One client brought over a legacy mold for rugged sensor housing.

After three production runs, they were still getting deep indentations around the internal support ribs. These marks weren’t just ugly—they were affecting how the parts stacked, sealed, and fit electronics.

The previous supplier told them, “It’s just the design.”

I knew that wasn’t the case.

As a custom injection molding manufacturer, I’ve spent years solving exactly these kinds of problems.

When it comes to surface quality and dimensional control, this is where I do my best work.

In this article, I’ll break down why sink marks happen, where they tend to form, and the practical steps I take to eliminate them.

Whether you’re dealing with new tooling or managing an older mold, you’ll walk away with clear solutions you can apply immediately.

So let’s get started!

1. What Are Sink Marks in Injection Molding?

If you’ve ever noticed small dents or dips in your molded plastic parts, you’ve seen sink marks in action.

They’re one of those frustrating surface flaws that seem minor at first but can quietly mess with the overall quality of your product.

When I first got into injection molding, I didn’t think much of these tiny imperfections. But once I realized they were a direct result of uneven cooling and shrinkage, it completely changed how I approached design and processing.

Here’s what’s really happening under the surface:

- Shrinkage at the Core: As molten plastic cools, it naturally shrinks. In thicker areas, the outer shell solidifies first, but the inside continues to contract — pulling the surface inward and forming a sink.

- Thicker Sections = Trouble: Sink marks almost always show up near thicker features, like bosses or ribs. If the transition between wall thicknesses isn’t smooth, expect trouble.

- Cooling Time Isn’t Just a Number: Skimping on cooling time to save a few seconds in the cycle can backfire fast. Insufficient cooling increases the risk of sinks dramatically.

- Tool Design Plays a Role: Poor gate location, ineffective packing pressure, or lack of uniform wall thickness all make it harder to compensate for shrinkage.

These marks might not affect the function of a part, but if your product is visible to end users, they instantly chip away at perceived quality.

And let’s be honest: one small flaw is all it takes to make a customer question the whole batch.

2. Primary Causes of Sink Marks

Before you can effectively eliminate sink marks, it’s crucial to understand their root causes. In my experience, sink marks usually result from a combination of key factors, each manageable once you spot them clearly:

Inconsistent Wall Thickness

One of the most common issues I see is inconsistent wall thickness across a molded part. Thicker areas naturally take longer to cool, leading to uneven shrinkage as they solidify later. The thicker sections pull inward during cooling, causing visible depressions that ruin the part’s appearance.

Establishing uniform wall thickness in your mold design can drastically reduce or even completely eliminate this problem.

Poor Cooling Rate

Another major culprit behind sink marks is inadequate or uneven cooling in the mold. When certain sections don’t cool quickly enough, they stay soft longer and continue shrinking even after other areas are solid.

I’ve often found that simply adjusting the cooling cycles or strategically placing cooling channels can dramatically improve the results. Managing your cooling system carefully is essential for consistently smooth, sink-mark-free parts.

High Melt Temperatures

Running your injection molding process at excessively high melt temperatures significantly increases the risk of sink marks. Hotter plastic remains fluid longer, leading to pronounced shrinkage as it cools and hardens unevenly.

Lowering melt temperature slightly has repeatedly proven effective for me in minimizing these frustrating defects. If sink marks frequently show up, double-checking your melt temperatures should become one of your first steps.

Low Pack and Hold Pressure

A sneaky yet critical factor is insufficient packing and holding pressure during molding. Proper packing ensures the plastic fully fills and stays in contact with the mold surface, even as shrinkage begins.

At MachMaster, this stage is closely monitored because even slight drops in hold pressure can lead to noticeable sink marks or internal voids.

Without enough pressure, the surface material sinks inward as underlying layers contract and shrink away.

3. How to Identify Sink Marks in Molded Parts

Quickly recognizing sink marks can save you both time and money, preventing minor defects from becoming major headaches. Over the years, I’ve found several reliable ways to spot these imperfections early in the production process.

Visual Inspection Under Good Lighting

The first method I always recommend is a careful visual check under bright, consistent lighting conditions. S

ink marks typically appear as slight dips or shadows, particularly around thicker sections or structural supports such as ribs.

