Ever look at a manufacturing quote and think, Wait—what’s thread machining?

You’re not alone. The first time I saw that term, I had no idea what it meant. I just wanted my parts to screw together properly. But it turns out, threading isn’t one-size-fits-all—and getting it wrong can cost you more than you think.

I learned that the hard way.

This article will help you avoid that. You’ll learn what thread machining is, why it matters, and how to figure out which method is right for your project.

By the end, you won’t just know the term. You’ll know exactly what to ask for and why it matters.

So let’s start!

1. What Is Thread Machining?

Thread machining is the process of cutting screw threads into a part.

These threads can be internal (inside a hole) or external (on the outside of a shaft or rod). You’ve seen them everywhere. On bolts. On bottle caps. On pipe ends. Anywhere, two pieces need to screw together and stay connected.

It’s a small detail—but it makes a big difference.

You’ll find threaded parts in:

- Mechanical assemblies

- Pipe fittings

- Metal housings and enclosures

- Fasteners of all kinds

Without threads, a screw wouldn’t grip. A lid wouldn’t seal. A part wouldn’t stay together under pressur

Why Thread Machining Matters

The quality of the thread affects:

- How well parts fit together

- How much load they can handle

- Whether they stay tight over time

- If they can be reused without stripping

Poor threads can ruin a whole assembly. They might feel loose. Or jam. Or fail completely under stress.

Industries that rely heavily on thread machining include:

- Automotive: for engine parts and suspension components

- Aerospace: for high-precision, load-bearing fasteners

- Medical: for surgical tools and implants

- Consumer electronics: for casings and connectors

So if you’re ordering a part that needs to be screwed into something—or have something screwed into it—thread machining is a big deal.

2. How Thread Machining Works?

Thread machining is the process of making spiral grooves—called threads on or inside a part. These grooves let one part screw into another. It sounds simple, but the process behind it involves careful steps and the right tools.

There are two main ways threads are made: internal and external.

- Internal threads go inside a hole.

- External threads go around the outside of a rod or shaft.

Here’s how it works:

- Start with a part: This could be a metal block, a rod, or a tube—whatever your design calls for.

- Drill the hole (for internal threads): If you’re cutting inside threads, the first step is making the right-size hole. The size has to match the thread type. Too small or too large, and the threads won’t form correctly.

- Choose the thread cutting method:

- Tapping: A tool called a tap is twisted into the hole. The tap has cutting edges shaped like the thread. As it spins, it cuts the groove.

