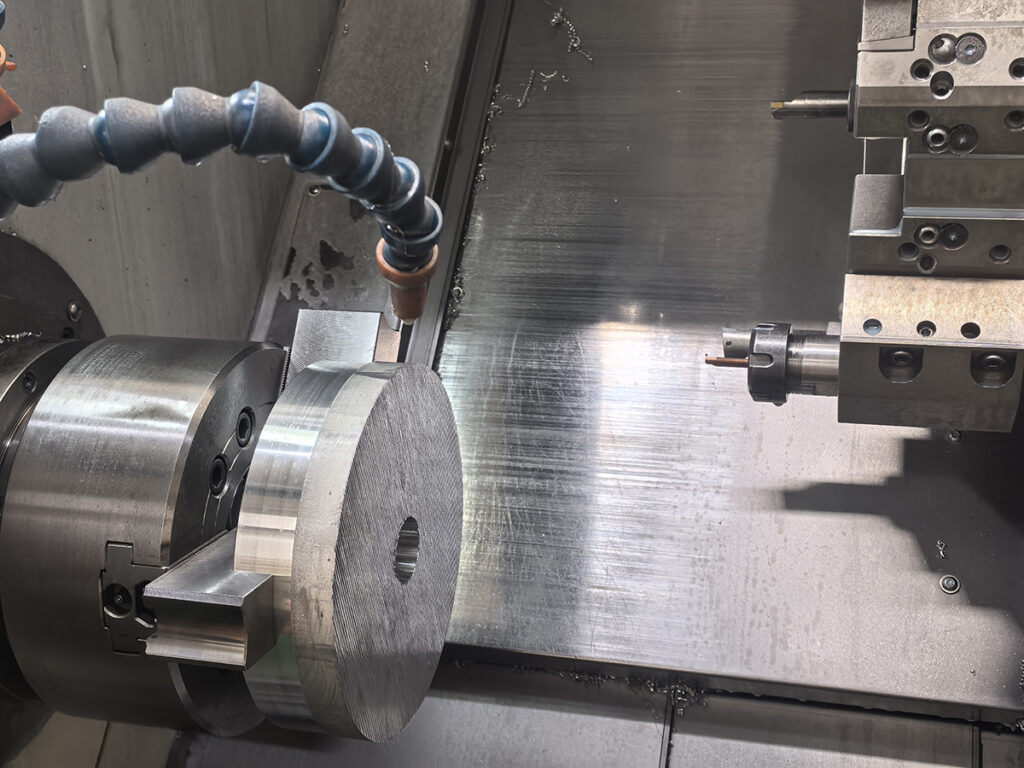

Step 1: Clamping the Raw Material

Everything starts by holding the material in place. This is usually a bar stock (a long rod) or a billet (a block of metal or plastic).

The machine uses a clamp called a chuck to grip it tightly. No slipping allowed. Why does this matter? Because any movement during cutting could ruin the whole part.

Step 2: Spinning the Material

Once clamped, the lathe spins the material fast. Sometimes thousands of times per minute.

Unlike other machines, a lathe spins the part—not the tool.

This setup works best for round or symmetrical parts.

Step 3: Tool Movement on X and Z Axes

While the material spins, the cutting tool moves in two directions:

- X-axis: Moves in and out to cut across the diameter

- Z-axis: Slides left and right to shape the length

This is how the part takes shape.

Step 4: Controlling with G-code

Nothing happens by hand. A computer runs everything using something called G-code.

This code tells the machine:

- Where to move

- How fast to spin

- When to cut

Think of it like a GPS for the cutting tool. No guessing. Just clear directions.

3. How Accurate is CNC Lathe Machining?

CNC lathes are known for their precision. A good machine can hit tolerances as tight as ±0.01mm. That’s about the thickness of a human hair. For many applications like shafts, bushings, or threaded parts—this level of accuracy is more than enough.

But it’s not just about hitting a number once. CNC lathes are also incredibly repeatable. That means the 10th part, the 100th part, and the 1,000th part can all match the first one. This is why lathe machining works so well for mass production or any job that can’t afford variation.

Surface finish also matters. A smooth finish can reduce wear, friction, and the need for extra polishing. Most CNC lathes can achieve a surface roughness of Ra 0.8μm or better, depending on the tool and material used.

Of course, none of this happens automatically.

