I remember seeing it in a project quote—“cast aluminum.” Then someone said it in a meeting. Everyone else seemed to get it. I didn’t. But I stayed quiet because I didn’t want to sound clueless.

Now I wish I had just asked.

Later on, I finally looked it up. I learned what cast aluminum is, how people make it, and why it shows up in so many products.

Once I got it, I started making smarter choices—both at work and with my own stuff.

If you’re reading this and thinking, “What is cast aluminum?”—you’re not alone. I’ve been there. And you’re in the right place.

In this article, I’ll explain:

- What cast aluminum means

- How it’s made

- Where it’s used

It’s simple and clear—just what I needed when I was learning, too.

Let’s get started!

1. What is Cast Aluminum?

I used to think all aluminum was the same. Light, silver, and used in soda cans. But then I learned about cast aluminum. It’s different. And once you understand how, things start to click.

Cast aluminum is aluminum that’s been melted down and poured into a mold. When it cools, it hardens into the shape of that mold. That’s what casting means: shaping something by pouring it into a form.

So instead of cutting or bending metal, you’re shaping it like jelly in a tray. Except it’s metal. Strong metal.

Why do people use it?

- It’s lightweight

- It cools quickly

- It takes on detailed shapes

- It’s used in everything from car engines to cookware

I remember holding a bike pedal for the first time and thinking, “This feels solid.” Later, I found out it was cast aluminum.

If you’ve ever held something made of metal that felt solid but light, it might have been cast aluminum.

Once I learned what it was, I started noticing it everywhere. You probably will too.

2. Advantages of Using Cast Aluminum

There’s a reason cast aluminum keeps showing up in project after project. It offers a mix of benefits that, when used right, bring real value. I’ve worked with cast aluminum on everything from industrial housings to consumer products, and while the applications vary, these core advantages keep coming back.

Here are the advantages that I keep seeing, job after job, across industries and project sizes:

Cost-Effective Production

Once your mold is dialed in, casting aluminum becomes one of the most economical ways to produce complex metal parts in bulk.

Why it pays off:

- Low cost per part at medium-to-high volumes

- Less waste than machining

- Minimal post-processing for many designs

I worked with a client who needed thousands of small brackets. Machining each one would’ve destroyed the budget. Switching to cast aluminum cut unit cost and hit every delivery target.

Ideal for Complex Shapes

Cast aluminum handles shapes that are too time-consuming or expensive to machine—like:

- Deep cavities

- Hollow channels

- Undercuts and rounded internal corners

Perfect for:

- Consumer casings

- Tool housings

- Structural parts with integrated features

Lightweight and Strong Enough

If you’re trying to reduce product weight without sacrificing durability, cast aluminum offers that sweet spot.

You get:

- Lower part weight for easier handling

- Enough structural strength for most industrial and consumer jobs

- Good fatigue resistance for repeated-use components

Especially helpful when building:

- Handheld equipment

- Vehicle parts

- Assemblies where weight affects shipping or performance

Recyclable and Widely Available

Aluminum is one of the most recycled materials in manufacturing—and casting makes it easy to reuse.

What this means for your project:

- More sustainable material sourcing

- Lower raw material costs

- Reliable supply chains that keep timelines on track

I’ve re-melted scrap from one project into a test batch for another. It saves money and cuts waste without hurting part performance.

When you need a material that balances cost, complexity, and performance, cast aluminum delivers—making it a smart choice across industries and production scales.

3. Key Features of Cast Aluminum

If you’re planning to use cast aluminum in your project, it’s important to look past just the surface-level benefits.

Here are some of the defining features of cast aluminum often seen:

- Density: About 2.7 g/cm³, which is relatively low. That’s why it’s preferred in industries that care about weight—like aerospace, automotive, and handheld devices.

- Melting Point: Roughly 660°C (1220°F). I’ve seen this play out when components are exposed to sustained heat. They hold up well—better than plastics—but it’s good to remember this limit.

- Tensile Strength: Generally lower than forged or wrought aluminum. In my experience, most cast aluminum parts hold their own in static applications but may not be the best fit for heavy load-bearing uses.

