We were behind schedule. The steel parts were eating into our tooling budget. And the finish? Not what the client expected.

That’s when we tried machining brass for the first time.

At first, I didn’t think much of it. But within one shift, everything changed—better chip control, smoother surface finish, less tool wear. That job turned into one of our most profitable short runs that year.

If you’re looking at brass and wondering, “Is it really worth the switch?”—this guide will give you the answer.

I’ve spent years in machining, working with suppliers, designers, and shop floor crews. I’ve seen what works and what doesn’t—especially with brass.

In this article, you’ll get the real-world knowledge I wish someone handed me earlier:

- What makes brass easy (and tricky) to work with

- Which brass alloys to choose and avoid

- Setup tips for cleaner, more precise machining

- Surface finish outcomes, tooling life, and more

By the end, you’ll know if brass is right for your parts—and how to get the most from it if you move forward.

So let’s get started!

1. What is CNC Machining Brass?

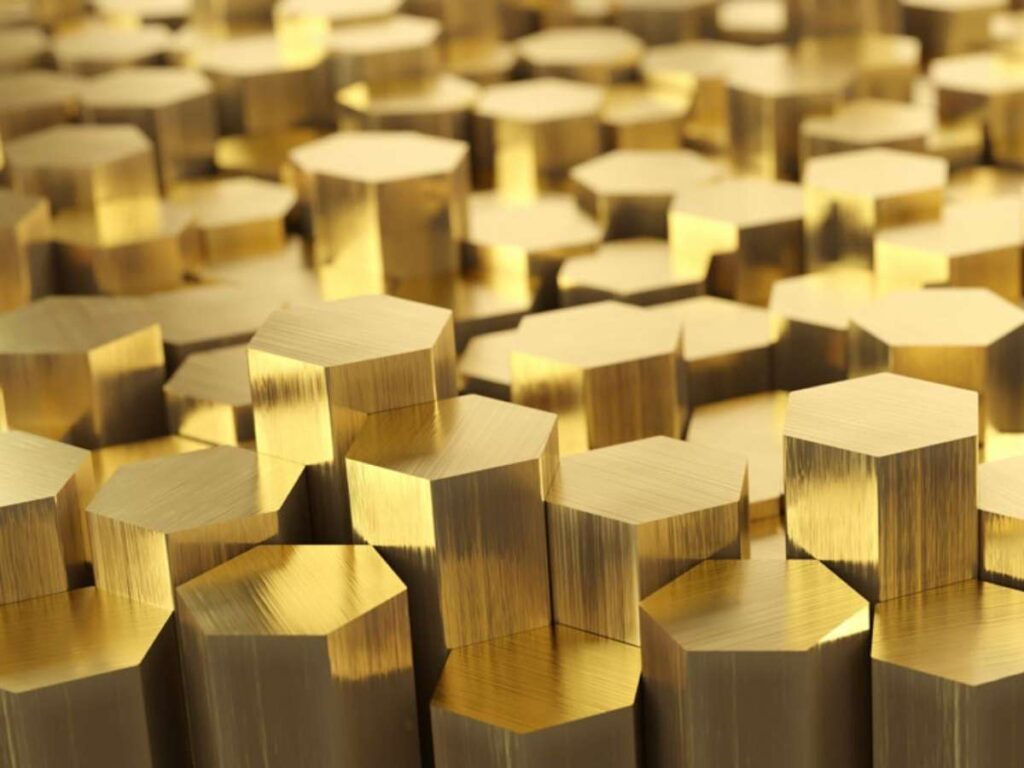

Brass is an alloy made from copper and zinc. The exact ratio of these metals affects everything from strength to color to how easily you can machine it. Some grades cut like butter, while others give you better durability for moving parts or structural uses.

You’ll recognize it by its warm, gold-like color. But it’s not just about looks—brass is corrosion-resistant, non-sparking, and non-magnetic. Those properties make it ideal for visible hardware, sensitive electronics, plumbing parts, and more.

Here are the essential properties why brass fits well in machining:

| Property | Brass |

| Melting point | 885 to 890 ℃ |

| Density | 8.5 g/cm³ |

| Modulus of Elasticity | 97Gpa |

| Thermal Conductivity | 115 W/m-k |

| Electrical Resistivity | 6.3*10-8Ω |

What makes brass stand out is that it’s not just easy to machine—it’s also forgiving. When something goes off, it’s usually a quick fix, unlike with stainless or harder alloys.

2. Features of Brass That Make It Fit for CNC Machining

If you’re comparing materials for a project, you might ask: Why do so many manufacturers use brass for CNC machining?

It behaves well in the machine, produces less wear on tools, and gives excellent finish quality.