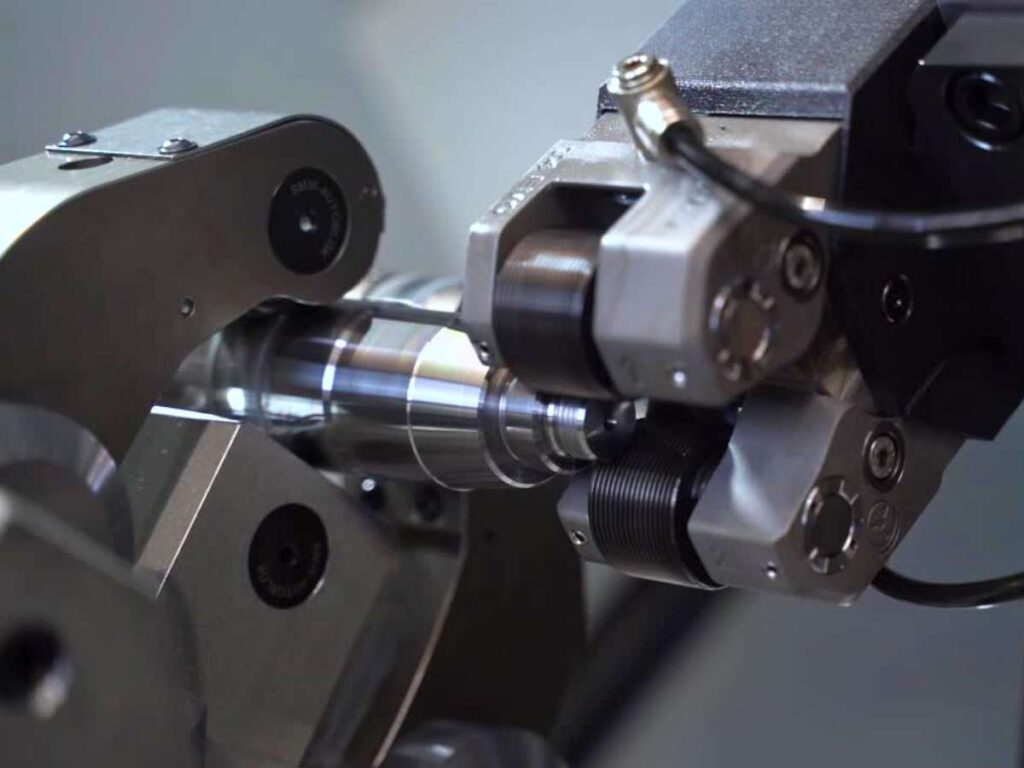

- Thread milling: A small cutting tool spins and follows a circular path. It cuts the thread shape gradually. This can be used for both internal and external threads.

- Single-point threading: This is done on a lathe. A cutting tool presses into the spinning part, carving out one thread at a time.

- Set the machine: CNC machines are often used. You load the part, set the tool, and run the program. The machine moves with precision, following the thread’s path.

- Check the result: After cutting, the threads are tested—either by using a gauge or screwing in a matching part.

Each thread must match the part it’s connecting to. The grooves need to be smooth, even, and the right size. That’s how you get a solid, reliable connection.

That’s thread machining—it turns flat material into parts that hold things together.

3. Types of Thread Machining Processes

Not all threads are made the same way. Depending on your part, your material, and how many pieces you need, different methods might be better suited.

Let’s look at the four main types of thread machining processes.

Tapping

Tapping is one of the most common methods. It’s used to make internal threads—the ones inside a hole.

Tapping is great if:

- You’re working with soft materials like aluminum or plastic

- You’re doing small production runs

- You’re working with a basic CNC setup or even by hand

But it does have some limits:

- It can be tough to remove chips

- You don’t have much control over the thread depth

Still, it’s simple and gets the job done when the job is simple too.

Thread Milling

Thread milling is a CNC-based process that works for both internal and external threads. It uses a rotating tool that cuts the thread as it moves in a spiral.

It’s a solid choice when:

- You’re working with hard materials like stainless steel

- You need cleaner chips

- You want more control over thread size and pitch

You’ll often see tools like solid carbide thread mills or indexable mills used here.

Single-Point Threading

This method is done on a lathe or mill. A cutting tool traces the thread shape while the part rotates.

It’s slower but perfect for:

- Large threads

- Custom sizes

- High-precision jobs

Industries like aerospace or mold making often rely on this method.

Die Threading

Die threading is used to cut external threads, usually on rods.

You’ll often find it:

- In home garages

- On repair benches

- Or in small-batch, low-speed setups

It’s simple and often done by hand, especially for quick fixes.

So what kind of thread do you need?

Choosing the right process can save time, improve fit, and make your parts work better for longer.

4. Design Tips for Better Threads

Good threads start with good design. So if you’re planning a part that needs threading, here are a few tips that can save you time, money, and frustration.

Pre-Drill Hole Sizes

Before cutting internal threads, you need to drill the right-size hole. This is called the tap drill size.

Here’s the deal:

- If the hole is too small, the cutting tool can jam or snap

- If it’s too big, the threads may strip or hold less weight

It helps to use a drill chart. You can easily find tap and thread mill charts online that match thread size with the right drill bit.

Take a moment to double-check before you start. It really makes a difference.

Thread Engagement Guidelines

So how deep should the threads go?

A general rule is this: Thread depth should be 1 to 1.5 times the diameter of the screw or bolt.

That’s usually strong enough for most jobs. Going deeper won’t always help and it just adds wear to the cutting tool.

For example:

- A 10mm screw needs around 10mm to 15mm thread engagement

Anything more? It’s likely overkill unless you’re working with very soft materials.

Avoiding Common Design Mistakes

Here are a few things I’ve seen (and done) that lead to trouble:

- Placing threads too close to a shoulder: This leaves no space for the cutting tool to exit

- Skipping thread relief: Without a small gap at the end, the tool can’t complete the thread cleanly

- Using the wrong tolerances: Too tight, and parts jam. Too loose, and they wobble

So before you send off that design, take a closer look.

Are the holes sized right? Is there enough thread length? Is the tool going to fit?

A few tweaks up front can lead to much smoother results down the line.

Need help with CNC-based thread milling or custom threads? MachMaster uses automated, high-precision systems to cut threads accurately and repeatably—even on complex part geometries.

