I thought I found the perfect supplier.

They had the right machines. The right price. The right promises.

But once I sent the deposit? Silence. No updates. No samples. Just… gone.

That was my first lesson in choosing a plastic injection molding manufacturer in China.

Since then, I’ve worked with dozens—some good, some not so good. I’ve learned what to look for, what to ask, and what signs to run from.

If you’re trying to find the right manufacturer for your product, I get it. It’s a big decision. And a risky one—if you don’t know where to look.

This article shares 9 reliable manufacturers in China, with key facts like company size, website, and founding year. I’ll also show you how to spot a trustworthy partner—so you don’t waste time or money.

By the end, you’ll have a clear list and a clear path forward.

So let’s begin!

Quick Comparison Chart

Before diving into the full reviews, here’s a quick snapshot of each manufacturer. This table gives you a clear view of how they compare at a glance.

| Manufacturer Name | Year Founded | Location | Certifications | Core Products | Special Capabilities |

| MachMaster | 2010 | Shenzhen | ISO 9001 | Plastic housings, brackets, enclosures | High-precision CNC, ±0.01mm tolerance |

| Tontec International | 1984 | Kowloon Bay | ISO 9001, ISO 14001, IATF 16949 | Automotive, medical, electronics | Multi-shot molding, global delivery network |

| TK Group | 1983 | Shenzhen | ISO 9001, ISO 13485 | Automotive, medical, electronics | Insert molding, overmolding |

| Hongrita Mold | 1988 | Shenzhen/Zhongshan | ISO 9001, ISO 14001, ISO 13485, IATF 16949 | Medical parts, baby care, electronics | LSR molding, multi-shot molding |

| HanKing Mould | 1996 | Shenzhen | ISO 9001, ISO 14001, ISO 13485, IATF 16949 | Automotive, electronics, medical parts | Two-shot molding, high-tonnage machines |

| Richfields Corporation | 2001 | Dongguan | ISO 9001, IATF 16949 | Large plastic parts, consumer goods | Gas-assisted molding, moldflow simulation |

| FOW Mould | 2009 | Taizhou, Zhejiang | ISO 9001 | Storage boxes, baby products, furniture | Insert molding, large-part molds |

| Eco Molding | 2008 | Shenzhen | ISO 9001:2008 | Electronics, appliances, automotive | Fast DFM review, small-mid batch focus |

| Star Rapid | 2005 | Zhongshan | ISO 9001, ISO 14001, BS-OHSAS 18001 | Prototypes, electronics, medical parts | Rapid prototyping, micro molding |

Now that you’ve seen the overview, let’s move into each manufacturer’s full profile.

1. MachMaster

I first found MachMaster while helping a friend who needed precision parts for a medical project. His last supplier couldn’t meet the tolerances. MachMaster didn’t just fix the issue—they helped refine the design and delivered everything on time, with better accuracy than expected.

Founded in 2010 and based in Shenzhen, China, MachMaster has around 100 employees. They specialize in CNC machining, plastic injection molding, and sheet metal, serving industries like electronics, medical, and automation.

Product Range

- Core Products: Plastic housings, brackets, connectors, enclosures

- Special Capabilities: ±0.01mm tolerance for high-precision parts

- Best-Sellers: CNC aluminum components, molded medical devices

- Limited Runs: Supports small batches and pilot production

- What Stands Out: Consistent accuracy, fast lead times, and engineering support

Manufacturing Capabilities

- Production Volume: Handles both low and high-volume orders

- Product Types: Injection molded parts, machined metal components, sheet metal parts

- Customization: Offers OEM (you design, we produce), ODM (we design and produce), and private label options

- In-House Work: All core processes are performed on-site

- Technology: Uses 4-axis/5-axis CNC, EDM, and advanced measuring tools

Quality Control & Assurance

- Raw Materials: Sourced from certified, traceable suppliers

- Standards: ISO 9001 certified with strong internal procedures

- Testing: Includes CMM inspection, visual checks, and stress testing

- Audits: Passed multiple third-party quality audits

- Defect Rate: Consistently low, based on client data

- Support: Dedicated account managers provide fast and clear communication

Final Verdict

MachMaster is well-suited for businesses that value precision, clear communication, and fast turnaround. Their in-house capabilities and quality systems make them a dependable choice for technical and custom parts.

