A while back, a client reached out in frustration. Their aluminum parts had just failed inspection for the third time—, and the project was already behind schedule.

The casting defects weren’t minor. They were deal-breakers.

They’d tried two other suppliers before us, but no one could get it right. That’s when they gave us a call.

I’ve been casting aluminum for over 12 years now, and this is exactly the kind of challenge I solve.

From custom mold design to tight-tolerance finishing, we handle it all in-house. My job isn’t just to deliver parts—it’s to make your production smoother.

In this article, I’ll walk you through what aluminum casting is, how it works, and when to use which method.

Whether you’re sourcing for the first time or rethinking your supply chain, this guide will give you real answers from someone who lives and breathes casting.

So, let’s get started!

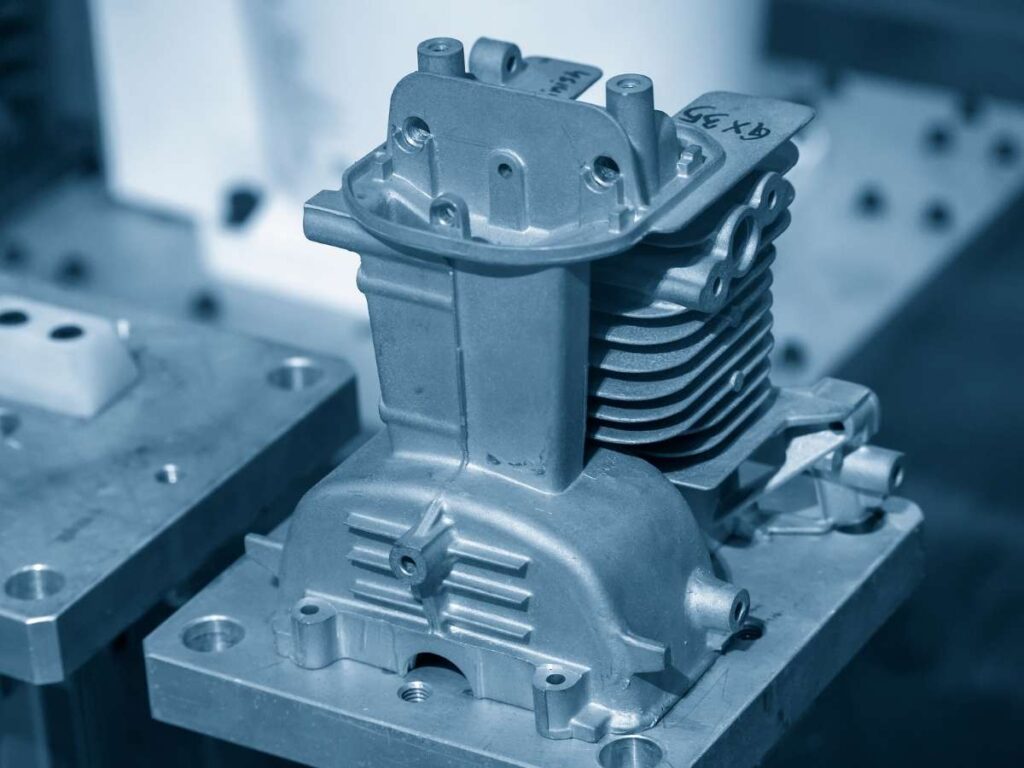

1. What is Aluminum Casting?

If you’ve ever picked up a lightweight part and thought, “Wow, this feels solid but not heavy,” there’s a good chance it came from an aluminum casting process.

Aluminum casting is the process of heating aluminum until it’s molten, pouring it into a mold, and letting it cool into the final shape. The type of mold—sand, metal, or die—depends on your production needs.

Once it’s solidified, you can either machine it further or use it right away, depending on the finish you’re after.

Here’s why aluminum casting is a go-to for so many businesses:

- Lightweight Yet Strong: You get parts that are easy to handle and ship, but still hold up under stress.

- Flexible in Shape and Size: From basic components to complex, thin-walled designs, casting handles it all.

- Scalable for Production: Whether you’re making ten units or ten thousand, casting scales without reinventing the process.

- Cost-Efficient: It’s a great balance between quality and price, especially when compared to full machining or forging.

- Faster Turnaround: With the right setup, casting gets you from idea to part on a much shorter timeline.

