It was 10:47 p.m. when my phone rang. A client was on the line panicked.

Their stainless steel parts had just warped during final inspection. They had a tight deadline, and their current supplier had no answers.

That night, I walked them through what went wrong and what should’ve been done differently from the start.

I’ve spent years in CNC machining. I’ve worked with stainless steel in all forms 304, 316, 17-4, you name it. I’ve seen what works, what breaks tools, and what quietly wastes your money.

If you’re here, you’re probably asking: Is stainless steel the right material for my project? Will it hold up? Will it cost too much?

This guide helps you answer those questions.

You’ll learn how stainless steel behaves under a CNC tool, which alloys are best for your needs, and how to weigh cost, precision, and lead times.

By the end, you’ll be able to decide technically, economically, and practically if stainless steel CNC machining is the right path for your part or product.

So let’s get down to it!

1. What Is Stainless Steel in Machining?

When I first cut stainless steel, I thought I knew what I was doing. But the tools wore out fast. The finish looked rough. And the machine ran hot. That day taught me stainless steel isn’t just another metal.

Stainless steel is an alloy. That means it’s made from iron mixed with other elements. The key one is chromium. If there’s at least 10.5% chromium, the metal forms a layer that protects it from rust. That’s what makes it “stainless.”

You’ll see stainless steel in many CNC jobs. It’s tough. It lasts. And it holds up in tough places wet, hot, or full of chemicals.

At MachMaster, we work with stainless steel every day. Whether it’s a bracket for a surgical device or a shaft for an automation system, we’ve learned how it behaves and what it takes to machine it right.

- High strength and corrosion resistance: Stainless steel is strong. That makes it good for parts that need to take pressure or wear. It also resists rust great for medical, food, or outdoor use. You don’t have to worry about it breaking down fast.

- Work hardening properties: This one can catch you off guard. As you cut stainless, the surface gets harder. It’s called work hardening. If you slow down or take light passes, your tools dull fast. I learned this the hard way. You’ve got to stay sharp literally and figuratively.

- Heat resistance and wear resistance: Stainless handles heat. That’s good for the part but bad for the tool. The heat builds up fast during machining. If you don’t cool it right, your tool won’t last long.

Stainless steel is used across many fields. Here are a few:

- Medical: implants, surgical tools, hospital equipment

- Food processing: mixers, tanks, and any part that touches food

- Aerospace and automotive: brackets, engine components, housings

- Marine and outdoor applications: boat parts, fasteners, gear exposed to water

I’ve helped make parts for all of these industries. Stainless steel stands out when you need durability, safety, and long-term performance. That’s why so many teams still choose it today.

2. Advantages of Stainless Steel CNC Machining

I’ve worked with a lot of materials—aluminum, plastics, brass. But stainless steel? It’s in a league of its own.

It’s not always the easiest to machine, but when done right, the results are worth it.

If you need a part that lasts, holds up under stress, and still looks sharp, stainless steel might be the right choice.

Key Benefits

- Excellent strength-to-weight ratio: Stainless is strong but doesn’t add too much bulk. Great when you need solid parts that aren’t overly heavy.

- Long-term durability: I’ve seen stainless parts still running after years of use. They don’t bend, rust, or break easily. That means fewer replacements and more uptime.

- Superior surface finish after machining: With the right setup, stainless can come out smooth and shiny. This helps when the part needs to be visible or touched often.

- High temperature and chemical resistance: Heat, cleaners, and even acids won’t wear it down easily. That’s why it’s used in food plants, hospitals, and engine bays.

- Aesthetic appeal for visible parts: Sometimes the finish matters as much as the function. Stainless gives a clean, professional look without extra coating.

Why CNC Is Ideal for Stainless Steel

- Precision control for tough materials: Stainless steel is strong, but CNC machines can handle it. You get clean cuts and accurate features—every time.

- Repeatable, accurate results: Whether you need 5 parts or 5,000, CNC keeps them consistent. That’s key when tolerances matter.

