Have you ever sat in a meeting about the rubber moulding process and felt like you were just pretending along? I’ve been there too.

One time, a supplier asked me if we wanted “flash trimmed off.” I froze. I had no clue what he meant. I left that meeting embarrassed. It pushed me to finally learn this process inside and out.

Since then, I’ve spent years around shop floors, talking to moulding experts, and watching these steps up close. I asked every “dumb” question so you wouldn’t have to.

That’s why you can trust me to break this down in a way that actually makes sense.

You’re here because you want to really understand how the rubber moulding process works. Each step. In clear words.

Whether you’re running a business, designing a new product, buying parts, or just curious for a project — this guide is for you.

By the end, you’ll have a simple, practical guide. You can pull it up before talking to suppliers, planning costs, or sketching your next design.

Let’s jump in!

Quick Guide

Before we dive deeper, here’s a quick snapshot of each step in the rubber moulding process. This will give you a clear path before we explore each one in detail.

| Step | What to Do |

| 1. Material Selection | Choose rubber based on environment, flexibility, and resistance needs. Ask for TDS and confirm tolerance class. |

| 2. Rubber Preparation | Cut, weigh, and pre-form the rubber. Keep it clean and label each batch. |

| 3. Mold Design & Cleaning | Review mold layout with your supplier. Confirm vents, parting lines, and regular cleaning routines. |

| 4. Preheating the Mold | Make sure the mold reaches the right temperature before loading. Ask how heat is applied and monitored. |

| 5. Loading the Rubber | Confirm rubber is centered, clean, and the right amount. Ask if it’s pre-warmed or pre-formed. |

| 6. Moulding Method Execution | Know which method is being used (compression, transfer, injection) and why it suits your part. |

| 7. Vulcanization (Curing) | Ask about temperature, cure time, and if post-curing is needed. Make sure curing is monitored. |

| 8. Demoulding & Finishing | Ask how parts are removed safely, trimmed, and inspected. Confirm cooling time and packaging details. |

Ready to dig in? Let’s explore every stage in detail, starting with material selection.

Step#1 Material Selection

Let’s start with the most important step—choosing the right rubber.

Sounds simple, right?

It’s not. I learned that the hard way.

Years ago, I used a general-purpose rubber compound because it was cheap and easy to get. But after molding, the parts cracked within days. I had to redo the entire batch.

That’s when I realized—not all rubber is the same.

You need to pick a rubber that matches your product’s job. Ask yourself:

- Will this part face heat or oil?

- Does it need to stretch?

- Will it be used outdoors?

Some common types of rubber include:

- Natural rubber (NR): Great for flexibility, but not good with heat or oil.

- Nitrile (NBR): Good for oil resistance.

- EPDM: Works well in outdoor settings.

- Silicone: Handles heat and stays flexible.

Talk to your supplier. Ask for technical data sheets (TDS). These show you key info like hardness, tensile strength, and temperature range.

Also, check if your material meets ISO 3302 tolerances. That’s the standard for rubber parts in manufacturing.

