I once sent a stamped part drawing to a supplier and they quoted me double what I expected.

Why? Because I didn’t understand the process.

Turns out, I had added features that required multiple setups. More tooling. More time. More cost. And I didn’t know any better.

That mistake taught me something: if you don’t understand the stamping process step by step, you can’t control outcomes. Not cost. Not lead time. Not even quality.

If you’re reading this, you probably feel the same way. You want clarity. You want the full picture, from sheet metal to shipping box.

This article gives you exactly that. We’ll break it down together each stage, what happens, what to watch for, and why it matters.

And I promise: by the end, you’ll be confident enough to speak the language and ask the right questions.

So let’s start!

Metal Stamping Process: Step-by-Step Summary

Before you move forward, here’s a quick look at the full stamping process—from design to delivery. If you need a fast refresher or want to see how everything fits together, this table gives you the big picture at a glance.

| Step | Process Name | Process |

| Step# 1 | Design & Engineering | CAD models and drawings are created. Tolerances and DFM rules are applied. |

| Step# 2 | Tooling Design & Fabrication | Dies are designed and built. Includes progressive, compound, or transfer dies. |

| Step# 3 | Material Selection & Preparation | Choose material type, thickness, and coil size. Clean and feed into the system. |

| Step# 4 | Blanking (Optional) | Raw sheet or coil is cut into flat blanks if not using coil-fed dies. |

| Step# 5 | Stamping/Forming Operations | Includes punching, bending, drawing, coining, and embossing. |

| Step# 6 | Trimming & Piercing (if needed) | Removes extra material and adds precise holes or cuts not done in main die. |

| Step# 7 | Cleaning & Surface Finishing | Parts are cleaned, deburred, and treated (plated, coated, or painted). |

| Step# 8 | Quality Inspection | Visual, dimensional, and functional checks are done to confirm part quality. |

| Step# 9 | Packaging & Delivery | Parts are packed, labeled, and shipped with care to avoid damage. |

Step#1: Design & Engineering

Every stamped part begins with a solid design.

Before any tooling is built or material is cut, you need a clear plan. That starts with a CAD model—short for Computer-Aided Design. This digital file shows the shape of your part, the holes, the bends, and the final dimensions.

From there, the manufacturer creates detailed engineering drawings. These include:

- Dimensions

- Hole sizes and positions

- Bend lines

- Material specifications

- Tolerances

Tolerances tell the manufacturer how much variation is allowed. A hole listed as 10 mm ±0.1 mm means it can measure between 9.9 mm and 10.1 mm and still be accepted. If tolerances are too tight, it can increase your costs and slow down production.

That’s where Design for Manufacturability (DFM) comes in. DFM means shaping your part in a way that works well with the stamping process.

Here are a few key DFM tips:

- Keep surfaces flat when possible

- Avoid sharp inside corners—these cause stress and tool wear

- Make sure hole diameters are at least equal to the material thickness

For example: if your sheet metal is 3 mm thick, your holes should be no smaller than 3 mm wide.

I once forgot that last one. The result? A rejected drawing and an unexpected tooling charge. It was a quick reminder that small details matter—especially in stamping.

A thoughtful design doesn’t just help your supplier. It helps you avoid delays, rework, and extra costs.

Get this step right, and the rest of the process runs smoother.

