At first, I thought casting was easy. Just heat some metal, pour it into a mold, and let it cool. Done, right?

That’s what I believed—until I stepped into a real foundry.

The heat was intense. The air smelled like burnt metal. I watched the liquid metal flow like lava, and I saw how one small mistake could mess up everything.

That day changed how I saw casting. It wasn’t just pouring. It was planning. Timing. Even a bit of art.

I made a few mistakes early on—wrong process, wrong material, wrong supplier. It takes time. And money.

So I started asking questions.

I talked to people who had done it for years—engineers, factory workers, and toolmakers. Slowly, I started to get it.

If you’re trying to understand casting, this article is for you. I’ll explain what it is, how it works, and when it makes sense to use it.

You’ll get the key steps, different types, pros and cons, and how to know if it fits your project. By the end, you’ll see casting clearly—and avoid the mistakes I made.

So let’s begin!

1. What Is Casting?

The first time I saw casting in action, I was surprised by how simple it looked—yet how powerful it was.

No high-tech machines buzzing. No toolpaths or cutting. Just hot liquid metal and mold. That’s it. But that simple setup can create the kinds of parts you see in cars, planes, and medical devices.

Casting is when you take a material—usually metal or plastic—melt it until it becomes liquid, and pour it into a mold.

Once it cools and hardens, you’ve got a part that’s shaped exactly like the mold.

It’s often used when parts are:

- Too large to machine

- Too complex to build any other way

- Needed at high volume

Imagine making 10,000 complex gears. Machining each one would take forever. Casting? Much faster. Much cheaper.

Materials used in casting include:

- Metals like aluminum, steel, or iron

- Plastics for lightweight or non-metal parts

- Even glass or ceramics in special cases

It’s a flexible process—used in everything from car engines to kitchen sinks.

Here’s the basic flow:

- Design a mold: You can use sand, metal, or other materials for mold depending on the project.

- Melt the material: This is usually done in a furnace. It gets hot—sometimes over 1,000°C for metals.

- Pour the liquid into the mold: You have to work quickly and carefully here.

- Let it cool and solidify: This step can take minutes or hours, depending on size and material.

- Remove the solid part: Break the mold or open it to get your new casting.

- (Optional) Finish the part: Some parts get polished, machined, or coated afterward.

At MachMaster, we follow this process daily for precision metal parts. Especially for complex geometries, casting allows us to hit tight tolerances while keeping production fast and efficient.

It’s like baking a cake—mix, pour, bake, and clean up. Just with a lot more heat.

Casting saves time when you need lots of the same part. It also works for shapes that would be expensive—or even impossible—to machine.

You’ll see casting used in:

- Automotive (engine blocks, wheels)

- Aerospace (turbine parts)

- Medical (implants, housings)

- Consumer goods (faucets, handles, cookware)

If your part has a complex shape or needs to be made in bulk, casting might be the answer. Ever thought about how those smooth car rims or heavy-duty valve bodies are made?

Chances are—they were cast.

It’s not just for big companies either. With the right partner, even small businesses can use casting to save time and money.

2. Advantages of Casting Process

Have you ever looked at a part and thought—how would anyone machine this? Curves, hollow areas, thick walls… Some shapes are just tough to make using regular machining.

I’ve seen it happen.

A team tried to machine thick housing with internal gaps. It took forever, and the scrap rate was high. We switched to casting and the whole thing got easier, faster, and cheaper.

If your part has tricky geometry, is big, or needs to be made in bulk—casting might be the smarter path.

Here’s why:

It Handles Complex Shapes

Casting can do things machining can’t—or would take hours trying.

Hollow sections? No problem. Curved surfaces and sharp inner corners? Casting forms them in one go.

Example: I once worked on a pump housing with an internal cavity. It would’ve taken three setups to machine. We cast it instead, and it came out clean—with no extra steps.

It Fits Large or Heavy Parts

Big parts are a headache for most CNC machines. But casting doesn’t need to “cut” the shape—it forms it from molten material.

So if your part is thick, bulky, or built to carry load, casting often makes more sense.

It’s Cost-Effective for Bigger Orders

Once you have the mold, casting gets cheap.

Each part is quick to make and costs less than machining—especially when you’re ordering in volume.

