When I was designing my first multi-material product, I thought I had everything figured out, until the prototype failed. The overmold peeled off after a few weeks, and my supplier told me I should’ve used insert molding instead.

That mistake cost me time, money, and trust. I don’t want that to happen to you.

This guide comes from years of trial, collaboration, and a fair share of expensive lessons. It’s built for designers, engineers, and decision-makers who need practical answers, not just theory.

Here, you’ll get a clear breakdown of what insert molding and overmolding are, where each works best, and how to pick the right one based on design needs, performance, and budget.

If you’re building a product that needs to work for the first time, and scale without surprises, this article is for you.

Let’s begin!

1. What Is Insert Molding

Picture this.

You’re on a tight production schedule. The prototype looks good, but now it’s time to make it real—stronger, scalable, and ready for actual use. You need a way to combine plastic and metal that’s clean, fast, and efficient. No glue. No screws. No assembly nightmares.

That’s exactly where insert molding shines.

Insert molding is a manufacturing process where a pre-formed part, usually a metal insert like a threaded bushing, terminal, or blade, is placed into a mold, and plastic is injected around it. The result? One solid, seamless component.

No post-molding assembly. No loose parts. Just one unified part that’s tougher, tighter, and ready to scale.

Materials Used

You’re typically combining:

- Metal Inserts: brass, stainless steel, aluminum, copper

- Thermoplastics: ABS, PC, nylon, polyethylene, or polypropylene

The magic happens when that molten plastic flows perfectly around the metal. Once it cools and cures, you’ve got a mechanically bonded hybrid part that performs like it was built that way from the start. Because it was.

Application

I remember our first time using insert molding for a medical product. We needed metal threads inside a plastic housing—tight tolerances, zero margin for error. If we had chosen bonding or ultrasonic welding, the failure rate would’ve crushed the budget.

Insert molding saved that launch. And we’ve used it ever since.

You’ll see insert molding used in:

- Electronics: USB connectors, circuit housings with embedded pins

- Medical Devices: Handles, surgical tools, enclosures

- Automotive: Dashboard controls, switches, seatbelt buckles

- Consumer Durables: Appliance knobs, plugs, fasteners

Importance

If you need repeatable strength, precision, and production speed, insert molding is worth your attention.

- It cuts down on labor.

- It eliminates multi-step assembly.

- It improves part integrity.

For many teams, it’s not just a cost saver. It’s a product saver.

2. What Is Overmolding

If you’ve ever picked up a power tool with a rubberized grip or a toothbrush that just feels right in your hand, you’ve experienced overmolding.

But in your world, it’s more than just comfort. It’s about function, feel, and first impressions. And for product teams, those aren’t optional, they’re the difference between getting shelf space or getting shelved.

Overmolding is a process where a soft or second material is molded over a rigid base component, often in two separate steps or using multi-shot molding. That outer layer could add grip, seal out moisture, or simply make your product look better than your competitor’s.

Materials Used

In most overmolding jobs, you’re working with:

- Substrate (the base): ABS, polycarbonate, nylon, or other rigid thermoplastics

- Overmold Layer: TPE, TPU, silicone, or other elastomers

These materials are carefully selected to bond without delaminating, even under stress, heat, or moisture.

Application

We once helped a client redesign their wearable device casing. The original version used a glued-on grip that peeled after a few weeks of use. Overmolding fixed that, with a seamless silicone layer that not only stayed put but made the product feel high-end.

You’ll see overmolding in:

- Consumer Electronics: Phone cases, wearables, control buttons

- Medical Devices: Syringe grips, soft-touch housings, handheld tools

- Industrial Tools: Power tool handles, gaskets, rugged casings

- Personal Care Products: Toothbrushes, razors, ergonomic grips

Importance

Overmolding doesn’t just make products more comfortable—it makes them more valuable.

- It helps differentiate your product on the shelf.

- It improves user interaction, durability, and aesthetics.

- It can eliminate the need for adhesives, assembly, or fasteners.

If your product is meant to be held, pressed, worn, or trusted, it probably needs overmolding.

3. Process Comparison

Now that you’ve seen what insert molding and overmolding are, let’s talk about how they actually work—and how they’re different behind the scenes.

Because even though they might look similar in the final product, the manufacturing flow, timing, and setup are very different. And that matters when you’re trying to plan production, manage lead times, or work with your supplier on tooling.

