A supplier once asked if I wanted a grain finish or a mill finish.

I said, “What do you recommend?”

They chose wrong. The part looked off. The client wasn’t happy.

That’s when I learned: if you don’t understand the steps, you give up control.

Since then, I’ve helped teams across industries avoid simple mistakes. By asking better questions. By knowing the process.

This guide will show you how.

There are 8 steps that every good fabrication project follows. We’ll walk through each one so you can avoid delays, wrong parts, and unexpected costs. You’ll walk away with a clear, repeatable process ready to use.

So let’s get down to it!

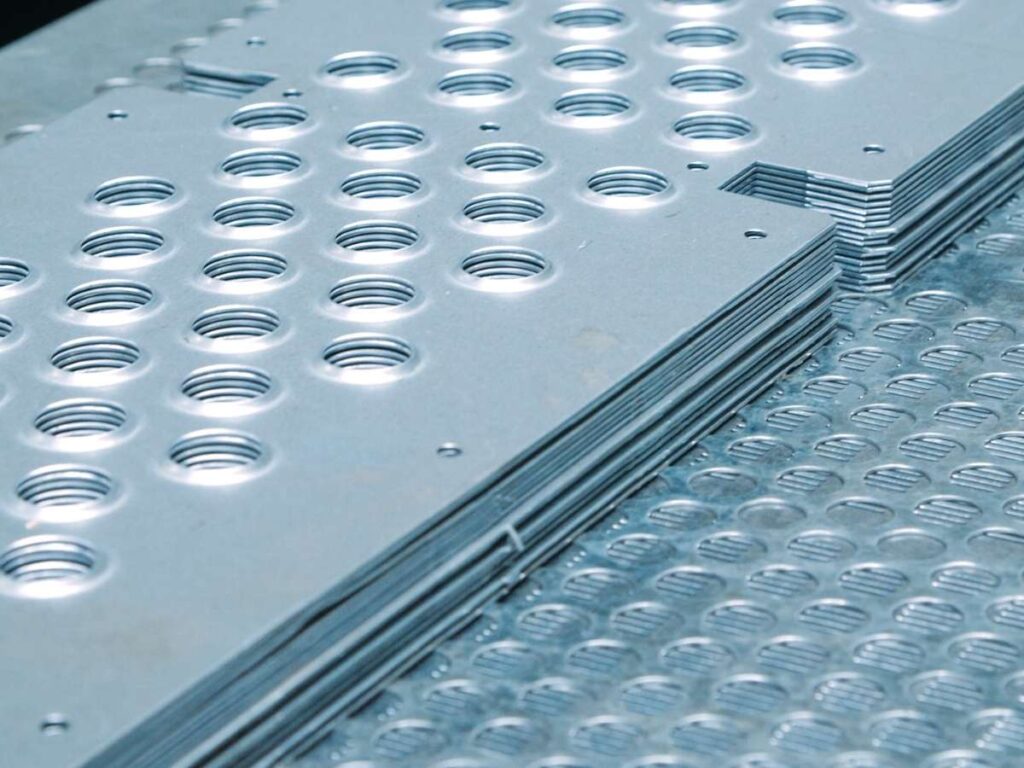

Step#1 Choose the Right Material

The material you choose will make or break your sheet metal project.

I learned that the hard way after selecting a metal that looked great, but bent like paper during forming. We had to scrap the entire batch. That mistake? It came from not knowing what each material was really good at.

Common Sheet Metal Options (and Why It Matters)

There’s no one-size-fits-all metal. Each type behaves differently during cutting, bending, and welding. Choosing wrong means higher costs, delays, or parts that fail in the field.

Here are the most common options used in sheet metal fabrication:

- Mild Steel: Strong, cheap, easy to weld

- Stainless Steel: Corrosion-resistant, hard to scratch, durable

- Aluminum: Lightweight, rust-proof, easy to machine

- Copper: Conductive, beautiful finish, very soft

- Galvanized Steel: Steel with a zinc coating to prevent rust

Not all vendors stock every material at every thickness. Always check what’s available before finalizing design.

Understand Thickness

Sheet metal thickness is measured in gauges (imperial) or millimeters (metric). But here’s the trick, a higher gauge means thinner metal.

| Gauge (Steel) | Thickness (inches) | Thickness (mm) |

| 10 GA | 0.1345″ | 3.42 mm |

| 14 GA | 0.0747″ | 1.90 mm |

| 20 GA | 0.0359″ | 0.91 mm |

- Thicker metals are stronger but harder to bend.