Think about this: Are you planning to make hundreds—or thousands—of the same part? Casting could save you money without cutting corners on quality.

It Gives You Material Options

Casting works with lots of metals—like:

- Aluminum (lightweight, corrosion-resistant)

- Iron (strong and affordable)

- Steel (durable, high strength)

- Brass (smooth finish, corrosion-resistant)

Some plastic materials work too, depending on the method.

That means you get to choose what fits best—strength, weight, finish, or cost.

It Supports Different Needs

Here’s where casting can be a good fit, depending on what you’re working on:

- Product Designers: Great for parts like knobs, handles, or covers—especially when you want clean curves and smooth surfaces.

- Auto Parts Buyers: Parts like engine blocks, brake components, and gear housings are often cast. They’re heavy, detailed, and built for strength.

- Procurement Teams: If you’re sourcing valves, pump bodies, or other high-volume parts, casting keeps unit costs low while staying reliable.

- Personal Projects: Got a custom part with curves, gaps, or thicker walls? Casting often outperforms 3D printing when it comes to strength and shape.

If your part is large, oddly shaped, or needed in bulk, casting might be your best move.

It offers flexibility, keeps costs in check, and handles shapes that machining or printing can’t do easily.

The goal? Get the results you need—without overcomplicating the process.

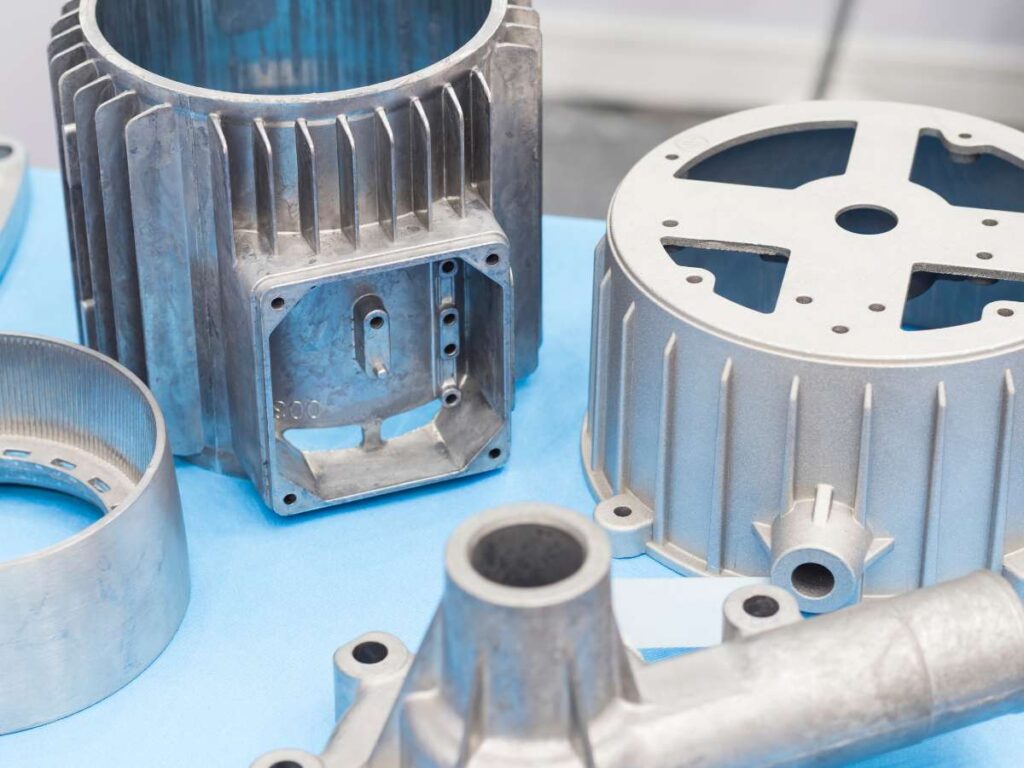

3. Types of Casting Methods

Every part has different needs. Some need a smooth finish. Others need to be strong. Some are made once. Others need to be made over and over again.

That’s why casting comes in many forms. Each method has its strengths. And the one you choose depends on your material, shape, and how many parts you need.

Sand Casting

This method uses packed sand to shape the mold. It’s one of the oldest ways to cast metal—and still very common today.