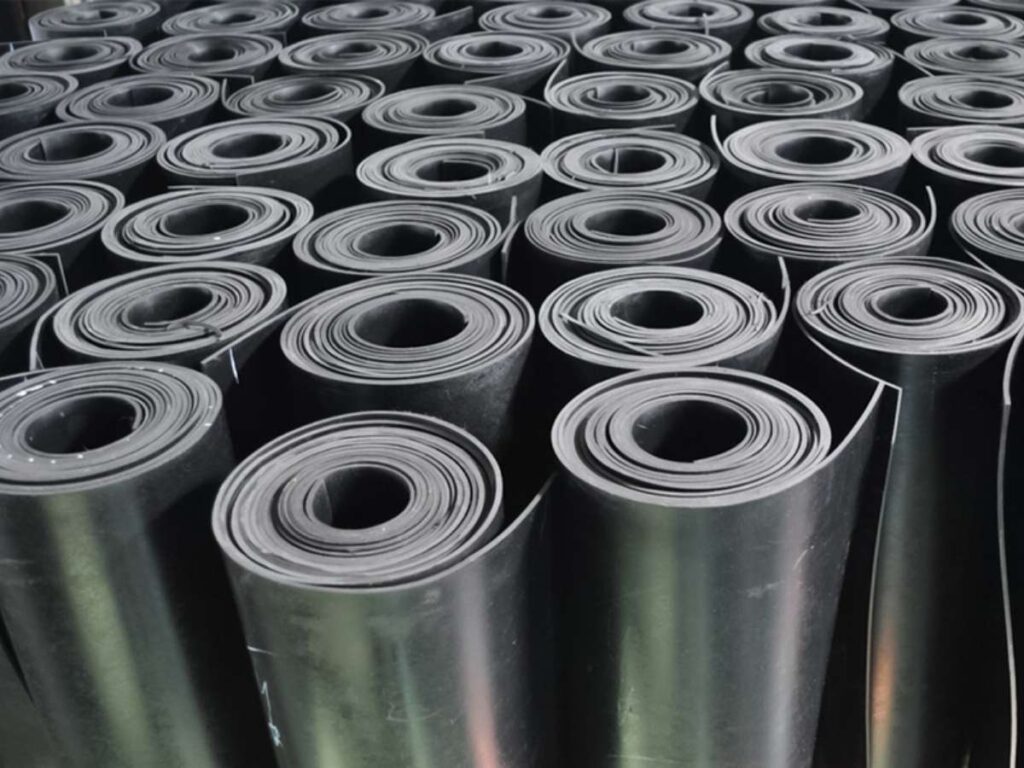

Step#2 Rubber Preparation

Once you’ve picked your rubber, the next step is getting it ready.

Rubber doesn’t come perfectly shaped and ready to mould. It needs to be processed first. I used to skip this part or rush through it—big mistake. The final parts came out with bubbles, uneven texture, or poor bonding.

So, how do you prepare rubber the right way?

Start with these basics:

- Weigh the rubber accurately. This helps avoid waste and makes sure the mould fills completely.

- Pre-form rubber. Roll it, cut it, or shape it so it fits your mould.

- Remove air pockets. Trapped air can cause defects. Use roller or pre-pressing tools.

Some rubber compounds also need to be warmed slightly before moulding. This improves flow and reduces moulding time.

If you’re using uncured rubber, it might feel sticky or stiff. That’s normal. But it also means you need to handle it cleanly. No dirt, oil, or metal flakes. These can ruin your final part project.

Step#3 Mold Design and Cleaning

Before you mould anything, your mold has to be right. I’ve learned the hard way that skipping this step leads to big headaches later.

You’ve got to ask the right questions upfront. At MachMaster, they’ve seen how small misses in mold shape or condition can turn into costly failures. This is where you set yourself up for success before any rubber even touches the cavity.

What You Should Ask the Manufacturer

- Where is the parting line located?: This affects both the appearance and sealing performance of the part. Poor placement can lead to defects.

- Are there vents in the mold?: Air needs to escape during molding. Ask how they handle venting to avoid trapped bubbles.

- What surface finish can we expect?: The mold surface affects the final texture. Clarify whether you need matte, smooth, or patterned finishes.

- What is the draft angle?: Even a 1–2° draft helps with part release and reduces sticking.

- What’s the mold material?: Steel is common for long runs. Aluminum might be used for prototyping. Cost and durability differ.

Why Cleaning Matters

Even the best-designed mold can fail if it’s dirty.

Before each run, ask your supplier:

- How often do you clean the mold?

- What do you use to clean it?

- How do you prevent material build-up or rust?

A clean mold gives you clean parts. Skipping this can lead to blemishes, sticking, or short shots.

Quick Tip: Always request mold maintenance logs for long-term projects. This helps track issues and proves preventive care.

Step#4 Punching and Notching

When the mold is properly heated, the rubber flows better. It fills every corner. It sticks to the mold surface just enough for a clean finish—and releases smoothly after curing.

But if the mold is too cold or heated unevenly?

You’ll run into:

- Short shots (incomplete parts)

- Trapped air pockets

- Poor bonding and surface defects

Each one leads to scrap or rework.

How It’s Done in Real Shops

Most manufacturers use electric heaters, oil heating channels, or steam. Some use external hot plates for smaller tools. But it’s not just about switching the heater on.

Ask if they:

- Check surface temp at several points

- Allow time for the entire tool to reach a steady temperature

- Use a digital control system—not just guesswork

The heat must match the rubber type.

For example, EPDM might need 160°C, while silicone could go up to 200°C. Always confirm the target temp.

Step#5 Bending and Forming

This part doesn’t get much attention. But it should.