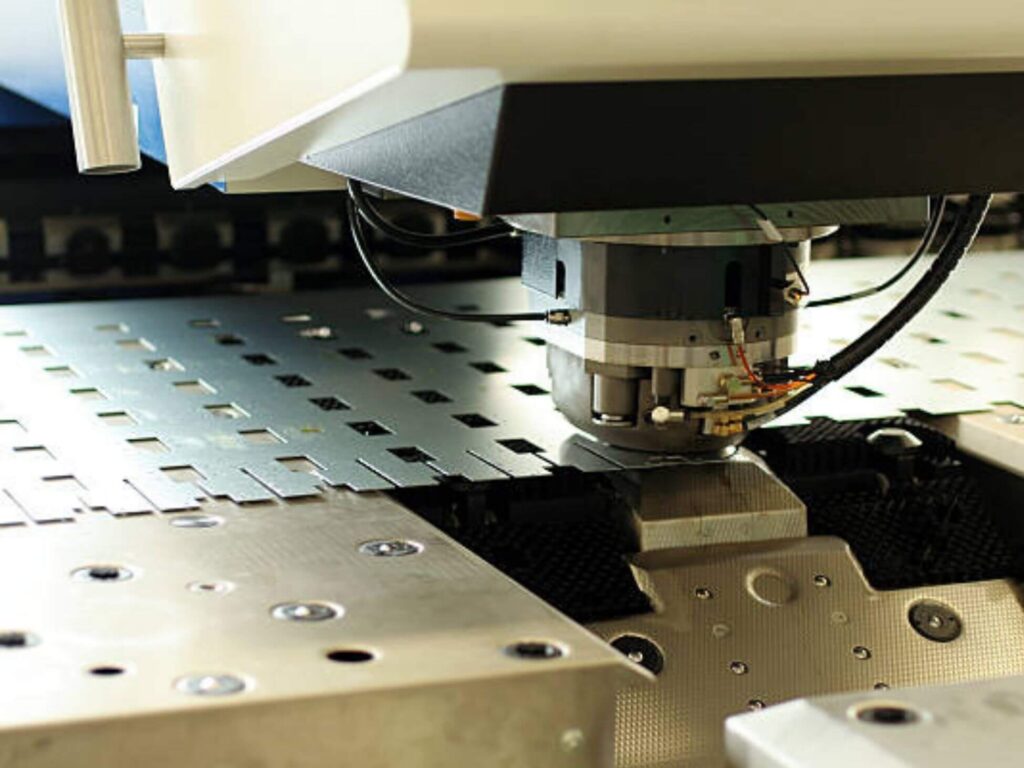

Step#2: Tooling Design & Fabrication

Once your part design is done, it’s time to build the tooling.

This step is critical. The tooling shapes your part. It also controls how accurate your part is—and how fast you can produce it. If the tooling is off, the entire production run suffers.

There are a few different types of dies used in metal stamping. Each works differently, and the right one depends on your part’s design and volume needs.

- Progressive die: This one runs in a single press. The metal strip moves through several stations, and each station does part of the work—like punching or bending. It’s fast and great for high-volume jobs.

- Compound die: All features are stamped in one stroke at a single station. It’s simpler but slower and best for flat parts with fewer features.

- Transfer die: Each station does one task, but instead of the strip moving through automatically, the part is transferred from station to station by mechanical arms. It’s used for deeper or more complex shapes.

Tooling is expensive. It also takes time to make often several weeks. If your design isn’t final, even a small change can throw the tooling off. That leads to delays, rebuilds, and added costs.

I once had a client approve a drawing, then ask for a small change after tooling started. That “small” change meant re-machining two cavities and delaying production by ten days. That part still makes me nervous when I think about it.

So here’s the rule: finalize your part geometry before tooling begins. If you’re still working out details, wait. You’ll save time and money in the long run.

Tooling is one of the biggest investments in the stamping process. Treat it like a foundation—because everything that comes next depends on it.

If you’re looking for a partner who can help design and produce custom tooling fast, MachMaster has you covered. We specialize in precision manufacturing with ISO 9001-certified systems and can support projects from trial to high-volume.

Step#3: Material Selection & Preparation

Once the tooling plan is in place, the next step is picking the right material and getting it ready to run.

Material choice affects everything. It shapes how the part bends. It affects the final weight, strength, and even cost. So it’s important to get this right.

There are three things you’ll usually need to decide on:

- Thickness: Thinner metal is easier to shape but may not hold up under stress. Thicker material offers strength but requires more tonnage to stamp.

- Grade: This refers to the metal’s specific type. For example, low-carbon steel is soft and formable, while stainless is harder and more corrosion-resistant.

- Coil size: Most stamping presses use material in coils. The width and weight of the coil must match the press and tooling setup.

