The first time I ran titanium through our shop, we chipped end mills faster than we could replace them. And that wasn’t even the worst part.

Our finish looked like it had been dragged down a gravel road.

That’s when I knew titanium wasn’t just another alloy.

Since then, I’ve worked with vendors, tool reps, and CNC programmers who specialize in titanium. What I’m sharing here is what we all wish we knew from the start.

This article walks you through the real challenges of titanium machining: heat, wear, rigidit, and shows you how to get clean cuts without killing your margins. If you’re in business, this is info worth reading.

So let’s get into it!

1. What is Titanium Machining?

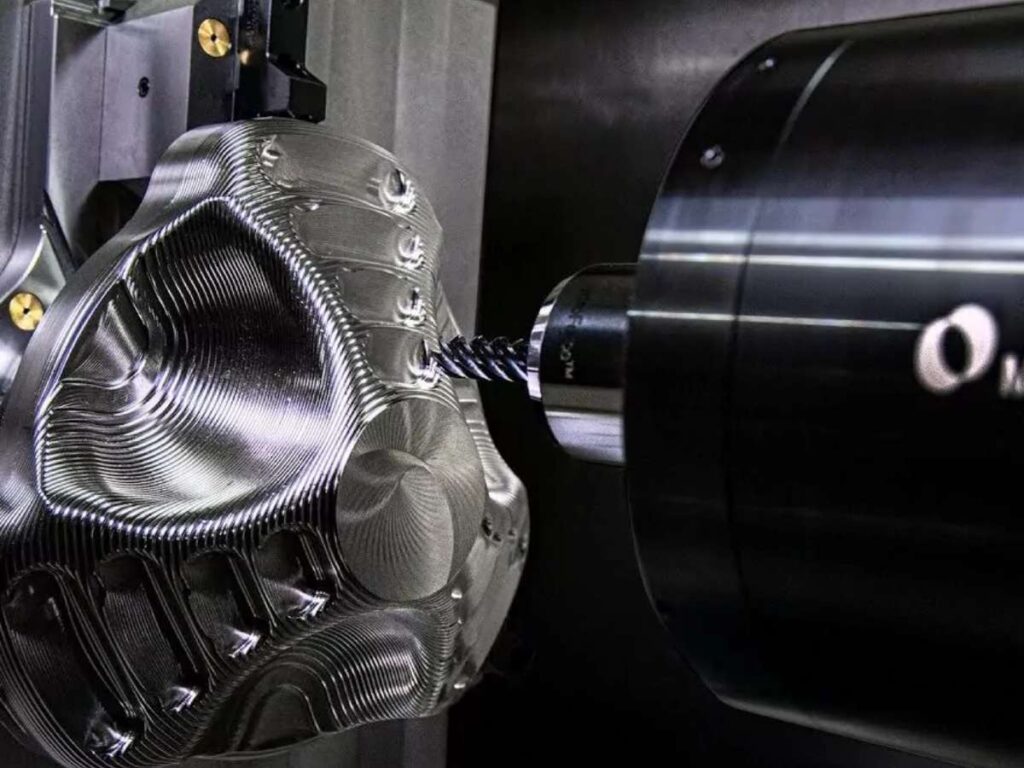

Titanium machining is all about shaping titanium, usually with CNC machines, sometimes with hand tools.

It shows up everywhere: in aircraft, medical implants, race cars, industrial equipment. Why? Because titanium is strong, super light, and practically immune to rust.

But here’s the catch: those same qualities make it a real pain to work with.

Titanium doesn’t like to let go of heat. While you’re cutting it, that heat doesn’t spread out. It builds up right at the tool’s edge. That leads to:

- Tools wearing out way faster

- Parts potentially warping or distorting

- More stress on machines and operators

- A steeper learning curve for everyone involved

On top of that, titanium is tough. It gets even harder as you work it. That’s called work-hardening. So you really have to know what you’re doing.

And as more industries chase lighter, stronger, better-performing materials, machining titanium isn’t just a specialty anymore.

It’s essential.

2. Advantages of Machining Titanium

I still remember the moment when we finally started getting clean, consistent results with titanium.

It felt like a turning point, like we had crossed into a new level of capability in the shop.

Before that, it was all trial and error, mostly error. But once you start understanding how titanium behaves, you realize just how much it has to offer.

Exceptional Strength Without the Bulk

Titanium brings incredible strength to the table without weighing you down like steel or other heavy metals.

This makes it a smart choice when you’re designing for performance, especially in industries where weight reduction matters just as much as durability.

I’ve seen parts that used to require reinforced steel swapped out for titanium, and they held up just as well while cutting overall mass. That’s a big deal when you’re trying to improve speed, fuel efficiency, or just make the entire assembly more manageable.

