I once lost a contract because a batch of bolts rusted after just two months in the field.

I thought I’d used the right coating. Turns out, I didn’t know the difference between galvanized and hot dip galvanized. And I paid for that mistake literally.

If you’re comparing these coatings right now, I get it. You’re probably trying to figure out which one lasts longer, which one costs more, and which one actually fits your job.

In this guide, I’ll break it all down for you.

You’ll learn:

- What each term really means

- How they’re made

- How long they last

- What they cost

- And which one makes sense for your use

By the end, you’ll know exactly what to choose and why. No guessing. Just facts from someone who’s made the wrong choice before.

So let’s start!

1. What Is Galvanization?

I used to think metal was metal. Strong, solid, and built to last. But then I left a few steel brackets outside overnight. A week later? Rust spots everywhere.

That’s when I first learned about galvanization.

Galvanization is the process of adding a thin layer of zinc to steel or iron. Think of it as giving metal a raincoat. The zinc protects the steel underneath from rusting.

Here’s why zinc works:

- It forms a barrier between moisture and metal

- It reacts first when exposed to water and air, protecting steel

- It slows down corrosion even if the coating gets scratched

Without this layer, steel rusts fast especially if it’s used outdoors or near water.

You’ve probably seen galvanized parts without even realizing it. They’re everywhere:

- Guardrails on highways

- Metal roofing and gutters

- Car frames and exhaust systems

- Fences, bolts, and outdoor signs

If something metal needs to survive outside, it’s often galvanized.

But here’s where it gets interesting. Not all galvanization is the same.

Some methods dip the steel into molten zinc. Others spray or electroplate it. The way it’s done affects how long it lasts, how much it costs, and what it’s good for.