The final result depends on:

- Machine quality: Newer machines tend to be more stable and precise

- Tooling: Dull or incorrect tools reduce accuracy

- Operator skill: Experienced machinists know how to fine-tune setups

So, how accurate is CNC lathe machining? In the right hands, with the right setup, it’s about as reliable as you can get. And if your part needs to meet tight specs or repeat perfectly, this process is built for that.

4. Types of Lathe Operations

Once you know how a CNC lathe works, the next question is: What exactly can it do? At first, I thought it just shaved things into round shapes. But once I saw it in action, I realized how many different operations it could perform and how each one serves a specific purpose.

Here are the five most common operations you’ll come across.

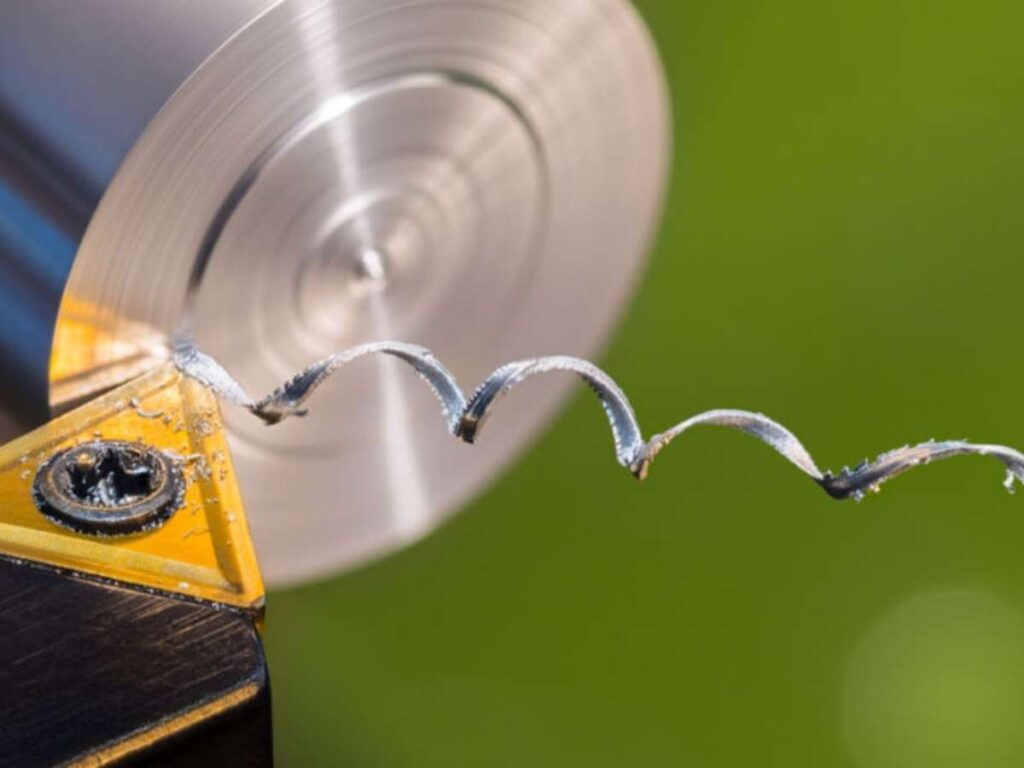

Turning

Turning is one of the core processes in CNC lathe machining. It’s used to reduce the diameter of a part by moving a cutting tool along its length as the material spins. You’ll often use turning to create straight, tapered, or contoured surfaces. It’s the go-to method for shaping cylindrical parts like rods, shafts, and pins.

Facing

While turning shapes the side, facing cleans up the front. In this operation, the tool moves across the face of the material to create a flat end. This is usually one of the first steps when prepping a piece of stock for more detailed work.

Drilling

If you need a centered hole in the part, drilling gets it done. A stationary drill bit is pressed into the spinning material. Because the material rotates and not the tool, the process creates clean, accurate holes. It’s often used before boring.