So when we talk about aluminum casting, we’re really talking about a smart way to build strong, detailed parts quickly, without sacrificing your bottom line.

2. Benefits of Aluminum Casting

Aluminum casting doesn’t just tick off a few boxes; it solves multiple business challenges at once.

In this section, I’ll walk you through why aluminum casting is often the go-to choice for businesses across various sectors.

Lightweight and Strong

One of the most striking qualities of aluminum is its incredible strength-to-weight ratio.

In my experience, aluminum parts are tough enough to withstand heavy use while still being light enough for easy handling and shipping. This balance makes aluminum casting a great choice for industries like aerospace, where weight savings lead to better fuel efficiency.

It’s a key advantage if you’re looking for durable parts without adding unnecessary weight.

Excellent Design Flexibility

Aluminum casting offers remarkable design flexibility, which is one of the reasons I recommend it so often.

When I’ve seen complex geometries, like thin walls, curved features, or intricate undercuts, aluminum casting was the solution that made it possible.

Manufacturers like MachMaster are especially equipped to handle these kinds of designs, using casting techniques that balance precision with efficiency.

Other manufacturing methods may struggle with these complexities, making aluminum casting a much more versatile option. If your product requires custom shapes, this process can handle it without breaking the bank.

High Thermal and Corrosion Resistance

Aluminum is especially useful for applications exposed to heat or outdoor environments.

I’ve worked with parts that need to perform in harsh conditions, and aluminum’s high thermal and corrosion resistance always stands out. Whether it’s for automotive components or machinery exposed to the elements, aluminum resists rust and handles high temperatures well.

This durability means fewer replacements and less maintenance for your parts.

Recyclability

If sustainability is a priority for you, aluminum casting is a great option to consider. Aluminum is 100% recyclable without losing any performance, which is a huge benefit for companies looking to reduce waste and energy consumption.

I’ve seen many manufacturers leverage this to promote eco-friendly practices and reduce overall material costs. It’s an easy win for businesses that want to balance cost with environmental responsibility.

3. Common Aluminum Casting Methods

Choosing the right aluminum casting method is a crucial decision for any business. I know you will agree that each technique has its own set of advantages and ideal use cases, depending on the volume, complexity, and finish requirements of your parts.

Die Casting

Die casting involves injecting molten aluminum into a steel mold under high pressure. This method is ideal for high-volume production runs, as it delivers parts with excellent surface finishes and dimensional accuracy.

However, the upfront tooling cost for the molds can be quite high, so it’s better suited for long-term, large-scale projects. If you’re planning to produce thousands of parts, die casting might be the best route for consistent quality at scale.

Sand Casting

With sand casting, the mold is made from a sand mixture, and molten aluminum is poured into it. It’s a great option when you’re working with low-volume runs or prototypes because the tooling is much cheaper compared to other methods.

While the surface finish may be rougher than die casting, sand casting offers a lot of flexibility and can handle a wide variety of part sizes and shapes. If cost is a concern and precision is less critical, sand casting might be your go-to method.

Permanent Mold Casting

Permanent mold casting, or gravity die casting, uses reusable metal molds without applying high pressure. This technique strikes a good balance between cost, precision, and surface quality, making it ideal for medium-volume production runs.

It’s a great middle ground between die casting and sand casting, offering a good mix of efficiency and part quality. If you need high-quality parts but don’t have the volume to justify die casting, permanent mold casting could be the perfect solution.

Investment Casting (Lost Wax)

In investment casting, a wax model is coated with ceramic to create a mold, which is then heated to remove the wax before pouring in molten aluminum.

This method is excellent for creating parts with intricate details and high precision, but it tends to be slower and more expensive than other methods.

It’s often used for parts that require fine features or complex geometries, like in aerospace or medical applications. If precision is a top priority and you’re working with detailed designs, investment casting may be the best fit for your project.

4. The Aluminum Casting Process

Getting a high-quality aluminum part starts with understanding the casting process.

Let’s walk through the typical steps of aluminum casting to help you get a better idea of what to expect and how to make informed decisions when working with suppliers.

- Step#1 Pattern or Mold Creation: The first step in the casting process is creating a pattern or mold, depending on the method. Getting the mold right means you’re off to a solid start, with accurate parts coming out of the process.