- Thinner sheets are easier to cut but may warp under load.

Pro Tip: Match your thickness to both function and process. A great design fails if it’s too thick for your supplier’s press brake.

How to Pick the Right Material

Before locking in your choice, ask:

- Strength vs. Weight: Is the part structural? Or does it need to stay light?

- Corrosion Resistance: Will it be used outdoors or in a wet environment?

- Formability / Weldability: Does it need complex bends or weld seams?

- Finish Requirements: Will it be seen by customers? Painted? Polished?

- Cost & Availability: Is the material in stock? Priced right for your volume?

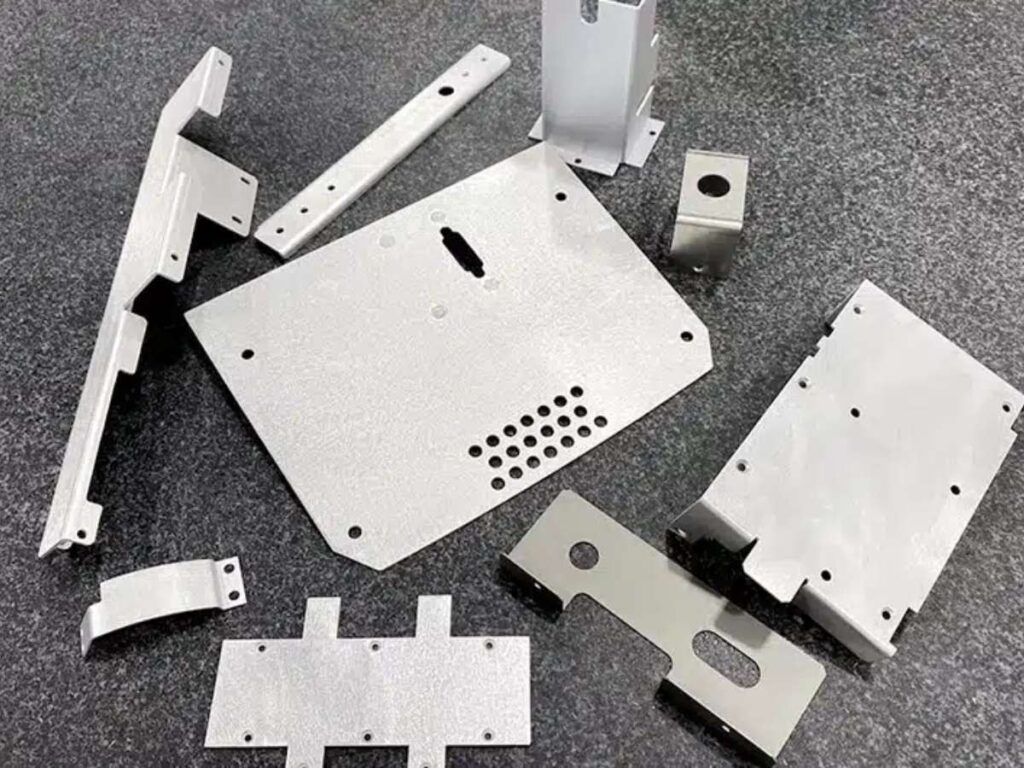

Step#2 Know the Core Fabrication Techniques

The tools your fabricator uses aren’t just technical choices, they directly impact your cost, speed, and quality.

I learned this when a project that required tight tolerances was sent to a shop using outdated shear cutters. The parts came back uneven, and we lost an entire week fixing it.

Stages of Fabrication

Every sheet metal part is made using a combination of these 4 stages:

- Cutting: Turns sheet stock into the rough shape

- Forming: Bends or reshapes the metal

- Joining: Connects parts together (if multi-piece)

- Finishing: Adds protection or visual appeal

Each method has trade-offs. Some are fast but imprecise. Others are slow but detailed. Choosing wrong adds waste.

