I had my design ready and the CAD file was good to go.

All I needed was someone to bring it to life.

That’s when I hit a wall. Finding a plastic injection molding company wasn’t easy. Some never replied. Others gave confusing answers. A few sent quotes that didn’t match what I asked for at all.

I didn’t care about fancy websites or big promises. I just wanted someone who could get the job done right—and deliver it on time.

After a lot of emails, sample tests, and chats with other customers, I finally found a few companies that really stood out. They were fast, honest, and made great parts.

In this article, I’ll show you 7 of the best ones I found. You’ll see what each one offers, what they’re best at, and how they might fit your project.

Let’s get started!

Quick Comparison Chart

Before we dive into the full details, here’s a quick side-by-side look at each manufacturer. This gives you a clear snapshot of who they are and what they offer—so you can start narrowing your options right away.

| Manufacturer | Year Established | Location | Core Products | Services Offered | Certifications / Reputation |

| The Rodon Group | 1956 | Hatfield, Pennsylvania, USA | Plastic parts for consumer, medical, and industrial use | Mold making, injection molding, DFM support | ISO 9001:2015, known for high-volume efficiency |

| Summit Plastic Molding | 1982 | Michigan, Texas, China | Automotive, medical, and defense parts | Prototyping, tooling, injection molding, engineering | IATF 16949, strong global footprint |

| MachMaster | 2002 | Xiamen, China | Precision plastic parts | Injection molding, CNC machining, die casting, finishing | ISO 9001, trusted for precision work |

| Protolabs | 1999 | Minnesota, Europe, Japan | Low-volume molded parts, prototypes | Injection molding, CNC machining, 3D printing, sheet metal | ISO 9001, ISO 13485, rapid turnaround |

| EVCO Plastics | 1964 | DeForest, Wisconsin, USA | Precision-molded plastic parts for medical, packaging, and more | Product design, mold making, injection molding, assembly | ISO 9001 certified; known for global manufacturing and DFM support |

| Texas Injection Molding | 2013 | Houston, Texas, USA | Medical, industrial, and consumer parts | Mold design, molding, packaging, assembly | ISO 9001, praised for client responsiveness |

| ACO Mold | 2000 | Shenzhen, China | Technical and high-precision parts | Mold building, injection molding, prototyping, DFM review | ISO 9001, respected for quality and value |

Now that you’ve seen the overview, let’s take a closer look at what each manufacturer brings to the table.

1. The Rodon Group

Back when I first looked for a molding supplier in the U.S., someone in my network said, “Try Rodon. They don’t mess around.” So I did—and they were right. Rodon handled everything from mold design to production without excuses or delays. That kind of support sticks with you.

The Rodon Group was founded in 1956 and is based in Hatfield, Pennsylvania. They operate out of a 125,000-square-foot facility and employ more than 125 people. Their team runs everything from one location, which helps them stay on schedule and avoid quality issues.

Product Range

- Plastic parts for industrial use: From window hardware to electrical components.

- Consumer product parts: Caps, closures, toys, and packaging pieces.

- Medical and healthcare items: Basic non-sterile parts like housings and connectors.

- Eco-friendly product options: They offer recyclable resins and waste reduction support.

- Private labeling and bulk production: Available for businesses that need consistency across large batches.

Research & Development (R&D)

- In-house engineers design and build molds from scratch.

- Their team helps improve part design for easier and faster molding (DFM = Design for Manufacturability).

- Prototypes go through small test runs before full production.

- They adapt quickly to changes in material or specs.

- Rodon holds mold design patents in several categories.

Lead Times & Production Turnaround

- Standard lead times: 4–6 weeks for production-ready parts.

- Molds take about 6–10 weeks depending on complexity.

- They accept rush orders when possible—at extra cost.

- Delays mostly happen during material shortages or tooling revisions.

- One client shared that Rodon delivered 250,000 parts in just under two weeks during peak season.

Final Verdict

Rodon is a solid pick for high-volume plastic molding, especially if you want everything handled under one roof. However, small custom runs might not be their strongest fit due to their large-scale focus.