2. What Is Hot Dip Galvanizing?

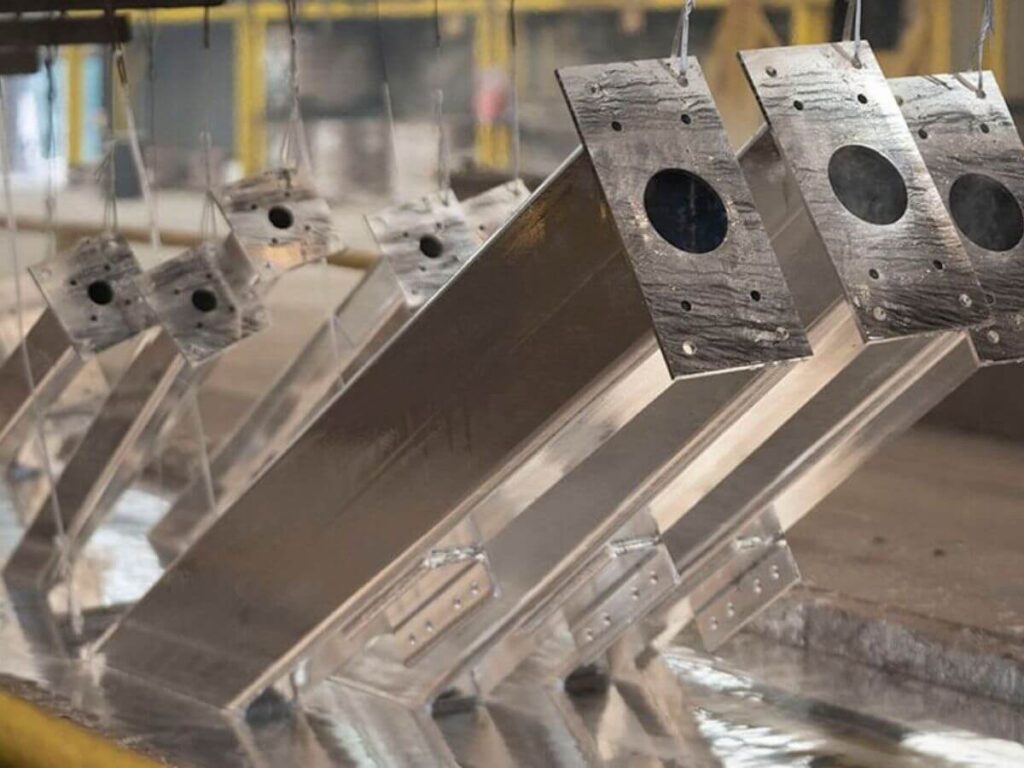

I remember the first time I visited a metal shop and watched hot dip galvanizing in action. It looked like something out of a science lab—bright sparks, thick smoke, and huge steel beams being dipped into a glowing vat of molten zinc.

That’s exactly what hot dip galvanizing is.

It’s a process where steel or iron is fully immersed in a bath of molten zinc. This isn’t a light coating. It’s deep. It covers every edge, corner, and gap. Even the inside of hollow tubes can get coated.

The result? A much thicker layer of protection than other types of galvanizing.

You might notice hot dip galvanized parts by their finish. They usually have:

- A dull gray or matte surface

- A slightly rough or spangled texture

- A rugged look that shows it means business

But it’s not just about looks.

This process creates a bond between zinc and steel. They actually react with each other. That means the zinc coating doesn’t just sit on top—it becomes part of the steel surface.

Because of that, it offers:

- Stronger protection against rust

- Longer life in outdoor or wet environments

- Better performance in tough conditions

Hot dip galvanizing is often used for:

- Structural beams

- Fencing and gates

- Highway barriers

- Marine hardware

- Steel used in bridges or buildings

If your project is exposed to weather, water, or wear, this method is worth a serious look.

So ask yourself: Will your metal be outdoors? Will it face moisture or salt? If so, hot dip might be the right move.

3. What Is Electro-Galvanizing or “Regular Galvanizing”?

When I first ordered galvanized steel parts, I didn’t ask how they were galvanized. I assumed galvanized was galvanized.

Big mistake.

The supplier sent me shiny brackets that looked great—until I used them outside. A few months later, rust started to creep in. That’s how I learned the difference between electro-galvanizing and hot dip galvanizing.

Electro-galvanizing, sometimes called regular galvanizing, uses electricity to coat steel with zinc. The steel is dipped in a zinc-based solution, and an electrical current helps the zinc bond to the surface.

This method creates:

- A thinner coating of zinc

- A smooth, bright, and shiny finish

- A cleaner look, often used for decorative or indoor parts

Another version you might hear about is pre-galvanizing. That’s when the steel is coated before it’s shaped, bent, or welded. It saves time but doesn’t always protect cut edges or welded joints as well.

Here’s the catch: electro-galvanized steel doesn’t hold up well outdoors.

It’s best for:

- Indoor use

- Appliance parts

- Furniture frames

- Light-duty hardware

If your parts are going to sit inside a dry environment, electro-galvanizing might be fine. But if they’ll face rain, snow, or salt? You might need something stronger.

4. Visual & Surface Differences

I’ll admit it I’ve made choices based on looks before.

Once, I picked electro-galvanized brackets for an outdoor display because they looked polished and clean. They matched the style. But 6 months later? Rust streaks down the side. That mistake taught me: don’t let looks fool you.

Both hot dip and electro-galvanizing protect metal, but they look—and behave—very differently.

Let’s break it down.

Surface Appearance

Hot dip galvanized steel usually has a dull, matte finish. You might see small flakes or patterns on the surface. That’s called spangling. It forms naturally when zinc cools.

Hot dip can feel:

- Rough or gritty

- Uneven in color

- Industrial or rugged

It’s often used where no one will see the metal up close. Think highway rails, buried fence posts, or steel beams inside a wall.

Electro-galvanized steel, on the other hand, looks clean and smooth. The zinc layer is thinner, so it doesn’t change the shape or texture much.