Cutting Techniques

- Laser Cutting: High precision, clean edges, ideal for tight tolerances

- Shearing: Fast, cheap, best for straight-line cuts

- Plasma Cutting: Good for thicker metals, less accurate

- Waterjet Cutting: Cold process, no heat distortion, great for delicate or layered materials

Forming Techniques

- Press Brake Bending: Precise, good for small to medium batches

- Roll Forming: Great for long, uniform parts (like channels or rails)

- Stamping: High-speed, low cost per part, best for mass production

Joining Techniques

- Welding: Strong, permanent joints, great for structural parts

- Fasteners: Bolts, screws, etc., allow for disassembly or maintenance

- Riveting: Reliable and cost-effective for high-volume assemblies

Finishing Techniques

- Powder Coating: Durable, uniform, wide color range

- Anodizing: Used mostly for aluminum, adds corrosion resistance and color

- Plating: Adds a metal coating (like zinc or nickel) for protection or conductivity

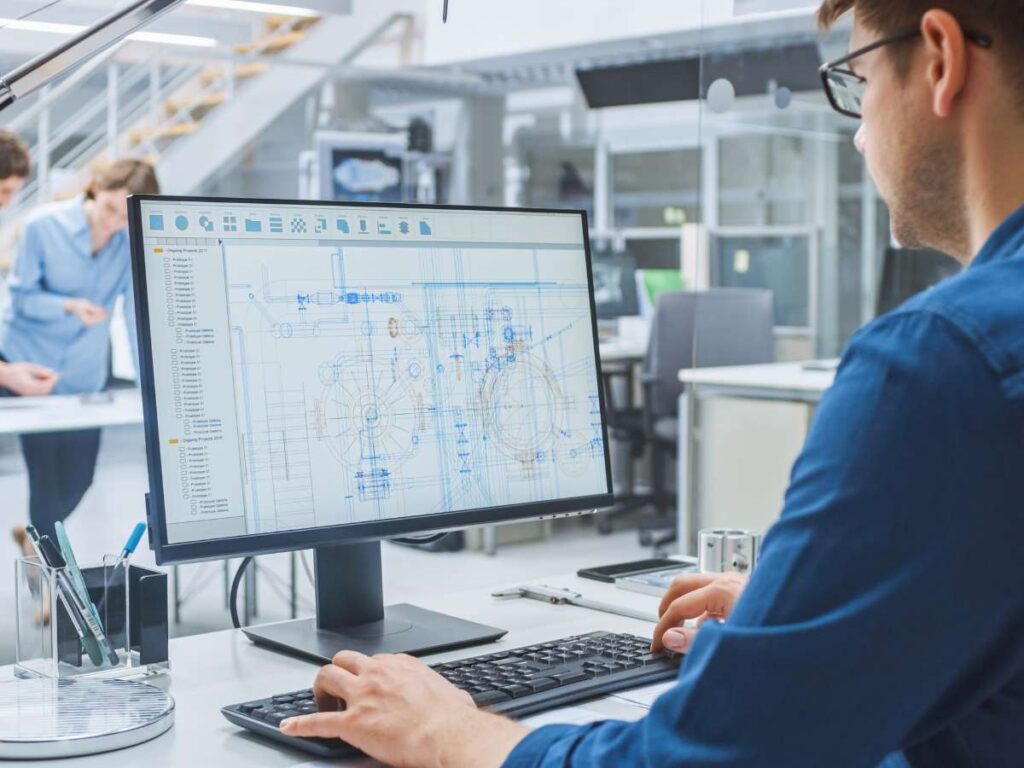

Step#3 Design for Manufacturability (DFM)

Design is where most fabrication problems begin, and where most of them can be solved.

Early in my career, I designed a part with tight internal corners and odd bend angles. It looked fine on-screen, but it snapped while forming. The fabricator called it “unfriendly.” I called it a learning moment.

DFM isn’t just about making the part “fit”, it’s about making sure it can be made accurately, efficiently, and without surprise costs. Smart DFM saves you time, money, and vendor headaches.

Here are the top rules to keep in mind:

DFM Design Considerations

- Avoid Sharp Internal Corners: These stress the metal during bending and may crack. Use fillets or radii instead.

- Use Standard Bend Radii: Design bends with radii that match your fabricator’s tooling. This speeds production and reduces wear.

- Allow for Kerf (Cut Width): Laser or waterjet cutting removes a small amount of material. Leave enough clearance, especially in tight-fitting parts.

- Reduce Part Complexity Where Possible: Fancy shapes mean more operations, more tooling, and more chances to mess up. Simple = scalable.

- Add Reliefs for Easier Bending: Relief notches prevent tearing or distortion near bends, especially in thicker material.

Use the Right CAD Tools for Sheet Metal

Not all CAD is created equal, especially when working with sheet metal.

