I was helping a client spec out a CNC machine when they casually asked, “What’s the big deal with 5 axis anyway?”

I didn’t just explain it. I showed them. Their reaction said it all.

That moment reminded me how many businesses still don’t know what they’re missing.

What you’re reading comes from hands-on experience, not sales copy. I’ve advised manufacturers, sat in demos, and watched real teams boost efficiency with this tech.

In this review, I’ll explain what 5 axis CNC machining means, how it differs from the rest, and what makes it so powerful. You’ll get the facts you need and none of the filler.

If your goal is tighter tolerances and fewer setups, this guide is exactly what you’re looking for.

Let’s get into it!

1. What is 5-Axis CNC Machining?

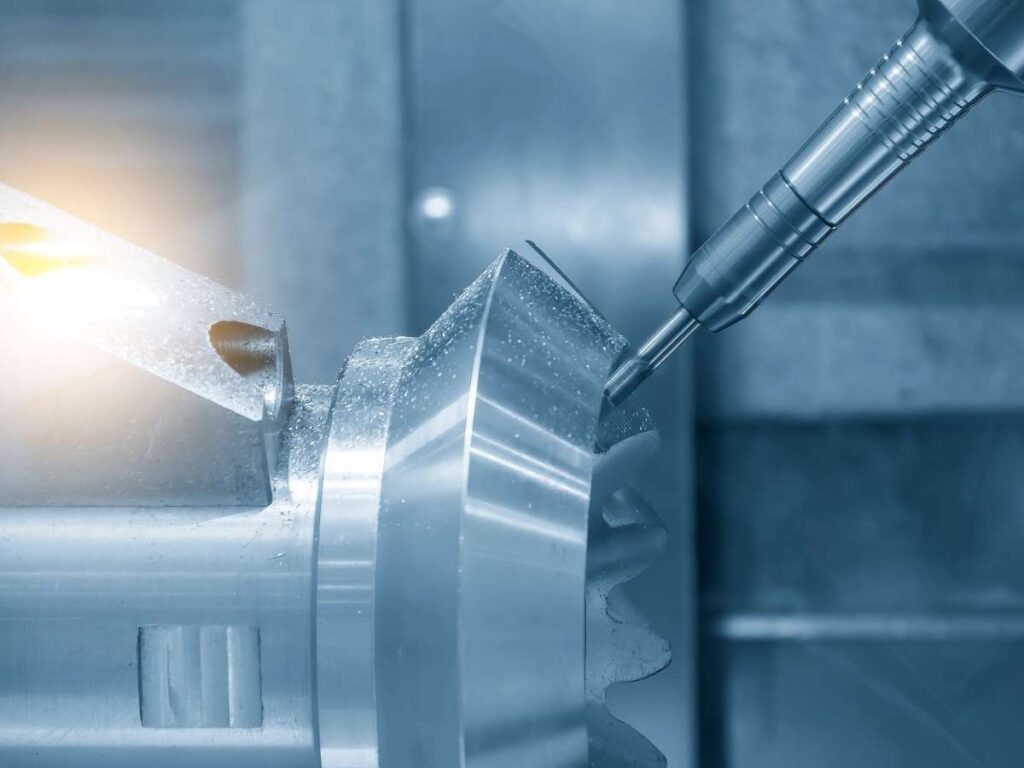

5-axis CNC machining refers to the ability of a machine to move a part or a tool on five different axes simultaneously.

Traditional 3-axis machines move the tool along the X, Y, and Z linear axes.

In contrast, 5-axis machines add two rotational axes, typically labeled A and B, allowing for more complex and precise machining.

This capability enables the machine to approach the workpiece from virtually any direction, reducing the need for multiple setups and allowing for the creation of intricate parts with tight tolerances.

It’s particularly beneficial for industries that require complex geometries, such as aerospace, automotive, and medical device manufacturing.

2. How 5-Axis CNC Machines Work

When I first started looking into 5-axis machines, I’ll admit I was overwhelmed. All those moving parts, extra axes, and rotating tables? It seemed like rocket science compared to the 3-axis machines I was used to. But once I saw how everything came together, it clicked.

Understanding how these machines move is the first step to unlocking their full power.

Now, not all 5-axis machines are built the same. They generally fall into two main types, and the difference comes down to which part moves, your table or your tool.

- Trunnion Style is the one you’ll hear about most often. In this setup, the table itself tilts and rotates while the cutting tool stays put. This is perfect when you’re working with smaller, more complex parts that need cutting from multiple directions, especially if you’ve got a lot of undercuts or compound angles.

- Swivel Head Style, on the other hand, keeps the table stationary while the spindle, the part that holds the cutting tool, tilts and rotates. This one is a go-to for larger parts where moving the entire workpiece just isn’t practical.

So how do you choose between the two?