It has:

- A shiny silver finish

- A smooth surface

- A polished, more modern feel

It’s a better choice for parts that will be seen: appliances, furniture frames, or trim pieces.

Paintability & Finish Compatibility

Need to paint your part? This matters.

- Electro-galvanized steel takes paint well. You can powder coat it or spray it with minimal prep.

- Hot dip galvanized steel is trickier. The thick coating and texture make it harder for paint to stick. It often needs extra prep—like cleaning, sanding, or using a special primer.

So, ask yourself: Will this part be visible? Do you plan to paint it?

Looks matter sometimes. Just make sure the surface fits the job, not just the eye.

5. Durability in Real Use

I’ve seen galvanized parts last decades and I’ve seen them fail in just a few years. The difference? Where and how they’re used.

If you’re deciding between hot dip and electro-galvanized coatings, durability might be the deal-breaker. Let’s take a closer look at how each performs out in the real world.

Corrosion Resistance Comparison

Hot dip galvanized steel has a thick zinc layer. It forms during the dipping process and bonds tightly to the surface.

This thick layer holds up well in:

- Coastal or marine environments

- Industrial zones with chemicals or heavy moisture

- High-humidity areas, like basements or crawl spaces

- Any outdoor setting where rain, snow, or salt is common

If you’re dealing with moisture, weather, or wear, hot dip is the safer bet.

Electro-galvanized steel, on the other hand, has a much thinner coating. It works fine indoors, but it won’t last long in harsh outdoor settings.

It’s best for:

- Indoor appliances like washing machines or microwaves

- Furniture frames kept inside

- Light-duty fixtures that won’t face moisture

I once used electro-galvanized brackets for a patio bench, thinking the overhang would protect them. Two years later, rust was creeping in from every screw hole. Lesson learned.

Life Expectancy (with Examples)

Let’s talk numbers.

Hot dip galvanized steel can last:

- 30 to 70 years depending on exposure

- Over 50 years in rural areas

- Around 20 to 40 years in coastal zones

Electro-galvanized steel typically lasts:

- 5 to 15 years indoors

- Less than 5 years outdoors in wet or salty air

So, what kind of exposure will your part face?

If you want it to last for decades without rust, hot dip might be the smarter choice.

6. Application Fit

Choosing the right galvanized finish really comes down to one thing: how and where you’ll use the part.

I used to think any galvanized steel would do the job. But after seeing fence posts rust from the bottom up and appliance panels dent from rough coatings, I realized every project needs the right fit—not just any fit.

Let’s break it down by application.

Structural Steel & Outdoor Projects

If your project involves weather, weight, or wear, go with hot dip galvanizing. That thicker zinc layer holds up better over time.

It’s a strong choice for:

- Structural beams

- Guardrails

- Bridge supports

- Chain-link fences and posts

I once built a gate using hot dip galvanized tubing. Years later, it’s still solid—even after storms, snow, and a few bumps from lawn equipment.

Automotive or Appliances

If the part needs to look good and won’t be exposed to much moisture, electro-galvanized steel might be a better match.

You’ll often find it in:

- Car body panels

- Appliance doors and control panels

- Electronics casings

That clean, smooth surface makes it easier to paint and finish.

Sheet Metal Parts or Pipe

Pre-galvanized steel is useful too especially if you don’t plan on cutting or welding it much after purchase.

It works well for:

- Light-duty pipe

- Cable trays

- Vents and ducts

Just keep in mind: cut edges lose protection.

Welding, Cutting & Bending Considerations

Every job has moving parts.

- Hot dip: The thick coating may burn off when you weld or cut. You’ll need to touch it up afterward.

- Electro-galvanized: Easier to weld or form, but the protection is thinner.

So ask yourself: Will you shape it? Will it face rain or rough use?

Match the finish to the work. It’ll save you time and trouble later on.

7. Procurement Considerations

I’ve made my share of last-minute purchases. And I’ve learned something: how you order galvanized steel matters just as much as what type you choose.

