Thinking about machining carbon fibre but not sure what you’re really getting into?

I don’t blame you. If you run a factory, design parts, handle purchasing, or even build things for fun — carbon fibre can feel like a big risk.

Mess it up, and it hits your wallet hard.

I’ve been on shop floors for years. I’ve stood by the machines, felt that jolt in my gut when a cutter snaps or when an edge starts to fray.

I’ve also watched what happens when people try to skip steps just to save a little money. Almost every time, it ends up costing way more.

I wrote this because I don’t want you stuck guessing.

In this guide, I’ll break down what machining carbon fibre really means. You’ll see how the process works, what tools and setups matter most, and where this material is truly worth using.

By the end, you’ll have a strong, simple foundation. You’ll know what questions to ask, what mistakes to watch out for, and how to feel sure about your next project.

So let’s get started!

1. What is Machining Carbon Fibre?

Machining carbon fibre might sound fancy. But really, it just means cutting, shaping, or drilling carbon fibre parts so they fit what you need.

Carbon fibre itself is a strong, lightweight material made from thin strands of carbon. These strands are woven together and set in a hard glue called resin. The result is a stiff, tough sheet or part.

So why would you machine it?

Because most times, carbon fibre parts come in big, flat sheets or rough shapes. To turn them into useful parts, you have to machine them. This could mean:

- Cutting them to size

- Drilling holes

- Smoothing edges

When I first tried it, I didn’t realize how different it was from metal. I thought I could treat it the same. Big mistake. The edges chipped, and I ended up wasting material.

Machining carbon fibre is not about trial and error. You need a supplier who knows the material, the risks, and how to keep quality high from prototype to production.

2. Properties of Carbon Fibre

Back when I first started working with carbon fibre, I made a lot of assumptions. I treated it like plastic one day, then like metal the next. Neither worked. It wasn’t until I slowed down and studied the material that things started to make sense.

Here are the properties I pay the most attention to when machining carbon fibre:

High Strength-to-Weight Ratio

Carbon fibre is known for being both light and strong.

Compared to steel, it can be up to five times stronger by weight, but far lighter. That’s why it’s used in aircraft parts, sports gear, and race car panels. In one client project, switching to carbon fibre cut the weight of a component by 40%—without changing the part’s strength.

If your product needs to be strong but light, this property alone could be a major advantage.

Very Rigid (High Stiffness)

Stiffness means a material resists bending.

Carbon fibre holds its shape under load much better than aluminum or plastic. This makes it perfect for things like frames, arms, or panels that need to stay straight and firm.

But here’s the flip side: it doesn’t bend much before breaking. It’s more brittle. That’s why parts must be well-supported and designed to avoid sharp impacts.

If your product needs precision and can’t afford flex, carbon fibre helps you keep things steady.

Corrosion Resistance

Carbon fibre doesn’t rust. It also doesn’t react with water or most chemicals.

That makes it useful in marine gear, outdoor equipment, or even lab tools exposed to moisture. One client we worked with used it to replace aluminum in a damp factory setting—it held up much better over time.

This resistance can mean fewer replacements, less maintenance, and better long-term value.

Carbon fibre isn’t a one-size-fits-all material. But when used correctly, it gives you an edge in strength, weight, and performance.

3. Step-by-Step Process of Machining Carbon Fibre

Thinking about using carbon fibre in your product? Then it helps to know how it’s actually machined—so you can ask better questions, spot problems early, and choose the right supplier.

Here’s a simple 5-step breakdown of the machining process:

Step#1 Review and Prepare the Design

Everything starts with your technical drawing or CAD model.

Your machining partner uses this to plan cut paths, tolerances, and hole positions.

Tip: Ask if the shop offers DFM (design for manufacturing) support. A small design change could save time and cost. I’ve seen teams cut lead times just by adjusting edge spacing or radius size.

Step#2 Select Material and Prep for Cutting

Carbon fibre usually comes in sheets or molded laminates. The shop cuts them down roughly before the final machining. This reduces waste and tool wear.

Key points:

- Make sure you specify the type of carbon fibre (standard, high-temp, multi-ply, etc.)

