I remember the day a client called us, frustrated.

Their CNC supplier had missed a tolerance. Just 0.02mm off but it meant the entire batch of surgical parts had to be scrapped. Deadlines were missed. Costs piled up.

That mistake wasn’t just about precision. It was about trust. And in medical manufacturing, that trust is everything.

I’ve seen what happens when the wrong supplier is chosen and what it takes to get it right.

If you’re here, you’re probably trying to figure out if a CNC machining supplier or even your current process is good enough for medical-grade work.

In this article, I’ll walk you through how to evaluate a supplier for medical CNC machining. You’ll learn what to ask, what to watch for, and how to make sure your parts meet tight tolerances, regulatory standards, and real-world use.

By the end, you’ll have a clear way to judge whether a machining partner is truly ready or just saying they are.

So let’s begin!

1. What Is Medical CNC Machining?

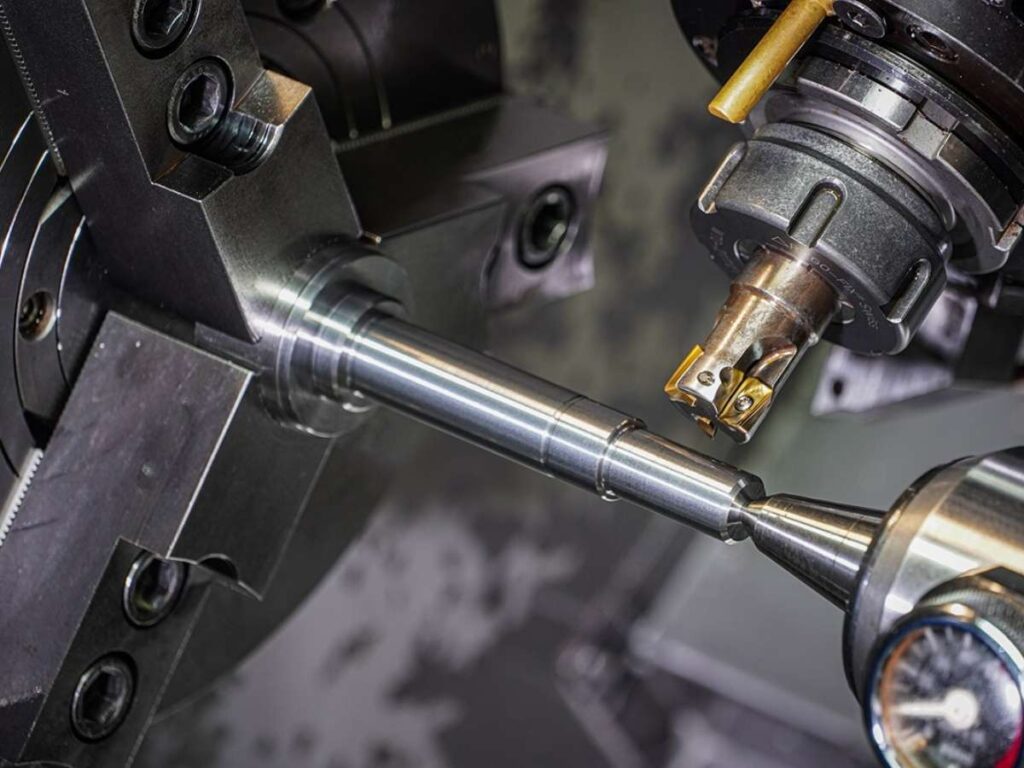

The first time I saw a CNC machine cut a titanium bone screw, I was amazed. No room for error. No guesswork. Just a perfectly machined part that could one day save a life.

Medical CNC machining means using high-precision machines to create parts for the medical field.

CNC stands for Computer Numerical Control. It’s a way of using a computer to control machining tools—like drills, mills, and lathes. The machine follows a set of digital instructions (called G-code) to cut or shape materials with incredible accuracy.

Everything is automated. Everything is repeatable. And most importantly it’s extremely precise.

How precise? We’re talking about tolerances as tight as ±0.01 mm or better. That’s thinner than a human hair.

In medical work, precision matters. Small flaws can lead to failure.

CNC machining gives you:

- Accuracy: parts fit right, function safely

- Repeatability: every part is the same

- Flexibility: complex shapes are no problem

- Scalability: works for one piece or thousands

Medical CNC machining includes several key methods:

- Milling: cuts shapes using spinning tools

- Turning: spins the part while cutting (great for round components)

- Drilling: makes precise holes

- EDM (Electrical Discharge Machining): uses sparks to shape very hard metals

Each method plays a role depending on the part’s design and material.

