One of our early partners once lost a high-value client due to inconsistent finishes on stainless steel components.

They had the right machines, but not the right process.

That situation could’ve been avoided with better information.

We’ve worked with dozens of machine shops, OEMs, and fabricators on stainless projects, so we’ve seen what works in real-time production.

Our advice comes from shop floor experience, not theory.

In this article, you’ll learn the keys to machining stainless properly: feeds, speeds, coolant, tools, and more. If you’re looking for practical help, you’ll get it here.

You don’t need to learn this the hard way, like so many others did.

So, let’s jump in!

1. What Is Stainless Steel Machining?

If you’ve ever worked with stainless, you know it’s not your average metal. It’s tough, corrosion-resistant, and built for extreme environments, but that also means it puts your tools and techniques to the test.

Stainless steel machining is the process of cutting, shaping, or drilling this resilient material, and believe me, it’s not something you just wing.

Here’s why stainless steel needs a specialized approach:

- Harder on Tools: Stainless doesn’t give in easily. Its strength and toughness mean standard tools wear down faster if you don’t prep properly.

- Lower Speeds, Higher Precision: You can’t treat it like mild steel or aluminum. You’ll need to slow your feed rates and use sharper, harder inserts.

- Heat Control Is Critical: This metal holds heat, and if you’re not managing temperature with the right coolant or technique, you’ll damage both the tool and the part.

- Not All Grades Are Equal: 304? 316? Duplex? Each comes with its own quirks. You’ve got to know what you’re working with before you even hit start.

Most of the stainless work we do is for industries that can’t afford failure—food processing, medical, marine, and high-heat industrial parts.

The payoff is worth it, but only if you machine it the right way. The material demands patience, prep, and precision. If you’re not adjusting your setup, you’re just burning through tools and time.

Bottom line?

Stainless steel machining isn’t just another job—it’s a craft. And once you get the hang of it, it becomes one of the most satisfying materials to work with.

2. Types of Stainless Steel and Their Machinability

Different types of stainless steel vary wildly in how they respond to machining. This chart breaks down the major stainless steel categories and popular grades, helping you quickly compare their machinability, common uses, and special considerations.

| Type | Grade | Machinability Rating | Key Properties | Common Applications | Machining Notes |

| Austenitic | 304 | Low (45%) | Excellent corrosion resistance, non-magnetic | Food processing, piping, kitchen equipment | Work-hardens quickly, requires sharp tools and high feed rates |

| 316 | Low (40%) | High corrosion resistance, especially in chlorides | Marine parts, chemical equipment | Similar to 304 but tougher; use carbide tools and high-pressure coolant | |

| 303 | Moderate (78%) | Good corrosion resistance, sulfur added for machinability | Fasteners, fittings, shafts | Best austenitic option for machining; chips break easily, but reduced corrosion | |

| 321 | Low (45%) | Stabilized with titanium for high-temp resistance | Aerospace, thermal processing equipment | Similar to 304, but slightly better for high-temp parts; still work-hardens | |

| Ferritic | 430 | Moderate (60%) | Magnetic, good corrosion resistance, lower cost | Automotive trim, appliances | Easier to machine than 304; more brittle, less ductile |

| 446 | Low (35%) | Excellent resistance to scaling at high temps | Furnace parts, exhaust systems | Brittle; slow speeds and sharp tools are essential | |

| Martensitic | 410 | Moderate (55%) | Hardenable, magnetic, fair corrosion resistance | Cutlery, valves, turbine blades | Machines better when annealed; heat-treated parts can be tough |

| 420 | Moderate (50%) | High hardness when heat-treated, fair corrosion resistance | Surgical tools, cutlery | Can cause tool wear if hardened; pre-heat-treating may help | |

| 440C | Low (30%) | Very hard, high wear resistance, fair corrosion resistance | Bearings, knives, valve parts | Best machined in annealed state; extremely abrasive when hardened | |