Tilting the part at various angles helps catch subtle imperfections that might otherwise escape notice.

Surface Touch and Feel

Sometimes sink marks aren’t immediately noticeable by sight alone, especially with textured or darker materials.

Running your fingers gently across the surface of a part often highlights subtle depressions you might otherwise miss.

I’ve frequently caught hidden sink marks simply by paying close attention to the feel of the plastic’s surface.

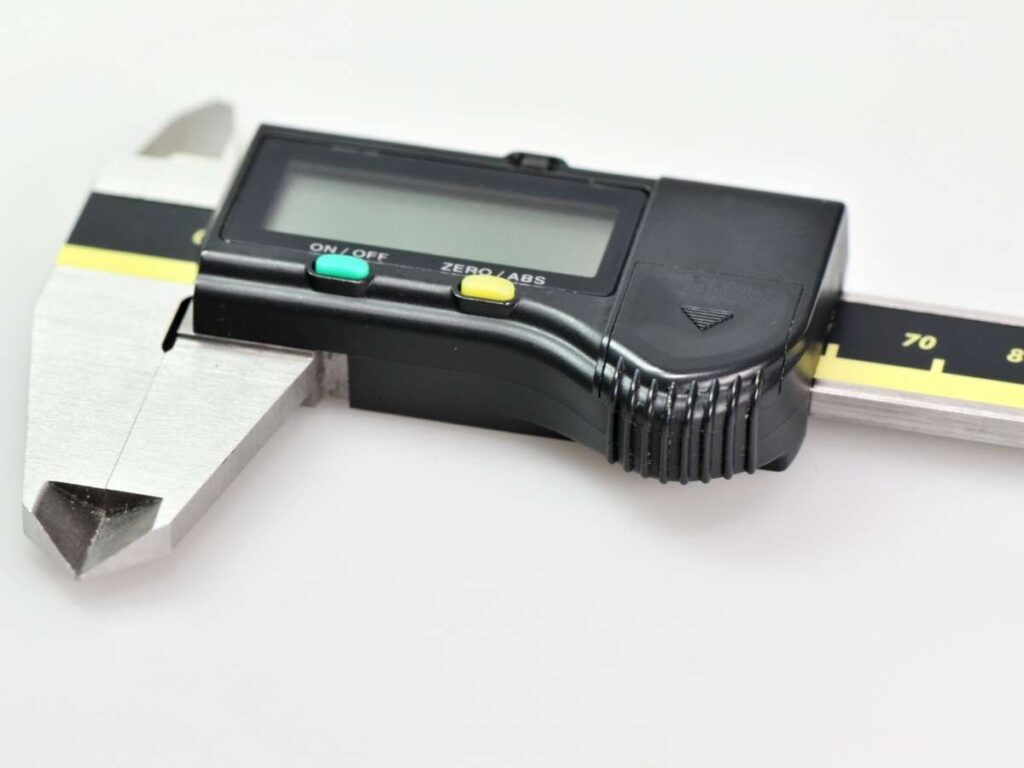

Measurement with Precision Tools

When accuracy matters most, using precision measurement tools is my go-to recommendation. Investing a little extra effort into measurement provides valuable certainty, especially for high-quality, precision-critical parts.

- Digital Calipers: This simple yet precise tool quickly measures the depth and dimensions of sink marks to the nearest fraction of a millimeter.

- Depth Gauges: A depth gauge easily captures how deeply a sink mark extends into the plastic surface, providing clear numerical data. These measurements help you track exactly how process adjustments are improving your results over time.

- Surface Profilometers: If your parts require exceptional precision, surface profilometers deliver detailed measurements of the surface profile. Using these tools, you can detect even microscopic surface variations, helping achieve consistently perfect molded parts.

4. Process Adjustments for Fixing Sink Marks

Making the right tweaks in your injection molding process can quickly eliminate sink marks, often without costly redesigns. I’ve personally found these minor adjustments to be powerful and effective:

- Increase Packing Pressure: Increasing your packing pressure keeps plastic firmly against mold surfaces as it solidifies. I’ve consistently seen dramatic improvements by slightly raising this pressure.

