If you’re unsure whether to prototype or go straight to production, you’re not alone.

I remember looking at mold quotes for the first time and thinking, “Is this even worth it?”

One supplier suggested prototype molding. Another said go straight to steel. And I wasn’t sure who to trust.

That’s why I wrote this guide. Because I’ve gone through the same process, made mistakes, and found solutions.

And now, you get to skip the confusion.

In this article, you’ll learn how prototype plastic injection molding works. You’ll understand the steps, costs, materials, and where it fits in your development process.

By the time you’re done reading, you’ll know whether this method can help you move forward with fewer risks, faster timelines, and better data.

Let’s start!

1. What Is Prototype Plastic Injection Molding?

Let’s say you’ve got a plastic part you need to test. It’s already designed, and you want to see how it feels, fits, and functions in real life.

That’s where prototype plastic injection molding comes in.

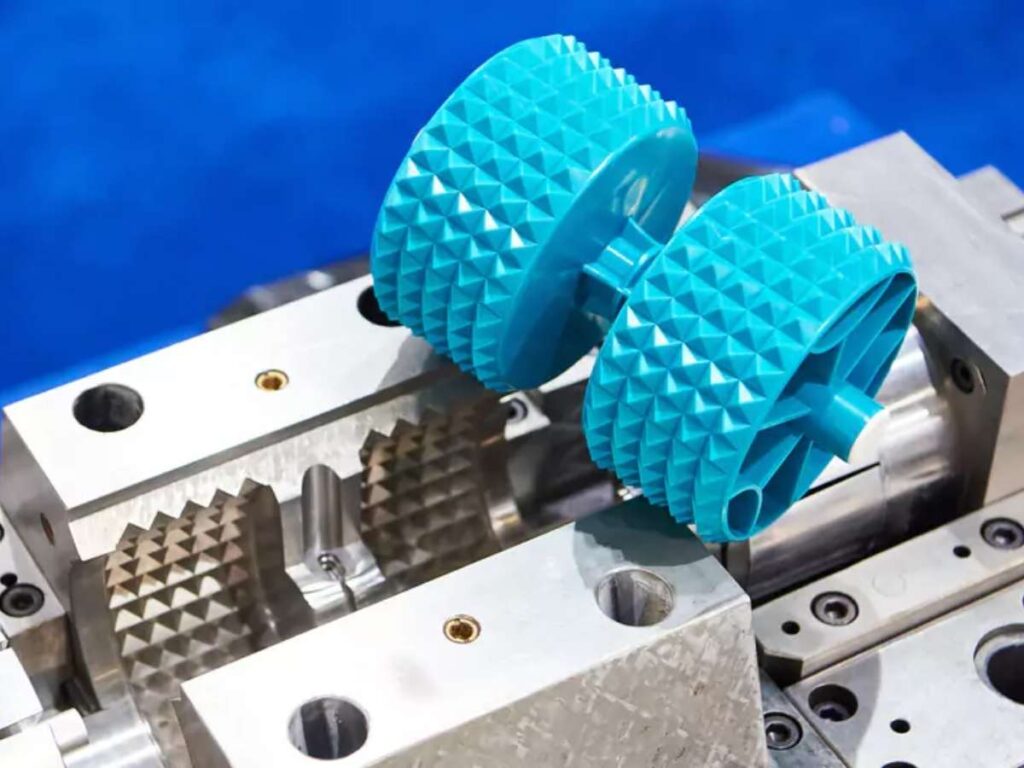

It’s a process that lets you make small batches of plastic parts using molds made from soft materials like aluminum or low-volume steel. These molds are cheaper and faster to make than the hardened steel ones used for full production.

You’re not committing to 100,000 parts. You’re testing a few dozen or maybe a few hundred to see if your design is ready.

That’s what I like about it. You can get real parts made from real production materials, without the stress of going all in too soon.

Here’s how it compares to production injection molding:

- Lower upfront cost: You don’t need to spend thousands on a hardened tool before you’re ready.

- Faster lead time: Soft tooling can be made in as little as 1 to 3 weeks.

- Shorter lifespan: A prototype mold might only last for 100 to 5,000 shots, depending on part design and materials used.

But that’s often all you need to test a design, get early customer feedback, or start a pilot run.