- Flexibility in part complexity and batch size: I’ve made small runs of complex parts and big batches of simple ones. CNC handles both. You don’t have to choose between detail and volume.

If you’re wondering whether stainless steel is worth the effort, here’s the truth: It lasts longer, performs better, and makes your final product look sharp. And with CNC, you get control and repeatability to do it right.

3. Types of Stainless Steel Used in CNC Machining

I remember a project where we used the wrong stainless grade. Looked fine at first. But during machining, the tools wore out fast. Then the part started rusting after just a few weeks. That job taught me something important: not all stainless steel is the same.

Each grade has its own strengths and tradeoffs. If you’re planning a CNC job, knowing which type to choose can save you time, money, and frustration.

Austenitic Grades (e.g., 304, 316)

- Non-magnetic and highly corrosion-resistant

- Good for medical tools, food equipment, and marine parts

- 304 is more common and lower-cost

- 316 costs more but resists chemicals better great for saltwater or harsh cleaners

- Machinability: Fair, but work hardens easily. Use sharp tools and don’t dwell too long.

- Example parts: Mixing bowls, boat railings, surgical trays

I use 304 and 316 a lot. They’re reliable. If rust is a concern, you can’t go wrong with these.

Martensitic Grades (e.g., 410, 420)

- Magnetic, hard, and heat-treatable

- Not as corrosion-resistant as austenitic types, but much stronger

- Great for parts that need to hold an edge or take wear

- Machinability: Better than 304 and 316, especially when softened

- Example parts: surgical scissors, pump shafts, knives

If you’re making parts that need to stay sharp or resist impact, martensitic grades are a solid choice.

Ferritic Grades (e.g., 430)

- More affordable than austenitic grades

- Good corrosion resistance, but not as strong under heat or stress

- Less ductile, which means it doesn’t bend as easily

- Machinability: Easier to cut than 304

- Example parts: Car trim, appliance panels, fan housings

I usually see 430 in automotive and household parts. It’s a budget friendly option if the job doesn’t need extreme strength.

Precipitation-Hardening Grades (e.g., 17-4PH)

- Very strong, with good corrosion resistance

- Can be heat-treated for even more strength

- Great for aerospace, military, and precision parts

- Machinability: Surprisingly good for how strong it is

- Example parts: Valve bodies, helicopter components, firearm parts

17-4PH is my go-to for high-performance parts. It’s strong, stable, and holds tight tolerances.

Picking the right stainless steel grade isn’t just about strength or price it’s about matching the material to the job. If you get that part right, the rest of the process runs smoother.

4. CNC Machining Processes for Stainless Steel

The first time I tried to machine stainless steel like aluminum, I ruined two tools in under 10 minutes. The heat built up fast. The finish was terrible. The part warped.

That’s when I realized: stainless steel needs its own approach.

It’s not just strong it’s tricky. It work-hardens, it holds heat, and it pushes back if your setup isn’t right. But once you understand how to handle it, it machines clean and consistent.

At MachMaster, we’ve refined our process for stainless over the years. Every step from tool choice to coolant strategy makes a difference. And when we follow it right, the results speak for themselves.