- Extend Cooling Time: Allowing your parts to cool a bit longer can reduce uneven shrinkage in thicker areas. Even a small increase in cooling time often leads to noticeably smoother results.

- Lower Melt Temperature: Reducing the melt temperature slightly speeds up cooling and reduces shrinkage. Lower temperatures have consistently delivered fewer sink marks in my experience.

- Slow Injection Speeds: Slowing down your injection speed can improve packing effectiveness and minimize internal voids. Although it sounds counterintuitive, I’ve seen slower speeds deliver significantly better part quality.

- Adjust Mold Temperature: Finding the optimal mold temperature is crucial for uniform cooling. Slight adjustments in mold temperature have helped me achieve visibly improved part surfaces.

- Balance Injection and Hold Times: Balancing injection and holding phases properly can directly influence part consistency. Careful fine-tuning here has frequently been the difference between flawed and flawless results for me.

5. Mold Design Improvements to Address Sink Marks

Sometimes, no matter how much you adjust the molding process, the mold itself is the root of the sink mark issues. Over time, I’ve realized that thoughtful mold design changes can dramatically improve the quality and appearance of your molded parts.

Consistent Wall Thickness

Keeping wall thickness uniform across the entire mold design is one of the best ways I’ve found to reduce sink marks. When walls have uniform thickness, plastic cools evenly, preventing areas that shrink slower and cause visible depressions. In contrast, thicker sections take longer to solidify, often resulting in unwanted surface imperfections.

Strategically Placed Cooling Channels

Properly positioning cooling channels within your mold can dramatically reduce sink marks. I’ve often seen significant improvements when cooling channels are placed close to thicker or critical areas, promoting even cooling.

Thoughtfully designed cooling channels have consistently delivered smoother surfaces and more reliable part quality.

Use Ribs and Gussets for Strength

Instead of making walls thicker for added strength, incorporating ribs and gussets is a smarter design approach I’ve consistently recommended.

These structural features reinforce your molded parts without significantly increasing thickness, helping to avoid problematic cooling differences. Thinner walls reinforced by ribs cool quickly and evenly, preventing common shrinkage issues that create sink marks.

6. 4 Best Preventive Practices to Eliminate Sink Marks

Eliminating sink marks entirely requires proactive measures rather than reactive fixes. From my experience, adopting these preventive practices has consistently delivered smoother, defect-free molded parts. Let’s explore 4 of the most reliable preventive practices I’ve personally found effective:

#1 Select Low-Shrinkage Materials

Choosing materials specifically formulated with lower shrinkage rates is an excellent preventive measure. Plastics vary significantly in how much they shrink during cooling, directly impacting the likelihood of sink marks.

In my experience, opting for materials known for dimensional stability greatly reduces the potential for surface imperfections.

This simple choice can substantially improve your overall production results.

#2 Use Mold Flow Simulation Software

Implementing mold flow simulation software is a proactive approach I’ve always recommended to predict sink marks before molding begins. These simulations clearly show potential problem areas in your design, allowing you to adjust mold or process parameters beforehand.

By virtually testing multiple scenarios, you can identify and correct issues early, avoiding costly trial-and-error cycles. It’s a powerful way to consistently mold perfect parts from the very first run.

#3 Regular Equipment Maintenance

Consistently maintaining and calibrating your molding equipment is vital in preventing sink marks.

From my experience, even minor temperature or pressure variations due to poorly maintained machinery can lead to frustrating defects.

Regularly scheduled maintenance keeps molding parameters stable and predictable, significantly improving part consistency.

#4 Real-Time Process Monitoring

Adopting real-time process monitoring helps catch potential issues early, before sink marks fully form. Continuous monitoring lets you detect small variations in temperature, pressure, or injection speed immediately, allowing for quick corrections.

This is one of the core quality-control strategies used at MachMaster to deliver consistently clean, high-performance molded parts with fewer defects.

Conclusion

I remember the frustration of seeing those annoying sink marks ruining my molded parts.

But sink marks aren’t unbeatable, now you know exactly how to identify, fix, and prevent them.

Don’t let sink marks slow you down; start making changes.

Ready to finally leave sink marks in the past?

Our team delivers precise injection molding solutions tailored to your needs.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.