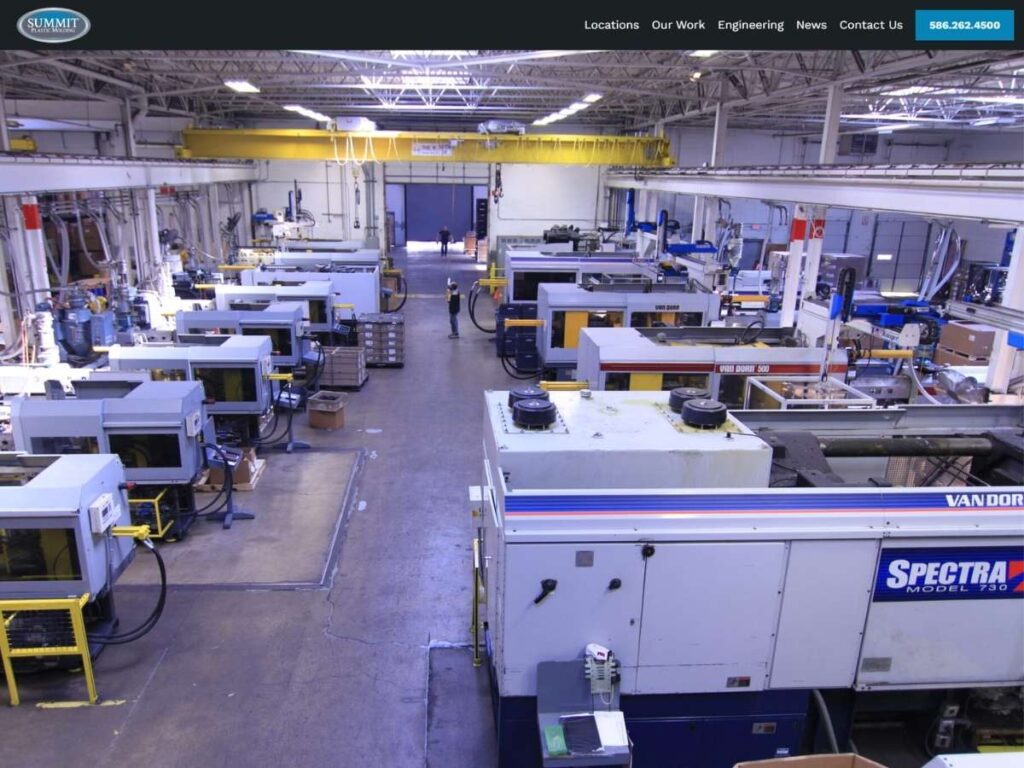

2. Summit Plastic Molding

If you’re tired of dealing with one company for tooling, another for molding, and a third for assembly, you’re not alone. I’ve seen projects fall apart just from poor coordination. That’s what led me to Summit Plastic Molding—one of the few companies that handles all of it in-house.

Founded in 1982, Summit is based in Shelby Township, Michigan, with facilities in Texas and China. With over 200 employees, they serve clients in automotive, medical, and defense manufacturing.

Product Range

- Automotive components: Door panels, brackets, HVAC housings, and structural parts.

- Medical and defense parts: Plastic housings, protective covers, and specialized enclosures.

- Consumer product parts: Custom-molded enclosures and packaging solutions.

- Insert molding and overmolding: Combining multiple materials or metal with plastic in a single mold.

- Custom tooling and engineering support: Ideal for clients needing full product development.

Research & Development (R&D)

- All tooling is built in-house, which helps speed up part development.

- Their engineers help you design for both cost and moldability.

- Small pilot runs are used to catch design flaws early.

- They can adjust quickly when part specs or materials change.

- Work closely with automotive OEMs for compliant, validated designs.

Lead Times & Production Turnaround

- Standard molding production starts in 4–6 weeks after tool completion.

- Tooling lead time can range from 6–12 weeks depending on part size and detail.

- Rush production may be available depending on schedule and material stock.

- Possible delays may include design changes or overseas tooling logistics.

- A customer once noted their 500,000-part order was completed and delivered ahead of schedule.