2. Tontec International Limited

Finding a reliable injection molding partner isn’t always easy. I’ve seen companies deal with long delays, poor follow-up, and parts that miss the mark. One client made the switch to Tontec—and the difference was clear right away.

Tontec was founded in 1984 and is headquartered in Kowloon Bay, Hong Kong. With over 4,000 employees, the company has global manufacturing sites and supports industries like automotive, electronics, consumer goods, and medical.

Product Range

- Core Products: Automotive parts, medical housings, electronic components

- Special Capabilities: Overmolding and multi-shot molding for combining materials

- Best-Sellers: Ventilator components, dashboard frames, device casings

- Limited Runs: Available but more efficient with high-volume projects

- What Stands Out: Strong design feedback and global delivery support

Manufacturing Capabilities

- Production Volume: Suitable for millions of units annually

- Product Types: Complex molded parts with fine tolerances and technical features

- Customization: Full OEM and ODM services available

- In-House Work: Mold design, molding, and assembly done onsite

- Technology: Advanced molding lines, robotics, and cleanroom operations

Quality Control & Assurance

- Raw Materials: Fully traceable, certified sources

- Standards: ISO 9001, ISO 14001, and IATF 16949 certifications

- Testing: Dimensional checks, chemical analysis, stress testing

- Audits: Regular client and third-party audits

- Defect Rate: Very low, due to automation and tight QC

- Support: International service team with bilingual engineers

Final Verdict

Tontec is a great match for businesses that need high-quality parts at volume with strong engineering support. However, they’re best suited for technical projects where design complexity and consistency are critical.

3. TK Group (Holdings) Limited

When I visited TK Group’s facility in Shenzhen, I could tell right away—they take their work seriously. The machines ran smoothly. The staff stayed focused. And the plastic parts coming off the line looked sharp and consistent. You could feel the quality in the air.

TK Group was founded in 1983 and is based in Shenzhen, China. They have more than 4,000 employees across multiple production sites within China and specialize in high-precision injection molding.

Product Range

- Core Products: Medical devices, car parts, electronics, packaging

- Special Capabilities: Multi-shot molding, overmolding, insert molding

- Best-Sellers: Device shells, dashboard panels, smart home casings

- Limited Series: Offers short-run and mass production

- What Stands Out: End-to-end support from design to delivery

Manufacturing Capabilities

- Production Volume: Handles millions of parts per year

- Product Types: Technical and complex plastic components

- Customization: OEM and ODM services offered

- In-House Work: Tooling, molding, and assembly all done internally

- Technology: Automated production lines and precision molding equipment

Quality Control & Assurance

- Material Sourcing: Traceable materials from certified suppliers

- Standards: ISO 9001, ISO 14001, IATF 16949 certified

- Testing: Includes visual checks, stress testing, and functional tests

- Audits: Regular quality audits by local and global clients

- Defect Rate: Maintains low rates through automation and quality checks

- Support: Clear feedback loops and fast issue resolution

Final Verdict

TK Group stands out for its comprehensive services and commitment to quality, making it an excellent choice for complex, high-volume projects. However, for smaller-scale endeavors, other manufacturers might offer more flexibility.

4. Hongrita Mold Engineering Co., Ltd.

If you’re working on a project that demands clean, precise, and consistent plastic parts, Hongrita is worth considering. I once helped a team source baby product molds that had to meet strict safety standards. Hongrita stood out. They didn’t just deliver the molds—they delivered confidence.

Hongrita was founded in 1988 and is based in Shenzhen, China. Today, they operate large production facilities in Zhongshan, with more than 1,700 employees across their China operations.