- Confirm thickness and fibre orientation—it affects strength and cut quality

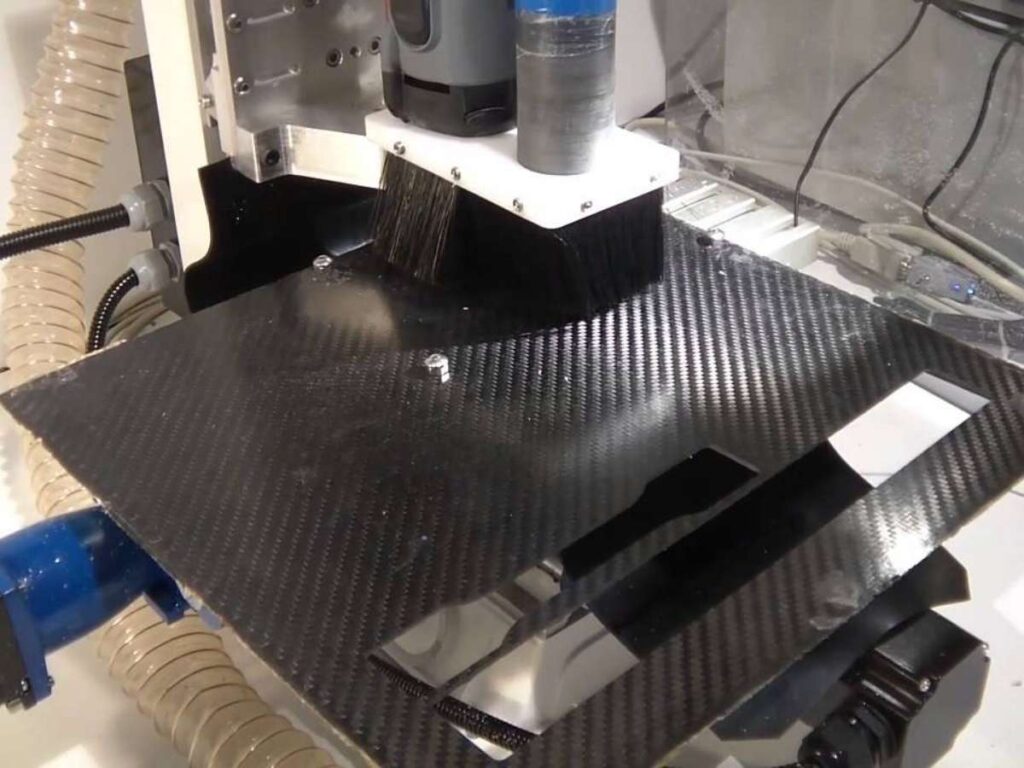

Step#3 Set Up the Machine and Tools

Carbon fibre is tough on tools. Most shops use diamond-coated or carbide bits, and adjust feed rates to avoid overheating or fraying.

They’ll also:

- Install dust control systems

- Set the correct spindle speed

- Use fixturing to hold parts in place

Warning sign: If they don’t mention tool wear or dust control, that’s a red flag.

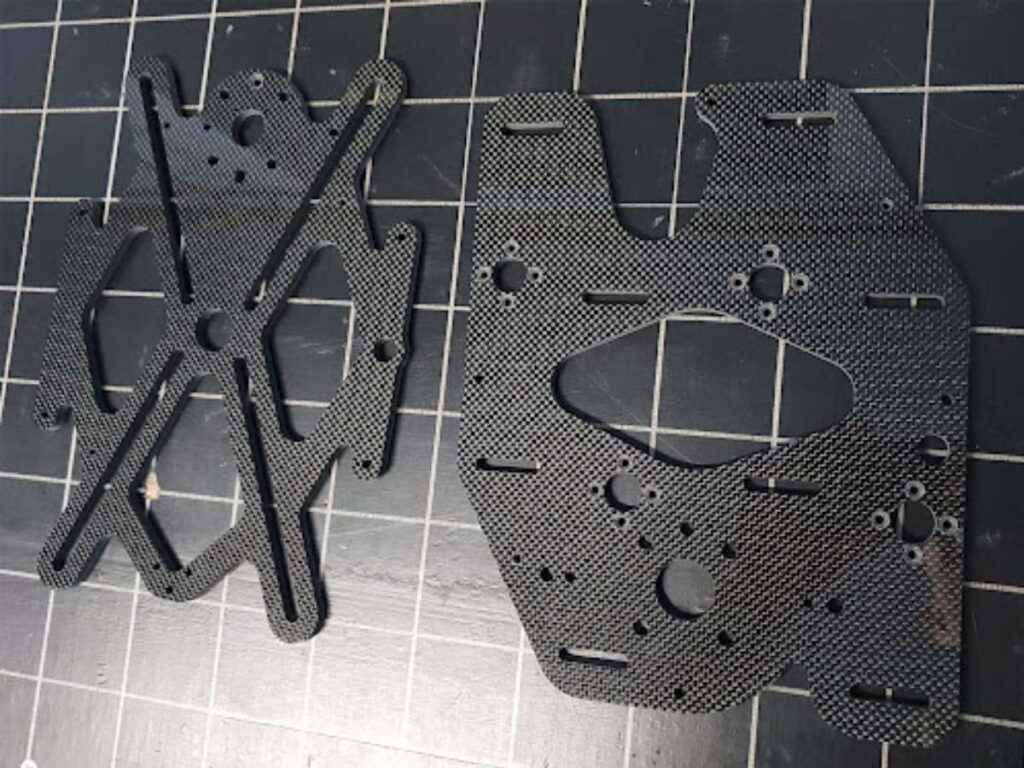

Step#4 Machine the Part

This is the actual cutting stage—shaping, drilling, and trimming.

