I still remember the smell.

A burnt, chemical stink that filled the room after I overheated a virgin PTFE block during a client prototype.

I thought I had it under control.

I didn’t.

Back then, I treated Teflon like any other thermoplastic. That was my mistake.

And it’s a mistake I see people repeat—especially if they’ve never worked with PTFE before.

I’ve machined Teflon in small R&D runs and in full-scale production. It’s different. It’s slippery. It moves. It pushes back. But once you understand it, it becomes manageable.

This guide is for you if you’re trying to:

- Stop material from deforming under the tool

- Get clean edges and consistent results

- Avoid wasting time, tools, and money

Whether you’re running a factory, prototyping a new part, or just working on a personal build, I’ll give you the tools and knowledge I wish I had that day.

Let’s start!

1. What is Machining Teflon?

You’ve probably heard of Teflon in cookware, but in your industry world whether it’s seals, gaskets, or chemical-resistant components—Teflon (PTFE) is much more than just non-stick.

If you need parts that handle chemicals, heat, or friction without breaking down, Teflon should be on your radar. I’ve cut everything from lab spacers to pump bushings using it—and chances are, it’s already in some part of your operation.

Properties of Teflon

Here’s what makes Teflon a challenge and a benefit when machining:

- Low friction surface: It’s extremely slippery. That’s great for performance but tricky for tool grip and work holding.

- Soft and pliable: It dents easily under pressure and is prone to deformation if your clamping setup is off.

- Chemically inert: It doesn’t react with most chemicals, making it perfect for lab, food, or medical uses.

- High thermal expansion: It changes size when heated—much more than metals or even other plastics. This can throw off your part dimensions if you’re not careful.

- Excellent heat resistance: It holds up under high temperatures, up to around 260°C (500°F). That’s one reason it’s used in high-performance environments.

Those properties are what saved my client’s job, once we understood how to machine Teflon the right way.

2. Advantages of Machining Teflon

There was a time I dreaded machining Teflon. It felt too soft, too slippery, and honestly, too unpredictable. I’d finish a run, and parts would come out warped, oversized, or just off. Now, I see why so many engineers and buyers specifically request Teflon for critical parts.

Here’s what makes Teflon a smart choice for your next project:

High Chemical Resistance

Teflon stands up well against strong acids, bases, and solvents. You can count on it for parts used in lab setups, chemical processing tools, and fluid systems. It holds up over time—even when exposed to harsh substances.

Low Coefficient of Friction

Teflon has one of the lowest friction levels of any solid material. That means smooth movement with less wear and heat. It’s ideal for sliding parts like bushings, bearings, and guides.

Wide Operating Temperature Range

Teflon remains stable in both high and low temperatures. It can operate continuously up to 260°C (500°F) and also perform well under cryogenic conditions. This versatility makes it suitable for aerospace, automotive, and industrial heat applications.

Electrical Insulation

Need something that holds up under wet or humid conditions? Teflon resists moisture and keeps its insulating properties. You’ll find it used in cables, housings, and electronic components where signal reliability matters.

Non-Stick Surface

Thanks to its natural non-stick properties, Teflon prevents buildup of sticky materials, powders, or fluids. This is especially valuable in food processing, pharmaceutical manufacturing, and applications where surfaces need to remain clean and functional.

Resistance to UV and Weather Exposure

Teflon does not absorb moisture, and it remains stable when exposed to UV light or outdoor conditions. It doesn’t become brittle, crack, or degrade easily, making it a solid option for long-term outdoor or field-based use.

With the right setup, machining Teflon unlocks performance that few materials can match—especially in demanding, high-precision environments.