For me, it always comes down to part size, material, and the kind of detail work required. If you’re making medical implants, mold cores, or aerospace brackets, trunnion is probably your friend.

But if you’re machining larger structural parts or components with tall profiles, a swivel head might give you the flexibility you need without sacrificing stability.

At the end of the day, both styles get you to the same result: fewer setups, tighter tolerances, and the ability to tackle parts that a 3-axis machine could only dream of. Once you see it in motion, you’ll understand why so many shops are making the switch.

3. Advantages of 5-Axis CNC Machining

Integrating a 5-axis CNC machine into your workflow isn’t just a leap in capability.

It’s a smart shift in how your team approaches production.

Whether you’re prototyping or scaling high-volume parts, these machines give you more control and fewer limitations.

Reduced Setup Time

Complex parts often require multiple setups on a 3-axis machine, which eats up time and increases the chance of mistakes.

With 5-axis machining, you can often complete the job in one go. I’ve seen firsthand how a single-setup process can shave hours off lead times. This kind of efficiency keeps jobs moving and customers happy.

Enhanced Precision

Being able to rotate and tilt the part while cutting unlocks a level of precision that’s hard to match with simpler setups.

Parts with tight tolerances or complex curves come out cleaner and more consistent.

I once worked with a shop that cut their reject rate in half after switching to 5-axis. When accuracy matters, this technology makes a measurable difference.

Improved Surface Finish

Smoother motion and better access to surfaces translate to cleaner cuts and fewer tool marks. Because there’s less need to stop and reposition the part, transitions between surfaces are more seamless.

I remember comparing two aluminum parts, one machined with 3-axis, the other with 5, and the difference in finish was night and day.

It’s one of those upgrades you notice right away.

Cost Efficiency

Upfront, the price of a 5-axis machine can be intimidating. But when you factor in labor savings, faster cycle times, and reduced scrap, the return is clear.

One client I worked with recovered their investment within 18 months just from increased throughput.

For operations that value long-term efficiency, the numbers often speak for themselves.

Versatility Across Projects

Whether you’re cutting a titanium bracket or sculpting a prototype from polymer, 5-axis machines adapt fast.

They can tackle a wide range of materials and part sizes without needing constant retooling.

Personally, I’ve seen shops use the same setup to handle aerospace brackets in the morning and custom tooling by the afternoon. That kind of flexibility makes it easier to say yes to more jobs without compromising quality.

4. Key Features to Look for in a 5-Axis CNC Machine

Shopping for a 5-axis CNC machine isn’t something you do on a whim. I’ve helped a few shops through the process, and I’ve learned that it’s not just about the specs.

Here are the features I always keep at the top of the list when making recommendations.

- Machine Configuration (Trunnion vs Swivel Head): Your choice here determines how the machine handles part movement. I’ve seen trunnion tables work great for complex undercuts, while swivel heads shine when space and part size are concerns.

- Spindle Power and Speed: A higher spindle power gives you the muscle for cutting harder materials, while speed helps with precision in lighter jobs. If you plan to run mixed materials, balancing both is key.

- Control System and Interface: An intuitive control system can save hours of training and reduce operator errors. I always suggest testing the interface firsthand if possible. It makes a bigger difference than people think.

- Tool Changer Capacity: The more tools your machine can hold, the fewer interruptions you’ll face during complex jobs. This is especially handy if you’re switching between parts or running varied programs.

- Table Size and Load Capacity: Make sure the table fits your largest expected part and can handle its weight. I’ve seen teams regret buying a machine that maxes out too quickly.

- Axis Travel Range: The physical travel range of each axis affects what geometries you can machine. More freedom here means fewer design limitations down the road.

- Cooling and Chip Management: Built-in coolant systems and chip conveyors save your operators a lot of cleanup and reduce tool wear. It’s a small detail that pays off fast on busy floors.

- Software Compatibility: Double-check that your current CAM software supports 5-axis toolpaths and is compatible with the machine’s controller. I’ve seen teams waste time and money fixing mismatches that should’ve been caught early.

5. Common Applications of 5-Axis Machining

5-axis machining isn’t just for niche use cases anymore.

The beauty of this technology is how adaptable it is across industries that demand complexity, precision, and reliability.

Below are four of the most common areas where 5-axis really proves its value.

Aerospace Components

The aerospace industry was one of the first to lean heavily into 5-axis machining, and for good reason. Many aerospace parts such as turbine blades, brackets, and housings require tight tolerances and intricate shapes that 3-axis machines simply can’t manage efficiently.

I’ve worked with suppliers who use 5-axis to produce parts that would otherwise require multiple fixtures and setups, which introduces room for error. With 5-axis, they can hold tight specs and reduce lead times at the same time. When you’re dealing with high-stakes flight hardware, that kind of control is essential.