- Good for low to medium quantities

- Works for large, heavy parts

- More affordable than other options

- Rougher surface that may need cleanup

- Works with materials like aluminum, steel, iron, and brass

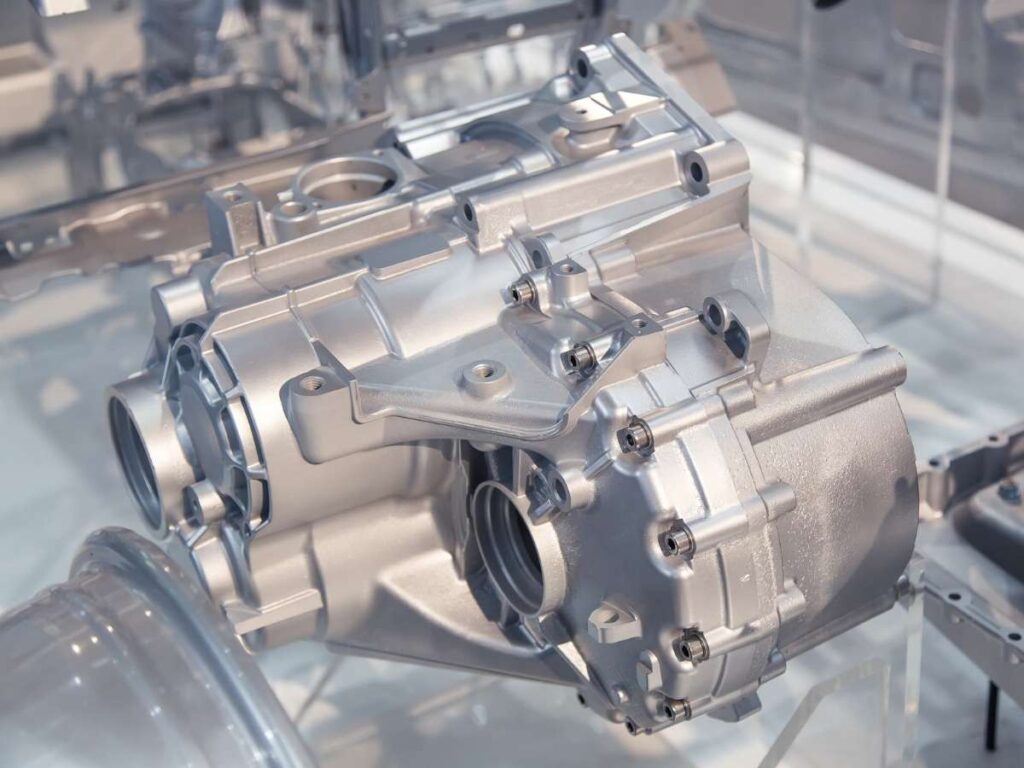

Die Casting

This process uses a metal mold and high pressure to shape the part. It creates parts fast and with clean, smooth finishes.

- Great for making lots of parts

- Excellent surface finish and accuracy

- Best for aluminum, zinc, and magnesium

- Doesn’t work well with steel or iron

- Upfront mold cost is higher, but it pays off at volume

Investment Casting

Also called lost-wax casting. A wax model is coated with ceramic, then melted out. The metal is poured into the empty shell.

- Perfect for complex, detailed parts

- Very accurate and smooth

- Slower and more costly than other methods

- Works with steel, aluminum, brass, and more

Centrifugal Casting

The mold spins while molten metal is poured. This pushes the metal outward and removes air pockets.

- Used for round parts like rings, tubes, and pipes

- Produces strong, dense parts

- Common for iron, steel, and bronze

Permanent Mold Casting

This uses metal molds that can be reused many times. Parts come out faster than sand casting.

- Good for medium to high quantities

- More consistent shapes and sizes

- Works well with aluminum, magnesium, and some brass

- Not ideal for very large or complex parts

Material Compatibility

Here’s a quick way to think about it:

- Aluminum is very flexible—you can use sand, die, permanent mold, or investment casting.

- Steel and iron work best with sand, investment, or centrifugal methods.

- Brass can be used for investment and permanent mold casting.

- Zinc is almost always used in die casting.

- Plastic isn’t cast in the same way—it’s molded, not poured like molten metal.

4. Common Applications of Casting

You might be surprised how often casting shows up in your life.