- Step#2 Melting the Aluminum: The next step is melting the aluminum. It’s typically heated in a furnace to temperatures above 660°C (1220°F), which is the melting point of aluminum. I’ve learned that maintaining the right temperature helps keep things smooth and prevents future problems.

- Step#3 Pouring or Injection: Once the aluminum is molten, it’s time to pour or inject it into the mold. For gravity casting, the molten aluminum flows into the mold by its own weight, while for die casting, it’s injected under high pressure.

- Step#4 Cooling and Solidification: The cooling process is essential because it determines the strength and finish of the part. The mold design helps control how quickly the aluminum cools, which can impact the final part’s durability.

- Step#5 Ejection or Mold Break: For reusable metal molds, the part is typically ejected, but with sand or ceramic molds, they’re broken apart to release the part. At this stage, you’ve got a solid piece, but it might still need a little cleanup to remove any leftover mold material or rough edges.

- Step#6 Trimming and Finishing: Excess material is trimmed away to bring it to the correct shape. Depending on the application, the part may also undergo additional processes like machining, heat treatment, or surface finishing.

- Step#7 Inspection and Quality Control: This is where any defects like porosity, cracks, or warping are identified. For high-stakes parts, methods like X-rays, pressure tests, or even CT scans may be used to ensure that everything is up to standard.

5. Key Applications of Aluminum Casting in Various Industries

Aluminum casting is a unique combination of precision, strength, and lightweight properties makes it incredibly versatile and valuable in many different sectors.

In this section, I’ll walk you through some of the key industries that rely on aluminum casting and how it benefits their operations.

Automotive

In the automotive industry, aluminum casting plays a critical role in reducing vehicle weight without sacrificing strength or durability.

From engine blocks to transmission housings and brake components, I’ve seen how aluminum parts help improve fuel efficiency while maintaining performance.

The ability to create lightweight, high-strength parts makes it a go-to material for modern vehicles.

Consumer Electronics

Aluminum casting also plays a big role in the consumer electronics industry. I’ve seen how aluminum-cast housings are used in everything from laptops to smartphones and wearables, providing both structural integrity and a sleek, modern finish.

Aluminum’s thermal conductivity is a key advantage here, helping dissipate heat and keep electronics running smoothly.

Industrial Equipment

In industrial applications, aluminum casting supports the creation of rugged and reliable components.

Parts like pump housings, valve bodies, and mounting brackets are commonly cast in aluminum for their durability and ease of use in heavy machinery.

I’ve found aluminum to be ideal for industrial equipment that needs to stand up to tough environments, like HVAC systems or construction machinery. Its resistance to corrosion and wear makes it a trusted material for long-lasting performance.

6. Aluminum Casting vs Other Metal Casting Methods

When it comes to choosing the right metal casting method, there’s no one-size-fits-all solution. Each metal casting method has its own strengths and weaknesses.

Below is a comprehensive comparison of aluminum casting against other common metal casting methods, such as steel, iron, and zinc casting.

| Feature | Aluminum Casting | Steel Casting | Iron Casting | Zinc Casting |

| Weight | Lightweight, reducing overall product weight | Heavy, increasing product weight | Very heavy, often used for high-strength, heavy parts | Very light, ideal for small, precise parts |

| Strength | High strength-to-weight ratio, good for structural parts | Stronger than aluminum, suitable for high-stress applications | Extremely strong and tough, ideal for heavy-duty use | Less strong than aluminum, best for smaller, non-stress parts |

| Cost | Cost-effective for medium to high volumes | More expensive, especially for high-volume production | Economical for high volumes but heavier tooling costs | Inexpensive tooling, ideal for high-volume, small parts |

| Mold Material | Metal molds or sand molds, flexible for various shapes | Requires strong, durable molds for higher temperatures | Sand or permanent molds, good for large parts | Typically uses permanent molds for high precision |

| Surface Finish | Good surface finish, smooth details for complex geometries | Rougher surface finish, needs post-processing for smoothness | Rougher finish, often requires further machining | Excellent surface finish, ideal for precision parts |

| Corrosion Resistance | Good corrosion resistance, ideal for outdoor applications | High corrosion resistance, ideal for structural parts | Generally rusts easily, requires coatings or alloys | Very good corrosion resistance, great for smaller parts |