Product Range

- Core Products: Medical parts, baby care molds, automotive seals, electronics

- Special Capabilities: LSR (liquid silicone rubber), multi-shot molding, mold-integrated automation

- Best-Sellers: Pacifiers, electronic casings, precision valve parts

- Limited Series: Supports both prototyping and full-scale runs

- What Stands Out: Strong mix of mold design and plastic production in one place

Manufacturing Capabilities

- Production Volume: Handles mass production for global brands

- Product Types: High-precision injection molded plastic components

- Customization: OEM and ODM services available

- In-House Work: Tooling, molding, and equipment setup done internally

- Technology: AI-assisted systems, cleanroom molding lines

Quality Control & Assurance

- Material Sourcing: Uses fully traceable, certified materials

- Standards: ISO 9001, ISO 14001, ISO 13485, IATF 16949 certified

- Testing: Optical checks, stress testing, and material analysis

- Audits: Frequent audits from local and global clients

- Defect Rate: Low rates supported by automated inspections

- Support: Strong after-sales communication with clear escalation processes

Final Verdict

Hongrita is a smart choice for projects that require strict quality and complex molding, especially in health and baby-related products. However, their advanced systems may be more than you need if your parts are simple and don’t require extra engineering.

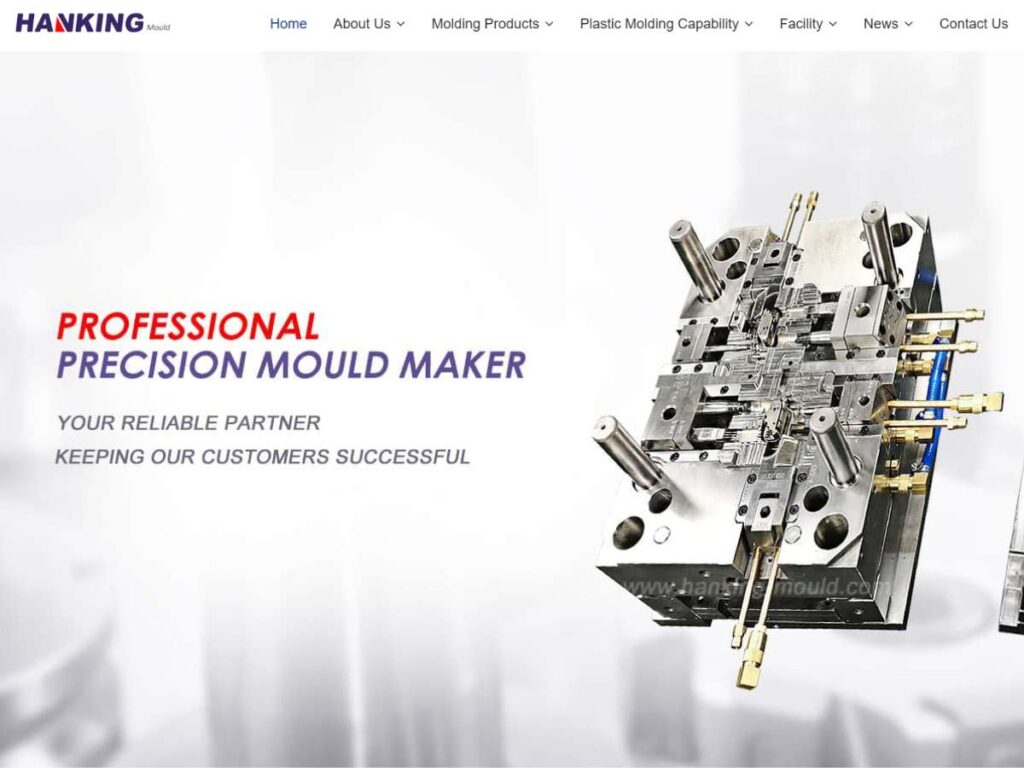

5. HanKing Mould Engineering Ltd.

I remember asking myself, “Can they really handle this kind of complex mold?” I was helping a client with a tight deadline and tricky specifications. HanKing didn’t just say yes—they showed me the steps, flagged possible challenges, and worked through the details without hesitation. It felt like I was working with a partner, not just a vendor.

Founded in 1996, HanKing is based in Shenzhen, China. They have over 600 employees and specialize in high-precision injection molds and molded plastics.