| Precipitation Hardening (PH) | 17-4 PH | Good (65%) | High strength, corrosion resistance, heat-treatable | Aerospace, military, pump shafts | Machines well before aging; stable during heat treatment |

| Duplex | 2205 | Low (35%) | Very high strength, excellent corrosion and stress resistance | Offshore, oil & gas, chemical tanks | Tough to machine; requires rigid setup, slower speeds, and tough tooling |

| 2507 | Very Low (25%) | Super duplex, even stronger than 2205 | Desalination, pressure vessels | Similar to 2205, but more aggressive on tools; use low feeds and sharp inserts | |

| Free-Machining Stainless | 416 | Very High (85%) | High sulfur content for improved machining | Screws, gears, shafts | Great machinability, but corrosion resistance is lower |

| 430F | High (75%) | Free-machining version of 430 with added sulfur | Solenoids, automatic screw machine parts | Machines cleanly with excellent chip control; not ideal for high-corrosion settings |

3. Tools Materials for Stainless Steel Machining

If you’ve ever watched a shiny carbide insert go dull halfway through a stainless pass, you know just how unforgiving this material can be.

You will learn that the right tool material isn’t just helpful, it’s the difference between making margin and making scrap.

- Carbide Tools: Carbide inserts are my go-to for most stainless jobs because they can handle the heat and pressure without flinching. Choose grades with tough substrates and advanced coatings to extend tool life and protect your finish.

- High-Speed Steel (HSS): HSS might not be as long-lasting as carbide, but it works well for light-duty milling, drilling, or tapping in softer stainless grades. I still use it when working at lower spindle speeds or manual machines.

- Cobalt-Alloy Tools: Cobalt tools bridge the gap between HSS and carbide, offering better wear resistance and heat tolerance. They’re especially handy when drilling deep holes or tackling stubborn alloys like 316.

- Coated Tools: Tool coatings like TiAlN and TiCN make a massive difference when machining stainless. They help reduce friction and shield the tool from heat, which means fewer tool changes and better surface finishes.

- Indexable Tooling: For high-volume stainless parts, indexable tooling gives you the ability to swap edges without resetting everything. I like it for turning jobs where consistency and speed really matter.

- Solid Carbide End Mills: When you need to plunge, slot, or profile stainless parts, solid carbide end mills are reliable performers. Just keep the radial engagement low and clear those chips fast to avoid overheating.

4. Common Machining Processes for Stainless Steel

If I had to name the most important lesson I’ve learned about machining stainless steel, it’s that every process comes with its own set of rules.

You can’t treat stainless like mild steel and expect clean results.

Let’s break down the most common processes and how to get them right.

Turning

Turning stainless requires a steady hand and consistent tool engagement.

If your tool dwells or rubs, the material will work-harden fast and ruin the next pass. I’ve had the best results with negative rake carbide inserts and aggressive depth of cut.

Always use flood coolant to keep temperatures down and chips clear. And above all, avoid shallow cuts that only skim the surface and invite tool wear.