Final Verdict

Summit is a smart option if you want one partner to manage everything from tooling to final parts. However, coordinating across locations may require more communication if your project includes overseas work.

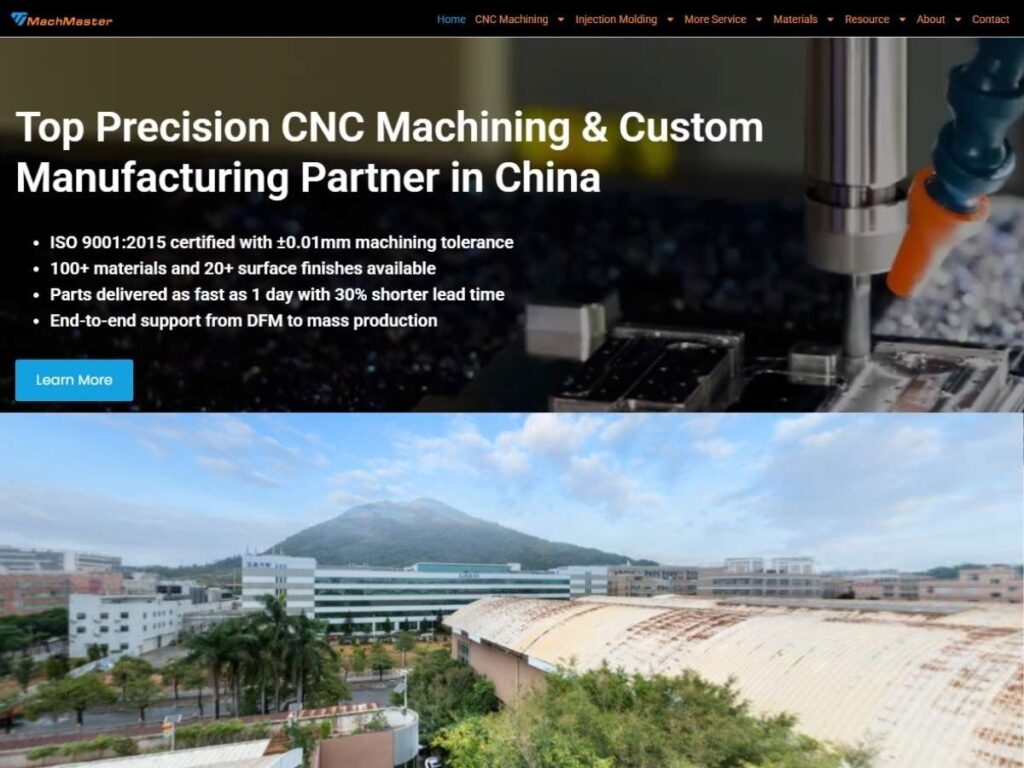

3. MachMaster

The first time I visited MachMaster, the scent of machine oil and the rhythmic hum of CNCs hit me all at once. It was clean, sharp, and focused—just like their work. You could tell the team took pride in every detail.

Founded in 2002, MachMaster is based in Xiamen, China, with over 150 employees. They’re ISO 9001 certified and serve industries like electronics, medical, and automation with high-precision plastic injection molding.

Product Range

- Precision plastic parts: Used in sensors, medical housings, automation components.

- Overmolded and insert-molded parts: Combine different materials in one part.

- Custom functional prototypes: Short-run molded samples for fit and function testing.

- Plastic enclosures and cases: For consumer electronics and industrial equipment.

- Assembly-ready components: Molded parts with added threads, metal inserts, or labels.

Research & Development (R&D)

- In-house engineering team supports mold design and product development.

- Design for Manufacturability (DFM) reviews to reduce cost and improve quality.

- Prototype testing with real production tools (not just 3D printed samples).

- Flexible to adjust specs and material types based on your project’s needs.

- Focused on continuous improvement with lean manufacturing practices.

Lead Times & Production Turnaround

- Average mold-making lead time: 4–6 weeks depending on part complexity.

- Standard production lead time: 2–3 weeks after mold approval.

- Offers fast-turnaround for prototypes and urgent orders upon request.