- Thermal Conductivity: Excellent. That’s why I keep seeing it in parts that need to shed heat—like housings for electronics or mechanical parts near engines.

- Machinability: Moderate. Some cast surfaces are easy to drill or trim, while others—especially those from sand casting—can be a bit tricky. I always advise checking the surface quality before planning any secondary work.

- Surface Finish: It depends a lot on the casting method. Die cast parts come out smooth and sleek. Sand cast parts tend to have a rougher, matte texture. I’ve had clients request a polished or coated finish to improve aesthetics.

Knowing how cast aluminum behaves will help you make better calls during design and production. It’s one of those things that can prevent costly do-overs later on.

4. Types of Cast Aluminum

Cast aluminum isn’t a one-size-fits-all material. The properties of each type depend on the specific alloy mixture and the casting process used.

Here are some of the most common cast aluminum types used in industry today:

A356 (Aluminum-Silicon-Magnesium Alloy)

When you need all-around strength, ductility, and corrosion resistance, A356 is often the go-to.

Key benefits:

- Excellent castability

- High strength-to-weight ratio

- Good response to heat treatment (T6)

- Suitable for surface finishing

Best for:

- Automotive suspension components

- Structural housings

- Load-bearing industrial parts

I’ve used A356 for parts with deep pockets and fine ribs. It fills out well and needs minimal cleanup—saving time on every batch.

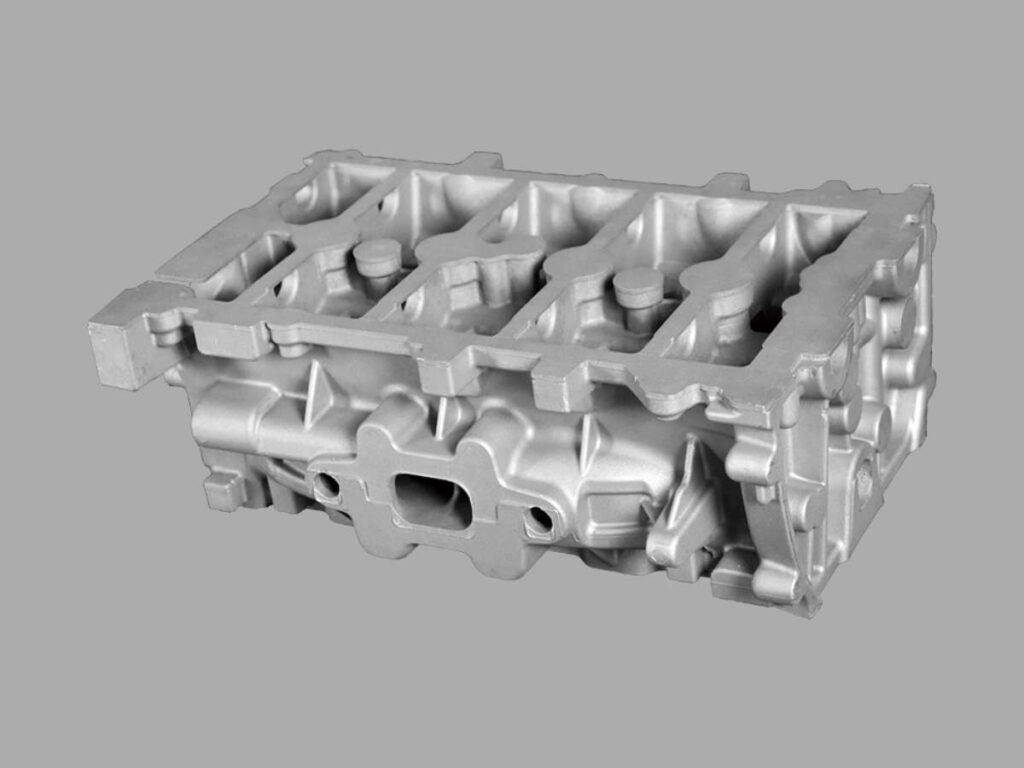

319 (Aluminum-Silicon-Copper Alloy)

319 is built for heat tolerance and wear resistance, thanks to added copper content.

