I paid for the wrong machining process and I didn’t know it until it was too late.

The parts looked okay. But they didn’t fit right. The surface finish was off. And when I added up the rework and delays, it cost me more than I wanted to admit.

That’s when someone asked if I had considered Swiss CNC machining.

I hadn’t.

Maybe that’s where you are right now—trying to figure out if this process makes sense for your part or product.

In this guide, I’ll walk you through what I wish I had known earlier:

- What Swiss CNC machining is

- Why it works better for certain parts

- And how to tell if it’s right for you

By the end, you won’t be stuck wondering anymore. You’ll be able to make a clear decision—and avoid the kind of mistake I made.

So let’s start!

1. What Is Swiss CNC Machining?

I’ll be honest—when I first heard the term Swiss CNC machining, I thought it was just another way of saying “precision.” Like a fancy label. But once I saw the machine in action, I realized it’s a whole different process.

Swiss CNC machining is a type of precision machining. It uses a special kind of lathe called a sliding headstock lathe. That might sound technical, but here’s what it really means for you:

- The raw material (usually a metal bar) slides through a guide bushing.

- The cutting happens right next to that bushing.

- This setup keeps the material steady while it’s being shaped.

Why does that matter? Because it gives you better control, especially for small, long, or slender parts. If your part needs to hold a tight tolerance or has fine details, this method can make a big difference.

Swiss CNC machining was actually developed in Switzerland—originally for making watch parts. Tiny gears. Thin shafts. Complex shapes. These machines were built to handle that kind of precision.

2. How Swiss CNC Machines Work

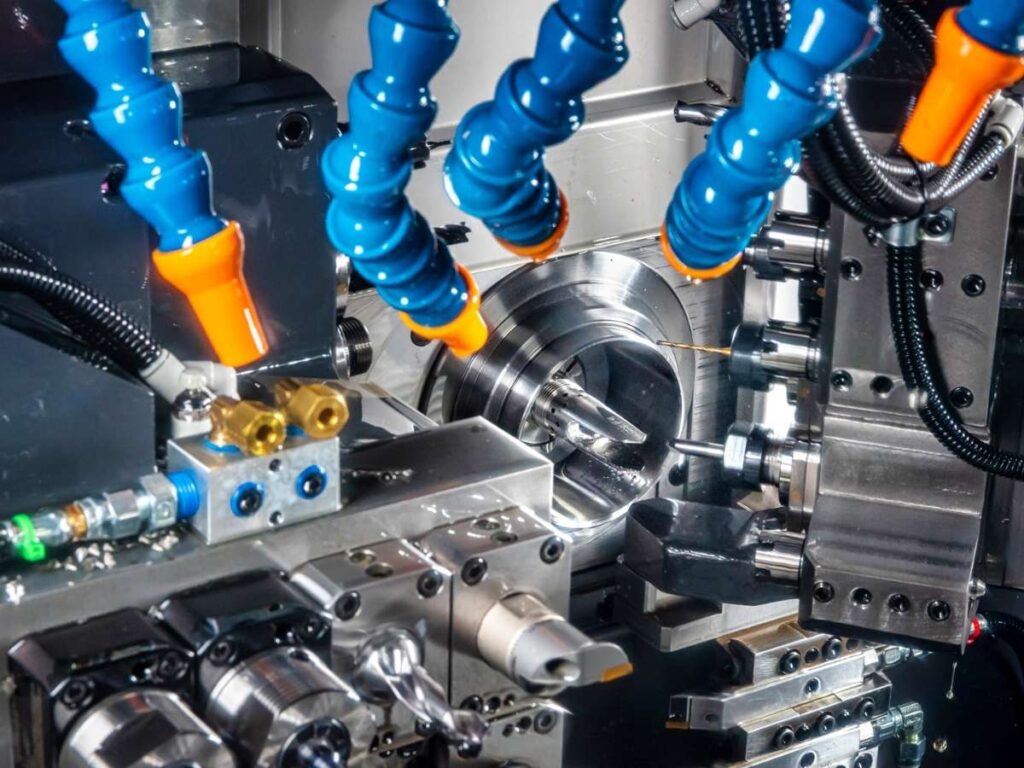

The first time I saw a Swiss CNC machine run, I was amazed by how smooth everything looked. But what’s actually going on inside?