CNC machining is used to make all kinds of medical parts, such as:

- Implants

- Surgical tools

- Prosthetics

- Diagnostic equipment

- Lab components

- Custom fixtures

These parts are often used in regulated industries like healthcare and medical devices. Many CNC shops are certified under quality systems like ISO 13485 to meet these strict standards.

2. Benefits of Medical CNC Machining

When you’re sourcing or designing a medical part, you don’t have time for guesswork.

The stakes are high. A tiny error can stop a product from working or keep it from passing inspection. I’ve seen it happen. A supplier misses tolerance by 0.01 mm, and the part fails the final check.

That’s why medical CNC machining is such a strong choice. It gives you what you need when precision, safety, and speed matter most.

Precision

CNC machining hits tight tolerances as close as ±0.01 mm or better.

This level of precision isn’t just technical it’s critical for:

- Functionality: parts must work exactly as designed

- Safety: especially for tools and implants

- Regulatory compliance: like FDA approval or ISO 13485 certification.

When you’re working with strict requirements, CNC machining gives you confidence. Each part will meet the drawing specs again and again.

Repeatability: Fewer Surprises

One good prototype means nothing if the next batch is off.

CNC machining is repeatable. That means you can run 10 or 10,000 parts and still get the same result.

This saves time. Avoids waste. And helps your team hit deadlines without chasing defects.

Fast Prototyping and One-Off Builds

Need a part fast? CNC can make it happen.

You can go from CAD model to physical part in just a few days. That speed is a big help when:

- You’re testing a new design

- You need a custom fit for a patient

- You’re trying to get investor samples ready

I’ve worked with clients who needed a rush part for clinical trials. CNC got them what they needed on time, no drama.

Works with Medical-Grade Materials

Medical parts use all kinds of materials.

CNC machines can cut:

- Titanium: strong and biocompatible

- PEEK plastic: used in implants and surgical tools

- Stainless steel: durable and corrosion-resistant

- Other specialized metals and polymers

You’re not locked into one material. CNC lets you pick what works best based on strength, weight, or how it reacts in the body.

You might start with one part. But later, you’ll need 500. Or 5,000.

CNC is ready for both.

It’s great for prototypes, but also handles high-volume production with tight quality control. That means no surprise shifts in part quality halfway through the run.

3. Materials Used in Medical CNC Machining

Choosing the right material is one of the most important steps in medical CNC machining.

I’ve worked on projects where the design was perfect but the material wasn’t. Parts cracked during sterilization, or failed biocompatibility tests. That’s why your material decision needs to match the part’s real-world use.

Common Metals Used

- Titanium: Lightweight, corrosion-resistant, and safe for implants that stay inside the body.

- Stainless Steel (316L, 17-4PH): Used for surgical tools and fasteners because it’s strong, rust-resistant, and holds up to cleaning.

- Aluminum: Good for instrument handles or housings that don’t go inside the body, thanks to its low weight and easy machinability.

- Cobalt-Chrome: A tough, wear-resistant metal often used in orthopedic and dental implants.

Plastics and Polymers

- PEEK (Polyether ether ketone): A strong, implant-grade plastic that’s biocompatible and works well for spinal or orthopedic parts.

- Ultem (PEI): A sterilizable plastic often used in medical devices that need both strength and heat resistance.

- Delrin (Acetal) and PTFE (Teflon): Great for moving parts, seals, and valves thanks to their low friction and chemical resistance.