It’s easy to get caught up in specs and forget the basics—like lead time or availability. That’s how delays start. Or worse, that’s how the wrong material shows up at your door.

Here’s what to keep in mind before placing that order.

Lead Time & Availability

Hot dip galvanized parts usually take longer. That’s because they’re often processed in batches. Your order might have to wait its turn.

Expect:

- More lead time for large or custom pieces

- Extra planning if you’re on a tight deadline

Electro-galvanized parts, by contrast, are often pre-made and kept in stock. If you need something fast, this might be your safer option.

I once needed brackets in a pinch. The supplier only had electro-galvanized ready to ship. I took the deal—then had to recoat everything weeks later. Don’t repeat that mistake.

Supplier Compatibility

Not every supplier does both hot dip and electro-galvanizing. Some specialize in just one.

So always ask:

- “Is this hot dip or electro-galvanized?”

- “What process are you using?”

- “Can you meet my coating spec?”

Getting clear on that early can prevent mix-ups.

If you’re looking for a partner that offers both coating options, clear specs, and fast turnaround—MachMaster can help. We support everything from custom prototypes to full production runs, all under one roof.

Specs to Include on Purchase Orders

Be specific. Vague orders lead to surprises.

Here’s what to include:

- Coating thickness (in microns or ounces per square foot)

- Process method: HDG (hot dip galvanized), EG (electro-galvanized), PG (pre-galvanized)

- Standards: ASTM A123, A153, A653 (depending on your part type)

That one extra line on your PO could save you thousands in rework.

8. Standards and Compliance

When I started ordering galvanized parts for my projects, I didn’t think much about standards. I figured if it looked coated, it was good enough. But after a failed inspection and a costly return, I realized: standards matter.

If you’re sourcing materials, especially across borders, paying attention to standards can save you serious headaches. Let’s walk through what to look for.

Common Galvanizing Standards

Different jobs call for different types of steel. And each type has a matching standard.

Here are a few you might come across:

- ASTM A123: Covers hot dip galvanizing for large structural shapes, plates, and bars

- ASTM A153: Meant for hot dip coatings on smaller items like bolts, nuts, and fasteners

- ASTM A653: Applies to electro-galvanized or continuously hot dip galvanized sheet steel

These aren’t just paperwork. They spell out coating thickness, adhesion, and test methods, so you know what you’re getting.

When I started including these codes in my quotes, I got better materials. Fewer surprises. And suppliers knew I was serious.

Compliance for International Buyers

Ordering from overseas? You’ll need to go one step further.

Two key international standards include:

- ISO 1461: Often required for hot dip galvanized products shipped across countries. It’s used globally to define coating requirements and inspection rules.

- RoHS Compliance: If you’re sourcing electro-galvanized parts for electronics or appliances, make sure they meet RoHS (Restriction of Hazardous Substances). This means they’re free of lead and other banned materials.

Have you ever had to re-source a part because it didn’t meet specs? It’s frustrating—and expensive.

Getting the standards right up front helps you avoid rework, fines, and delays.

9. Cost Comparison

If you’re like me, you probably check prices first before you check specs. It’s natural. Budget matters especially when you’re ordering in bulk.

But I’ve learned the hard way that the cheapest option up front isn’t always the cheapest overall. Let’s walk through how hot dip and electro-galvanizing stack up in terms of cost.

Hot Dip Galvanizing

Hot dip usually costs more per part. That’s because:

- It uses more zinc

- It takes more time

- It involves dipping full parts into molten metal

But here’s what you get in return:

- Less maintenance

- Longer-lasting protection

- Fewer replacements over time

I once paid extra for hot dip posts on a rural fencing job. Ten years later, I still haven’t touched them. That job paid for itself in the long run.

Electro-Galvanizing

Electro-galvanized steel is cheaper upfront. It uses less zinc and can be processed faster—especially for standard parts.