Common Machining Techniques

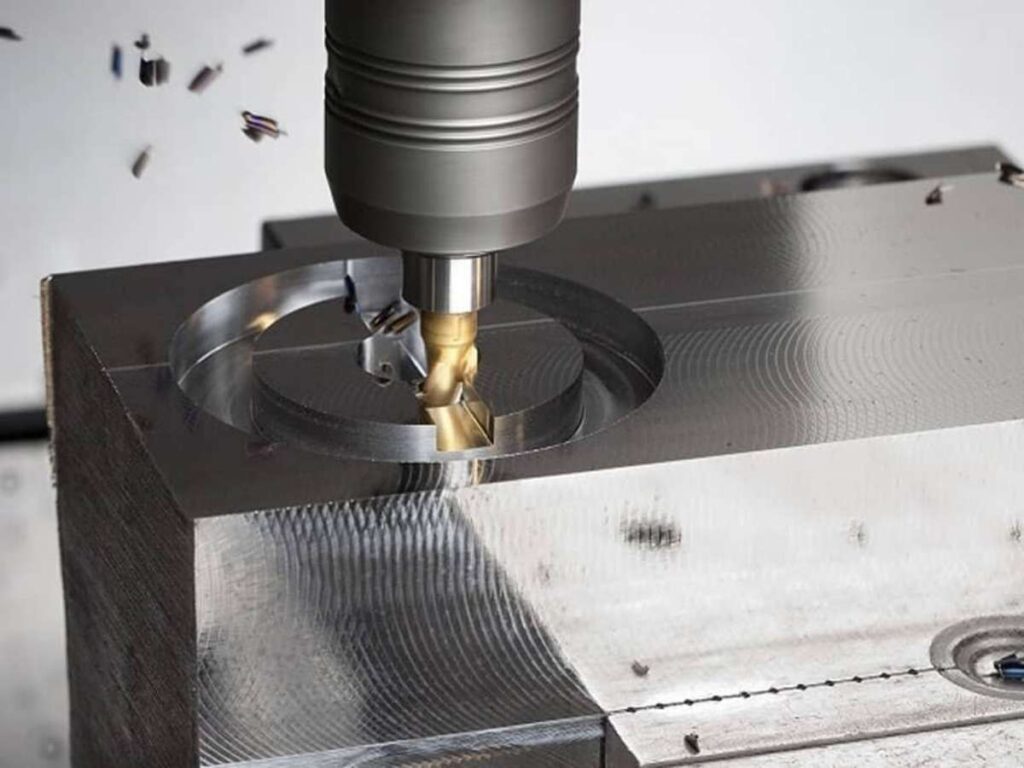

CNC Milling:

- Best for: pockets, slots, and complex shapes

- Great for parts with multiple faces or fine details

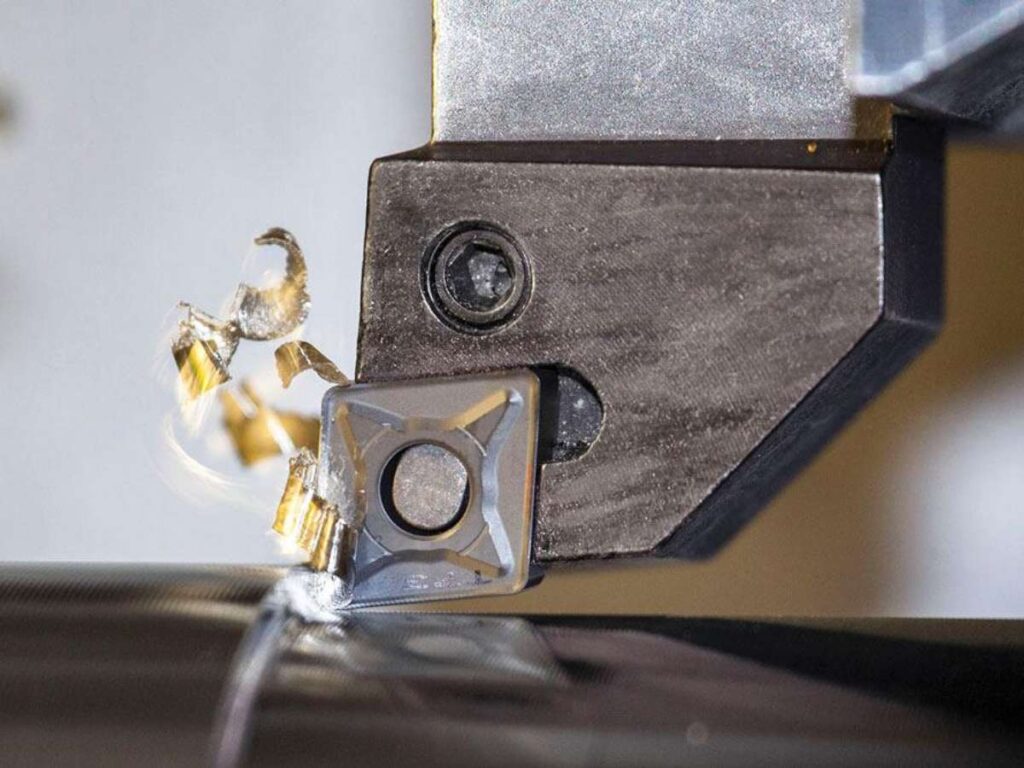

CNC Turning:

- Best for: round or cylindrical parts like shafts, pins, and bushings

- Offers a good surface finish and tight tolerances

Drilling:

- Use carbide coated drill bits

- Run at lower speeds to prevent heat build-up

- Clear chips regularly to avoid jamming

Tapping and Threading:

- Stainless is sticky it grabs taps and breaks them if you’re not careful

- Always use lubrication

- Back the tap out to break chips and reduce tool stress

Tooling Tips

- Use carbide tools: They last longer and handle stainless better than high-speed steel.

- Apply coolant continuously: Stainless builds heat fast. Coolant keeps the temperature down and helps the tools last.

- Use rigid setups: Any flex causes chatter, which ruins the finish. Keep your part clamped tight.

Feeds and Speeds (General Guidance)

For Roughing Passes:

- RPM: 400 to 800

- Feed: 0.04 to 0.1 in/rev

- Depth of cut: 0.05 to 0.08 in

For Finishing Passes:

- RPM: 800 to 1200

- Feed: 0.01 to 0.03 in/rev

- Depth of cut: 0.01 to 0.03 in

Tips to Remember:

- Keep RPM lower than you would for aluminum

- Don’t feed too slow it causes work hardening

- Take shallow passes to control heat and tool wear

I’ve learned these numbers through trial, error, and lots of broken tools. You’ll fine-tune things based on your machine and material grade. But once you get it dialed in, stainless steel machines beautifully.

5. Applications of Stainless Steel CNC Parts

If you’ve ever held a stainless steel part in your hand smooth, solid, and clean you’ve probably thought, “This thing’s made to last.”

And it is.

I’ve made stainless parts for all kinds of industries. Some were small, like a watch case. Others were critical, like a surgical implant.

What they all had in common? They needed strength, precision, and durability.

Industry

Medical

- Parts: Bone screws, surgical handles, dental implants

- Why stainless: Cleanliness and corrosion resistance

- Grade used: 316 and 316L (low carbon)

- These grades are non-magnetic, easy to sterilize, and biocompatible. I’ve worked on surgical components that had to pass strict cleanliness checks stainless passed every time.

Aerospace

- Parts: Mounting brackets, structural clamps, custom fasteners

- Why stainless: High strength and heat resistance

- Grade used: 17-4PH

- I’ve seen this grade used in high-stress areas where failure isn’t an option. It’s tough, heat-treatable, and machines well for a hard alloy.

Automotive

- Parts: Fuel rails, exhaust flanges, sensor housings

- Why stainless: Can handle heat, pressure, and fuel exposure

- Grade used: 304 or 409

- In one project, we machined flanges for a turbo setup using 304. They ran hot, but held shape perfectly.

Consumer Products

- Parts: Watch casings, kitchen tools, outdoor gear

- Why stainless: It looks good, resists rust, and doesn’t wear out easily

- Grade used: Often 430 or 304

- I once made a custom pocketknife using 420 stainless steel . It polished up beautifully and held an edge.

Why Use This

- Hygiene: In food and medical work, rust or bacteria isn’t an option. Stainless gives a clean surface that’s easy to sanitize.

- Strength: In cars and planes, parts face stress, heat, and vibration. Stainless holds up.

- Weather resistance: For outdoor gear or marine parts, stainless doesn’t corrode like regular steel.

If you’re making a part that needs to last, look sharp, or stay clean, stainless steel might be your best option. It’s what many industries rely on because it works.