Think of it as a dress rehearsal before opening night. You want to catch issues early before you lock into a high-volume mold that’s harder and more expensive to change.

You might be wondering: Is this enough for my project? Or should I just skip straight to production?

That depends on your goals, budget, and timeline.

In the next sections, we’ll walk through when prototype molding makes sense, what to expect from the process, and how to avoid common mistakes.

Let’s take a closer look at whether it fits your needs.

2. Is Prototype Molding Right for Your Project?

Before you spend time or money on tooling, it helps to stop and ask: Is this the right approach for me?

Prototype plastic injection molding is a smart option in many cases—but not always. It depends on your timeline, your part goals, and how far along you are in development.

Let’s walk through a few questions that can help you decide.

Questions to Ask Yourself First

- Are you testing a product design before full launch?

- Do you need real, functional parts to test fit and performance?

- Is your expected volume under 10,000 pieces—for now?

- Are you trying to avoid paying for expensive hardened steel molds too early?

If you answered yes to most of these, prototype molding might be a good fit.

When I was launching my second product, I didn’t want to risk going straight into production. A prototype mold helped me spot a design flaw that didn’t show up in 3D prints. That one adjustment saved my team a lot of headaches later.

When You Should Use It

Prototype molding is great when you need:

- Fast turnaround on plastic parts made from real production materials

- Better tolerances than 3D printing can give

- Short production runs for investor demos, customer feedback, or pre-sales

It bridges the gap between early-stage testing and full-scale manufacturing.

When You Shouldn’t Use It

There are times when prototype molding may not fit your needs. For example:

- You need 50,000 parts or more

- Your product uses abrasive materials that wear molds out quickly

- Your design includes ultra-fine details that require hardened steel tooling

In those cases, going straight to production molds might make more sense—if your design is locked.

Still unsure?

The next section will help you understand what this process offers and where it fits into your project timeline. Let’s keep going.

3. Benefits of Prototype Injection Molding

Once you’ve decided to test your design before going all-in on production, the next question is: Why choose prototype injection molding over other options?

There are several reasons. And if you’re like me trying to balance time, cost, and quality it’s worth understanding each one.

Let’s start with what most people care about first.

Speed

Getting to market fast matters.

Prototype molds are typically made from aluminum, which is easier to machine than hardened steel. That means shorter lead times.

Most suppliers can deliver prototype molds in:

- 7 to 15 days, depending on part complexity

- Even faster if the mold base is standardized

For one of my earlier projects, I needed functional parts before a trade show. 3D prints weren’t enough. I used prototype molding, and I had testable parts in hand within two weeks. That wouldn’t have been possible with a full production mold.

Lower Cost

If you’re working with a limited budget especially in the early stages this process helps.

Because the tooling is simpler, the upfront cost is much lower. It’s a good fit for:

- Startups trying to stay lean

- R&D teams that need multiple design iterations

- Projects with uncertain demand

You get the benefit of real parts without the pressure of big commitments.

Design Feedback

You can also catch design issues early.

Prototype molds let you validate DFM (Design for Manufacturability) and test the function of your part in real use. That’s something 3D prints and simulations often miss.

Scalability

In some cases, the same tool can be used for low-volume production.

It won’t last forever, but it might carry you through pilot runs or early customer orders.

Still thinking it over?

Next, we’ll talk about the limits of prototype molding. so you can weigh the pros against the tradeoffs.

4. Limitations You Should Know

Prototype plastic injection molding comes with a lot of benefits. But like any process, it also has its limits.

Knowing these upfront can help you plan better, avoid surprises, and choose the right method for your parts.

Let’s break down the most common limitations so you can weigh them against your project needs.

Mold Lifespan

This one often catches people off guard.

Prototype molds are usually made from aluminum. It’s softer than the hardened steel used in production molds, so it wears out faster.

Depending on your part’s design and the resin you’re using, an aluminum mold might give you:

- As few as 100 parts

- Or up to 5,000 shots, sometimes more with simple shapes and gentle resins

For one of my early designs, I thought I’d get 10,000 parts out of a prototype mold. I didn’t. The mold started breaking down around 3,000. Lesson learned.

If you need high volumes, you’ll want to plan for a second mold—or go straight to steel.

Material Compatibility

Not every plastic works well in a prototype mold.

Some resins run hotter. Others are abrasive. If your part needs something like glass-filled nylon or high-heat PEEK, that could damage a soft mold fast.