Outstanding Corrosion Resistance

One thing I’ve come to appreciate about titanium is how it just doesn’t give in when it’s exposed to the elements. Whether it’s saltwater, acid, or just constant humidity, titanium holds its own far better than many other metals I’ve worked with.

That means fewer replacements, less downtime, and a lot more confidence when your parts are going into tough environments.

Long-Term Durability in Critical Conditions

When we started machining titanium for high-heat applications, I realized just how stable and reliable it is under stress.

Some materials start to lose their integrity when temperatures rise, but titanium stays strong and holds its shape even in brutal operating conditions.

That reliability gives both us and our clients peace of mind, especially in aerospace or power generation projects.

Biocompatibility for Medical and Food Use

What really makes titanium stand out is how safe it is for use in medical devices and food processing.

It doesn’t trigger allergic reactions, it’s not toxic, and it naturally resists bacteria and contamination without needing any extra treatment.

I’ve worked with clients who needed implants and surgical tools that had to meet the highest safety standards, and titanium always checked every box. You can machine it into something that’s not just strong and durable but also trusted inside the human body.

Excellent Return on Investment Over Time

Titanium may feel expensive upfront, and I won’t sugarcoat it—tooling and setup take some fine-tuning. But over time, when you look at how long those parts last and how rarely they fail, the payoff becomes clear.

I’ve seen clients come back and thank us because the titanium components we made outlasted everything else in their system.

3. Common Grades of Titanium You’ll Work With

Here’s a chart that breaks down the most common grades of titanium you’ll encounter in machining.

Each grade comes with unique properties, so choosing the right one can make a big difference in part performance, tool wear, and machining strategy.

| Titanium Grade | Composition | Machinability | Common Uses |

| Grade 1 | Commercially pure | Good – softer and easier to cut | Heat exchangers, marine parts, chemical tanks |

| Grade 2 | Commercially pure with slightly higher strength | Fair – more strength but still workable | Piping systems, architectural applications, marine hardware |

| Grade 5 (Ti-6Al-4V) | 6% Aluminum, 4% Vanadium | Moderate – tougher, needs rigid setup | Aerospace, automotive, medical implants |

| Grade 9 (Ti-3Al-2.5V) | 3% Aluminum, 2.5% Vanadium | Better than Grade 5 – more forgiving | Sports equipment, aerospace tubing, bicycle frames |

| Grade 23 (Ti-6Al-4V ELI) | 6% Aluminum, 4% Vanadium (Extra Low Interstitials) | Similar to Grade 5 – used for delicate work | Surgical implants, dental tools, orthopedic devices |

4. Tools and Equipment for Machining Titanium

Back when we first started machining titanium, we tried using our standard tooling setup.

That didn’t go well.

The tools wore out fast, the heat built up quickly, and the finish was rougher than we expected. After a few painful mistakes, we learned that titanium needs a dedicated approach with the right gear.

- Use Coated Carbide Tools: Titanium loves to build heat, and standard tools won’t last long under that kind of stress. Go with carbide inserts or end mills that have high-performance coatings like TiAlN or AlTiN to reduce friction and resist wear.

- Invest in Rigid Machines: Titanium pushes back hard, and machines with weak spindles or loose setups just can’t handle the job. A rigid, high-torque CNC mill helps maintain accuracy and avoid chatter.

- High-Pressure Coolant Makes a Big Difference: Regular coolant setups just don’t cut it when you’re dealing with titanium’s heat. Through-spindle or directed high-pressure coolant systems help cool the cutting zone and clear chips fast.

- Short Tool Lengths Help With Stability: The longer your tools are, the more chance you’ll run into vibration and deflection. Keep your tools as short and sturdy as possible to maintain control and precision.

- Use Toolpaths That Spread the Load: Constant engagement strategies like trochoidal or dynamic milling help reduce spikes in pressure and heat. At MachMaster, these paths make cutting smoother and extend tool life noticeably.

- Strong, Vibration-Free Fixturing Is Essential: Titanium doesn’t forgive sloppy setups. Use heavy-duty fixtures that hold your part tight and steady, or you’ll be fighting vibration with every pass.

5. Finishing Techniques for Titanium Parts

After the last cut is made, the job isn’t over. I learned that the hard way when a batch of titanium parts came off the mill looking rough and inconsistent.

The structure was fine, but the surface needed serious work before it could ship out.

With titanium, finishing is just as important as the machining itself.

Deburring Without Damaging the Edges

Titanium tends to form tough burrs that can be stubborn to remove cleanly. Using simple deburring tools often isn’t enough, especially on tight corners or detailed features.