After choosing the right material, it’s time to prepare it. That starts with cleaning or lubrication, depending on what your part needs. Some materials arrive with oil from the mill. Others need added lubricant to reduce friction during stamping.

Next is decoiling. The coil is unrolled and straightened. Then it’s fed into the press. This setup needs to be precise. If the feeder pulls too fast or too slow, the whole operation goes off track.

I remember watching a line shut down once because the decoiler wasn’t aligned right. The material bunched up at the entrance of the press, and we lost half a shift fixing it. Since then, I always double-check feed systems, especially on tight timelines.

So don’t skip this step. Material prep might seem basic, but it’s the difference between a smooth run and constant downtime.

The right material, fed the right way, sets you up for consistent, high-quality parts.

Struggling to match material specs with part needs? At MachMaster, we support you from material selection through to production, with ±0.01mm tolerance and experience across hundreds of material types.

Step#4: Blanking (Optional)

Blanking is a step you might need or might skip depending on how your stamping process is set up.

Here’s what blanking means: it’s the process of cutting raw sheet or coil into flat pieces, called blanks. These blanks are shaped like the outer edges of your final part, but without any bends, holes, or fine features.

Think of it like this: if your part were a cookie, blanking would be cutting out the shape before decorating it.

You’ll usually see blanking in two types of setups:

- When using transfer dies, where each blank moves through different stations for forming

- In low-volume production, where it makes more sense to work with separate blanks

- Or if the part shape is too complex to run directly from coil

On the other hand, blanking is often skipped if you’re using a progressive die with a coil-fed press. In that case, the coil feeds directly into the press, and each step happens in one continuous flow. No need to cut the metal into blanks first.

I once worked on a job that started with blanking, but later switched to coil-fed tooling to save time. It shaved almost two full days off production each week. But that only worked because the part design allowed it. If your shape doesn’t cooperate, you’ll need to blank.

So how do you know if blanking makes sense for you?

It depends on your part, your tooling, and your production volume. But if blanking is part of the process, it must be done precisely. If the blank is off, even by a little, the forming steps won’t work right.

Blanking might seem simple, but it plays a big role in making sure the rest of the process goes smoothly. It’s the setup before the real forming begins.