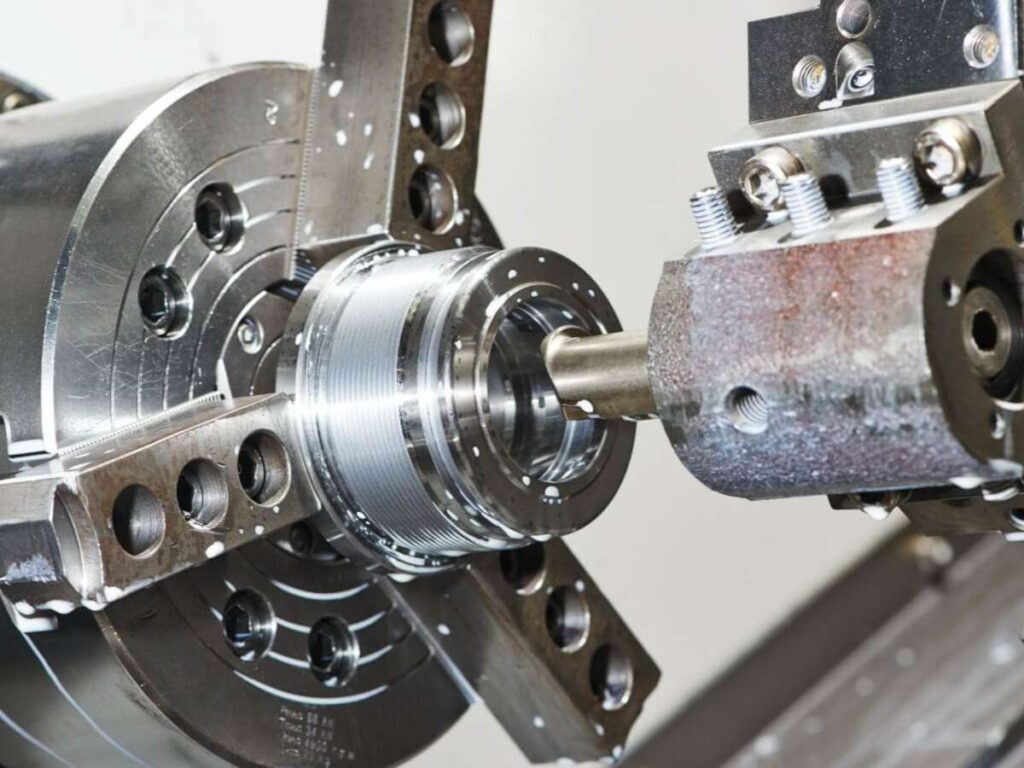

Boring

Let’s say the drilled hole needs to be larger or more precise—that’s where boring comes in. This operation fine-tunes the inner diameter by slowly enlarging the hole from the inside. It’s useful when tolerances are tight and accuracy matters.

Threading

If your part needs screw-like grooves, either on the inside or outside, threading is the solution. This process uses a specific tool and feed rate to cut consistent, usable threads. It requires perfect timing and setup, because even a slight misalignment can ruin the whole part.

5. CNC Lathe Applications by Industry

Once I understood what a CNC lathe could do, I started noticing its work everywhere. From the axle on my car to the knob on my stove, the signs were all around me. If you’re wondering where this type of machining actually gets used, here’s a breakdown by industry.

These examples show the kind of parts that benefit most from precision, repeatability, and symmetry. Most of them are round or cylindrical and they have to fit and function without fail.

Automotive

Cars and trucks rely heavily on CNC lathe work. You’ll find turned parts in:

- Shafts

- Axles

- Pistons

These parts rotate, slide, or move under pressure, so accuracy really matters.

Aerospace

In planes, helicopters, and space systems, the margin for error is even smaller. Lathes are used to make:

- Housings

- Bushings

- Fittings

The parts have to hold up under heat, vibration, and force and they have to be light.

Medical

CNC lathe machining also plays a big role in health care. You’ll see it in:

- Surgical tools

- Bone screws

- Implants

These parts often need tight tolerances and clean finishes that won’t irritate tissue.

Consumer Goods

Even in everyday items, you’ll find lathed parts. Think about:

- Knobs

- Connectors

- Fasteners

They may be small, but they still need to be smooth, strong, and consistent.

Machinery and Equipment

Industrial machines use:

- Spindles

- Rollers

- Pulleys

These parts often repeat the same motion all day long. If they’re not accurate, the whole system can wear out fast.

6. Materials That Can Be Machined with a CNC Lathe

When I started sourcing machined parts, I didn’t think much about materials. I figured metal was metal. But after a few pricing surprises and one tool that wore out way too fast, I realized that the material you choose matters more than you think.