4. Common Medical Components Made with CNC Machining

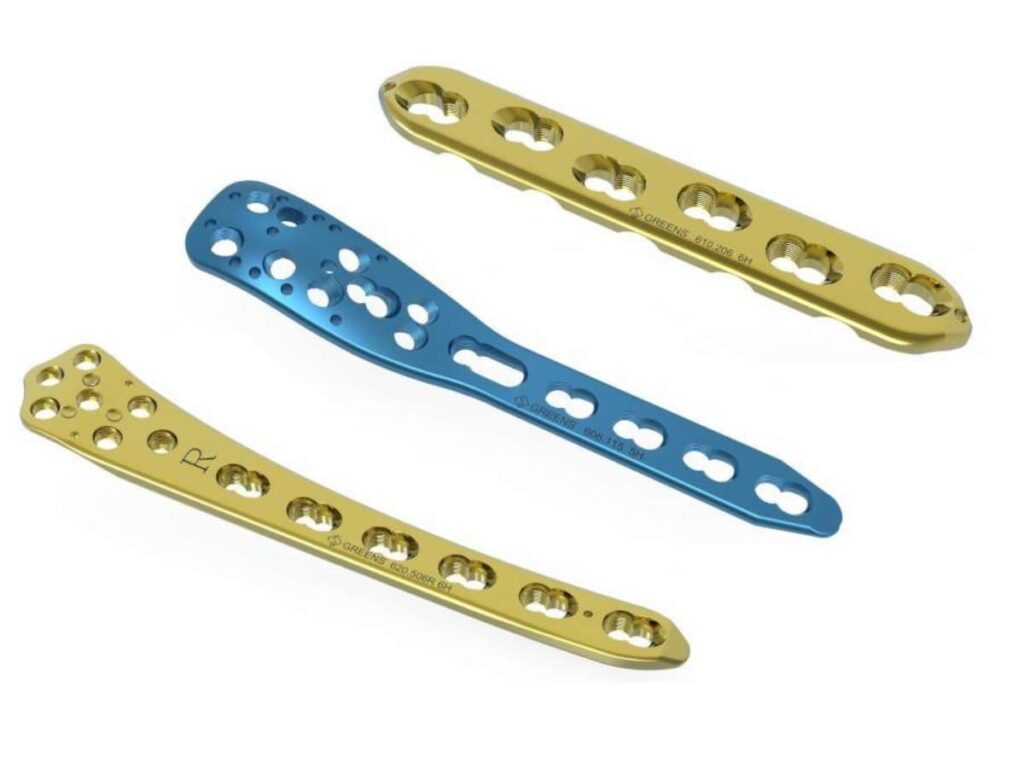

I still remember the first time I held a titanium bone plate fresh off the machine.

It was small, smooth, and shaped with incredible detail. You could tell it wasn’t just metal it was something made to help someone heal.

That’s the power of CNC machining in medicine. It creates real, working parts that doctors and patients depend on every day.

Orthopedic Implants

CNC machining is often used to make parts that go inside the body. These parts need to fit the patient perfectly and hold up under stress.

Examples include:

- Bone plates

- Bone screws

- Hip stems

- Spinal cages

These parts are often made from titanium or other strong, biocompatible materials.

Surgical Instruments

Surgery tools must be sharp, clean, and easy to handle. CNC machines can make these tools with precision and repeatability.

Examples include:

- Scalpels

- Scissors

- Forceps

- Needle holders

These tools need smooth finishes and perfect edges, which CNC machining can provide.

Diagnostic and Monitoring Equipment

CNC is also used to make parts for machines that help diagnose or monitor health conditions.

You’ll find CNC parts in:

- Imaging machines

- Scanners and monitors

- Instrument brackets

- Protective housings

These parts may not go inside the body, but they still need to be accurate and reliable.

Dental Tools and Implants

Dentists rely on CNC-made parts, too. These need to be small, detailed, and safe for long-term use.

Examples include:

- Dental crowns

- Bridges

- Implant abutments

- Dental drills

Most of these are custom-made to fit a specific patient’s mouth.

Custom Prosthetics and Assistive Devices

Not every medical part is for surgery. CNC machining also helps people move and live better.

Examples include:

- Artificial limbs

- Joint supports

- Custom handles or grips

- Mobility aids

Each one can be made to match a person’s exact needs.

If you’re designing or sourcing medical parts, it helps to see what’s already being made. CNC machining is used across the medical field for tools, implants, and equipment that people rely on every day.

5. Medical CNC Machining vs Other Manufacturing Methods

When you’re deciding how to do a medical part, the options can get overwhelming.

I’ve worked with teams who chose the wrong method just to save money and ended up losing more in the long run. Others overpaid for CNC when a simple mold would’ve worked.

To help you make the right call, here’s a simple breakdown.

| Feature/Factor | CNC Machining | Injection Molding | 3D Printing | Casting / Forging |

| Best for | Custom parts, low to mid volumes, tight tolerances | High-volume plastic parts with fixed designs | Concept models, low-strength or one-off parts | High-volume metal parts where slight variation is okay |

| Tolerances | Very high (±0.01 mm or better) | Moderate; depends on mold quality | Low to moderate | Lower precision than CNC; post-processing may be needed |

| Tooling required | No | Yes (mold cost is high upfront) | No | Yes (requires molds or dies) |

| Setup time | Fast | Long (tooling must be made first) | Fast | Long |

| Material options | Metals, plastics, biocompatible materials | Mostly plastics (medical-grade possible with right resin) | Plastics, limited metal options | Mostly metals |

| Surface finish | Smooth, clean, suitable for implants and surgical use | Good for plastics, may need post-processing | Often rough; needs extra finishing | Varies; often rough, may need machining after casting |

| Strength and durability | High | Good, but depends on plastic type | Lower than CNC | High, but part accuracy is harder to control |

| Regulatory track record | Strong; widely used in FDA- and ISO-regulated parts | Good; especially for housings and disposables | Weak; limited approvals for final medical parts | Moderate; may need CNC finishing to meet medical standards |

| Cost per part | Moderate to high (varies by complexity) | Low after tooling is made | Low for prototypes, high for functional parts | Low at scale, high setup cost |

| Design flexibility | Very high; easy to make changes | Low; design changes mean new tooling | Very high; ideal for testing ideas quickly | Low to moderate; changes are costly |

6. Challenges in Medical CNC Machining

CNC machining is a strong choice for medical parts. But like anything worth doing, it comes with challenges.