From the brake system in your car to the knobs on your furniture, casting plays a role in making things strong, repeatable, and cost-effective.

I’ve seen teams overlook it—thinking it’s just for big factories.

But whether you’re building equipment, restoring old parts, or creating something new, casting might already be part of your world.

Automotive

Cars and trucks depend on cast parts every day.

- Brake drums

- Engine blocks

- Transmission housings

- Suspension arms

These parts are often too complex or large to machine efficiently. Casting makes it possible to produce them in large quantities, without breaking the budget.

I’ve worked with buyers who switched from machining to casting on engine components and cut lead times by half.

Medical Devices

In healthcare, cast parts need to fit the human body—and last under stress.

- Joint replacements

- Dental frames

- Orthopedic braces

These parts require precision and strength. Casting handles both, especially with metals like stainless steel or titanium.

Aerospace

Planes and spacecraft rely on parts that are strong but lightweight.

Casting is used for:

- Turbine blades

- Gear components

- Mounting brackets

Materials like aluminum and titanium are often used to keep weight down while still holding shape and strength under pressure.

Electronics

Ever opened up a computer or power supply?

You’ve likely seen cast components.

- Heat sinks

- Connectors

- Metal housings

These parts manage heat and fit into tight spaces. Casting makes them compact, durable, and efficient to produce.

Furniture & Design

Casting isn’t just for machines—it’s also creative.

Interior designers and furniture makers use casting for:

- Metal chair legs

- Decorative handles

- Lighting frames

It’s great for detailed shapes with clean surfaces. I’ve even seen home projects use cast brass parts for a custom finish.

Custom Tools

Need a tool that doesn’t exist?

Casting can help you build it—fast and cheap—without needing a big machine shop.

Art and Jewelry

Casting is how many artists bring their ideas to life.

- Bronze sculptures

- Metal jewelry

- Custom hardware

You can take a wax or clay model and turn it into a solid, lasting piece.

Repair or Reproduction

Can’t find a replacement part?

Casting lets you copy worn or broken components.

It’s useful for:

- Antique restoration

- Farm machinery repairs

- One-off reproductions

I’ve seen people use a broken gear as a pattern and cast a new one—saving time, money, and hassle.

Are you working with a complex shape, tight space, or a part you need to make more than once?

Casting might be your answer.

It’s used across industries because it works—and it might be just what your project needs to move forward.

5. Casting vs. Other Manufacturing Processes

Casting is powerful—but it’s not always the best fit. It depends on your part, the quantity, the material, and how precise things need to be.

Let’s compare casting to some other popular manufacturing methods. This will help you figure out what works best for your project.

| Process | Best For | Limitations | Common Materials | Common Software |

| Casting | Complex shapes, strong metal parts, medium to high volume production | Less precise than machining, longer lead time for mold setup | Aluminum, steel, iron, brass | SolidWorks, Fusion 360, Magmasoft |

| CNC Machining | Prototypes, low-volume parts, tight tolerances | High cost for large volumes, more waste | Metals, plastics | Fusion 360, Mastercam, SolidWorks |

| Injection Molding | High-volume plastic parts, smooth finishes | Expensive mold tooling, not for metals | ABS, PP, PC, and other plastics | Moldflow, SolidWorks Plastics, NX |

| 3D Printing | Custom one-offs, rapid design changes, prototyping | Slow for batches, weaker parts, limited heat resistance | PLA, ABS, resins, some metals | Cura, PrusaSlicer, Autodesk Netfabb |

6. Challenges and Limitations of Casting Process

Casting is useful—but like any process, it has its limits.

If you’re thinking about using it for your next part, it’s good to know what challenges might come up. That way, you’re ready to deal with them—or even avoid them altogether.

Casting can be a great process—but like anything, it has its limits.

I’ve worked on projects where casting was the right call and others where it created problems no one expected. If you’re considering casting for your part, it helps to know what could go wrong so you can catch it early—or avoid it altogether.

Let’s take a look.

Porosity

Porosity means tiny air bubbles get trapped inside the part as it cools.

- Weakens structural areas

- Can cause leaks in parts holding pressure

- Often hidden inside the part until testing

I once saw a cast pump cover fail during water testing. Turned out the center had internal porosity that wasn’t caught during inspection. Fixing it delayed production by a week.