Here’s what you should do:

- Check with your supplier before choosing a resin

- Ask whether the material is suitable for aluminum tooling

- Be ready to test with a similar, lower-risk alternative if needed

Finish and Tolerances

Let’s talk about part quality.

Soft tooling can’t always hold the same tight tolerances or surface finishes that hardened molds can. You might see:

- Slight texture differences

- More variation in precision from one part to the next

Is that a dealbreaker? It depends.

For early testing or pilot runs, it’s usually fine. But if your product has cosmetic requirements or needs ultra-precise fits, this is something to think about.

5. Materials Available for Prototype Molding

Now that you know the pros and cons of prototype molding, let’s talk about materials. Because what you mold with matters.

One of the big advantages of prototype plastic injection molding is that you can often use the same materials you plan to use for full production. That means better testing and fewer surprises down the line.

Some common plastics you can use include:

- ABS (Acrylonitrile Butadiene Styrene): good for strength and toughness

- PC (Polycarbonate): clear, impact-resistant

- Nylon (Polyamide): strong and flexible, but absorbs moisture

- POM (Acetal): good for precision parts and wear resistance

- TPE (Thermoplastic Elastomer): soft and rubbery

- PP (Polypropylene): lightweight and chemical-resistant

- PE (Polyethylene): great for flexibility and low cost

I’ve used ABS in most of my early prototypes. It gave me enough toughness to test mechanical parts without driving up the price. Later, I swapped it out for a blend more suited to production. But for those early runs, ABS worked fine.

Still, just because a material is common doesn’t mean it’s perfect for every mold.

Soft tooling behaves differently than hardened steel. You have to think about:

- Flow: Some materials don’t flow well into small or complex features

- Cooling: Each plastic shrinks differently as it cools

- Insert-molding: Not all resins bond well with inserts like metal pins or threaded parts

So how do you pick?

Tips for Material Selection

- Try to match your production material whenever you can. That gives you a better read on how the part will behave later.

- If cost is tight, go with a cheaper material that has similar shrinkage and processing temperatures.

Testing with the wrong material can lead to false results, so this step matters more than you might think.

6. Comparing Prototype Molding vs. Other Prototyping Methods

There’s no one-size-fits-all when it comes to prototyping.

You have options. And each one comes with its own strengths and limits.

Let’s compare prototype plastic injection molding with two other common methods to help you figure out which fits your project best:

| Feature / Factor | Prototype Injection Molding | CNC Machining | 3D Printing |

| Lead Time | 1–3 weeks for tooling + parts | 1–7 days (no tooling needed) | 1–3 days |

| Upfront Cost | Medium (tooling cost involved) | Low to Medium | Low |

| Per-Part Cost | Low (after tooling investment) | High | Low to Medium |

| Material Options | Production-grade plastics | Metals and plastics | Limited (mostly plastic/resin) |

| Tolerances | ±0.1 mm or better (design-dependent) | Very tight (±0.01 mm possible) | Medium to low |

| Part Complexity | Moderate to High (with design-for-mold) | Limited by tool access | High (no tooling constraints) |

| Best Use Case | Functional testing, short runs | Functional prototypes, high-precision parts | Early concept models |

Next, we’ll take a closer look at the tooling process itself, so you know exactly what happens once you submit your design.

7. Prototype Mold Tooling

Once you decide to move forward with prototype molding, the next step is tooling.

This part of the process is easy to overlook, but it matters. Your mold is what shapes every part you make, so it’s worth knowing what goes into it.

Let’s start with the material.

Tooling Material

Most prototype molds are made from aluminum.

Why? Because it’s quicker to machine and cheaper than hardened steel. That’s what makes it perfect for short runs and fast turnarounds.