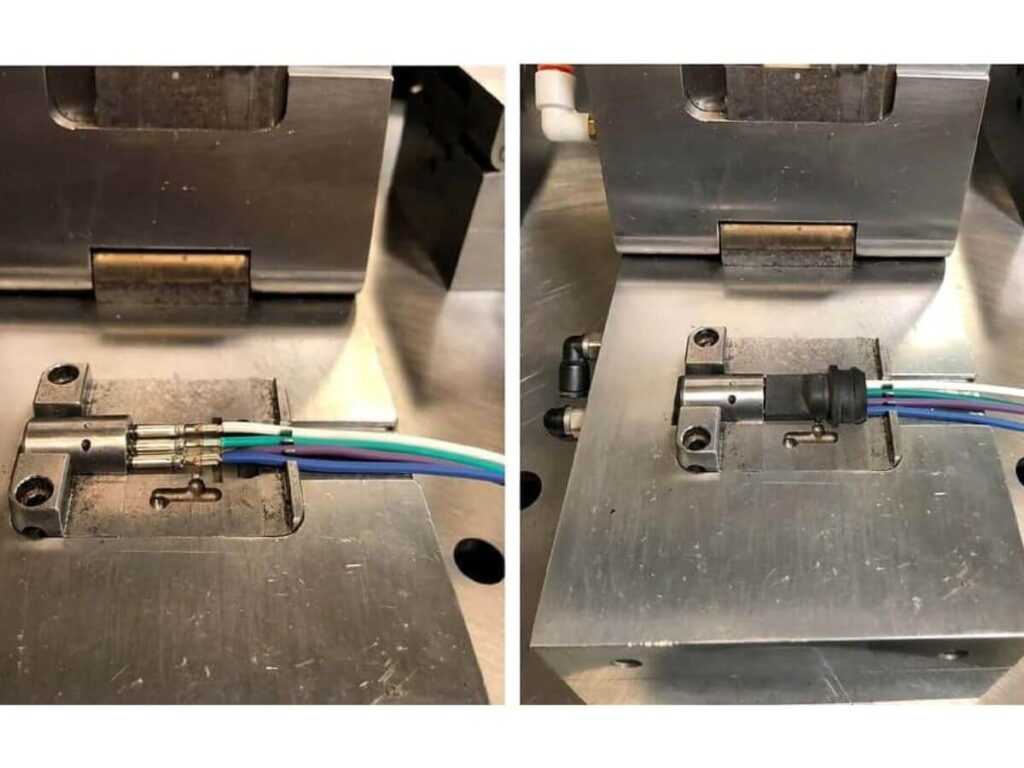

Insert Molding: One Mold, One Shot

Insert molding is usually a single-shot process. Here’s how it goes:

- You (or your supplier) prepare the metal insert, this could involve stamping, turning, or CNC machining (and yes, we do that at MachMaster).

- The insert is manually or robotically placed into the mold.

- Plastic is injected around it in a single cycle.

- The part cools, is ejected, and it’s done, no secondary operations.

It’s efficient, repeatable, and great for integrating metal and plastic without adhesives or fasteners.

Overmolding: 2 Steps, One Purpose

Overmolding involves 2 molding cycles:

- First, the rigid base part is molded or pre-produced.

- Then, it’s placed into a second mold (or a second cavity in the same mold if you’re using multi-shot machines).

- A soft or secondary material is injected over or around the original part.

That means more complexity, but also more flexibility. Especially for parts that need to be ergonomic, sealed, or dual-colored.

4. Tooling & Equipment

Here’s where it gets real.

Whether you’re a factory owner trying to budget for tooling or a product designer working with a contract manufacturer, this part can make or break your timeline—and your margins.

Tooling isn’t just a line item. It’s a strategic choice.

Insert Molding: Simpler Tooling, Tighter Precision

With insert molding, your tooling setup looks pretty straightforward:

- A single-shot mold designed to accommodate inserts

- Fixtures or guide pins to hold the metal component in place

- Standard injection molding machine (with optional automation for insert loading)

If you’re doing low to medium volume, manual insert placement might work fine. But for high volume, it’s worth exploring robotic arms or pick-and-place systems to speed things up without losing precision.

One thing you can’t afford to ignore? Tolerance control. The inserts need to sit exactly where they should. Even a half-millimeter shift can cause bonding failure—or worse, safety issues.

Overmolding: Multi-Shot or Multi-Step Molds

Overmolding ups the tooling game. You’re either:

- Using a multi-shot mold that injects two materials in one cycle (more advanced, more expensive)

- Or you’re using two separate molds and moving the part from one to the next (can slow down cycle time)

That second layer of tooling needs to:

- Align perfectly with the base part

- Prevent material overflow or shifting

- Maintain bonding surface conditions (clean, dry, tacky if needed)

The machines? You’ll typically need:

- A multi-shot injection molding machine, or

- Two compatible molding presses with precision handoff or robotics

Overmolding can be heavier on capital equipment, but when done right, it eliminates entire post-processing steps—no adhesives, no assembly lines, no extra labor.

5. Design Flexibility

Let’s be honest—great design isn’t just about how something looks. It’s about how it functions, fits, and holds up under real-world use.

And when you’re choosing between insert molding and overmolding, design flexibility can tip the scales.

Insert Molding: Built for Strength and Structure

Insert molding shines when you’re designing parts that:

- Need structural integrity

- Combine metal and plastic in precise configurations

- Require wear resistance, conductivity, or high-load tolerance

Because you’re starting with a solid component, like a machined metal insert, you can design features like:

- Threaded fasteners

- Electrical terminals

- Reinforced anchor points

We’ve seen customers design incredibly robust housings with embedded metal cores that hold torque, carry current, or resist vibration. And when those metal inserts need CNC-level accuracy, we handle that in-house at MachMaster, so your tolerances are locked in from day one.