Here’s what makes it stand out:

Excellent Machinability

Brass is one of the most machinable metals available.

That means:

- Less resistance during cutting

- Fewer tool changes

- Shorter production times

This matters to you because it cuts cost and keeps lead times short.

Many of our clients choose brass specifically for this reason—especially when deadlines are tight.

Low Tool Wear

Unlike harder metals like stainless steel, brass doesn’t wear down cutting tools as fast. That leads to:

- Fewer machine stops

- More consistent parts

- Lower tooling costs over time

This is especially important if you’re sourcing a large batch or repeating orders regularly. We’ve had orders in the thousands where a single set of inserts lasted the full run.

Tight Tolerance Capability

Do you need precision parts? Brass is a smart choice.

It holds shape well under cutting loads, which means you can achieve:

- Fine threads

- Sharp edges

- Repeatable dimensions

We’ve made pressure fittings and sensor parts for clients that required ±0.01 mm. Brass made that achievable without special equipment.

Smooth Surface Finish

Brass naturally takes on a smooth, bright finish when machined.

For you, this means:

- Less time spent on polishing

- Better-looking parts right off the machine

- Ideal for decorative, display, or contact surfaces

One client asked us for visible housing components for a luxury hardware line. We machined the brass with standard settings, and the parts needed no extra finishing, just a quick clean.

We choose it often for projects that demand speed, repeatability, and appearance. It just works—especially when paired with the right CNC setup.

3. Types of Brass Grades for CNC Machining

We’ve worked with many brass types over the years. Some machine are beautiful. Others… not so much.

Did you know that at MachMaster, they always select the right brass grade upfront—so your CNC parts come out clean, accurate, and production-ready.

Here’s a breakdown of the most common brass grades we recommend for CNC machining—and when to use each one:

C360 – Free-Cutting Brass

Also known as: C36000

If you want the smoothest machining experience, C360 is your best bet. This brass grade contains a small amount of lead, which helps chips break cleanly and reduces cutting friction. That means crisp threads, clean surfaces, and fewer tool changes.

C360 is perfect for high-speed turning or milling. It holds tight tolerances and rarely causes issues during tapping, slotting, or facing. If speed and consistency are your priorities, this is the go-to grade. We use it often when the job demands precision and efficiency.

Typical uses include:

- Threaded inserts

- Valve stems

- Custom bushings

- Instrument components

C464 – Naval Brass

Also known as: C46400

Need something that holds up in wet or salty conditions? C464 is your answer. It contains tin for extra corrosion resistance, especially in marine or outdoor environments. While it’s not as free-cutting as C360, it still machines well with the right speeds and feeds.

If your parts need strength and long-term durability in tough environments, this grade delivers. It’s especially useful when your application involves pressure, motion, or exposure to the elements.

Typical uses include:

- Marine hardware

- Pump shafts

- Heat exchanger plates

C230 – Red Brass

Also known as: C23000

C230 has more copper, giving it a darker, reddish tone. It’s softer and more ductile, which makes it great for bending, forming, and shaping. You can still machine it—but expect to use slower feeds and sharper tools.

If your part needs both visual appeal and moderate strength, C230 is a solid choice. It’s especially popular in applications where form and finish both matter.

Typical uses include:

- Plumbing fixtures

- Decorative components

- Low-pressure fittings

C385 – Architectural Brass

Also known as: C38500

C385 isn’t about speed—it’s about form and appearance. It’s easier to forge or extrude than to machine quickly, but you can still get clean results with the right approach. Take your time on finish passes, and you’ll be rewarded with consistent parts.

If your project involves furniture, architecture, or any visible trim work, C385 gives you the look you want with enough strength to back it up.

Typical uses include:

- Trim and decorative panels

- Hinges and frames

- Window and door hardware

Choosing the right brass grade means fewer tool changes, smoother finishes, and more reliable CNC machining results.

4. Surface Finishes for CNC Machined Brass

I’ve seen projects completely change just by adjusting the surface finish. A basic part can look premium with the right polish—or last longer in harsh environments after the right coating.

Here are some of the most effective finishes you can ask your supplier to use on CNC-machined brass:

Polishing

Polishing smooths out tool marks and brings a natural shine to the brass. It’s often done using soft cloth wheels, buffing pads, or fine abrasives. The goal is to bring out the clean, gold-like finish that brass is known for.

One of our early jobs involved a set of knobs for a vintage audio brand. The parts weren’t anything special—until they were polished. Suddenly, they looked high-end. That single step made the product look more expensive without changing the part design.

Sandblasting (or Bead Blasting)

Want a soft, matte finish? Sandblasting is your go-to. It blasts fine abrasive particles across the surface to even out imperfections and remove small scratches.