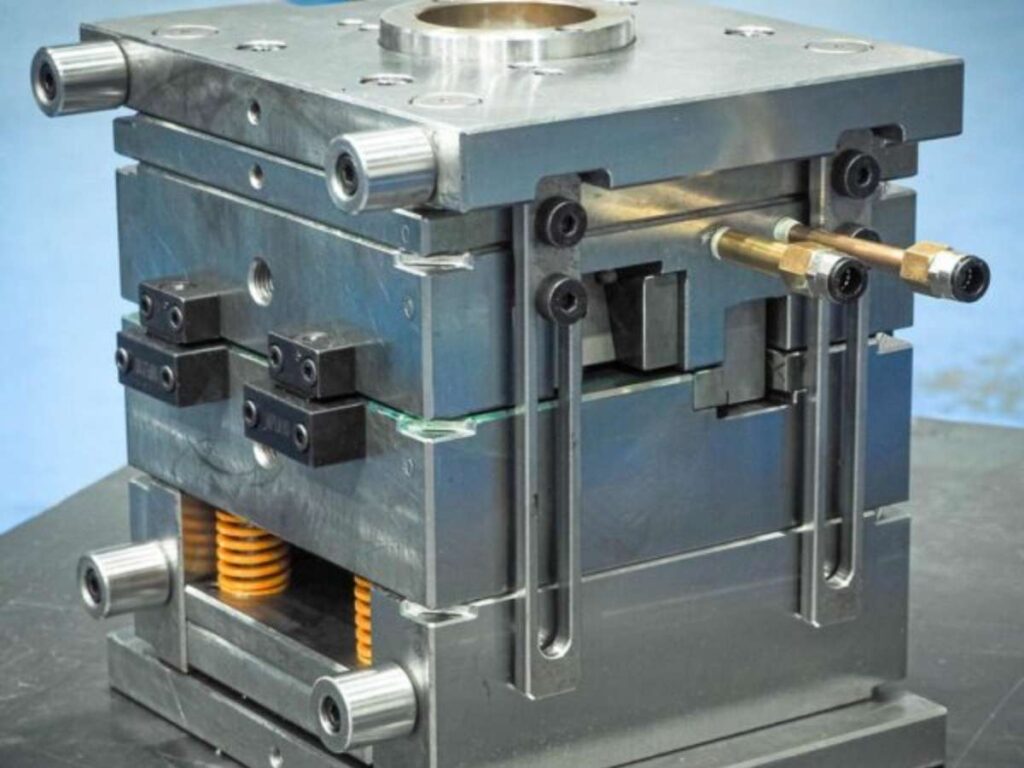

If you need a few thousand parts, or plan to run the tool longer, your supplier might use P20 or mild steel. These hold up better over time, but they take longer to machine and cost more.

I once used aluminum for a small project with just 300 parts. It worked perfectly. But later, when we planned a second run, the tool was already wearing down. If you’re expecting repeat orders, steel might be worth it.

Tooling Cost Factors

Tooling costs vary. Some molds are simple. Others are more involved. A few key things drive the price:

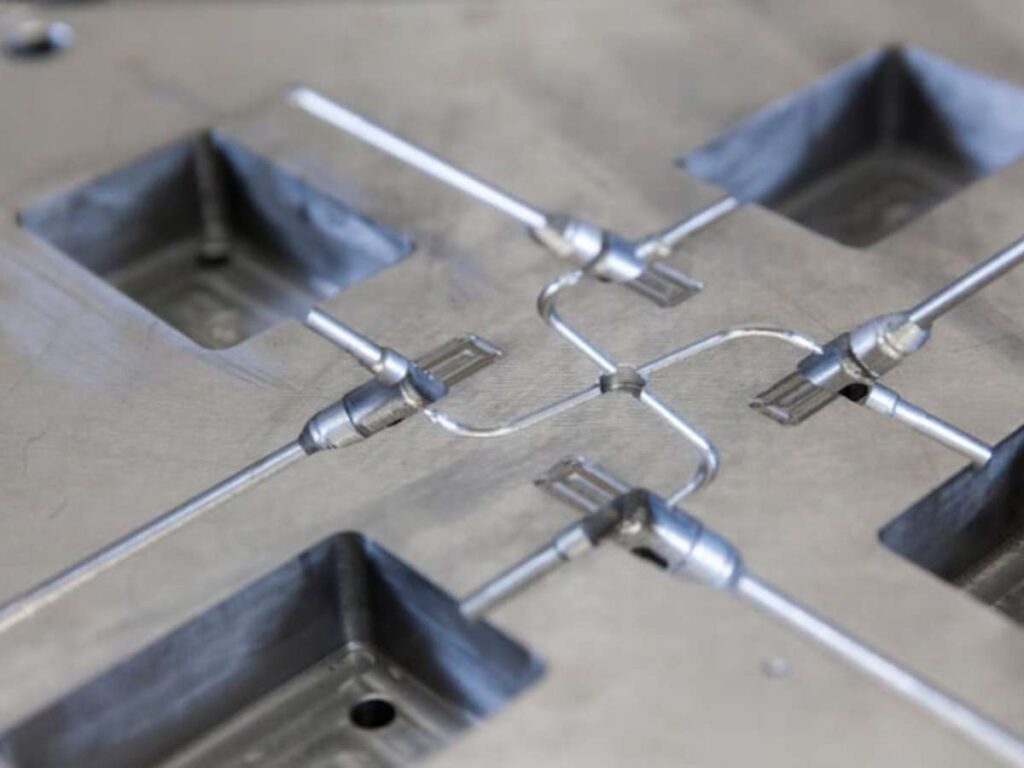

- Number of cavities: One cavity makes one part per cycle. More cavities mean more output—and more cost.

- Part size and shape: Larger or more complex parts take more time and material to mold.

- Ejector and cooling design: These help the part release cleanly and cool evenly. If the part sticks or warps, the tool might need extra work.

Expected Lead Time

Most prototype molds are ready in 1 to 3 weeks.

That depends on your supplier, the mold’s complexity, and how custom the setup is. If the mold base is already standardized, you might get it even faster.

Understanding tooling is a big step toward avoiding delays and mistakes.

8. Prototype Injection Molding Process

If you’ve never gone through prototype plastic injection molding before, the process might seem a bit unclear.

What actually happens once you send in your part design? How long does each step take? And where do mistakes usually happen?

Let’s break it down so you know what to expect and how to avoid the common traps.

Step 1: Submit Your CAD File

The first step is sending in your design.

Most manufacturers prefer neutral file types like:

- STEP (.stp)

- IGES (.igs)

These formats are easier to work with than native files from specific CAD programs.

If you have important dimensions or tolerances, it’s smart to also send a 2D drawing. That helps clarify what really matters and can avoid a lot of back-and-forth later.

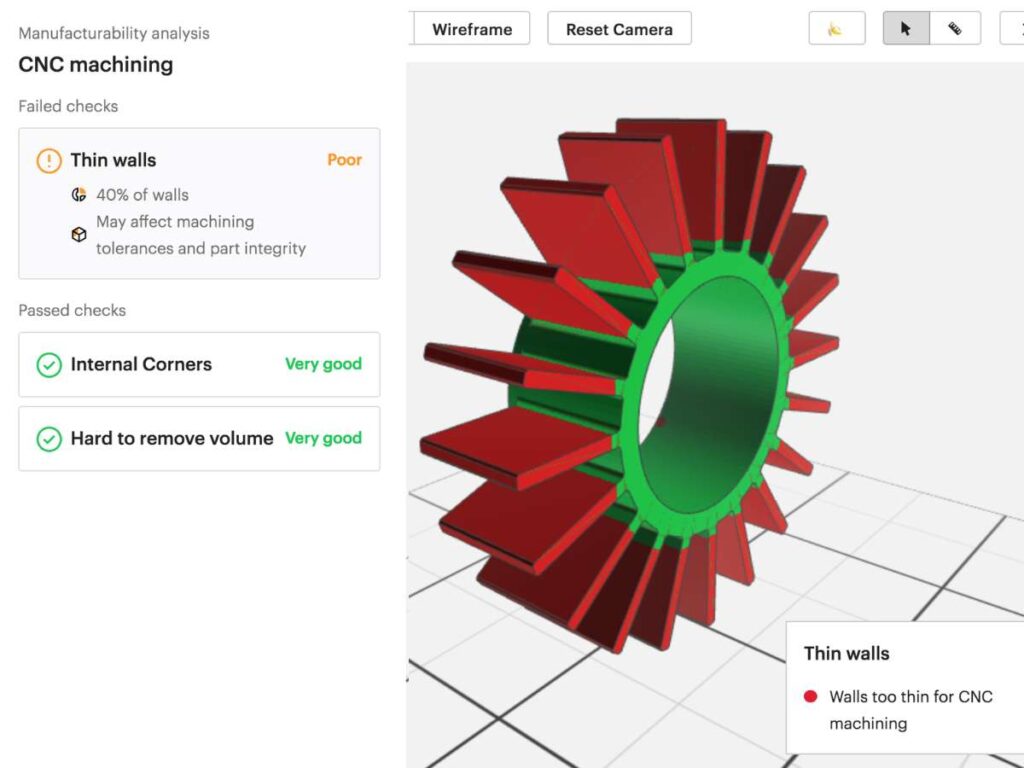

Step 2: Design for Manufacturability (DFM) Review

Next comes the DFM check.