| Production Speed | Fast, especially for high-volume production | Slower due to higher mold and cooling times | Slower cooling times, less efficient for complex parts | Fast, suitable for mass production of small parts |

| Complexity of Parts | Excellent for complex shapes, thin walls, and intricate designs | Limited by the toughness of steel, can handle simple designs | Best for simple, large parts with thick walls | Excellent for small, detailed parts with fine tolerances |

| Recyclability | 100% recyclable without loss of quality | Recyclable, but less common due to higher cost | Recyclable, but less commonly recycled due to weight | 100% recyclable, commonly recycled due to lower cost |

| Applications | Automotive, aerospace, consumer electronics, industrial parts | Heavy machinery, automotive, infrastructure | Engine blocks, pipe fittings, industrial machinery | Small, precise parts for electronics, automotive, hardware |

7. Challenges and Considerations in Aluminum Casting

Aluminum casting offers great benefits, but it also comes with its own set of challenges. By understanding these potential pitfalls ahead of time, you can avoid costly mistakes and ensure smoother production.

In this section, I’ll walk you through some of the key challenges that come with aluminum casting and what you can do to address them.

- Porosity Issues: Porosity occurs when gas pockets form inside the cast part, weakening its structural integrity. Using proper degassing techniques and mold design can help reduce the risk of this defect.

- Tooling Costs: Die casting and permanent mold casting require significant upfront investment in tooling. However, this cost becomes more justifiable with high-volume production runs.

- Shrinkage and Warping: Aluminum shrinks as it cools, which can lead to dimensional inaccuracies or internal stresses. Careful planning and simulation are key to managing this issue during production.

- Limited Thickness: Aluminum doesn’t handle very thick sections well, leading to potential issues with strength and cooling. For larger, thicker parts, alternative methods like machining or welding may be more effective.

- Supplier Consistency: Not all foundries provide the same level of quality and consistency. Choosing the right supplier is crucial to maintaining the reliability of your parts as production scales.

8. 4 Tips on How to Choose the Right Aluminum Casting Partner

Choosing the right aluminum casting partner goes beyond just looking at costs, it’s about finding a supplier with the right technical capabilities to meet your needs.

Here are 4 key technical factors to consider when evaluating potential casting partners.

#1 Expertise in Multiple Casting Methods

Aluminum casting comes in various methods such as die casting, sand casting, permanent mold casting, and investment casting.

You’ll want a partner who has extensive experience with different casting techniques, as each method has its own advantages and challenges.

MachMaster works across all major casting methods, helping match the right process to the specific needs of each project—whether it’s low volume, complex geometry, or tight mechanical specs.

#2 Advanced Simulation and Modeling Capabilities

A strong aluminum casting partner should be equipped with advanced casting simulation tools, such as solidification and flow analysis software. These tools allow them to predict issues like porosity, shrinkage, and thermal stresses before the casting process begins.

I’ve seen how this capability leads to fewer defects and a smoother production process. Simulation helps optimize the mold design, aluminum flow, and cooling rates, ultimately saving you time and reducing the risk of costly post-casting corrections.

#3 Precision in Tolerances and Surface Finish

Aluminum casting often requires tight tolerances and high-quality surface finishes, especially for industries like aerospace and automotive.

When evaluating a partner, look for their ability to consistently meet these precision requirements. Check their machining capabilities and surface treatment options, including polishing, coating, or shot blasting.

If your part needs specific features like thin walls, complex geometries, or intricate detailing, make sure they have the tools and experience to handle these challenges without compromising accuracy or quality.

#4 In-House Quality Control and Testing

A reliable casting partner will have a rigorous in-house quality control system that includes both visual and non-destructive testing methods.

This should involve techniques like X-ray inspection, ultrasonic testing, or dye penetration tests to detect internal and surface defects such as cracks or porosity.

Make sure your partner can provide detailed reports of these inspections and test results. Their commitment to thorough testing is critical to preventing defects from slipping through the cracks and ensuring the final parts meet your specifications.

Conclusion

You’ve now seen what aluminum casting is, where it shines, and how to avoid common pitfalls.

You learned why it’s strong yet light, and how to pick the right method and partner.

Now it’s your turn to act. Imagine cutting costs and boosting efficiency with smarter casting choices.

Will you take the first step toward better parts today?

Contact MachMaster today! Our team is ready to help you bring your next project to life and exceed your manufacturing goals.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.