I helped a small business that kept getting rubber parts with rough edges and air pockets. At first, they blamed the mold. But the real problem? The rubber wasn’t being loaded right.

Why It Matters to You

How the rubber is placed inside the mold controls:

- How well it fills the shape

- Whether air gets trapped

- If too much material spills out (flashing)

If it’s not done right, the parts may look bad—or worse—fail during use.

Questions You Should Ask Your Manufacturer

To avoid surprises, talk with your supplier about:

- Do you pre-form the rubber before loading it?: This helps it fit the mold better and reduces defects.

- How do you make sure the right amount is used?: Under-filled parts can come out short. Over-filled ones may need trimming.

- How do you keep the rubber clean during loading?: Dirt, dust, or oil can ruin the finish.

Some materials also benefit from being kept warm before loading. This helps the rubber flow into corners more easily—ask if that applies to your part.

Step#6 Assembly and Joining

This is where the real transformation happens—rubber becomes a shaped, functional part.

I had a project where the wrong moulding method was used. The part technically “worked,” but it didn’t meet tolerance, and the surface finish looked sloppy. We had to change suppliers mid-project.

Common Rubber Moulding Methods

Your manufacturer will choose one of these:

- Compression moulding: Rubber is placed into the mould, then pressed into shape using heat and pressure.

- Transfer moulding: Rubber is loaded into a chamber and pushed into the mould through sprues. Good for complex shapes.

- Injection moulding: Rubber is injected directly into the mould cavity. Best for high volumes and tight tolerances.

Each method affects:

- Part cost

- Cycle time

- Tooling complexity

- Finish and precision

What You Should Clarify

Before production starts, ask your manufacturer:

- Which moulding method are you using, and why?

- Does this method match my volume, tolerance, and material needs?

- What’s the expected cycle time per part?

These questions help you align process choice with your priorities—whether it’s speed, cost, or consistency.

Step#7 Surface Finishing

Before this step, it’s just soft material shaped in a mold. But during vulcanization—also called curing—the rubber gets its strength, elasticity, and durability.

I’ve always thought of this step as the true make-or-break moment. It decides whether you end up with a solid part or something that fails on the job.

What Actually Happens Here?

The mould closes. Heat and pressure are applied.

This triggers a chemical reaction that “locks in” the rubber’s shape and properties.

Depending on the rubber type, curing may take just a few minutes or or much longer. Silicone, for example, often needs 170–200°C to be fully cured.

What You Should Ask or Confirm

You’re not curing the part yourself—but you can ask:

- What is the target temperature and cure time for this material?

- How is curing monitored do they use sensors or timers?

- Is post-curing required in an oven afterward?

Post-curing is common for high-performance rubber parts and helps remove any leftover byproducts.

Step#8 Demoulding and Finishing

This is the final step. It might look simple from the outside, but trust me it’s still easy to get wrong. How your part comes out of the mold is just as critical as how it went in. I’ve watched more than one good batch get ruined right here at the end.

At MachMaster, they don’t rush this final step. They know from hands-on experience that careful finishing reduces rework, improves fit, and ensures every part performs exactly as needed.

Why Demoulding Matters

Rubber stays flexible after curing—but it’s also hot and slightly soft. If it’s pulled too soon or without care, it can:

- Tear at thin sections

- Stick to the mould surface

- Warp or lose detail

Some parts need a cooling period before they’re removed. Others need release agents or special tools to protect the finish.

You can ask:

- How do you protect the part during demoulding?

- Do you allow cooling time before removal?

- What kind of release tools or agents are used?

What Happens After Demoulding?

That’s where finishing comes in.

This includes:

- Trimming flash (excess material at the edges)

- Surface inspection

- Cleaning or post-curing if needed

- Packaging to protect the part

If your part has tight tolerances or needs a clean look, finishing should be part of your quote—not an afterthought.

This step might feel like the end, but it’s the first thing your customer sees.

Good finishing equals good first impressions.

And good demoulding protects all the effort that came before it.

Conclusion

We covered it all from prepping rubber to mould release and trimming.

Now you know exactly how and why each step shapes your product.

Remember my story?

That moment pushed me to learn, so I could help you skip the confusion.

Looking for a partner that gets it?

MachMaster supports engineers, designers, and makers with CNC machining that meets high standards and tight timelines.

Contact us today. Let’s make it work!

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.