- Material sourcing and design changes can affect timelines.

- One client received a full pilot batch of precision medical housings in just 12 days.

Final Verdict

MachMaster is a great choice if you need consistent precision and fast, flexible production. Its wide service range helps you move from idea to final part with confidence.

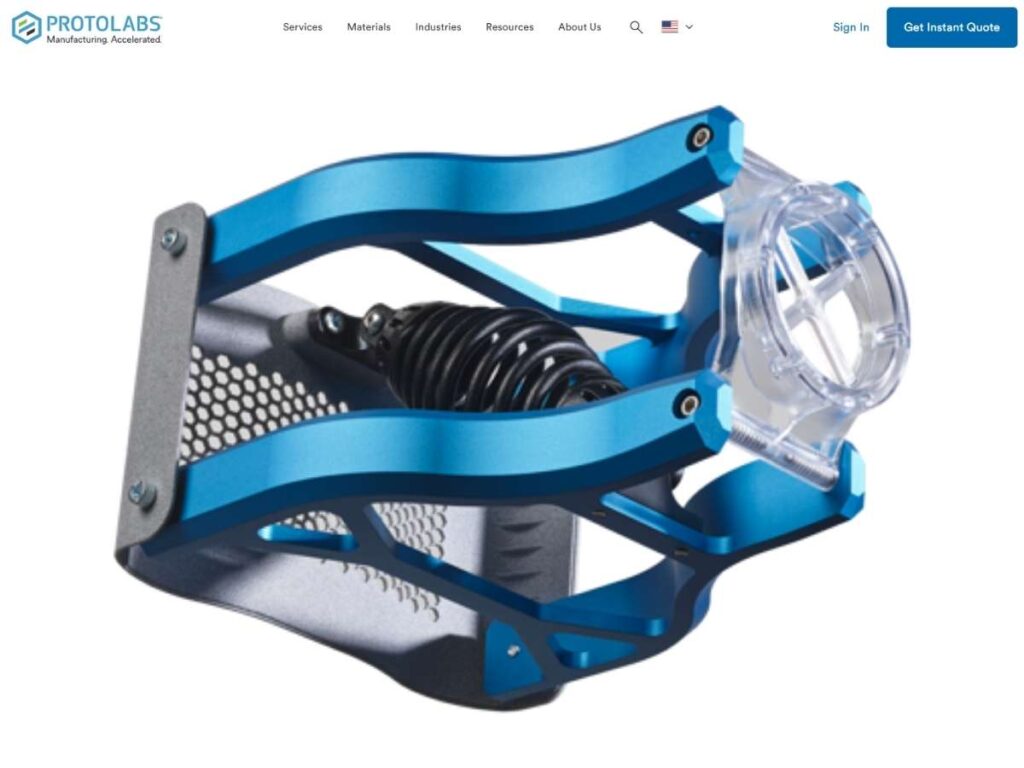

4. Protolabs

If you need parts fast—really fast—Protolabs might be exactly what you’re looking for. I’ve worked with them on urgent prototypes when every hour counted. The process was smooth, the quotes were instant, and I had parts in hand within days. It helped keep a project on track that was slipping fast.

Founded in 1999, Protolabs is based in Maple Plain, Minnesota, with over 2,500 employees worldwide. They serve customers across North America, Europe, and Japan through a digital-first manufacturing model.

Product Range

- Plastic injection molded parts: Low-volume runs for functional parts and prototypes.

- CNC machined parts: Milled or turned parts with quick lead times.

- 3D printed prototypes: Used for concept testing and product development.

- Sheet metal parts: Simple brackets, enclosures, and flat components.

- Engineering-grade resins: Wide material selection to simulate production conditions.

Research & Development (R&D)

- Uses software-driven quoting and design feedback.

- Engineers can review manufacturability before production begins (DFM).

- Prototype testing done using actual materials and final geometries.

- Quick to adopt new materials and 3D printing technologies.

- R&D teams focus on speed and precision for short-run production.

Lead Times & Production Turnaround

- Molded parts ship in as fast as 1–15 business days.