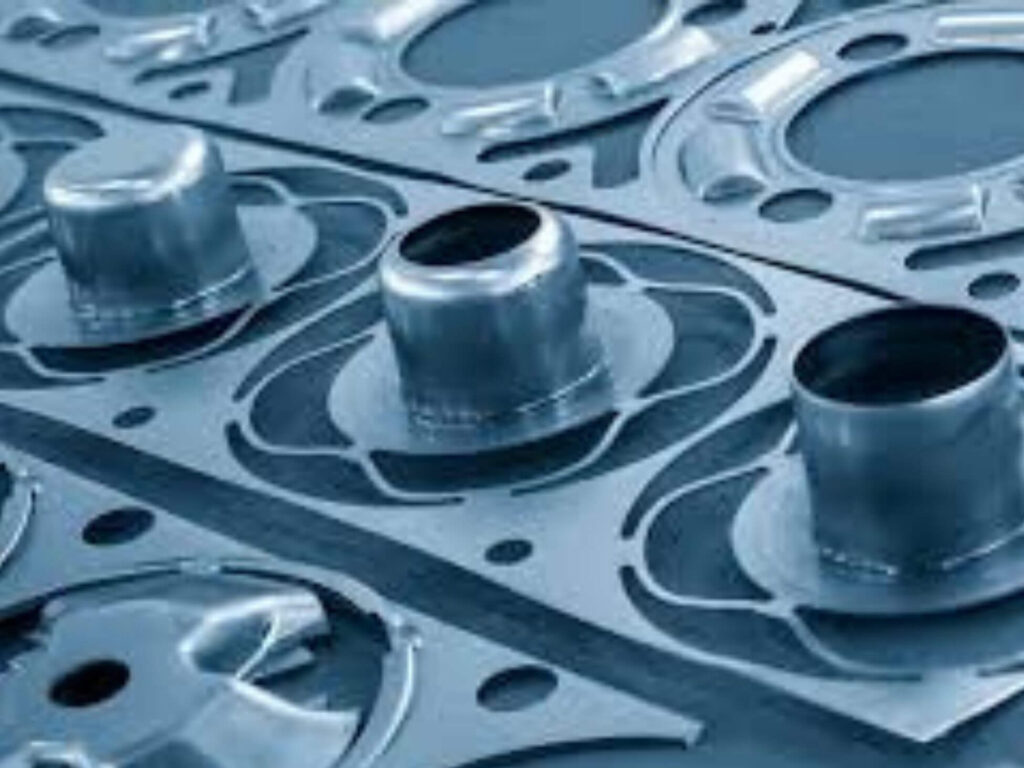

Step#5: Stamping/Forming Operations

Now we get to the part most people picture when they think of stamping.

This is where the flat metal finally starts to take shape. After feeding the blank or coil into the press, the stamping machine begins its job. It uses a die—built from the tooling you designed earlier—to shape the part through one or more forming operations.

Here are the main ones you’ll see:

- Punching: This step creates holes or cutouts in the metal. A punch pushes through the material, and the scrap falls away.

- Bending: The metal is forced into a new angle. This is how flanges, tabs, and corners are made.

- Drawing: This is used to pull the metal into a 3D shape, like forming a cup or box. It stretches the material into a deeper form without tearing it.

- Coining: A high-pressure press flattens or compresses specific areas of the part to create fine details or tighter tolerances.

- Embossing: This creates raised or indented features, usually for functional or decorative purposes—like part numbers or stiffening ribs.

Depending on the die you’re using, many of these steps can happen in a single press cycle. That’s one of the biggest benefits of a progressive die. The material moves through multiple stations, and each one does a specific job—like bending, then punching, then drawing. It’s fast and efficient.

I remember standing beside a progressive press for the first time. Watching raw coil turn into a finished part in seconds felt like magic. But I also saw how one misaligned punch could ruin the entire batch. Timing and precision matter here more than anywhere else.

This is the heart of the process. It’s where your flat sheet becomes something useful. And every stroke of the press brings you one step closer to a finished part.

Step#6: Trimming & Piercing (if not done in main die)

After forming, your part might look close to finished—but there’s often still work to do.

That’s where trimming and piercing come in. These steps clean things up. They remove extra material and fine-tune the part before it moves to finishing or assembly.

Trimming is used to cut off excess material around the edges. Sometimes, forming leaves a thin flap of metal called flash. This happens when material squeezes between the die halves during stamping. Trimming cleans that up and gives your part a clean edge.

Piercing adds any extra holes or cutouts that weren’t included in the main die. This is often done when the part shape is too complex to handle everything at once or when different features need tighter spacing or cleaner finishes.

Here’s what trimming and piercing might include:

- Cutting away flash from the part edges

- Adding mounting holes, slots, or notches

- Cleaning up edges for a better fit or appearance

- Adjusting tight features that need a second pass

Not all parts need these steps. If you’re using a progressive die with all features built in, trimming and piercing are often handled during the main press stroke. But in many cases—especially with transfer dies or complex shapes—these steps happen separately.

I once worked on a bracket that looked fine after forming. But when we skipped the final trim pass, the mounting edge had burrs. They caused problems during assembly. We had to go back and run the whole batch through a secondary trim die just to get clean edges.

So don’t overlook this step. It might feel like cleanup, but it plays a big role in final quality.

A part that looks finished isn’t always ready—trimming and piercing often give it that last bit of precision.

Step#7: Cleaning & Surface Finishing

After stamping, your part is formed, trimmed, and shaped—but it’s not done yet.

Stamped parts often come off the press with sharp edges, leftover oil, or visible marks. That’s why cleaning and surface finishing are an important final step.

The first task is usually deburring. Deburring removes tiny, sharp bits of metal left along the edges after cutting or forming. If these aren’t removed, they can cause injuries, damage nearby parts, or make the part hard to assemble.