Swiss CNC machines aren’t built like your standard lathe. They use a few key parts to pull off their precision.

Key Machine Components

- Guide Bushing: This is a support piece that holds the bar stock steady near the cutting tool. It reduces movement and keeps the part from flexing or bending.

- Sliding Headstock: Unlike traditional machines, the headstock here moves. It slides back and forth, pushing the material through the guide bushing as it gets cut.

- Sub-Spindle: This is a secondary spindle that grabs the part for extra operations. It can take over the work, so the main spindle is free to start the next part.

- Multiple Tooling Stations: Swiss machines are built to handle many tools at once. This means less downtime and faster cycles. You can turn, drill, and mill without stopping.

Process Flow

So how does it actually work?

Here’s a simple breakdown:

- A bar of material (called bar stock) is loaded into the machine.

- The headstock slides, feeding the bar through the guide bushing.

- As the material moves, cutting tools shape it—drilling holes, turning surfaces, or milling slots.

- Multiple tools work at the same time. That’s one reason Swiss machines are fast.

- Once the part is finished, it’s cut off near the collet or passed to the sub-spindle to complete back-end features.

The entire process is tight, controlled, and repeatable.

If you’ve ever had trouble with part movement or tool chatter, this setup can solve that.

3. Benefits of Swiss CNC Machining

When I first started pricing out production options, I thought all CNC machines gave similar results. But once I tried Swiss CNC machining, I saw the difference right away—especially on tricky, high-precision parts.

Let’s talk about why that matters for you.

Precision and Tolerances

Swiss CNC machines are known for holding very tight tolerances. That means your parts come out nearly identical every time. Why is that possible?

Because the guide bushing supports the material close to the cutting tool. Less vibration. Less movement. Less chance for the tool to drift.

If you’re dealing with thin or small parts, this setup can help avoid headaches. I’ve had parts that used to come out warped—until we switched to Swiss. After that, there were no issues.

Speed and Efficiency

These machines don’t just focus on precision—they’re fast too.

Here’s why:

- Multiple tools can be cut at the same time

- You can mill and turn in one setup

- There’s no need to move the part between machines

All of this leads to shorter cycle times, even for parts with complex features.

Need to hit a deadline without sacrificing quality? This helps.

Surface Finish and Reduced Secondary Operations

The finishes on Swiss-machined parts are often smooth right off the machine. No polishing. No grinding.

That means:

- Clean threads

- Sharp grooves

- Precise holes

All without extra steps. For me, this cuts down on inspection time and rework.

4. Design Tips for Swiss CNC Machining

When I first designed a part for Swiss machining, I went overboard. Tight angles. Deep grooves. Sharp undercuts. I thought I was being clever. But what I actually did was make it harder and more expensive to machine.

If you’re designing a part for Swiss CNC machining, here are some tips to make your life easier and your parts better.

Keep Geometry Simple

Swiss machines love clean, simple shapes. That doesn’t mean your part has to be boring. But avoiding overly complex features will make things smoother.

- Use straight or gently curved surfaces

- Avoid deep recesses that are hard to reach

- Stick to consistent shapes when possible

Watch Out for Undercuts

Undercuts are tricky. They often require special tooling, which can increase cost and setup time. If you don’t really need that groove or notch skip it.

If it’s a must-have, talk to your machinist early. I’ve found that a quick check-in can save hours later.

Use Consistent Diameters and Transitions

Try to keep diameters consistent. If your part does need changes in size, make the transitions smooth.

Why? Because sudden jumps in diameter are harder to machine cleanly. They also slow down cycle time.

Plan for Cutoff and Secondary Ops

Every part has to be cut off from the bar stock. If your design doesn’t allow room for that, it could create problems at the end of the process.

Also think about:

- How will the part be held?

- Is there space for back-side features to be machined?

These details matter more than you’d think.

The more you design with the machine in mind, the easier your part will be to produce. And trust me—it saves a lot of back and forth later.

5. Swiss CNC vs Standard CNC Machining

I used to think all CNC machines were basically the same.