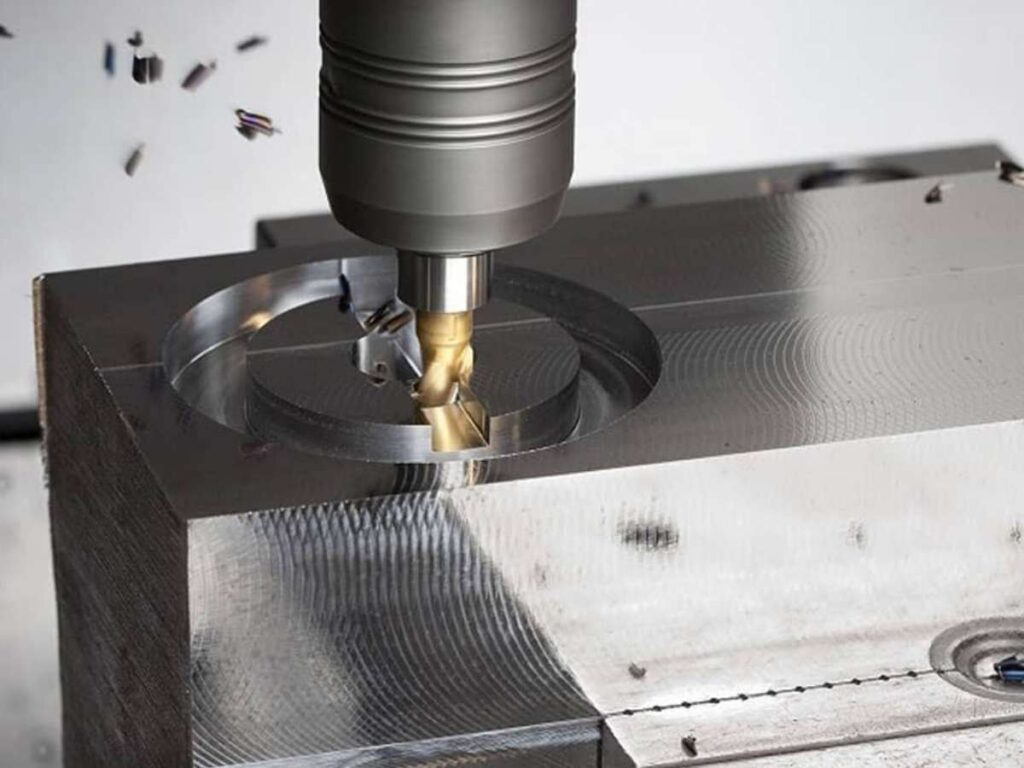

Milling

Milling stainless is where tool life gets tested hard. Slotting tends to trap heat and chips, which leads to premature wear and poor surface finish.

I always go for climb milling and try to keep radial engagement low to reduce pressure on the cutting edge.

High-pressure coolant and a rigid setup will save your end mills from early failure. If you must slot, use a stubby tool with lots of chip clearance and back off between plunges.

Drilling

Drilling into stainless isn’t as simple as it looks. The material grabs the tool, forms stringy chips, and builds heat fast—which can lead to work hardening or tool breakage.

To get better results, Machmaster recommends using solid carbide or cobalt drills with split points. These are more resistant to heat and wear, and they help maintain alignment in tough material.

Always peck when drilling deep. It helps clear chips and keeps heat from building in the hole. Strong, consistent coolant flow is key, both for chip evacuation and controlling thermal expansion.

Threading

Tapping stainless steel is one of the trickiest operations due to the risk of tool breakage and chip clogging.

Coated taps help, but they still wear quickly in tough alloys like 316. I often switch to thread milling instead, especially for expensive parts or deeper threads.

It gives better control, cleaner threads, and makes tool changes less painful. Plus, you can use one tool for different diameters if you’re running mixed parts.

Grinding

Sometimes milling or turning just can’t deliver the finish or accuracy you need. That’s when grinding steps in. Stainless responds well to grinding, but the key is to avoid overheating the surface, which can cause discoloration or warping.

Use a sharp, well-dressed wheel and take light passes to maintain control.

Make sure the part is well-supported to avoid flex and preserve surface integrity.

5. Key Challenges in Machining Stainless Steel

Stainless steel doesn’t give you much room for error. I’ve had parts go from perfect to ruined just from a slight miscalculation in speed or tool pressure.

Let’s look at the top challenges that can make or break your results.

Work Hardening

One of the biggest issues with stainless steel is how fast it work-hardens under pressure.

If your tool isn’t sharp or your feed is too slow, the surface gets tougher with every pass. That forces your cutter to work harder and wear out faster, which usually ends with a scrapped part.

Staying aggressive with your cuts and avoiding unnecessary dwell time makes a huge difference.