Some materials are easy to machine. Others take more time, more expensive tools, and more care. So, if you’re wondering what works well on a CNC lathe, here’s a simple guide to get you started.

Commonly Used Metals

Lathes are built to handle a wide range of metals, especially when precision and strength are important.

- Aluminum: Lightweight, easy to machine, and great for prototyping. It cuts fast and keeps costs low.

- Brass: Smooth to cut, doesn’t wear down tools quickly, and gives a nice finish. Good for fittings and connectors.

- Steel(mild or stainless): Strong and durable. Mild steel is easier to cut. Stainless takes longer and wears tools faster.

- Titanium: Lightweight and strong, but tough on cutting tools. Best used when strength-to-weight really matters.

Common Plastics

Not all lathe jobs require metal. Many plastics can also be turned, especially when weight or chemical resistance is important.

- Nylon: Tough and flexible, commonly used for bushings and washers.

- Delrin: Machines cleanly and holds tight tolerances. Great for moving parts.

- ABS: Cost-effective and easy to shape. Not as precise, but fine for low-load parts.

- PEEK: Very strong and heat-resistant. Used in medical and aerospace parts, but expensive.

7. CNC Lathe vs CNC Mill

I used to think a CNC machine was a CNC machine. If it cuts, it cuts—right?

But after working on projects that needed different kinds of parts, I learned that the type of machine makes a huge difference. Choosing between a lathe and a mill isn’t just about preference. It’s about getting the part right the first time.

If you’re unsure which one fits your part, here’s a simple comparison to help you decide:

| Feature | CNC Lathe | CNC Mill |

| What Rotates | The material (workpiece) | The cutting tool |

| Material Position | Spins in place | Fixed in place |

| Tool Position | Stays still (moves linearly) | Rotates and moves around |

| Best For | Cylindrical or round parts | Flat, boxy, or prismatic parts |

| Typical Parts | Shafts, bushings, threaded rods | Brackets, enclosures, complex blocks |

But, which should you use?

Ask yourself these questions to make a better decision:

Use a CNC lathe if your part:

- Is round or cylindrical

- Needs threads (internal or external)

- Has features that repeat around a central axis

Use a CNC mill if your part:

- Is flat or angular

- Has slots, pockets, or holes on multiple faces

- Needs complex 3D shapes or steps

8. How to Choose a CNC Lathe Machining Supplier

I’ve worked with both great suppliers and ones I’d never use again. At first, I didn’t know what to ask. I just went with whoever responded fastest or had the lowest price. But I learned that what looks easy up front can lead to missed deadlines, poor part quality, and a lot of back-and-forth.

If you’re sourcing CNC lathe machining services, choosing the right supplier matters. A lot.

Here’s how to make a smart decision—before you place the order.

What to Look For

Not every shop is the same. Some focus on small runs. Others handle only large batches. Some will promise anything just to win the job.

Here are the basics you should expect:

- ISO 9001 certification: Shows they have a quality system in place

- Capacity for prototypes and production: You don’t want to switch suppliers halfway through

- Tolerance capabilities: Make sure they can hit the specs you need

- In-house quality checks: Inspection tools, reports, and documentation matter

- Clear quoting process: You should understand what you’re paying for

- Relevant experience: Have they made parts like yours before?

If you’re looking for a supplier that can handle both prototypes and production with consistent quality, MachMaster is ready to help.

As an ISO 9001-certified manufacturer with precision capabilities down to ±0.01mm, we support businesses across industries with fast, reliable, and scalable CNC lathe services.

Questions to Ask

A good supplier won’t mind questions. In fact, they’ll welcome them. Here are a few to start with:

- What machines do you use for turning?

- Can you meet our lead time and volume requirements?

- What surface finishes can you provide?

- How do you handle quality control?

- Can you share examples of similar projects?

If you’re managing sourcing, this isn’t just about checking boxes. It’s about finding a partner who can grow with you, catch issues early, and help you deliver great parts on time.

Conclusion

You don’t have to feel stuck anymore.

This article gave you a full walkthrough on how CNC lathes work, what they’re good for, and how to choose the right partner.

I’ve been in your shoes trying to make sense of quotes, designs, and decisions. Once I learned how the process worked, I could finally move forward with confidence.

And now you can too.

What’s your next move?

If you’re ready to get started, contact us today. We’re here to help.