Use design tools that include native sheet metal features, such as:

- SolidWorks

- Fusion 360

- Inventor

- Siemens NX

Look for features that allow you to:

- Apply standard bend rules

- Generate flat patterns automatically

- Add bend lines, reliefs, and edge flanges with real-world parameters

- Export 2D DXF files directly for laser cutting

The better your design fits real-world processes, the fewer questions your vendor will have, and the more accurate your quote will be.

When in doubt, ask for a DFM review before submitting. Many shops will offer one for free, and it’s cheaper than fixing errors after the fact.

Step#4 Create Manufacturing-Ready Documentation

You can have the best design in the world, but if your documentation is unclear, your parts won’t be made right.

I’ve seen perfectly modeled components get delayed, over-quoted, or rejected outright, just because the files were missing critical details.

They need clear, complete files to quote and produce your part. Missing or vague documentation is the fastest way to get miscommunication, rework, or pricing surprises.

Here’s what you should always include:

What Fabricators Need From You

- 2D Technical Drawings: Include all key dimensions, hole locations, bend lines, and tolerances. Use a clear title block.

- 3D Models (STEP, DXF, etc.): These help the shop simulate bends and prepare toolpaths. Avoid sending native CAD files unless requested.

- Material Callouts and Finishes: Specify the material type (e.g., 5052 aluminum, 304 stainless) and any coatings or finishes.

- Quantity and Volume Estimates: Include both prototype and production volumes. This affects tooling choice, pricing, and lead time.

Avoid These Common Mistakes

- Missing Dimensions: If it’s not dimensioned, it will be guessed, or delayed.

- Unclear Tolerances: Default tolerances vary by shop. If your part has tight fits, say so clearly in the drawing.

- Over-Specified Finishes: Don’t request aerospace-grade coatings if they’re not needed. It’ll spike your cost and lead time for no reason.

Well-prepared documentation not only makes your vendor’s life easier, it puts you in control of cost, quality, and delivery.

If you’re unsure, ask your vendor for a documentation checklist or sample drawing. It’s a 5-minute step that could save you 5 weeks.

Step#5 Prototype and Test Early

There’s nothing worse than scaling a design that doesn’t actually work.

One time, I rushed a sheet metal assembly straight into production. It looked great in CAD. But in reality, the tabs didn’t align, one bend interfered with a mounting hole, and the finish scratched during handling. We trashed 300 units.

Why Prototyping Is Non-Negotiable

Prototyping isn’t just a technical step, it’s a risk filter. It helps you:

- Validate the Design: Make sure everything fits, assembles, and functions as expected

- Spot DFM Issues Early: You’ll catch problems that aren’t obvious in CAD

- Test Durability and Finish: Will it bend cleanly? Will the coating hold up?

Skipping prototyping is like approving blueprints without seeing the building. What looks perfect on paper may fall apart in production.

Best Practices for Prototyping

- Start Small: Order a single unit or small batch. Don’t overcommit until you know it works.

- Use Rapid Prototyping Vendors: Choose a shop that specializes in fast turnarounds. Many offer short lead times on test runs.

- Ask for Feedback: Fabricators can flag risky bend areas, tight tolerances, or material changes. Use their input before reordering.

Step#6 Select and Vet Your Fabrication Partner

Your parts are only as good as the shop that makes them.

I’ve worked with vendors who over-promised and under-delivered, missed deadlines, sloppy finishes, and inconsistent results. I’ve also partnered with fabricators who made me look like a hero to my team.

Choosing the right partner means more than just comparing quotes. You need someone who understands your industry, meets your quality expectations, and communicates clearly.

Here’s how to evaluate your fabrication partner:

How to Evaluate Vendors

- Core Capabilities and Specialties: Do they focus on prototyping, production runs, or both? What materials and processes are they best at?

- Certifications: Look for ISO 9001 or other quality certifications, especially if your parts have strict tolerances or safety requirements.

- Tooling Investment Requirements: Will you need to pay for custom tooling upfront? Or can they work with flexible setups for smaller runs?

- Lead Times, MOQs, and Pricing Transparency: Can they handle short lead times without compromising quality? Do they clearly state minimum order quantities and cost breakdowns?

Questions to Ask Before Committing

- “What’s your average turnaround for prototyping vs production?”

- “Can you handle finishing in-house, or do you outsource?”

- “Do you offer DFM review or design feedback before production?”

Providers like MachMaster, who offer both prototyping and full-scale runs, can help simplify your vendor list and reduce risk.