Product Range

- Core Products: Automotive parts, electronics, medical device housings

- Special Capabilities: Two-shot molding, insert molding, overmolding

- Best-Sellers: Fuse blocks, medical sensor housings, precision connectors

- Limited Series: Handles both small-batch and full-scale orders

- What Stands Out: Full in-house process from CAD design to final part

Manufacturing Capabilities

- Production Volume: Over 700 mold sets annually

- Product Types: Complex, tight-tolerance injection molded parts

- Customization: OEM and ODM options available

- In-House Work: Full design, tooling, and production handled onsite

- Technology: CNC, EDM, and injection machines from 60–1600 tons

Quality Control & Assurance

- Material Sourcing: All materials are traceable and certified

- Standards: ISO 9001, ISO 14001, ISO 13485, IATF 16949

- Testing: Includes IQC (incoming), IPQC (in-process), OQC (outgoing), and full dimensional checks

- Audits: Regular third-party and customer audits

- Defect Rate: Very low due to multiple QC layers

- Support: Clear reporting and fast follow-up with dedicated engineers

Final Verdict

HanKing is a great fit if you need a partner that combines engineering depth with hands-on communication. However, because their process is highly structured, urgent last-minute changes may require more lead time.

6. Richfields Corporation

When I needed help with a large injection mold project a few years ago, Richfields came highly recommended. I remember thinking, “Let’s see if they can really pull this off.” They didn’t just meet expectations—they made smart tweaks to the design and delivered clean, consistent parts right from the first run.

Richfields was founded in 2001 and is based in Dongguan, China. With over 250 employees, they focus on tooling and plastic injection molding for global clients.

Product Range

- Core Products: Automotive housings, home appliances, consumer electronics

- Special Capabilities: Overmolding, insert molding, gas-assisted molding

- Best-Sellers: Large plastic covers, precision enclosures, interior parts

- Limited Series: Handles both prototypes and high-volume jobs

- What Stands Out: Large-part molding with strong design feedback

Manufacturing Capabilities

- Production Volume: Over 300 molds per year

- Product Types: Complex plastic parts, mid-to-large size molds

- Customization: OEM and ODM services available

- In-House Work: All design, tooling, and molding done internally

- Technology: CNC, EDM, and machines up to 3,300 tons

Quality Control & Assurance

- Material Sourcing: Certified and traceable vendors

- Standards: ISO 9001 and IATF 16949

- Testing: Moldflow simulation, first-article inspections, and stress tests

- Audits: Regular third-party and client reviews

- Defect Rate: Low, backed by real-time QC monitoring

- Support: Clear reporting and responsive technical support

Final Verdict

Richfields is a strong choice if your parts are large, detailed, and need precision right from the start. However, their expertise is best used for medium-to-large molds—projects with simple, tiny parts might not fully benefit from their setup.

7. FOW Mould

If you’ve ever tried to source molds for bulky plastic parts, you know how tricky it gets. I was once helping a client who needed crate molds—strong, durable, and ready fast. FOW Mould stood out right away. They didn’t just say they could do it. They explained how they’d do it, step by step. That gave us confidence.

FOW Mould was founded in 2009 and is based in Taizhou, Zhejiang, China. They have decades of industry experience and a team that serves global brands.

Product Range

- Core Products: Plastic storage crates, buckets, baby product molds, bins, and furniture parts

- Special Capabilities: Insert molding, overmolding, gas-assisted molding

- Best-Sellers: Crate molds, baby product molds, tool storage box molds

- Limited Series: Can support both short-run and mass production

- What Stands Out: Strong in large-part molds with quick turnaround

Manufacturing Capabilities

- Production Volume: Around 900 molds made each year

- Product Types: Medium to large plastic products

- Customization: Offers OEM (you design) and ODM (they design) services

- In-House Work: All tooling and production done inside their own factory

- Technology: High-tonnage machines, precision CNC, and automated handling

Quality Control & Assurance

- Material Sourcing: All plastic and steel is certified and traceable

- Standards: ISO 9001 certified manufacturing

- Testing: Moldflow analysis, trial runs, and full QC checks

- Audits: Reviewed regularly by outside clients

- Defect Rate: Kept low through early-stage design checks

- Support: Fast response with English-speaking project managers

Final Verdict

FOW Mould is a smart pick if you’re building large plastic parts and need both speed and support through the whole process. However, their focus on big-item tooling means they may not be the best fit for tiny, high-detail components.