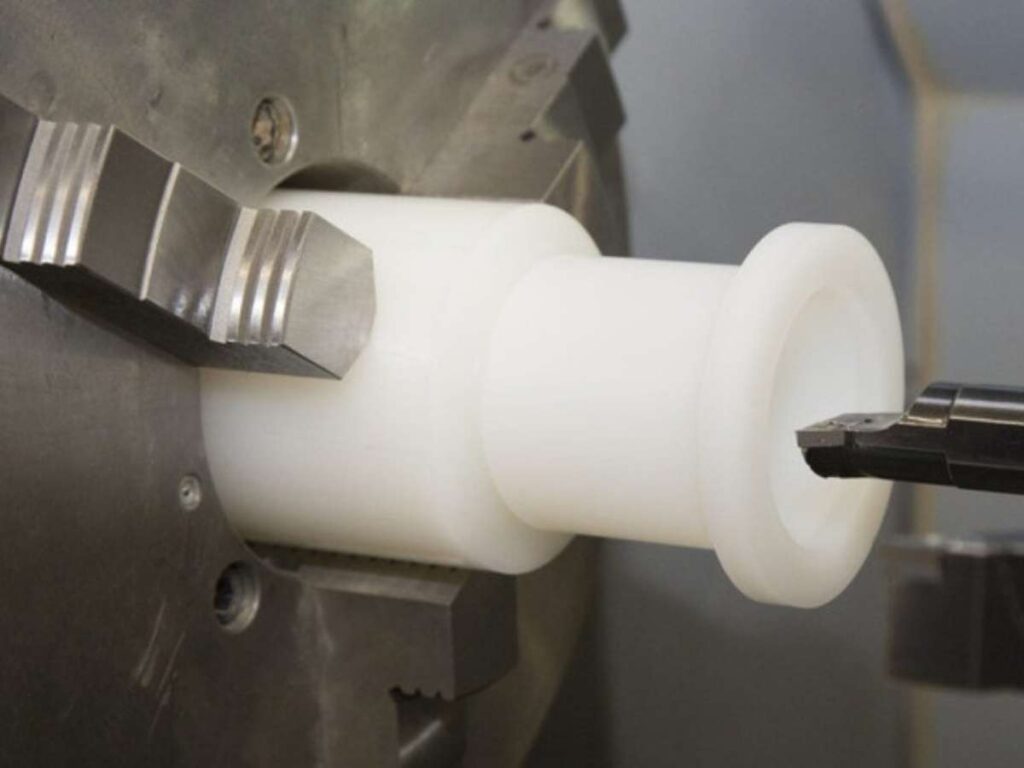

3. Step-by-Step Process of Machining Teflon

Teflon parts look easy on paper. But machining them the wrong way can lead to warping, surface defects, or loose tolerances—costing time and money.

If you’re planning to work with a machining supplier, here’s what a proper Teflon process should look like.

Step#1 Select the Right Grade of Teflon

Start by picking the grade that fits your part’s job.

- Virgin PTFE is soft and great for seals or insulators.

- Glass-filled or carbon-filled PTFE gives more strength and better wear resistance.

If your part needs to stay tight on size or deal with stress, filled grades work better. Choosing the wrong grade can lead to cracks, fast wear, or sizing issues later.

Step#2 Prepare the Material and Setup

Teflon moves. After it’s rough-cut, it needs time to rest.

A good supplier will rough-machine oversized blanks, then let them sit for several hours.

This reduces internal stress so parts don’t warp later.

If your parts are going out of spec after delivery, ask if this step was skipped.

Step#3 Use Sharp Tools and Gentle Settings

Teflon behaves differently from metal or other plastics.

Shops should use:

- Polished tools made for soft plastics

- Low spindle speeds to reduce heat

- Faster feed rates to get clean chips

Cut too fast, and the material melts. Cut too slow, and it smears.

Step#4 Control Heat and Movement During Cutting

Teflon dents under pressure. Clamping too hard can leave permanent marks.

Ask your vendor how they secure parts. They should use:

- Soft jaws or pads

- Even, gentle pressure

- Fixtures made for soft plastics

I once helped a client solve surface damage just by switching to padded vises.

Step#5 Finish with Light Cuts and Minimal Pressure

The final step should be all about control. Light finishing passes, minimal clamping, and careful handling go a long way. At this point, the part is close to its final shape—but it’s also the easiest time to damage it. Teflon dents and marks easily, especially when it’s warm. That’s why I always treat the last step like a cleanup. No aggressive feeds. No force. Just gentle final passes to bring the part to spec without pushing it out of shape.

When done in the right order, these five steps lead to better surface finish, tighter tolerances, and fewer reworks and MachMaster follows these exact practices in every Teflon machining project, so they get consistent results without trial and error.