Done right, it produces clean edges and tight tolerances without delamination (layer splitting).

Processes may include:

- Profiling (cutting outer shapes)

- Drilling holes

- Pocket milling

- Edge finishing

Precision matters here. Good shops balance speed with care.

Step#5 Inspect, Clean, and Pack

After cutting, the shop should:

- Check part accuracy

- Clean off dust and particles

- Pack parts with care—flat foam, wrap, or anti-static bags for sensitive applications

If your parts go straight into assembly or shipping, proper cleaning and packaging help avoid contamination or damage.

Final checks help catch issues early. A small chip or crack might not matter now—but it could fail under load later. By taking a few extra minutes here, I’ve saved a lot of trouble down the line.

At MachMaster, they don’t skip this step. Every machined carbon fibre part goes through a strict visual and dimensional inspection before it leaves the table.

4. Applications of Machined Carbon Fiber

After learning how to machine carbon fibre properly, I started to notice something. The more I worked with it, the more I saw just how useful it was—especially in places where strength and weight both mattered.

Here’s where machined carbon fibre tends to shine:

Aerospace and Drones

In aerospace, weight savings are critical. Carbon fibre components reduce load without giving up strength. That’s why it’s used in satellite panels, brackets, and even internal supports.

The drone industry depends on this too. Carbon fibre is used for arms, camera mounts, and frames—especially in racing or industrial models. Machined parts are preferred here because they fit better, reduce vibration, and hold up under high speeds.

Automotive and Motorsports

Carbon fibre isn’t just about looks. In high-performance builds, you need strength without weight. That’s where machined carbon fibre really earns its spot.

You might use it for battery trays, dashboards, or mounting plates. In EV projects and track-day builds, even shaving off a few grams can boost acceleration and handling. The bonus? Machined parts tend to fit better and last longer than cut-and-glued alternatives.

Robotics and Industrial Automation

Robotics depends on precision and speed. Lighter moving parts help reduce wear on motors and joints.

Machined carbon fibre components are common in robotic arms, sensor mounts, and moving brackets. Their stiffness keeps alignment accurate, while the low weight helps boost overall performance. Many automation setups also benefit from its non-conductive properties, depending on the resin used.

Medical and Wearable Devices

For medical and wearable designs, you often need parts that are strong, light, and kind to the skin.

Machined carbon fibre is ideal for brace components, prosthetic sockets, and other rehab tools. Whether you’re prototyping or producing, this material helps reduce bulk without sacrificing strength. It’s the kind of upgrade patients feel—lighter gear that still holds its shape under stress.

From aerospace to wearables, machined carbon fibre delivers lightweight strength where precision and performance matter most.

5. Machining Carbon Fibre vs Other Materials

After you’ve worked with carbon fibre for a while, it’s hard not to compare it to other materials. You’ll notice right away that it doesn’t behave like metal or plastic. From how it cuts to how fast it dulls tools—and even how it holds its shape—carbon fibre has its own way of doing things.

Here’s a table showing how carbon fibre stacks up against aluminum, plastic, and stainless steel in key areas:

| Aspect | Carbon Fibre | Aluminum | Plastics (ABS/Nylon) | Stainless Steel |

| Weight | Very light | Light to medium | Very light | Heavy |

| Rigidity | Very high | Medium to high | Low to medium | High |

| Tool Wear | Very high (abrasive fibres dull tools fast) | Low (machinable with standard bits) | Very low (gentle on tools) | High (due to density and heat) |

| Dust or Chips | Fine, hazardous dust (requires filtration + PPE) | Metal chips (easier to collect) | Plastic shavings or melted edges | Metal chips (sharp, heavy) |

| Machining Speed | Slow, shallow passes required | Fast feeds possible | Moderate to fast (care needed to avoid melting) | Slow to moderate (depends on tool and coolant setup) |

| Edge Quality | Prone to fraying and delamination if mishandled | Clean edges with right feeds | Can melt or deform if overheated | Clean with proper speed and coolant |

| Thermal Conductivity | Low (heat builds up at cutting point) | High (spreads heat evenly) | Low (heat buildup possible, especially with nylon) | Very high |

| Vibration Handling | Poor (vibrates easily, needs strong workholding) | Decent | Flexible, absorbs some vibration | Stable, depending on setup |

| Finish Work | May require light sanding or sealing | Often ready after machining | Sometimes needs smoothing or de-burring | Minimal post-processing with good tool path |

Knowing how carbon fibre differs from other materials helps you avoid costly missteps—and dial in a process that actually works.