A strong vendor relationship doesn’t just get your parts made, it protects your schedule, your budget, and your reputation. Vet carefully, ask questions, and work with a partner who can grow with your needs.

Step#7 Optimize Cost, Quality & Scalability

If your parts are built perfectly but cost too much or can’t scale, you’re still at risk.

I’ve seen teams get excited about a flawless prototype, only to realize they couldn’t afford to mass-produce it. The result? Weeks of redesign and a product launch pushed back by a quarter.

You can’t chase one without considering the others. Cost savings that hurt quality will come back as rework. Overbuilding for perfection will kill your margins. Smart optimization is about balance.

Here’s where to focus:

Key Cost Drivers to Watch

- Material Selection: Use only what’s needed for strength or appearance, don’t over-specify high-grade metals without purpose.

- Sheet Utilization: Nest parts efficiently to reduce scrap. Your fabricator can help optimize the layout.

- Part Complexity: Tight tolerances, deep bends, and unnecessary features add cost through extra setup and handling.

- Tooling & Setup Time: If your part requires unique tooling or long setup, it’ll be more expensive, especially in small batches.

- Finish Requirements: Specialty coatings or multiple finishes per part drive up both cost and lead time.

Ask your vendor for feedback on where costs can be trimmed without impacting function. Many can suggest small changes that reduce operations or material waste.

How to Ensure Scalability

- Standardize Features Across Parts: Using the same hole sizes, radii, or flange styles across parts simplifies tooling and inspection.

- Batch Production Planning: Group orders when possible to benefit from economies of scale. Even combining different parts in one run can reduce cost.

- Design for Automation: If you expect a large volume, minimize the need for manual deburring, welding, or inspection. Think: fewer fasteners, easier fixturing, and flat-pack designs.

- Pre-Validate with Prototyping and DFM Reviews: Scaling a bad design only magnifies the risk. Fix issues early, then scale with confidence.

Quality Should Never Be an Afterthought

Cutting corners on inspection or tolerances may save money in the short term, but it damages trust in the long-term.

- Set acceptable tolerances from the start

- Build a QC checklist with your vendor

- Plan for first article inspection (FAI) before full runs

- Track part performance in the field and feed issues back into design

Great quality systems prevent defects before they happen, and save money over the product’s lifecycle.

When cost, quality, and scalability are aligned, your sheet metal parts stop being a bottleneck and start being a competitive advantage.

Work closely with your fabricator to strike that balance, and you’ll unlock smoother production, fewer surprises, and better margins.

Step#8 Quality Control and Inspection Standards

No matter how well you design or plan, if your parts aren’t inspected properly, quality is just a guess.

I once approved a batch of enclosures based only on visual checks. A week later, we discovered that mounting holes were misaligned by just 0.5mm, enough to cause a full assembly line shutdown.

Quality Starts With Clear Standards

The key is to define what “good” looks like before production begins, and to make sure your vendor can measure it. Quality isn’t just about the end result. It’s about having controls in place at every stage.

Common Inspection Methods

- First Article Inspection (FAI): One part from the first batch is fully measured against the drawing before proceeding.

- In-Process Inspections: Spot checks are done during forming, cutting, or welding. These catch issues before they spread.

- Final Dimensional Checks: Using tools like calipers, gauges, or coordinate measuring machines (CMM) to confirm accuracy.

- Surface and Finish Checks: Ensure coatings are uniform, protective, and meet appearance specs.

What to Include in Your Quality Plan

- Tolerance specs for all critical features

- A list of key dimensions to check

- Surface finish expectations

- Acceptable deviation ranges

- Sample inspection frequency (e.g., 1 per 10 units)

This gives your vendor a clear target, and gives you peace of mind.

Not every shop will offer structured quality controls. At MachMaster, we follow ISO-based inspection standards and perform in-process checks throughout fabrication. We believe consistent quality isn’t an extra, it’s the baseline.

Conclusion

I gave up control when I didn’t know the process.

But you don’t have to.

Now you’ve seen the full picture. You know what to ask. What to avoid. And how to move from design to part the right way.

These 8 steps work. I’ve used them with companies big and small.

So can you.

And if you need a partner who lives this process daily, Machmaster is here.

Don’t guess your way through another project. Take the lead. Ready to get more control over your next fabrication job?

Contact us today, we’ll help you get it right.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

If you enjoyed this read, here are a few more articles packed with helpful information:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.