This is where your supplier looks at the design and points out anything that might cause issues during molding.

They’ll look for:

- Undercuts

- Thin walls

- Sharp corners

- Missing draft angles (which help the part release from the mold)

This step has saved me more than once. I’ve had parts that looked fine on screen, but would’ve stuck in the mold or warped after cooling. Fixing that early saved time and tooling costs.

Step 3: Mold Fabrication

Once the design is cleared, the mold is built.

This can be aluminum for speed, or steel if you need more durability.

If you’ve requested special surface finishes, they’re added during this step.

Step 4: Trial Shots and First Article Inspection

Here’s where things get exciting.

The first parts are molded and inspected. These are called trial shots or first articles.

Your team will check dimensions, surface quality, and part function.

If something’s off, you’ll send feedback so the supplier can adjust the mold.

Step 5: Full Prototype Run

Once the parts pass inspection, the full run begins.

Whether you need 100 or 5,000 pieces, they’ll all be molded using the approved tool and then shipped to you.

Knowing this process helps you stay on track and catch problems early.

9. How to Choose the Right Supplier

Once your design is ready and you’ve decided to move forward, the next big step is finding the right supplier.

And this part? It matters more than most people think.

A good supplier won’t just give you a mold. They’ll help you improve your design, work within your budget, and avoid setbacks later on.

So how do you know who to trust?

Must-Have Capabilities

Start by looking for a few key things. These are non-negotiable if you want reliable results:

- In-house tooling shop: If the shop builds its own molds, you’ll get better control, faster changes, and fewer delays.

- Experience with both prototype and production: Some shops only do small runs. Others only do mass production. You want someone who understands both.

- DFM support and fast quoting: A supplier who offers design-for-manufacturing feedback and clear pricing helps you plan better.

- ISO 9001 certification: This means they follow consistent quality practices and meet global standards.

I once picked a supplier who sent parts late and didn’t spot a design flaw that cost me two weeks. Now, I always check for these four things before signing anything.

Questions to Ask

When talking to potential partners, don’t be afraid to ask questions. Good ones will welcome it.

Start with:

- What’s your typical lead time for prototype molds?

- What materials do you work with in prototype runs?

- Can you support the transition to full production later?

These questions help you figure out if they’re in it for the long haul or just the first step.

Looking for a partner who can do both?

At MachMaster, we support your project from concept through production with ISO-certified quality, fast tooling, and custom solutions for every stage.

10. Common Mistakes to Avoid

Even with a good design and a clear plan, a few small mistakes can cause big delays. I’ve made them myself—and I’ve learned the hard way.

Let’s talk about what to watch out for.

Skipping DFM Feedback

Don’t skip the design review.

Your supplier can catch problems like thin walls, missing draft angles, or tricky undercuts. These issues might not show up on your screen, but they’ll cause real trouble during molding.

Take the time to ask for feedback before tooling starts.

Choosing the Wrong Resin

Not all plastics behave the same.

If you test with the wrong resin, you might get the wrong results. Use a material close to your final choice or at least one with similar shrinkage and flow.

Ask your supplier if you’re unsure what works in soft molds.

Expecting Production-Level Cosmetic Finishes

Prototype molds aren’t built for showroom polish.

They’re great for function testing, but you might see minor surface flaws. That’s normal. If you need a perfect finish, you’ll likely need a polished steel tool later.

Not Planning for Part Revisions

Almost no one gets it perfect on the first try.

Make room in your timeline and budget for small design changes after testing.

Avoiding these common mistakes can save you time, money, and frustration.

Conclusion

You don’t need to gamble on full production.

Prototype molding is your chance to test, adjust, and grow with less pressure and more control.

We covered:

- What the process looks like

- When it makes sense

- What materials and designs work best

- How to avoid the common mistakes

If you’re building something new, don’t wait. Take that smart first step.

Want to talk through your design? Contact us today. We’re here to help.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.