This option works great for:

- Indoor parts

- Projects with tight budgets

- Jobs where looks matter more than lifespan

But be careful. If the part fails early and you have to replace it? That lower price won’t save you much.

What Drives Price Differences?

Several factors affect pricing:

- Zinc usage: Hot dip uses more material

- Processing method: Batch dipping is slower than electroplating

- Prep work: Masking, cleaning, or surface treatment adds labor

So, ask yourself: Are you planning for the next five years or the next fifty?

Choosing based on price alone can work if you know what trade-offs come with it.

10. Tips for Choosing the Right Coating Based on Your Needs

By now, you’ve probably seen just how different these coatings really are. But if you’re still unsure which one to go with, you’re not alone.

I’ve had moments where I stood in front of two quotes—one for hot dip, one for electro-galvanized—and couldn’t decide. It all comes down to what your job needs.

Let’s keep it simple.

Choose Hot Dip Galvanized If You Need:

You’re working with steel that’s going outside or into rough conditions? Hot dip might be your best bet.

Use it for:

- Long-term outdoor exposure

- Marine environments

- Industrial zones

- Structural steel projects

- Fence posts, gates, or highway barriers

It gives you that extra layer of protection. I once used hot dip for a job near the coast. Salt in the air destroys most coatings fast, but this one held up for years without touch-ups.

Choose Electro or Pre-Galvanized If You Need:

Will your parts stay dry and look clean? Then electro or pre-galvanized may work just fine.

Choose it for:

- Indoor appliances

- Furniture frames

- Decorative hardware

- Projects with a short lead time

- Large volume orders where price matters more than extreme durability

I’ve used electro-galvanized sheet metal for indoor panels that needed a sharp finish. It saved money and looked great.

So ask yourself: Where will the part live? Will it face rain, salt, or wear? Or does it just need to look good and ship fast?

Once you’re clear on that, the choice gets easier.

If you’re building for strength, finish, or volume, MachMaster can support your entire job. We handle galvanizing, CNC machining, and more—with precise results and on-time delivery.

11. Final Comparison Table

Still deciding between hot dip and electro-galvanized coatings? It’s okay if you are. Even after years of working with steel, I still need a quick side-by-side to make the call.

This chart pulls everything together so you can see the differences at a glance.

| Feature | Hot Dip Galvanized | Electro / Pre-Galvanized |

| Surface Appearance | Dull, rough, sometimes spangled | Smooth, shiny, clean finish |

| Durability in Real Use | 30–70 years outdoors | 5–15 years indoors (less outside) |

| Best For | Structural parts, outdoor, marine use | Indoor use, visible panels, appliances |

| Lead Time | Longer (batch process) | Shorter (readily available) |

| Supplier Fit | Fewer suppliers, check availability | Easier to find, commonly stocked |

| Specs to Include | ASTM A123 or A153, thickness in µm or oz/ft² | ASTM A653, RoHS (if needed) |

| Cost | Higher up front, lower long-term cost | Lower up front, more frequent replacements |

This kind of side-by-side helped me avoid a major headache last year. I needed parts fast and went with electro-galvanized. The finish was clean, it shipped quickly, and it fit the job.

But for that fence near the ocean? I’ll always pick hot dip. No question.

So now it’s your turn. What’s more important to you—looks and lead time, or strength and life span?

You’ve got all the details. You know how they compare. Use this table as your final gut check before you place that order.

Conclusion

I used to think galvanized was just one thing. One choice. One result.

Now I know better. And you do too.

You’ve learned:

- What hot dip and electro-galvanizing really are

- Where each works best

- How to match them to your job

You’re no longer guessing. You’ve got facts and a clear next step.

So here’s my challenge to you: Don’t settle for “good enough.” Pick what truly works.

Need help? Reach out and let’s find the best fit together.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Machining & Molding Services:

Finishing Processes:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.