Key benefits:

- Performs well under thermal cycling

- Stable during prolonged high-temperature exposure

- Moderate castability

Best for:

- Engine blocks

- Cylinder heads

- Valve bodies and pump housings

If your part lives near a combustion source or in high-load applications, 319 is worth serious consideration. It’s not the most ductile, but it holds its shape under stress.

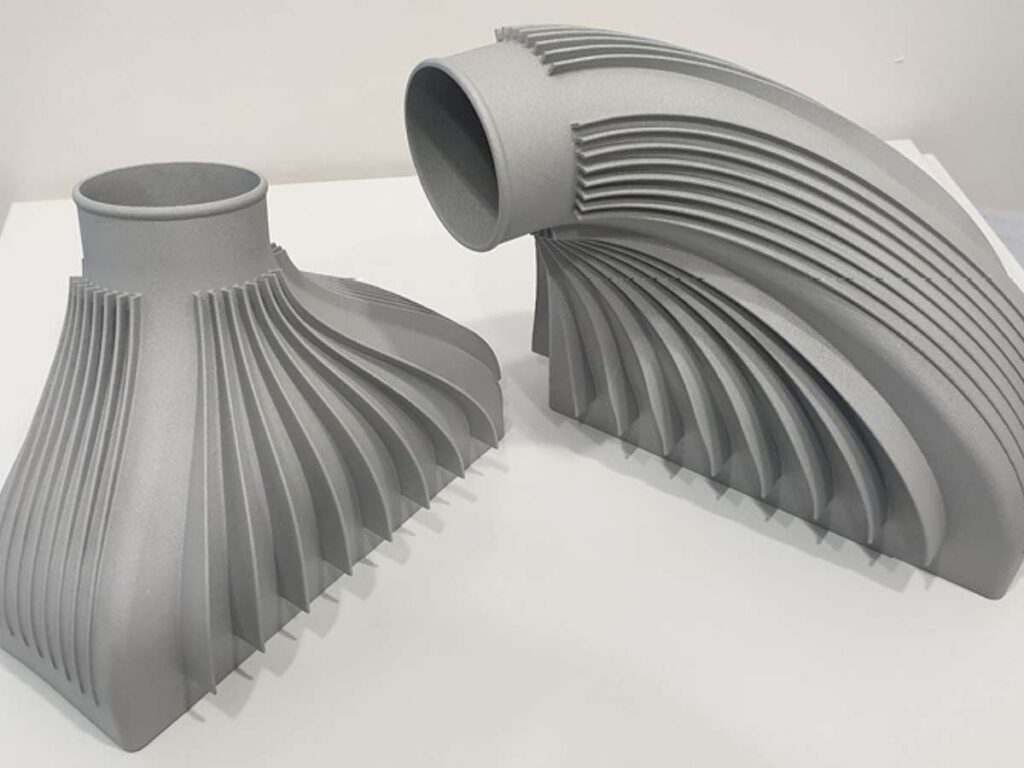

AlSi10Mg

A favorite in both casting and metal 3D printing, AlSi10Mg offers tight tolerances and high surface quality.

Key benefits:

- High corrosion resistance

- Strong mechanical properties

- Good weldability

- Suitable for thin-walled, detailed parts

Best for:

- Aerospace brackets

- Motorsports parts

- Precision housings and covers

I’ve seen teams use AlSi10Mg to replace machined aluminum in critical aerospace brackets—and get the same performance with fewer steps.

ZL101

ZL101 is an economical, high-silicon alloy ideal for parts that require fine detail and consistent casting.

Key benefits:

- Excellent fluidity—great for complex shapes

- High dimensional stability

- Good thermal conductivity

- Budget-friendly for volume production

Best for:

- Heat sinks and motor housings

- Consumer electronics enclosures

- General-purpose industrial parts

When we ran a thin-walled electronics housing at scale, ZL101 gave us clean fills and minimal defects—even in tight corners.

By selecting the right alloy for your design and working environment, cast aluminum becomes a performance asset—not just a material. That’s why partnering with a trusted supplier like MachMaster is critical to achieving project success.