Medical Devices and Implants

Few industries demand the precision that medical manufacturing does. Whether it’s a custom orthopedic implant or a surgical tool, 5-axis machining allows for complex shapes and fine detail with very little margin for error. One of my clients uses it to produce titanium spinal implants with intricate features that would be impossible with traditional setups.

The smoother surface finishes also help reduce post-processing, which is crucial when turnaround time can impact patient care. It’s one of those fields where quality can’t be compromised, and 5-axis delivers on that promise.

Automotive and Motorsports

In automotive and motorsports, 5-axis machines bring both speed and flexibility to the shop floor. From engine components to gearbox casings, the need for quick turnarounds and exact tolerances is constant. I’ve seen race teams use 5-axis to iterate design tweaks between events, something they could never do with slower, multi-step setups.

The ability to machine more faces in a single pass means fewer delays and better part consistency. Whether you’re building concept prototypes or production parts, the gains in efficiency and quality are clear.

Mold and Die Making

Mold and die work often involves curved surfaces, deep cavities, and fine details that push 3-axis limits. That’s where 5-axis machines shine, giving toolmakers the ability to cut complex forms without sacrificing precision.

I’ve toured mold shops where these machines run almost non-stop, producing tools that go into everything from consumer electronics to automotive interiors. With fewer setups and better access to tight angles, production becomes faster and more accurate. This is one application where 5-axis isn’t just helpful, it is quickly becoming the industry standard.

6. 5 Axis vs 3 Axis and 4 Axis: What’s the Difference?

When it comes to CNC machining, not all machines are created equal. I’ve worked with all three types, and the difference in performance, flexibility, and output can be massive depending on your parts, volume, and quality expectations.

| Feature / Capability | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

| Movement Axes | X, Y, Z (linear only) | X, Y, Z + 1 rotational (usually A) | X, Y, Z + 2 rotational (A and B) |

| Part Access | Limited to three sides per setup | Allows access to more sides with rotation | Full access to five sides in one setup |

| Setup Requirements | Multiple setups for complex parts | Fewer setups than 3-axis | Usually one setup for complex geometries |

| Precision Potential | Good for basic parts | Better than 3-axis with fewer repositioning steps | Excellent for high-precision, intricate work |

| Best Use Cases | Simple parts, basic geometry | Moderate complexity like gears, cams | Complex parts, undercuts, contoured surfaces |

| Speed & Efficiency | Slower with multiple re-clamps | Moderate improvement over 3-axis | Fastest due to one-pass completion |

| Learning Curve | Easiest to program and operate | Slightly more complex | Steeper learning curve, more programming skill needed |

| Software Needs | Basic CAM software | Moderate CAM capabilities | Advanced CAM with 5-axis support |

| Machine Cost | Lowest entry-level cost | Mid-range investment | Highest upfront investment |

| Operator Skill Level | Basic machining knowledge | Intermediate skill required | High-level skill, especially in toolpaths and collision control |

| Material Flexibility | Good for general materials | Works well with a wider variety | Best choice for exotic, hard-to-machine materials |

| Surface Finish Quality | May require post-processing | Improved over 3-axis | Excellent finish with minimal secondary work |

| Common Industries | General machining, education | Automotive, general engineering | Aerospace, medical, mold making, defense |

7. Tips for Transitioning to 5-Axis Machining

Jumping into 5-axis CNC machining isn’t something you want to do without a plan.

I’ve seen shops get overwhelmed by trying to scale up too fast, but with the right approach, the transition can go a lot smoother than you might expect.

Below are some key tips I always recommend when a business is adding 5-axis to their capabilities.

- Training: Make sure your operators and programmers understand the full range of motion, potential risks, and workflow differences with 5-axis systems. Even experienced machinists benefit from formal training when switching to this level of complexity.

- Start Small: Don’t go straight into machining complex aerospace parts on day one. Begin with simpler projects to get a feel for how the machine behaves and what adjustments need to be made to your process.

- Software Integration: Verify that your CAD/CAM software is built for 5-axis toolpaths and has features to prevent collisions and optimize tool movement. I’ve seen teams get stuck simply because their software wasn’t up to speed.

- Tooling and Fixtures: 5-axis machining often requires different tooling strategies and more advanced fixtures. Investing in the right setup early on will make your jobs more accurate and save time in the long run.

- Maintenance: These machines are complex and need consistent maintenance to stay in top shape. A proactive schedule will help prevent downtime and protect your investment.

- Collaborate with Experts: Don’t hesitate to reach out to consultants, application engineers, or your machine supplier. I’ve worked with a few teams who saved weeks of frustration by getting help upfront instead of waiting for something to go wrong.

Conclusion

I get it. The leap to 5-axis feels huge.

But now you’ve got the facts: the what, the why, the how. You’ve seen the benefits and how to make it work for your business.

And you don’t have to go it alone.

So tell me, what’s the one thing holding you back right now?

Break the barrier with MachMaster. Contact us today and let’s build precision into every part.