Depending on the part, deburring can be done by:

- Tumbling

- Grinding

- Polishing

- Vibratory finishing

Next comes cleaning. During stamping, parts pick up lubricants, metal flakes, and dust. These need to be removed before any surface treatment is applied. Cleaning is usually done with solvents, ultrasonic baths, or industrial washers.

Then you have surface finishing. This step protects the part and can also improve its appearance.

Common surface finishes include:

- Plating: A thin layer of metal (like zinc or nickel) is added to prevent rust or improve conductivity.

- Coating: Paints or powder coatings give color and corrosion resistance.

- Anodizing (for aluminum parts): Add a hard, protective layer.

I once skipped the cleaning step before coating a batch of steel clips. The result? The paint peeled within days. We had to strip and re-coat every single part. It was a costly mistake and one I don’t repeat anymore.

The cleaning and finishing step might feel like an afterthought, but it has a real impact. It protects your part, makes it safer to handle, and gets it ready for the next stage—whether that’s packaging, assembly, or final use.

Step#8: Quality Inspection

Once your part is formed and finished, it’s time to check if it meets your specs.

This is where quality inspection comes in. It’s the last step before the part moves to packaging, shipping, or assembly. If you have a problem here, you can still fix it. But if you miss it, those problems carry forward.

Inspection usually starts with a visual check. This means looking for obvious issues:

- Surface scratches

- Dents

- Burrs

- Missing features

- Finish defects

After that comes dimensional inspection. This checks the part’s size and shape. You can use:

- Calipers for measuring thickness, hole sizes, or flange lengths

- Go/no-go gauges for checking fit

- CMM (Coordinate Measuring Machine) for more precise or complex parts

If the part is meant to perform a task—like snap into place or hold weight—then a functional check may be added. That might mean testing a bend, checking alignment, or seeing if the part fits in an assembly.

I remember once skipping the functional check on a stamped tab. It looked fine, passed all the measurements, but didn’t fit into the bracket during final assembly. We lost a full day figuring it out. That mistake stuck with me.

One more thing to keep in mind: inspection frequency matters in mass production. Checking one part out of a thousand isn’t enough. Most shops use sampling plans—like checking one part every 50 units—or run inline checks with sensors and cameras during the press run.

You don’t need to inspect every part by hand. But you do need a system to catch problems early, before they pile up.

Good inspection is the safety net. It’s how you protect your project—and your reputation.

Step#9: Packaging & Delivery

Once your parts are done and pass inspection, the final step is getting them to you safely.

This part might feel simple, but it’s more important than most people think. A great part can still arrive damaged if the packaging isn’t right. And that damage can cost time, money, or even your customer’s trust.

Most stamped parts need custom packaging. This helps prevent scratches, dents, or bending during shipping. The right packaging depends on the part. For flat parts, layers of foam or paper between each piece work well. For formed or sensitive parts, trays or custom inserts help protect the shape.

Next is labeling. Every box, and sometimes every part, should be labeled clearly. Labels usually include:

- Part number

- Revision level

- Quantity

- Lot or batch number

This makes traceability easier. If there’s ever an issue, you can trace that part back to the batch, machine, or date it was made.

Storage and transportation also matter. You’ll want to think about:

- How long the parts will be stored

- Whether they need protection from rust or moisture

- How heavy the packaging is

- How many units fit in a box or on a pallet

I once received a batch of stamped brackets packed in plain cardboard—no wrapping, no separators. Every piece had scratches. They looked used. We had to return them and wait for a re-run. Ever since, I’ve been picky about packaging plans.

This step matters to procurement professionals, who want reliable supply chains. And it matters to personal buyers, who just want their parts to arrive clean and usable.

Getting the part made is only half the job. Getting it delivered right? That’s how you finish strong.

Conclusion

You’ve now seen the full stamping process step by step.

From design and tooling to forming and delivery, each step connects. Each one shapes your results.

I started this article with a mistake. A drawing I didn’t fully understand. It cost me time, money, and confidence. But now? I know what to ask. What to look for. And how to avoid costly surprises.

You can too.

Start now. Use this guide as your map. Revisit each section whenever you feel stuck.

Need help getting started? Contact us today.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.