But once I started working with smaller, more complex parts, I realized how wrong I was. Some jobs run fine on standard CNC lathes. Others failed completely—until we switched to Swiss.

Let’s look at the differences side by side.

Comparison: Swiss CNC vs Standard CNC

| Feature | Swiss CNC Machining | Standard CNC Machining |

| Material Support | Guide bushing holds material close to cutting tool | Material held at one end only |

| Part Type | Ideal for long, slender, or small parts | Better for short or larger-diameter parts |

| Precision | Very high; tight tolerances easily repeatable | High, but can vary with part length |

| Cycle Time | Faster for complex parts with simultaneous tools | Slower on complex parts with multiple setups |

| Tooling | Multiple tools working at once | Usually fewer tools operating at once |

| Setup Time | Longer due to tooling and alignment needs | Often quicker and simpler |

| Cost Efficiency (High Volume) | High—faster cycles, less rework | Moderate—good for short runs |

Knowing how these machines work will help you choose the right one for your part—and avoid problems before they start.

6. Limitations of Swiss CNC Machining

Swiss CNC machining is powerful. But it’s not perfect.

I’ve made the mistake of choosing it for the wrong kind of part. And honestly? It cost more than it needed to. That’s why it’s just as important to know when not to use it.

So, let’s talk about where this process might fall short for you.

Not Ideal for Large or Bulky Parts

Swiss machines are designed for small, slender parts. If your part is thick, wide, or heavy, it may not even fit in the machine.

Even if it does, you might not get the results you’re hoping for.

This process works best on:

- Pins

- Shafts

- Small cylindrical parts

If your design is more like a block than a rod, another method might suit you better.

Not Great for Extremely Low-Volume Runs

Swiss machining usually takes more time to set up. If you only need a handful of parts, it might not be worth it.

The setup time doesn’t pay off unless you’re making a larger batch.

For short runs, a simpler CNC lathe could get the job done faster and with fewer headaches.

Setup and Programming Can Be Complex

These machines can do a lot—but they make an effort to program. If you’re managing this in-house, expect:

- A steeper learning curve

- More time spent dialing in your first setup

- Possibly new tooling or workholding strategies

Swiss CNC machining is a strong option—but only if your part and your workflow match the process. Knowing where it doesn’t fit can help you avoid wasted time and cost.

7. What to Look for in a Swiss CNC Supplier

Finding the right Swiss CNC machining partner isn’t just about price.

I’ve worked with a few suppliers who promised precision—but couldn’t hit tolerances or meet deadlines. That experience taught me one thing: Ask better questions up front.

Let’s break it down.

Must-Have Capabilities

A good Swiss CNC supplier should have more than just machines. They need real experience and the right setup to match your needs.

Here’s what to check for:

- Certifications: ISO 9001 is a good start. If your parts are used in medical or aerospace applications, ask about industry-specific certifications too.

- Lights-out machining: This means the shop can run machines automatically, even overnight. It’s useful if you need consistent volume without delays.

- Material and geometry expertise: Your part might be simple. Or it might have tricky features. You want a shop that’s worked with similar shapes and metals before.

I’ve made the mistake of assuming any shop could handle any part. Trust me match experience to your design.

Questions to Ask the Supplier

Here are a few questions I always ask now:

- What machines do you use? (Look for names like Star, Tsugami, or Citizen.)

- What tolerances can you hold, and how consistent are they? (Ask for actual numbers and examples.)

- Do you give DFM feedback before quoting? (DFM means “design for manufacturability.” It’s feedback to help you avoid design issues.)

I’ve worked with suppliers who didn’t hit tolerances and others who went above and beyond.

MachMaster is one of the few that actually delivers both precision and support. From tight deadlines to complex parts, they’ve helped companies like mine get it done right the first time.

Conclusion

I learned the hard way that using the wrong process can cost you.

Swiss CNC machining gave me the precision, speed, and consistency I couldn’t get anywhere else.

So now it’s your turn.

Are you ready to stop guessing and start choosing the right process for your parts?

Take the next step. Ask questions. Get quotes. Start smart.

Need help deciding? Contact MachMaster today.