I’ve had good luck with ceramic abrasives and small rotary tools for precision work. For higher volumes, we’ve used abrasive blasting to speed things up while keeping part integrity intact.

Polishing for Smooth, Professional Surfaces

Getting a smooth, polished surface on titanium takes patience and the right materials. We usually start with medium grit abrasives and work our way up to fine polishing compounds.

It’s a slow process, but it brings out that clean, consistent finish clients love. When appearance or aerodynamics matter, this step can really set your work apart.

Anodizing to Boost Performance and Visuals

Anodizing isn’t just for aesthetics, even though the color options are pretty striking.

It actually helps improve corrosion resistance and adds a protective oxide layer to the titanium.

MachMaster uses it to color-code parts by batch or function, which helps with tracking and assembly. It also gives the final product a clean, high-end look that stands out.

Cleaning and Surface Prep Before Delivery

Titanium tends to hold onto oils and particles from the machining process, and those need to go before the part goes out the door. We use ultrasonic cleaning when we can, especially for smaller or more complex parts.

It makes a noticeable difference in final appearance and helps avoid rework or customer complaints.

A clean part just feels more professional and ready for action.

6. Preventing Common Titanium Machining Problems

Titanium doesn’t leave much room for guesswork. I remember one job where everything seemed fine, until the tool broke mid-cut and left a gouge right through the part. We realized later it was due to poor chip evacuation and a dull insert we should’ve replaced earlier.

Since then, I’ve made it a habit to flag these common problems early and plan around them.

Managing Heat and Tool Wear the Right Way

Titanium doesn’t conduct heat well, so the heat builds up fast right at the cutting edge. That’s where your tool starts to wear down, and once it goes dull, the cutting becomes more like rubbing.

We’ve had the most success using coated carbide tools and dialing back the spindle speeds while keeping feed rates steady.

High-pressure coolant also helps push the heat away from the cutting zone and out of your tooling.

Controlling Vibration and Chatter

The sound of chatter during a titanium job used to make my stomach drop, because I knew it meant surface damage or tool failure was coming.

Titanium’s resistance can throw your machine into vibration if your setup isn’t solid. We reduce this by keeping tools short, increasing clamping force, and tightening up tool paths with constant engagement strategies.

You want everything to feel locked in and quiet while it cuts.

Avoiding Work Hardening and Material Springback

If you’re not aggressive enough with your feed rate, titanium can start to harden at the surface while you’re still cutting.

That makes every pass harder than the one before and can shorten tool life fast. I’ve learned to avoid babying the cut—better to go in strong with sharp tools and steady feed than let the material fight back.

Springback is another issue, especially with thin parts, so always leave enough stock for a final cleanup pass.

7. Safety Tips When Machining Titanium

I’ll never forget the moment a titanium chip shot across the shop and hit the wall with a loud snap. That sound alone made everyone stop what they were doing.

Over time, I’ve picked up a few safety habits that help keep both people and equipment safe.

Handle Chips With Extra Caution

Titanium chips are long, sharp, and sometimes even hot enough to burn on contact. I’ve seen them curl like razors and fly off unpredictably if chip control isn’t dialed in.

We always use chip breakers, and if we need to remove chips manually, we do it with tools, never bare hands.

It only takes one slip to cause an injury.

Fire Risk Is Real With Fine Titanium Particles

Grinding or cutting titanium dry can create fine dust that’s more flammable than most people realize. That dust can ignite from a spark or even friction if it builds up too much. We keep all grinding wet when possible and always have Class D fire extinguishers nearby, just in case.

It’s a step we hope to never need, but we never skip it.

Always Use Proper Eye and Face Protection

Titanium jobs can throw chips faster and farther than you’d expect, especially with higher feed rates.

I’ve had chips bounce off machine guards and come right toward me during a finishing pass. That’s why everyone near the machine wears safety glasses and, in high-risk setups, a full face shield too.

It might seem like overkill until it saves your eyesight.

Maintain a Clean and Organized Work Area

Loose tools, tangled hoses, and scattered chips create unnecessary hazards in any machine shop.

But with titanium, where you’re dealing with sharp materials and high temperatures, clutter can make things go wrong fast.

We make a point to clean the area between each setup and keep coolant and debris under control. A tidy workspace makes it easier to focus, move safely, and react quickly when needed.

Conclusion

Remember how I struggled with our first titanium job? That part finally shipped. Flawless, durable, and right on spec.

Now you know what makes titanium tricky, but you also know how to beat it.

So what’s stopping you from leveling up your shop?

Contact MachMaster today for expert support and custom CNC solutions tailored to your exact needs.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.