5. Common Applications of Cast Aluminum

Cast aluminum is one of those materials that quietly shows up in daily life—both in personal use and on the production line. Over the years, it’s turned up in more projects than I can count. Each one with a slightly different purpose but often the same goal: reliability without extra weight.

Here are some of the most common places cast aluminum is used:

Automotive Components

Cast aluminum plays a major role in the automotive world—where strength-to-weight ratio is everything.

Common uses include:

- Engine blocks

- Transmission cases

- Suspension arms

- Alloy wheels

These parts reduce overall vehicle mass, which improves fuel efficiency, handling, and emissions.

Consumer Electronics

Lightweight, yet rigid—cast aluminum is a top pick for sleek, durable tech enclosures.

You’ll find it in:

- Laptop chassis

- Smartphone frames

- Audio and camera housings

Its ability to support thin walls with tight tolerances makes it ideal for compact, high-end designs.

I’ve helped teams meet rapid launch cycles by pairing cast aluminum with CNC finishing. The result? Precision, durability, and speed—all in one workflow.

Cookware

Beyond the factory floor, cast aluminum is a staple in kitchens worldwide.

Common applications:

- Frying pans

- Sauce pots

- Griddles and bakeware

Its excellent thermal conductivity and low weight make it a user-friendly alternative to cast iron—especially for home cooks and commercial kitchens alike.

Construction and Architectural Parts

From support frames to exterior features, cast aluminum adds strength without bulk in structural and architectural settings.

Often used in:

- Railing systems

- Wall brackets

- Decorative panels

- Outdoor signage and facade supports

It’s especially valued for its corrosion resistance and ease of installation in both indoor and outdoor projects.

I’ve worked on installs where the lightness of cast aluminum made mounting safer and faster—saving time and labor on site.

6. Cast Aluminum vs. Other Materials

When you’re deciding on a material for a new part, the real challenge usually starts with comparison. You’ll likely weigh cast aluminum against other options like wrought aluminum, steel, plastic, or even cast iron.

Here’s a simple side-by-side table to help you compare cast aluminum with some of the most commonly used materials:

| Property | Cast Aluminum | Wrought Aluminum | Steel | Plastic | Cast Iron |

| Cost | Moderate | Higher than cast aluminum | Moderate to High | Low to Moderate | Low to Moderate |

| Weight | Light | Very Light | Heavy | Very Light | Very Heavy |

| Strength | Good, but lower than wrought | Excellent | Very High | Poor to Moderate | Good (brittle under tension) |

| Durability | Good corrosion resistance | Better corrosion/fatigue resistance | Excellent with coatings | Poor to fair, depending on polymer | Excellent under compression |

| Machinability | Very good | Excellent | Moderate | Excellent | Moderate to Poor |

| Thermal Conductivity | High | Very High | Moderate | Very Low | Moderate |

| Electrical Conductivity | Moderate | High | Low | Insulator | Low |

| Corrosion Resistance | Naturally corrosion resistant | Anodizable for high resistance | Needs coating or stainless variant | High (non-metallic) | Poor, rusts without treatment |

| Impact Resistance | Fair | Excellent | High | Poor to Good | Poor (brittle) |

| Tensile Ductility | Low to Moderate | High | High | High (flexible) | Very Low |

| Heat Resistance | Moderate (up to ~500°F/260°C) | Higher than cast, ~600°F/315°C | Excellent (varies with grade) | Poor (melts at low temps) | High (~2100°F/1150°C) |

| Wear Resistance | Moderate | Fair to Good | Excellent with treatment | Poor | Excellent |

| Fabrication Method | Sand casting, die casting, permanent mold | Extrusion, rolling, forging | Hot/cold rolling, forging, welding | Injection molding, extrusion | Sand casting, permanent mold |

| Recyclability | High | High | High | Varies (some are not recyclable) | High |

| Common Applications | Engine housings, brackets, structural casings | Aircraft, marine, structural frames | Machinery, structural, automotive parts | Consumer goods, electrical housings | Machine bases, pipe fittings, manhole covers |

Choosing the right material starts with understanding these differences—match the properties to your application’s needs to get the best performance and value.