Use this when you need uniform texture—especially for covers, housings, or mechanical parts that will be touched or seen regularly.

Electroplating

Electroplating coats your brass part with another metal—often nickel, chrome, or gold. This improves both the appearance and the wear resistance.

If you’re producing electrical connectors, hardware, or high-end consumer parts, this finish gives lasting polish and protection. It adds cost, but for long-life products, it’s often worth the investment.

Lacquering or Clear Coating

Lacquering adds a transparent coating that protects your brass from tarnish, moisture, and fingerprints. You can spray it or dip it on.

This is a smart move if your part needs to stay bright—like in retail displays or showroom installations. The coating keeps it clean and cuts down on maintenance.

Just be sure to match the coating type with your end-use environment. Some clear coats handle heat better than others.

Brushed Finish

A brushed finish gives your part a clean, directional grain. It’s made by rubbing the surface with an abrasive in one consistent direction.

This finish doesn’t scream for attention—it feels high-quality without the shine. It’s a favorite for architectural, furniture, or appliance hardware that’s touched often but shouldn’t look too flashy.

Finishing isn’t just about looks. It affects cost, function, and lead time.

If you’re not sure what your brass part needs, we’re happy to give options. Some finishes are simple. Others add steps. Either way, we’ll help you get the result you expect.

5. Step-by-Step Process of Machining Brass

If you’re thinking about brass CNC machining, you might wonder—what exactly happens once your order is placed?

I’ve learned the hard way that skipping just one can lead to tool chatter, poor finish, or wasted material.

Here’s how we break it down into five essential steps:

Step#1 Material Selection and Drawing Review

First, we help you choose the right brass grade—most often C360 for fast, clean machining.

Then, we review your CAD drawing or 3D file to check:

- Dimensions

- Threads

- Tolerances

- Surface finish notes

This step avoids confusion later and helps us plan the right approach.

Step#2 CAM Programming and Tool Selection

Next, we program the CNC machine using your file.

This sets the cutting path, tool speeds, and feed rates.

We select tools that match the brass type—usually carbide tools that cut clean without gumming up.

Step#3 Machine Setup and Machining

Now we load the brass stock, install tools, and run the job.

Depending on the part, we’ll:

- Turn it (for round parts)

- Mill it (for flat or complex shapes)

- Drill or tap threads

We monitor chip control and surface quality throughout the run.

Step#4 Inspection and Finishing

After machining, we check:

- Critical dimensions

- Thread accuracy

- Surface finish

If needed, we polish, brush, or coat the parts based on your specs.

We also remove any burrs or sharp edges.

Step#5: Cleaning, Packaging, and Delivery

Finally, we clean the parts and pack them carefully to avoid surface damage—especially for polished or plated parts.

From start to finish, the goal is simple: give you parts that match your drawing, fit your assembly, and arrive on time.

Each of these steps supports the next. Skipping one often leads to problems later—missed tolerances, tool breaks, or surface flaws. At MachMaster, they treat every part like it’s going into production. Inspection isn’t the end—it’s what makes repeat runs possible.

6. Applications of Machined Brass

Once your part is machined and it passes inspection, the next question is: where does it actually get used?

Brass fits that role better than many metals. It machines clean, holds tight tolerances, and doesn’t rust like steel. Because of that, it’s become a go-to material for many applications, across different sectors. Here are some:

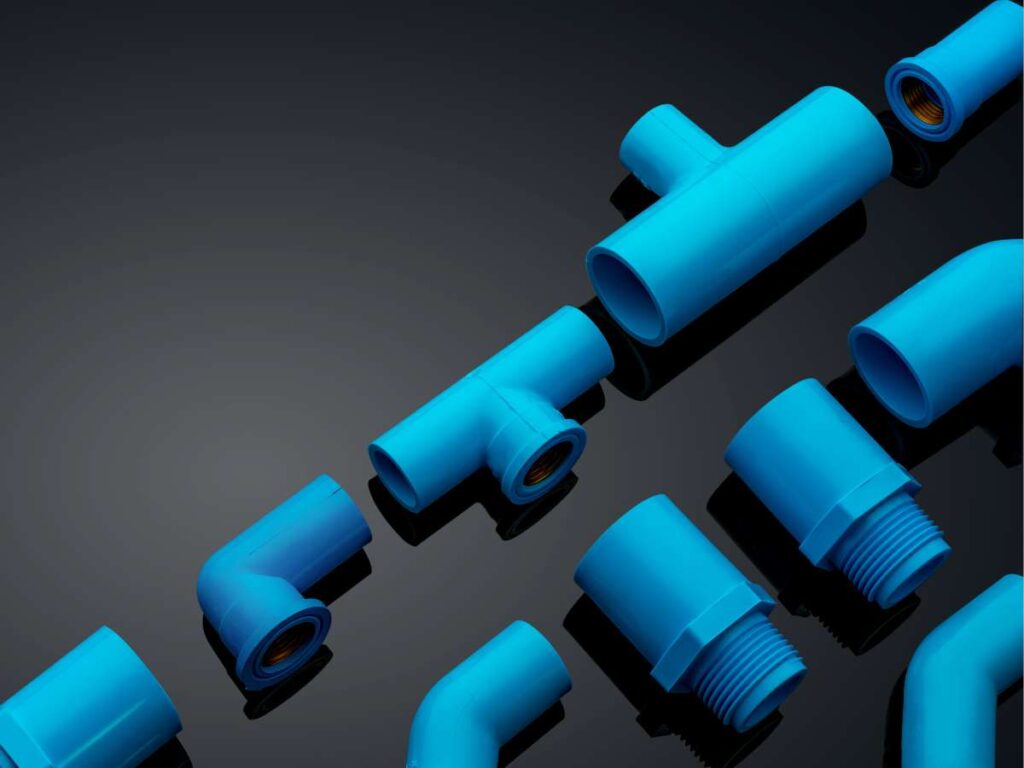

Plumbing and Fluid Control Systems

If you’re machining parts for valves, hose connectors, or pipe fittings, brass is likely your top choice. It resists corrosion, threads cleanly, and seals well—making it ideal for leak-proof systems. We once ran a batch of custom valve bodies for a high-pressure plumbing setup. No coating was needed, and every thread held tight.

Electrical and Electronic Components

Thanks to its electrical conductivity and workability, brass is also common in connectors, pins, terminals, and switch housings. The metal allows for precise machining on small parts without warping or distortion. Brass also stays stable under heat, which makes it useful in power systems and control panels.

Automotive and Machinery

In vehicles and industrial machines, brass works well in low-wear, low-friction parts like bushings, fuel connectors, and sensor housings. We’ve machined brass guides that outlasted their aluminum counterparts—even under vibration and frequent use. It’s a great option when durability and accuracy matter.

Aerospace, Marine, and Defense

Although less common here than in plumbing or electronics, brass still has a place—especially in low-pressure components, instrument housings, and marine parts. Its corrosion resistance and long-term stability make it ideal for coastal or wet environments.

Whether it’s for fluid control, electrical performance, or corrosion resistance, machined brass continues to prove its value across industries.

7. Factors To Consider Before Machining Brass

Before you lock in a design or ask for services, there are a few things worth checking. We’ve worked with buyers and engineers who skipped this step—and ended up with delays, added costs, or the wrong material.

Here’s what you should think through first:

What’s the Right Brass Grade for Your Part?

Not all brass types behave the same.

Ask yourself:

- Is this part cosmetic or functional?

- Does it need corrosion resistance?

- Will it be tapped or threaded?

For fast, clean machining, C360 is the standard.

For outdoor use or forming, you might need C464 or C260.

Choosing the wrong grade can lead to poor finish or higher cost.

Are Your Tolerances Reasonable?

We sometimes get drawings with overly tight tolerances—far beyond what the part actually needs.

That affects:

- Machining time

- Cost

- Rework risk

Stick to functional tolerances unless the part truly demands ±0.01 mm or less.

We’re happy to help you review drawings before quoting.

How Many Parts Do You Need—Prototype or Production?

Machining one part vs. machining 1,000 requires different setup plans.

- For prototypes, we focus on speed and flexibility

- For production, we plan tooling, fixture design, and repeatability

Letting us know early helps you get a better result, faster.

Do You Have a Target Lead Time?

Brass is quick to machine—but lead time depends on part complexity, volume, and finishing.

Here’s what affects timeline:

- Custom tooling

- Special finishes (like plating or polishing)

- Post-machining processes (deburring, coating)

We’ve turned small orders around in under 3 days. For bigger jobs, it helps to plan a week or more.

I’ve seen projects succeed because the client asked one key question before ordering:

“What do I need this part to do—and how should it look when it arrives?”

Answer that clearly, and machining brass becomes easier, faster, and more cost-efficient.

Conclusion

Now you’ve seen how we machine brass—the alloys, feeds, tools, and finishes we count on daily.

No fluff. Just real advice from a team who lives this.

Whether you’re troubleshooting bad parts or comparing suppliers, this guide gives you the edge.

You’ve already taken the first step by reading.

Looking for support with your next machining brass project? MachMaster can help.

Contact us today to get started!

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.