Overmolding: Made for Comfort, Grip, and Ergonomics

Overmolding gives you creative freedom, especially when your product needs:

- A soft-touch feel

- Added friction or grip

- Shock absorption or moisture sealing

- Visual appeal with dual-color or dual-material layers

The real value? You can shape how the user interacts with your product. Whether it’s a grip on a surgical tool, a waterproof ring on a handheld scanner, or a non-slip finish on industrial controls, overmolding lets you control the tactile experience.

Even better, you can overmold in zones, layers, or textures—turning a single part into a multi-function, multi-material product without additional assembly.

Just keep in mind: design for bonding compatibility. Not all plastics stick to each other. Surface prep, texture, and wall thickness all play a role.

The Takeaway

- If you need structure, precision, and embedded function, insert molding gives you the edge.

- If you need user interaction, aesthetics, or environmental protection, overmolding is your tool of choice.

Great design isn’t about picking the coolest process. It’s about picking the right one for what your product needs to do.

6. Use Case Comparison

Knowing how each process works is one thing. But knowing where it works best? That’s how you avoid mistakes, and make the right call upfront.

Let’s break it down across real-world scenarios.

Structural Parts with Embedded Functionality

If your product requires strength, rigidity, or metal-to-plastic integration, insert molding is the go-to.

Think about:

- Automotive connectors that need to hold torque and conduct electricity

- Medical housings with embedded threads or surgical-grade stability

- Industrial controls where inserts need to resist vibration, pressure, or temperature shifts

In these cases, the insert is doing more than just sitting there—it’s working. It’s structural, functional, and critical.

Ideal Process: Insert Molding

Ergonomic or User-Facing Components

When feel, grip, and interaction matter, overmolding wins every time.

You’ll find it in:

- Power tool handles where slip-resistance is critical

- Consumer electronics like earbuds or wearables that demand tactile comfort

- Handheld scanners or syringes that need a soft, safe touch

Overmolding helps you shape the user experience, not just the product.

Ideal Process: Overmolding

Products Requiring Dual-Function or Hybrid Design

Sometimes you need both, mechanical strength and a high-touch finish.

Example:

- A rugged handheld device for field use, with a metal-plastic internal structure (insert molded) and a shock-resistant outer layer (overmolded)

- Electrical tools with embedded copper inserts and soft overmolded grips

You’ll need to plan tooling around multi-step production or work with a vendor that can handle both processes in sequence.

Ideal process: Hybrid (Insert Molding + Overmolding)

Rapid Prototyping or Low-Volume Production

When you’re testing a concept or launching a short-run part, you want speed, flexibility, and minimal tooling costs. Insert molding often makes more sense here, especially if:

- You’re using standard CNC-machined inserts

- You want to avoid the higher tooling investment of multi-shot overmolding

- You’re iterating on fit and function

But for touch-sensitive products, you might still prototype with overmolding, just know it takes more setup.

Ideal Process: Insert Molding (sometimes Overmolding if the user feels it is key)

7. How to Choose Between Insert Molding and Overmolding

This is the moment where everything comes together.

You know what each process is. You’ve seen the tooling, the use cases, the pros and cons. Now the question is: Which one is right for your product, your budget, and your timeline?

Let’s break it down:

Define the Role of the Part

Start by asking: “What job does this part actually do?” If it’s there to:

- Reinforce structural load

- Carry current or resist torque

- Hold threaded fasteners

Then you’re designing around functionality and mechanical strength. That’s a clear sign: Go with Insert Molding.

But if the part is:

- Touched by the user

- Exposed to weather or chemicals

- Meant to seal, protect, or grip

Then comfort and surface interaction matter more. That’s your signal: Go with Overmolding

Look at Your Materials

Insert molding requires metal + plastic combinations. Overmolding uses plastic over plastic, or rubber over plastic.

Here’s the checklist:

- Need metal in the part?. Insert molding

- Need a soft-touch layer?. Overmolding

- Need both?. Use both processes or hybrid molding

Just remember: not all materials bond well. You’ll want to test compatibility early or work with a team that can help you dial it in.

Match Your Volume and Budget

This is where many teams get stuck—and overspend.

- Insert Molding: Best for low to mid-volume production. Tooling is more affordable, especially if inserts are CNC machined or pre-fabricated.

- Overmolding: Best for mid to high volume. Tooling costs more, but it’s faster at scale and reduces assembly.

If you’re prototyping or doing short runs, insert molding is often the better fit. You can outsource insert production, keep molds simple, and move fast.

Conclusion

That costly delay? It never had to happen.

With what you’ve learned—process, tooling, use cases, and real-world comparisons—you can avoid wasted time, budget overruns, and missed deadlines.

Insert molding. Overmolding. Now you know what they are, when to use them, and why choosing wrong affects more than just parts—it affects business.

Start now. Don’t wait for production issues to force your hand.

Contact us today and let’s plan the right process for it.

Discover More Options

There’s so much more to discover! Check out our other products and find what fits your needs:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.