- CNC parts available in 1–3 days depending on complexity.

- Fast-track options available for critical deadlines.

- Delays may happen if models need redesigns or require uncommon materials.

- I once got CNC parts delivered in under 48 hours using their rush option.

Final Verdict

Protolabs is perfect if you need quick, accurate parts to test or launch a new idea. However, the cost per part may be higher if you’re producing at large volumes compared to traditional molding shops.

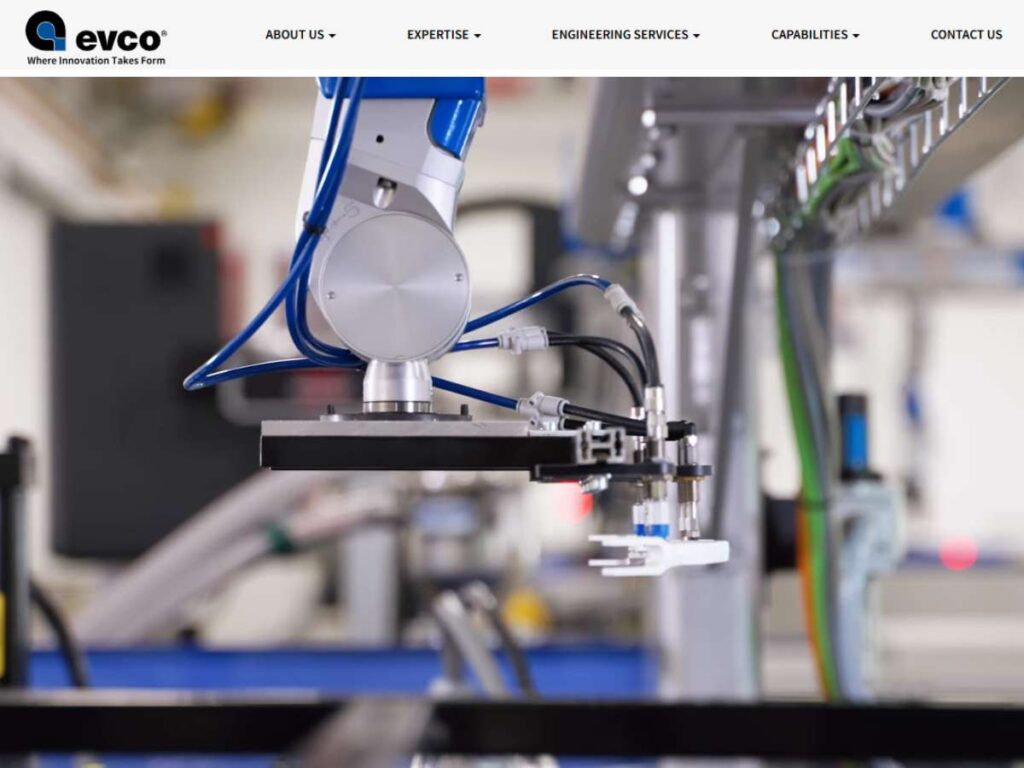

5. EVCO Plastics

I first came across EVCO Plastics while reviewing tooling specs for a tight-tolerance housing. I needed a partner that could handle high-cavitation molds, communicate well across time zones, and still hit quality targets. EVCO checked those boxes quickly. Their global setup made it feel like I was working with a local shop—just with far more capability.

Founded in 1964, EVCO Plastics is headquartered in DeForest, Wisconsin. The company operates nine facilities across the U.S., Mexico, China, and Germany, with over 1,000 employees worldwide. They serve industries like medical, packaging, electronics, and automotive.