5. Thread Standards You Should Know

I’ve been there. I once approved a part with the wrong thread standard just because I didn’t recognize the code. When the pieces didn’t fit, I had to remake the whole batch. That mistake taught me: knowing thread standards isn’t optional. It’s part of getting the job done right.

Here are a few of the most common thread types you’ll run into.

ISO Metric Threads

These are used all over the world, especially outside the U.S.

You’ll see labels like:

- M4

- M6

- M8

The “M” stands for metric. The number tells you the outer diameter in millimeters. So, an M6 thread is 6 millimeters wide. Simple, right?

Metric threads are easy to work with and widely used in consumer products and general engineering.

Unified Thread Standard (UNF/UNC)

This is the most common system in the U.S.

You’ll see it written like:

- ¼-20 UNC

- ⅜-16 UNF

Here’s what that means:

- The first number is the diameter in inches

- The second is the number of threads per inch

- UNC means coarse threads

- UNF means fine threads

These are used in everything from cars to appliances.

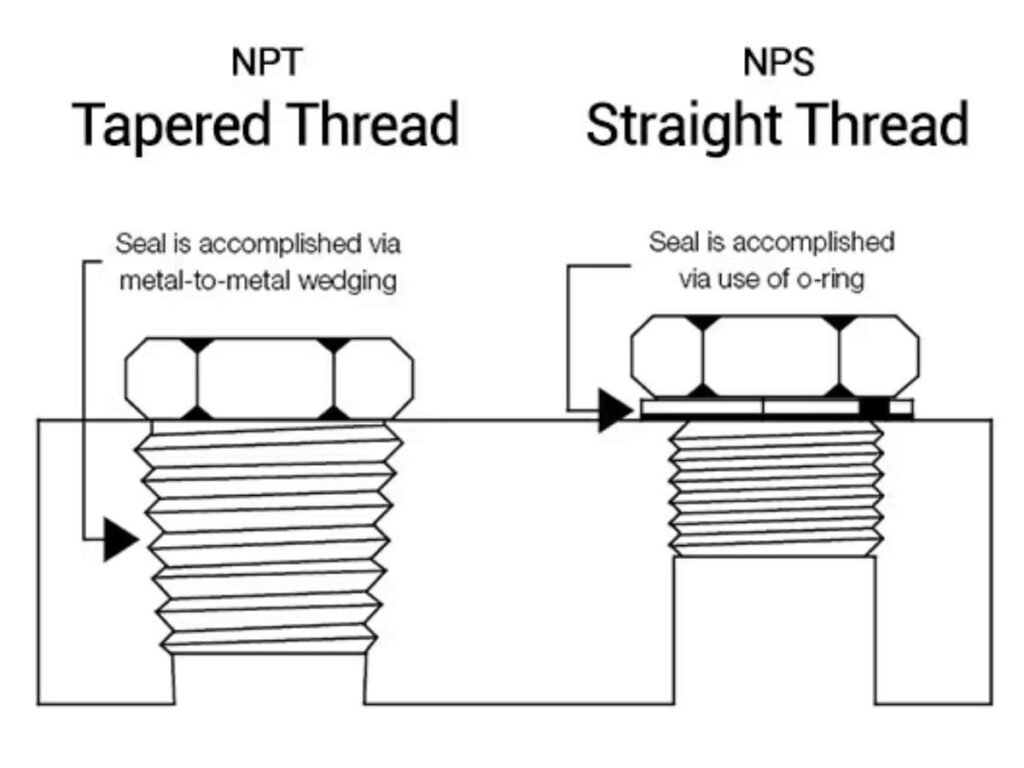

NPT and NPTF Threads

These are tapered pipe threads. They get tighter as you screw them in, making a seal.

Used for:

- Gas lines

- Hydraulic fittings

- Plumbing

NPTF threads are a tighter version that helps reduce leaks.

Custom Threads

Sometimes, standard threads won’t cut it.

That’s where custom threads come in. These include:

- ACME threads: flat-topped and strong

- Trapezoidal threads: used in machines for heavy loads

These are often used in lead screws, vises, and other high-force tools.

So before you choose a thread, stop and check: is it the right type for your job?

Knowing the standard helps you avoid mismatched parts, stripped threads, and extra costs.

6. In-House Threading vs. Outsourcing

Should you cut threads in your own shop? Or send the work to someone else? Both options have trade-offs. It depends on your budget, tools, skills, and deadlines.