8. Eco Molding Co., Ltd.

If you’ve ever stressed over late samples or unclear communication from a supplier, I’ve been there too. One of my projects depended on getting precise plastic housings made fast. I remember thinking, “Please let this one go smoothly.” Eco Molding made it happen.

Founded in 2008, Eco Molding is located in Shenzhen, China. Their team includes over 100 employees, and they focus on small-to-mid volume plastic injection molding with fast lead times.

Product Range

- Core Products: Plastic parts for electronics, appliances, and automotive components

- Special Capabilities: Insert molding, overmolding, mold design for precision fit

- Best-Sellers: Control housings, bracket covers, casing components

- Limited Series: Good for small-batch or medium-volume production

- What Stands Out: Fast DFM review and clear, English-friendly project updates

Manufacturing Capabilities

- Production Volume: Roughly 40–50 molds per month

- Product Types: Tight-tolerance plastic parts with moderate size and complexity

- Customization: Offers OEM and ODM support

- In-House Work: Tooling, molding, and finishing done under one roof

- Technology: CNC, EDM, and injection machines up to 650 tons

Quality Control & Assurance

- Material Sourcing: All materials are traceable and certified

- Standards: ISO 9001:2008 certified

- Testing: Includes mold flow analysis, first-article inspection, and fatigue testing

- Audits: Regular audits from clients and third parties

- Defect Rate: Low, thanks to strict in-process quality checks

- Support: Quick response and bilingual project engineers

Final Verdict

Eco Molding is a smart choice if you want tight tolerances, fast response, and strong design support on small-to-mid sized parts. However, if your project needs heavy automation or advanced packaging services, they may not offer those in-house.

9. Star Rapid

I was once sitting across from a client who said, “We need this fast, but it has to be perfect.” I remember thinking, “Who’s fast and precise—and actually good at both?” That’s when I turned to Star Rapid. We didn’t just get parts delivered—we got support, updates, and results that made us look good.

Star Rapid was founded in 2005 and is based in Zhongshan, China. With over 250 employees, they focus on rapid prototyping and low-volume production for global clients.

Product Range

- Core Products: Plastic parts, CNC components, 3D-printed metal parts

- Special Capabilities: Micro molding, overmolding, insert molding

- Best-Sellers: Consumer electronics cases, medical prototypes, lighting parts

- Limited Series: Best for prototypes or short-run production

- What Stands Out: Full-service support from design to finished part—delivered fast

Manufacturing Capabilities

- Production Volume: Specializes in short runs, up to a few thousand units

- Product Types: Technical plastic and metal parts

- Customization: OEM (you design) and ODM (they design) services available

- In-House Work: All work—including CNC, molding, and finishing—is done on-site

- Technology: CNC, EDM, and molding presses from 25 to 1000 tons

Quality Control & Assurance

- Material Sourcing: Certified and traceable materials

- Standards: ISO 9001, ISO 14001, and BS-OHSAS 18001 certified

- Testing: Moldflow, CMM inspection, and 3D scanning

- Audits: Reviewed by third parties and overseas clients regularly

- Defect Rate: Low, backed by real-time QC systems

- Support: Dedicated service team with fluent English and fast responses

Final Verdict

Star Rapid is ideal for fast-turn projects that need design input, technical guidance, and tight deadlines. However, if you’re planning a high-volume rollout, their low-volume setup may not be the most cost-efficient in the long run.

Conclusion

You’ve seen how each manufacturer compares—what they offer, how they operate, and where they shine.

When I first helped a friend choose the right partner, it changed everything. He didn’t just find a supplier—he found confidence in his product again.

Now it’s your turn.

Ready to make your idea real?

Contact us today and let’s take the next step—together.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.