Product Range

- Precision injection-molded parts: Used in consumer electronics and appliances

- Medical enclosures and components: Molded in controlled environments

- Automotive parts: Interior and under-hood plastic components

- Industrial housings and covers: Designed for strength and longevity

- Custom packaging solutions: Thin-wall and reusable applications

Research & Development (R&D)

- In-house product design and engineering teams

- Early-stage design support and manufacturability analysis

- Mold flow simulations to reduce trial-and-error

- Strong experience with multi-material and overmolding projects

- Global engineering collaboration across regions

Lead Times & Production Turnaround

- Tooling lead times vary: typically 6–10 weeks for production molds

- Pilot runs often delivered within 2–3 weeks after tool approval

- Global facilities help balance capacity and reduce shipping time

- Real-time project tracking helps customers stay updated

- One client reduced lead time by 30% after shifting tooling to EVCO’s U.S. plant

Final Verdict

EVCO is a solid choice if you want precision molding with strong global reach and design support. However, their large-scale infrastructure means they’re best for ongoing programs, not low-volume or one-off projects.

6. Texas Injection Molding

If you’re looking for a molding company that actually listens and works with you—Texas Injection Molding might be it. I’ve recommended them to businesses that needed flexibility, solid quality, and someone who’d pick up the phone when questions came up. The feedback? Always positive. One client told me, “They felt like an extension of our own team.”

Founded in 2013, they’re based in Houston, Texas, with around 100 employees. They serve the medical, industrial, and consumer markets across the U.S.

Product Range

- Medical-grade plastic parts: Housings, covers, and support structures.

- Consumer products: High-volume parts for packaging, tools, and accessories.

- Industrial components: Valves, connectors, handles, and structural pieces.

- Overmolding and insert molding: Adds strength or function by combining materials.

- Complete packaging and labeling: Ready-to-sell product prep straight from the factory.

Research & Development (R&D)

- In-house engineers help optimize designs for injection molding.

- Offers DFM (Design for Manufacturability) feedback to prevent mold defects.

- Partners with clients early to avoid redesign costs.

- Rapid prototyping available using soft tooling.

- They often support startups and early-stage product developers.

Lead Times & Production Turnaround

- Standard tooling lead time: 6–8 weeks depending on size and part count.

- Production begins in 1–3 weeks after tooling is approved.

- Rush production is possible on select orders.

- Delays typically come from design changes or specialty resins.

- One team I worked with got their parts out in under 10 days after final approval.

Final Verdict

Texas Injection Molding works well for teams that want responsive service and dependable U.S.-based production. However, if you’re sourcing internationally, lead times and costs may be higher compared to overseas suppliers.

7. ACO Mold

If you’re working on a project with complex parts or tight tolerances, ACO Mold is worth a look. I’ve recommended them to clients who needed high precision on a limited budget—and they delivered. One client even said, “They made our drawings into real parts faster than anyone we tried before.”

Founded in 2000, ACO Mold is located in Shenzhen, China, and has around 120 employees. They serve automotive, medical, and electronics markets worldwide.

Product Range

- Precision injection molded parts: For medical devices, connectors, and electronics.

- Multi-cavity and family molds: Designed to produce more parts in each cycle.

- Insert and overmolding: Great for combining plastic and metal or rubber materials.

- Custom plastic enclosures: Often used for consumer devices and instruments.

- Bridge tooling: Temporary tools used before mass production begins.

Research & Development (R&D)

- Offers mold flow analysis to improve part design before tooling begins.

- DFM support from engineers helps reduce cost and cycle time.

- Short-run prototype tools are made for testing and refinement.

- Adapts easily to design revisions or material changes.

- Known for helping customers develop durable molds at competitive prices.

Lead Times & Production Turnaround

- Standard mold building takes 4–6 weeks depending on complexity.

- Production parts can ship in 1–2 weeks after mold approval.

- Fast-track production available on request.

- Delays may occur with international shipping or extended approval cycles.

- I once worked with a team that got final parts delivered in less than three weeks from the first design sign-off.

Final Verdict

ACO Mold is a great fit if you’re looking for a balance of precision, cost savings, and responsive engineering. However, projects that require in-person visits or on-site audits may be harder to coordinate due to geographic distance.

Conclusion

You’ve now seen what each injection molding company offers—from location and lead times to what sets them apart. This guide gives you the tools to choose wisely, save time, and avoid costly mistakes.

When I started, I didn’t know who to trust. Now you do.

So, where do you go from here? Start with what matters most to you—speed, scale, or support.

Contact us today—we’re here to help you move forward.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.