Here’s a side-by-side look to help you decide:

| Feature | In-House Threading | Outsourcing Threading |

| Cost per part | Lower for high volume, higher for small runs | May be more affordable for low volume |

| Control | Full control over schedule and quality checks | Less control, depends on the supplier |

| Setup cost | High: needs machines, tools, training | None: no equipment needed |

| Lead time | Faster if you’re set up already | Slower, depending on vendor backlog |

| Skill required | Needs trained machinists or CNC programmers | You rely on their experience |

| Flexibility | Good for urgent changes or design tweaks | May require re-quoting or added costs |

| Tool maintenance | Your responsibility | Not your problem |

Still unsure?

Ask yourself:

- Do you have the equipment and people to do this right?

- Can you afford delays if the threads come back wrong?

- Will threading be a regular part of your production?

In my case, I’ve done both. Some jobs make sense to keep in-house. Others? I happily outsource to someone who does it better and faster.

Pick the option that fits your workflow and gives you confidence in the final part.

7. Common Thread Machining Problems and How to Avoid Them

Thread machining might look simple, but even small mistakes can cause big problems. I’ve seen threads that looked fine until someone tried to screw them in. Then came the stripped metal, broken tools, or just plain frustration. Sound familiar?

Here are a few common issues that show up, and how you can avoid them.

Chip Evacuation Issues

One of the biggest problems?

Chips are getting stuck in the hole.

When you’re cutting threads, especially with taps, the material you’re removing needs somewhere to go. If it stays trapped, it can:

- Snap the tool

- Leave rough, damaged threads

- Cause jams during assembly

Here’s what helps:

- Use spiral-flute taps. These push chips out of the hole.

- Or switch to thread milling, which creates smaller chips and clears them better.

I made this change myself after snapping one too many taps in a stainless steel job. It saved both time and tools.

Thread Tolerance Issues

Ever get threads that are too tight? Or so loose they rattle?

That’s a tolerance issue. Tolerance refers to how tight or loose the threads fit.

To get it right:

- Choose the correct thread class (like 2A/2B or 3A/3B)

- Use tools like pitch micrometers to check thread size as you go

Don’t skip inspection. It’s better to catch a mistake on the machine than after assembly.

Tool Breakage or Poor Surface Finish

Another common issue: dull or broken tools and threads that feel gritty.

Often caused by:

- Using the wrong cutting speed or feed rate

- Working with hard materials

- Skipping coolant or using the wrong cycle

Try these fixes:

- Add coolant or use pecking cycles to reduce heat

- Upgrade to higher quality tooling made for your material

Taking these steps helps you cut smoother threads and keep your tools in better shape.

Getting threads right isn’t luck—it’s knowing what to watch for and how to fix it before it costs you.

8. How to Choose the Right Thread Machining Method

Not sure which thread machining method fits your project?

You’re not alone. I’ve stood at that same crossroads, comparing options, trying to guess what would work best. And I’ve made the wrong call too—picking a method that slowed things down or gave me parts that didn’t fit.

Here’s a breakdown to help you figure it out based on what you’re working with.

Material Type

The kind of material you’re cutting really matters.

- Soft materials like aluminum or plastic: Tapping or using dies is usually enough

- Harder metals like stainless steel: Thread milling or single-point threading gives better results

I once tapped into a hardened steel block and snapped the tool in seconds. Lesson learned.

Thread Size and Tolerance

Tiny threads need a light touch.

- Small threads (like M2 to M6): Tapping or thread milling works well

- Large or custom threads: Go with single-point threading or thread milling for more control

If your parts need high accuracy, thread milling usually gives better precision.

Production Volume

How many parts are you making?

- High-volume production: Use tapping with a rigid holder to speed things up

- Low-volume or prototypes: Thread milling gives flexibility without needing a custom tap

For small runs, flexibility often matters more than speed.

Machine Type Available

Your equipment plays a big role too.

- Manual machines like drill presses or bench lathes: Stick with taps or dies

- CNC machines: Thread milling or single-point threading opens up more options and tighter control

Ask yourself: what do you have access to? What matters more—speed, precision, or simplicity?

Choosing the right method isn’t just about what’s available. It’s about what fits your part, your timeline, and your budget. Make the call that sets you up for success.

Conclusion

I still remember that part that didn’t fit.

It taught me a lesson: threads aren’t just grooves. They’re the difference between success and rework.

Now you know what thread machining is. How it works. The methods, the standards, the problems, and how to avoid them.

You’ve got what you need to make the right call—whether you’re buying parts, making them, or choosing a partner.

So where do you go from here?

Start asking the right questions. Start choosing with confidence.

Want to talk about your project? Contact MachMaster today.