Shrinkage

All metals shrink when they cool. If you don’t plan for that shrinkage, it can cause trouble.

- Gaps or thin areas in cast walls

- Uneven or warped surfaces

- Unexpected size changes in thicker sections

This happens a lot in first-time designs—especially if the part was originally meant for machining.

Surface Defects

Not every cast part comes out smooth, especially when using sand molds.

- Rough finishes may need extra polishing

- Sharp edges may need grinding

- Some parts may require secondary machining

If your part is cosmetic—or needs to fit tightly with other parts—this can add cost and time.

Cracking or Warping

I’ve seen castings crack during cooling, especially at corners or where thick areas meet thin ones.

- Happens when cooling is too fast or uneven

- Can twist, bow, or crack open

- Common in parts with sharp angles or bulky sections

Careful mold design and consistent cooling can help, but this issue still shows up when designs push limits.

Tooling Takes Time

Before you cast anything, you need mold. And that mold isn’t instant.

- Takes days or weeks to design and make

- Complex parts may need more than one tool

- If you’re rushing production, this step can slow you down

One team I worked with skipped mold planning to save time—and ended up waiting longer when the first casting failed.

If your design fits casting and the setup is done right, most of these issues can be caught early—or or avoided altogether.

Quality Control Needs

Casting isn’t just about pouring metal. You also need to check that the part came out right.

Some common testing methods include:

- X-ray inspection to find air pockets or cracks inside the part

- Pressure testing for parts that need to hold fluid or gas

- Visual checks and measurements to confirm surface quality and dimensions

At MachMaster, we use these checks every day. It’s part of how we help customers avoid costly rework or part failure down the line. When you work with a supplier who knows casting inside and out, many of these problems don’t even make it to your desk.

7. Factors to Consider When Choosing Casting Services

Choosing the right casting partner isn’t just about price. It’s about trust.

I once worked on a small batch of aluminum housings. Looked simple on paper. But the first supplier delivered parts with surface pits and uneven sizes. We lost weeks. That taught me a valuable lesson—the right partner makes all the difference.

If you’re looking for casting services, here’s what really matters.

Key Criteria

- Material Expertise: Not every supplier works with all materials. Some specialize in aluminum. Others focus on steel or iron. You need someone who knows how to cast the exact material your part needs.

- Tolerances and Surface Finish: What level of accuracy do you need? Some applications require tight tolerances or a smooth finish. Others don’t. If the supplier isn’t used to your quality standards, you might get stuck doing extra finishing work.

- Production Volume: Are you making 10 parts or 10,000? Some shops are better for small runs. Others are built for high-volume orders. Pick one that matches your needs—both now and later.

- Lead Time and Delivery: Time matters. Ask how long it takes to get tooling ready. Ask how they handle urgent jobs. If delivery is unpredictable, it could hurt your whole schedule.

- Certifications: If you’re in industries like aerospace, medical, or automotive, certifications matter. Look for things like ISO 9001, which shows they follow quality systems and consistent processes.

Questions to Ask Suppliers

Before choosing a casting partner, ask questions like:

- Can you handle my part size and volume?

- What inspection methods do you use to check quality?

- Can you help me improve the part design for casting? (This is often called Design for Casting or DFC)

- Do you offer machining, coating, or finishing after casting?

You want a team that’s ready to support you—not just deliver a raw part and move on.

Conclusion

Casting offers great potential but only when executed correctly.

You’ve seen the advantages, limitations, and key decisions involved.

If you’re unsure about materials, methods, or scaling production, don’t leave it to trial and error.

Contact us. We’ll guide you in choosing the most suitable casting method for your part—saving time, cost, and rework.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Curious for more? These additional articles offer even more insights and advice:

Die Casting Basics & Processes:

- What Is Die Casting?

- Die Casting Process: Step by Step Guide

- Top 8 Industries Benefiting from Die Casting Parts

Casting in Manufacturing:

- What Is Casting in Manufacturing Process?

- What Is Casting in Manufacturing?

- Top 7 Aluminum Casting Part Manufacturers in Asia

Comparisons & Global Context:

- Top 7 Die Casting Manufacturers in China

- Metal Injection Molding vs Die Casting: What’s the Difference

- Die Casting vs Injection Molding: What’s the Differences

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.