7. Challenges and Limitations of Cast Aluminum

Cast aluminum is useful, but it’s not perfect. Some problems appear early, while others emerge with repeated use.

Knowing its limitations upfront helps avoid costly surprises later.

Here are the key challenges to watch for.

Lower Mechanical Strength

Cast aluminum generally offers lower tensile strength compared to wrought aluminum or steel. That’s because its internal structure may contain tiny pores or inconsistencies created during the casting process.

If you’re working with parts that handle heavy loads or repeated stress, this can lead to cracking or failure. It performs well in light-duty jobs—but for structural applications, you’ll need to take a closer look.

Porosity and Surface Defects

Porosity is one of the most persistent challenges in aluminum casting.

- Caused by air or gas trapped during solidification

- Creates weak points that can’t always be seen until machining begins

- Affects surface coatings, sealing, and pressure-bearing performance

I’ve machined parts that looked flawless—until the cutter exposed pinholes just beneath the surface. That scrap added hours to what should’ve been a quick run.

Good mold design and process control can reduce porosity, but it can’t be fully eliminated.

Limited Ductility and Brittleness

Cast aluminum isn’t designed to flex. If your part experiences:

- Impact loads

- Vibration

- Shock or torsion

..it’s more likely to crack than bend.

This limits its use in:

- Drop-prone consumer gear

- Industrial parts under cyclic stress

- Moving assemblies exposed to vibration

We once tested a cast enclosure in a vibration chamber—cracked corners after two rounds. Switched to forged aluminum and the issue disappeared.

Surface Finish Variation

Not all casting methods leave parts looking clean or ready for use.

- Sand casting = rough, uneven texture

- Die casting = smoother, but may still require finishing

- Coatings (paint, powder, anodizing) may highlight surface flaws

If your part is cosmetic or user-facing, expect to spend time and budget on post-processing.

I’ve had to retool entire batches just to meet finish expectations for a customer-facing part. Better to plan for it up front.

Cast aluminum delivers versatility and value—but only when its mechanical limits, surface variability, and structural risks are factored into the design from the start.

8. Factors to Consider When Choosing Cast Aluminum for Your Needs

Choosing the right material is one of the first decisions that shapes your entire project. If you’re considering cast aluminum, it’s essential to know where it works best—and where it might fall short. Making that call early helps avoid costly redesigns and delays.

Here’s what you should evaluate before moving forward:

Mechanical Requirements

Start with the job the part needs to do. Will it support weight? Be exposed to vibration or impact?

- Use cast aluminum for enclosures, housings, and components with static loads.

- Avoid it for parts that need to flex, absorb frequent shocks, or require high impact resistance—cast aluminum can be brittle.

Always work with a trusted partner like MachMaster to evaluate the right materials and tolerances. They will help you confirm the part functions correctly—before it’s ever made.

Production Volume

Think about how many parts you really need. Casting only starts to pay off when volumes are high enough to offset the tooling cost. For one-offs or small runs, machining is often cheaper and faster. But once your mold is ready, casting becomes much more efficient.

In my experience, you really start seeing the savings at around 500 parts—though that can vary based on shape and size. If you’re planning for scale, casting can definitely lower your per-part cost over time.

Surface Finish and Appearance

Ask yourself: how important is the final look? If function matters more than finish, you might be fine with a rougher surface—like what you’d get from sand casting.

But if the part will be visible or part of a consumer-facing product, surface quality becomes critical.

Die casting gives you a cleaner, more consistent finish. But either way, if the part needs to shine—literally or figuratively, be ready to add post-processing like polishing, painting, or powder coating.

I’ve seen solid parts get rejected just because they didn’t look right. Don’t let that be your project.

Conclusion

I wish I had spoken up in that meeting.

But you just did—by choosing to learn. Now you understand what cast aluminum is, how it’s made, and why so many people use it.

It’s not just a label on a quote. It’s a smart choice that affects how your part performs, how much it costs, and how long it lasts.

So ask yourself: does cast aluminum fit your next project?

If it does, MachMaster’s CNC machining services are here to help. We turn your ideas into real parts—fast, accurate, and built to last.

Ready to get started?

Reach out today. Let’s build something great together.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.