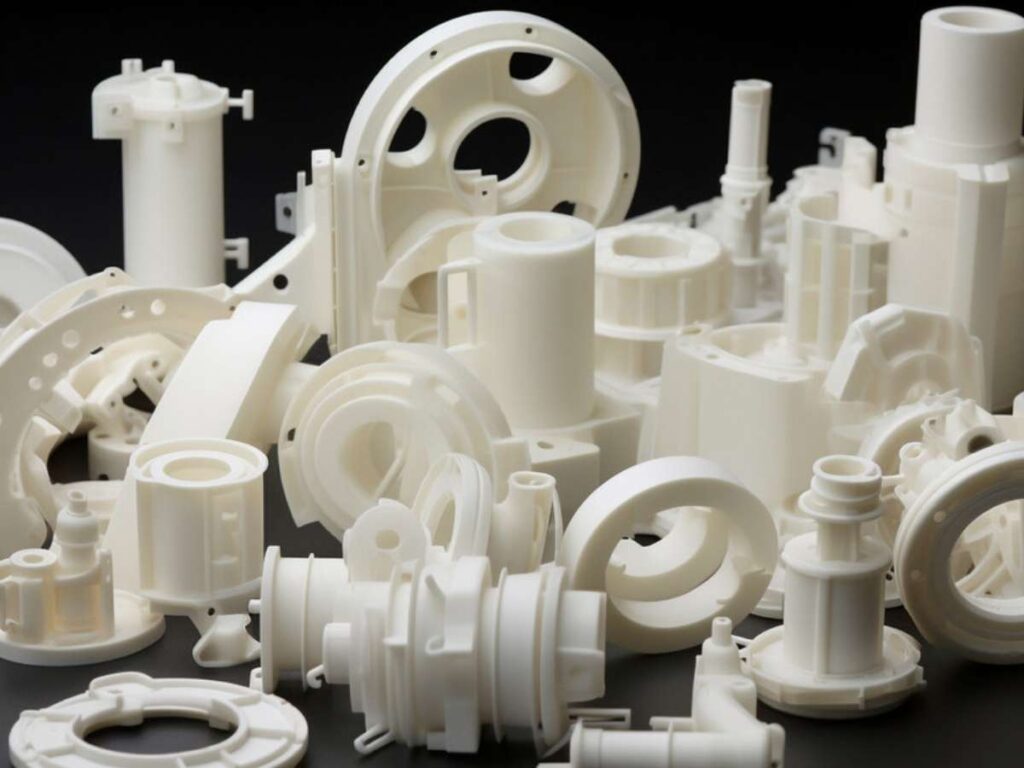

4. Applications of Machined Teflon

After going through the machining process, you might ask—where do these Teflon parts actually end up?

Here’s where you’ll commonly find machined Teflon in use:

Chemical Processing and Fluid Handling

If you’re working with corrosive fluids, Teflon is a solid choice. You can use it for:

- Seals and gaskets

- Valve seats

- Pump parts

It doesn’t react with acids, solvents, or aggressive chemicals. That’s why it’s widely used in chemical plants and fluid handling systems where other plastics fail over time.

Food and Beverage Equipment

Need something non-stick, clean, and safe for food contact? Teflon works well in:

- Filling lines

- Mixers

- Chute liners

- Sealing elements

It’s easy to clean, doesn’t hold moisture, and helps keep your equipment sanitary. For many small operations, it’s a practical option when stainless steel replacements get too expensive.

Medical and Pharmaceutical Devices

In cleanroom environments, Teflon components help avoid contamination. Its smooth surface doesn’t hold onto powders or residue, and it won’t react with drugs or cleaning chemicals. It’s often used for sample trays, stirrers, sealing blocks, and delivery system parts.

Electrical and Electronics

Teflon resists moisture and doesn’t conduct electricity, making it a good fit for:

- RF systems

- Circuit insulation

- Connectors

If your parts need to perform in damp or humid spaces—like telecom or industrial sensors—Teflon gives you a reliable option.

Aerospace and Automotive

Working in high-heat or high-pressure environments? Teflon handles both. You can use it in:

- Thermal shields

- Engine gaskets

- Vibration dampeners

- Fluid system parts

Large manufacturers often mold parts for volume. But for smaller production runs, CNC-machined Teflon helps you get tighter tolerances and faster lead times.

Across industries, machined Teflon delivers quiet performance in tough spots—where precision, safety, and durability aren’t optional.

5. Machining Teflon vs Other Plastics

Each plastic has its own strengths. Some are better for detail. Others hold size better under load. And some, like Teflon, are built for conditions where nothing else holds up.