I’ve seen projects get delayed not because the machining failed, but because small details were missed. If you’re buying or designing medical components, it’s important to know what can go wrong and how to plan for it.

Regulatory Compliance

Medical parts are held to strict standards. Depending on where you plan to sell or use them, you may need to meet ISO 13485, FDA rules, or CE marking for Europe. These are not just checkboxes they affect every step of the process, from material sourcing to inspection. If your supplier hasn’t worked within these systems before, it can lead to delays or rejections.

Surface Finish Requirements

Getting the part to the right size isn’t always enough. Many medical components need a clean, smooth surface. That could mean polishing sharp edges, passivating stainless steel to fight corrosion, or adding special coatings. These finishing steps take time and skill. If they’re skipped or rushed, the part might fail visual checks or worse, real-world use.

Documentation and Traceability

In the medical world, you can’t just say a part is good you have to prove it. That means tracking where the material came from, who machined it, and how it was inspected. You may need serial numbers, batch records, and quality reports. If something goes wrong in the field, being able to trace the issue back to a specific lot can make or break your response.

Tight Tolerances and Complex Designs

Medical parts often require tolerances tighter than ±0.01 mm. Holding that kind of precision especially on small, intricate parts takes more time, more tools, and more care. It’s possible, but it adds cost. And if the design is complex, the setup gets even trickier. These parts may need slower feeds, multiple operations, or custom fixtures.

Material Waste and Cost

CNC machining cuts away material to make each part. That means more waste, especially with high-end metals like titanium or cobalt-chrome. When you’re working with small runs or expensive materials, scrap adds up fast. It’s something many buyers don’t think about until it affects the bottom line.

7. Tips for Choosing the Right Medical CNC Machining Services

Choosing the right machining partner for medical parts isn’t just about who has the best machines.

It’s about who understands your industry. Who communicates clearly. Who follows the rules every time.

I’ve worked with suppliers who looked great on paper, but couldn’t back it up. So here’s how to ask the right questions and find someone who can deliver.

Check Certifications

Start by asking what certifications the shop has. These show whether they follow medical-grade quality systems.

Look for:

- ISO 13485: Covers quality systems for medical device manufacturing

- ISO 9001: A general quality management standard, still helpful

- FDA Registration: Important for U.S. sales or FDA-regulated parts

At MachMaster, we’re proud to hold ISO 9001 certification and follow the same quality systems required by regulated industries. We’re used to the demands of medical, electronics, and automation projects and we build quality into every part.

Industry Experience

You don’t want to be someone’s test project. Ask what industries they’ve worked in.

Focus on:

- Previous medical jobs

- Related fields like aerospace or defense

- Experience with tight tolerances and exotic materials

Ask for real examples: What parts have they made? What were the results? Can they provide references?

Inspection and Quality Control

This is where great shops stand out. A solid inspection process gives you confidence before you commit to production.

Ask about:

- CMM Reports: These measure the part with extreme accuracy

- First Article Inspection (FAI): Confirms the first piece matches the design

- Full dimensional Reports: Lists actual measurements for key features

These documents help catch mistakes early before they become expensive.

Capabilities and Turnaround Time

Don’t assume every shop can machine medical-grade parts.

Ask direct questions like:

- Can you hold ±0.01 mm tolerances?

- Can you machine titanium, PEEK, or cobalt-chrome?

- What’s your lead time for a prototype?

- How fast can you scale up to production?

At MachMaster, we specialize in fast turnarounds without cutting corners. Whether you need one prototype or thousands of production parts, we’re built to deliver with precision and on time.

Communication and Documentation

Medical parts need traceability. You need to know where materials came from and how parts were made.

Ask if they provide:

- Lot tracking

- Revision control

- Traceability reports

Good shops will have systems in place and won’t hesitate to share them.

Conclusion

You’ve learned what medical CNC machining is, how it works, what materials to use, and how to pick a trusted supplier.

Whether you’re sourcing your first part or switching partners, you know what to look for and what to avoid.

So, what’s stopping you?

Start asking smarter questions. Start building parts that meet real standards.

Need a shop that actually gets medical work?

At MachMaster, we work with medical-grade materials and precision requirements every day.

Contact us today. We can help you turn your drawings into reliable, production-ready parts.