6. Limitations and Challenges in Stainless Steel CNC Machining

Stainless steel gives you strength, durability, and a clean finish.

But it’s not all smooth sailing.

I’ve worked on jobs where the material pushed back hard literally. Tools wore down fast. Parts didn’t hold tolerances. Costs crept up.

Work Hardening

This is one of the biggest issues with stainless steel.

- The more you cut it, the harder it gets

- If your feed is too slow or you pause mid-pass, the surface toughens

- This leads to tool breakage, warping, or parts that come out undersized

I’ve had entire runs go off-track just because the cutter sat too long in one spot. To avoid this, I always keep cuts steady and tools sharp.

Tool Wear

Stainless steel is tough on tools without sugarcoating it.

- Wears down faster than aluminum or plastic

- Carbide or coated tools are a must

- Tool changes happen more often, especially in larger batches

I’ve learned to keep backups ready and track tool wear carefully. It’s better to swap early than risk a failed part halfway through the cut.

Heat Generation

Stainless holds heat more than it lets it go. That creates problems fast.

- Heat builds up at the cutting edge

- Tools can dull, burn, or even snap

- Part surfaces can discolor or warp from trapped heat

To fight this, I use constant coolant—flood or high-pressure mist. Without that, the job gets risky.

Cost Factors

Stainless steel is more expensive all around.

- Higher material cost

- Slower machining speeds

- More tool wear and setup time

But that doesn’t mean it’s a bad choice. You just need to plan for it.

One thing that helps? Working with a vendor who knows stainless. Ask for DFM (Design for Manufacturability) feedback. Even small tweaks like adjusting corner radii or reducing depth can save hours of machining and bring the cost down.

7. How to Choose the Right Stainless Steel for CNC Machining

I’ve had customers hand me a drawing and say, “Just make it in stainless.”

But not all stainless steel is the same. And choosing the wrong one can cost you time, money, and performance.

If you’re not sure where to start, don’t worry.

Define the Application

Ask yourself: What does the part actually do?

- Is it a load-bearing bracket?

- A cover plate that just needs to look good?

- A precision part that needs tight tolerances?

The job your part needs to do should guide everything else. A fuel injector and a mixing bowl don’t need the same type of stainless.

Assess the Environment

Where will the part be used?

- Wet or salty areas? You’ll want corrosion resistance (think 316).

- Food contact? Look for food-safe grades like 304 or 316L.

- High temperatures? Go with grades like 309 or 17-4PH that can take the heat.

One client of mine used 304 in a marine job. Looked fine until the saltwater hit it. We had to remake the batch in 316.

Check Mechanical Needs

Does the part need to flex, resist wear, or take impact?

- For high strength, look at 17-4PH or 420.

- For ductility (ability to bend without breaking), 304 is a good pick.

- For hard edges or cutting tools, go with martensitic grades like 410 or 420.

Factor in Machinability

Is the part simple or complex? Are you making just a few or a few hundred?

- Austenitic grades (like 304) are tougher than machines.

- 17-4PH and 430 offer better machinability for complex jobs.

If you’re running high volumes, pick a grade that cuts cleaner and doesn’t wear tools fast.

Match Budget and Timeline

Finally, balance performance with cost.

- 316 is more expensive than 304 but may be worth it for corrosive jobs.chmaster

- 430 is cheaper and works well for decorative or low-stress parts.

- Some grades take longer to machine factor than into your lead time.

Choosing the right stainless isn’t just about the spec sheet. It’s about the job the part needs to do and how you plan to make it.

Once you answer those questions, the right material usually stands out.

Conclusion

This isn’t just about material selection.

It’s about making parts that last. That work. That feels right in your hands.

You now know what makes stainless steel special and where it can trip you up.

So what’s stopping you?

You don’t have to figure it out alone.

MachMaster has helped thousands of product teams get stainless steel parts right the first time whether for prototypes or production.

Contact us today and we’ll help you move forward with confidence.