Excessive Heat

Stainless steel holds heat rather than dispersing it, and that’s a recipe for tool wear. I’ve seen end mills glowing after long slotting passes, and once the heat builds, your edge is gone.

Coolant helps, but only if it reaches the cutting zone effectively.

The best approach is balancing lower surface speed with high-pressure coolant and tool coatings that can handle thermal stress.

Chip Contro

Stainless loves to produce long, stringy chips that wrap around tools and fixtures.

If they aren’t cleared quickly, they trap heat, scar your part, and can even break tools mid-cut.

Using chip breakers and peck cycles helps, especially when drilling or threading. I’ve also found that adjusting feed rates can change chip shape just enough to make cleanup easier.

6. Common Mistakes and How to Avoid Them

I’ve made my share of mistakes with stainless steel, and most of them could have been avoided with a bit more prep.

When you’re machining this material, small missteps quickly turn into big problems. Here are the most common pitfalls I’ve seen, and how you can steer clear of them.

- Running Too Slow or Too Shallow: Low speeds and light cuts tend to rub the surface instead of slicing through, which leads to work hardening. Always aim for a deeper cut and a faster feed to keep the tool actively cutting.

- Using the Wrong Tool Coating: Standard coatings like TiN wear out quickly under stainless heat and pressure. You’ll get better results with TiAlN or similar heat-resistant coatings designed for stainless steel.

- Ignoring Coolant Flow and Pressure: A weak coolant stream does little to prevent overheating or flush chips away. Invest in high-pressure coolant systems or make sure your flow is hitting the cutting edge directly.

- Skipping Tool Change Intervals: Trying to stretch tool life often backfires by damaging the part or creating out-of-tolerance features. Stick to a scheduled tool change, even if the insert looks okay on the surface.

- Overlooking Workholding Rigidity: Any movement in your setup can lead to chatter, poor finishes, or even tool breakage. Always double-check that your part is clamped securely and your tooling is as short and stable as possible.

7. Tips for Selecting the Right Stainless Steel Grade for Machining

Choosing the wrong stainless steel grade can quietly ruin a job before the first cut is made. I’ve seen teams struggle with tool wear, part distortion, and post-machining issues all because the material wasn’t a good fit.

The following tips will help you pick smart and avoid surprises later on.

Know the End Use of the Part

Start by asking how the part will be used and what conditions it needs to survive.

If it’s for food or medical applications, 304 or 316 is a safe bet thanks to their corrosion resistance.

But if strength and hardness matter more than corrosion, 17-4 PH or 410 might make more sense. Matching the grade to the job avoids both overengineering and costly failures.

Balance Machinability with Performance

Some stainless grades are easy on the tools but compromise on strength or corrosion resistance. For example, 303 machines like a dream, but it won’t hold up well in marine or acidic environments.

On the other hand, 316 is tougher to cut, but it delivers outstanding durability in harsh conditions.

At MachMaster, we often help clients weigh machining difficulty against part performance. Choosing the right grade isn’t just about cutting ease, it’s about where and how the part will be used.

Consider Post-Machining Operations

Will the part be welded, heat-treated, or polished after machining?

Some grades, like 304, weld beautifully but are tough to machine. Others, like 416, machine fast but don’t handle welding well at all.

Always think two steps ahead before locking in a grade.

Check Material Availability and Cost

Sometimes the best technical choice is not the best business choice if the lead time is six weeks.

I always check with suppliers to see what’s readily available before quoting a job. You might be better off with a similar grade that’s in stock and easier to replenish.

Cost, delivery, and local inventory can tip the scales in a real-world decision.

Conclusion

I started with a broken tool and a mess of chips. You? You’ve got a full guide in your hands.

This article covered what stainless steel is, how to cut it, what tools work, and which traps to avoid. Every tip is built for your shop, your team, and your bottom line.

Why wait to get better results?

Contact MachMaster today. Your one-stop shop for high-precision stainless machining.

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.