If you’re trying to decide whether Teflon is the right fit—or if another plastic might do the job better—this side-by-side comparison can help:

| Property/Performance | Teflon (PTFE) | Delrin (POM) | Nylon (PA) | UHMW | Acrylic |

| Machinability | Very easy, low tool wear | Excellent, tight tolerances | Good, some tool wear | Fair, stringy chips | Brittle, chips easily |

| Surface Finish | Waxy, soft edges | Smooth, sharp detail | Smooth, slightly fibrous | Rougher finish | High gloss possible |

| Thermal Expansion | High, must adjust machining settings | Low, holds size well | Moderate | High | Moderate |

| Chemical Resistance | Excellent (most chemicals) | Moderate | Low to moderate | Moderate | Low |

| Heat Resistance | Up to 260°C (500°F) | Around 120°C (248°F) | Around 100°C (212°F) | Around 80°C (176°F) | Around 90°C (194°F) |

| Moisture Absorption | None | Low | High | Very low | Moderate |

| Electrical Insulation | Excellent | Good | Moderate | Good | Poor |

| Friction | Very low (non-stick) | Moderate | Moderate | Very low | High |

| Cost | High | Medium | Medium | Low | Medium |

Understanding how Teflon compares to other plastics helps you choose smarter—before the first chip even falls.

6. Challenges and Limitations in Machining Teflon

Teflon is known for its chemical resistance and thermal stability—but it’s also known for being hard to machine well. When I first started with it, I thought it would behave like other plastics. But jobs didn’t come out clean. Parts warped. Chips stuck. Tolerances didn’t hold.

Here are the key challenges you’ll face when machining Teflon—and how to deal with them:

Dimensional Instability

Teflon expands when it gets warm and shrinks as it cools. This can throw off your tolerances, even if the part looks good right after the cut.

To reduce this:

- Do a rough cut first, then let the part cool fully before finishing.

- Use slower feed rates and lower cutting speeds to reduce heat.

- After machining, let the part sit for a few hours before measuring or assembly.

This gives the material time to settle and helps you hit your size targets.

Workholding Problems

Teflon’s slick surface and softness make it hard to clamp. Too much pressure, and the part dents. Not enough, and it slips.

You can fix this by:

- Using soft jaws or padded fixtures that spread pressure evenly.

- Keeping your clamping force light but steady.

- Trying vacuum fixtures or strong double-sided tape for small parts.

The goal is to keep the part stable without leaving marks or deforming it.

Poor Surface Finish and Burr Formation

Teflon doesn’t always shear cleanly. If your tools are dull or your cut is too aggressive, you’ll get rough finishes or hard-to-remove burrs.

What helps:

- Use very sharp tools with a positive rake angle.

- Make light finishing passes near the end.

- For cleanup, skip heavy sanding. A sharp blade or soft cloth usually works better.

This gives you a cleaner part and helps you avoid extra rework.

Chip Control and Tool Loading

Teflon makes long, stringy chips that tangle up around tools. This builds heat and affects the surface finish.

To keep things clean:

- Use air blasts or light mist coolant to move chips away.

- Use tools with chip breakers when possible.

- Adjust your cutting path to avoid corners or tight areas where chips can build up.

Controlling heat and chip buildup helps you get more consistent results.

Teflon can be tricky—but with the right strategy, you can machine it cleanly, hold tight tolerances, and avoid unnecessary rework. Always communicate with your supplier to align on tolerances, fixturing, and post-processing needs.

7. Factors To Consider Before Machining Teflon

Over time, I’ve built a short list of what to think about before any Teflon job begins. If these factors are addressed up front, everything that follows—from tool choice to final inspection—runs smoother.

Here are some factors to consider:

Material Grade

Not all Teflon is created equal. You’ve got virgin PTFE—great for chemical resistance, soft, and pure. But if your part needs more wear resistance or dimensional stability, you’re better off with a filled grade like glass-filled or carbon-filled PTFE.

Before you start, confirm the exact grade your project calls for. Is the part exposed to chemicals, movement, or heat? If you are still not sure, you can partner with MachMaster because they help clients choose the right material grade from the start, so projects stay on track and meet performance goals.

Low Rigidity

Teflon is soft. It flexes. That’s great for seals—but not always for structural parts.

Machining soft materials means:

- Tools can dig in too deep

- Edges may feather or fray

- Clamping pressure needs extra care

To solve this, good machinists use sharp tools, light cuts, and padded fixtures.

Poor Heat Dissipation

Teflon holds heat instead of shedding it. That’s a problem when the tool rubs instead of cuts.

Why it matters:

- Heat causes thermal expansion

- Melted edges = bad surface finish

- Chips may fuse or gum up tools

This is why the right speeds, feed rates, and coolants matter so much in Teflon work.

Conclusion

We covered what Teflon is, how it’s cut, why it warps, and where it shines.

I’ve spent years figuring this out so you don’t waste time or money.

So, what could a perfectly machined Teflon part do for your build?

Let MachMaster help you cut through the confusion. From prototype to full run, we’ve got your back.

Contact us today and let’s build something that lasts!

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.