6. Challenges and Limitations of Machining Carbon Fibre

Every mistake I’ve made has come from skipping a step or misjudging how the fibres would react. But each challenge has a solution, and once the limitations are understood, they become easier to manage.

Let’s look at what makes carbon fibre tricky to work with—and what you should watch for before committing to this material:

Delamination Risk

Carbon fibre is made of layered fibres held together with resin.

If cut incorrectly—usually with dull tools or the wrong speed—the layers can separate. This is called delamination. Once it happens, the part usually can’t be saved.

What to ask your supplier:

- Do you use sharp, coated tools like diamond or carbide?

- How do you prevent layer lifting during machining?

High Tool Wear

Carbon fibre is abrasive—like sandpaper. It eats through regular tools quickly.

Shops that aren’t used to this will either machine too slowly (driving up your cost), or break tools mid-job.

What matters to you:

- Make sure your shop budgets for frequent tool changes

- Ask if they have experience balancing cost with tool life

Health and Safety Risks

Machining carbon fibre produces very fine dust. It’s not just messy—it’s dangerous if inhaled.

It can also settle into nearby electronics and cause short circuits.

You don’t want your supplier machining without proper dust collection, especially in clean environments.

Ask this directly:

- What dust filtration system do you use?

- Is your machining area enclosed and vented?

Brittle Edges and Cracking

Carbon fibre is strong—but not flexible.

It can chip or crack if mishandled during or after machining. Thin sections or sharp internal corners are especially vulnerable.

One client I worked with had parts that looked great—until they tightened the screws during assembly. Cracks appeared immediately.

Design tip: If you’re still designing the part, avoid ultra-thin walls or overly tight hole spacing.

Machining carbon fibre isn’t without its issues. But with good prep, smart tool choices, and a steady approach, those challenges don’t have to hold you back.

Carbon fibre offers big advantages, but only when handled by the right supplier.

If you’re sourcing parts, your job isn’t to know how to run the machines—but to know which questions to ask. A good shop will be transparent about these challenges and have answers ready.

7. Tips To Consider Before Machining Carbon Fibre

By the time I got comfortable working with carbon fibre, I realized most of the success came from what happened before the machine even turned on.

Here are the tips I wish more clients followed before starting their carbon fibre projects:

Choose the Right Supplier (Not Just Any CNC Shop)

Not all shops know how to handle carbon fibre. Some try to treat it like metal or plastic—and that leads to fraying, chipping, and ruined parts.

Ask directly:

- How often do you machine carbon fibre?

- What kind of tooling and dust control systems do you use?

If they hesitate, keep looking. When you need a supplier who understands the material, the tools, and the pressure to get it right the first time, choose Machmaster—they’re ready to help.

Use the Correct Carbon Fibre Type for Your Application

There are different grades and layups of carbon fibre:

- Standard modulus vs. high modulus (affects stiffness)

- Pre-preg vs. cured sheets

- Plain weave vs. twill weave

Each one behaves differently when cut. Your supplier should help match the material to your needs—whether it’s strength, temperature resistance, or surface appearance.

Design for Machinability

If you’re still in the design phase, keep these tips in mind:

- Avoid sharp inside corners—round them when possible

- Leave enough space between holes and edges to avoid cracking

- Avoid very thin walls unless necessary

A small change in geometry can save big on cost and reduce failure risk.

Confirm Dust and Safety Practices

Carbon fibre dust is a serious health hazard and can harm electronics.

Ask your supplier how they:

- Collect and filter carbon dust

- Clean parts before shipping

- Protect machines and people during the process

If you’re planning to do any post-processing in-house, make sure your team is prepared to handle the material safely.

Conclusion

We’ve walked through what machining carbon fibre means, where it’s used, when it matters, and how to pull it off right.

Carbon fibre can be frustrating, but now you have a real-world guide to cut clean and work smart.

We’ve handled the splintered mess so you don’t have to.

What’s stopping your next carbon fibre project?

MachMaster is here to help you get started with the tools, knowledge, and support to make every cut count.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.