Have you ever stood by a grinding machine and thought, “What’s really going on here?” I sure have.

The first time I saw one with a friend at his shop. Sparks flew, metal sizzled, and I couldn’t believe how something so rough could turn a piece of steel into a smooth, shiny part.

Back then, I didn’t have a clue. But I was lucky. I had mentors, those people who took the time to show me that good grinding isn’t just about power.

It’s skill, patience, and knowing exactly how much to take off.

Why trust me? Because I’ve been right there on noisy shop floors, watching parts get ruined by the tiniest mistake.

So if you want to finally get what grinding is all about how it works, what parts make it tick, and where it’s used, you’re in the right spot.

By the end, you’ll walk away with a clear, simple view of grinding you can use, whether you’re running a shop, designing a part, choosing a supplier, or just curious for your next project.

Let’s get started!

1. What is Grinding?

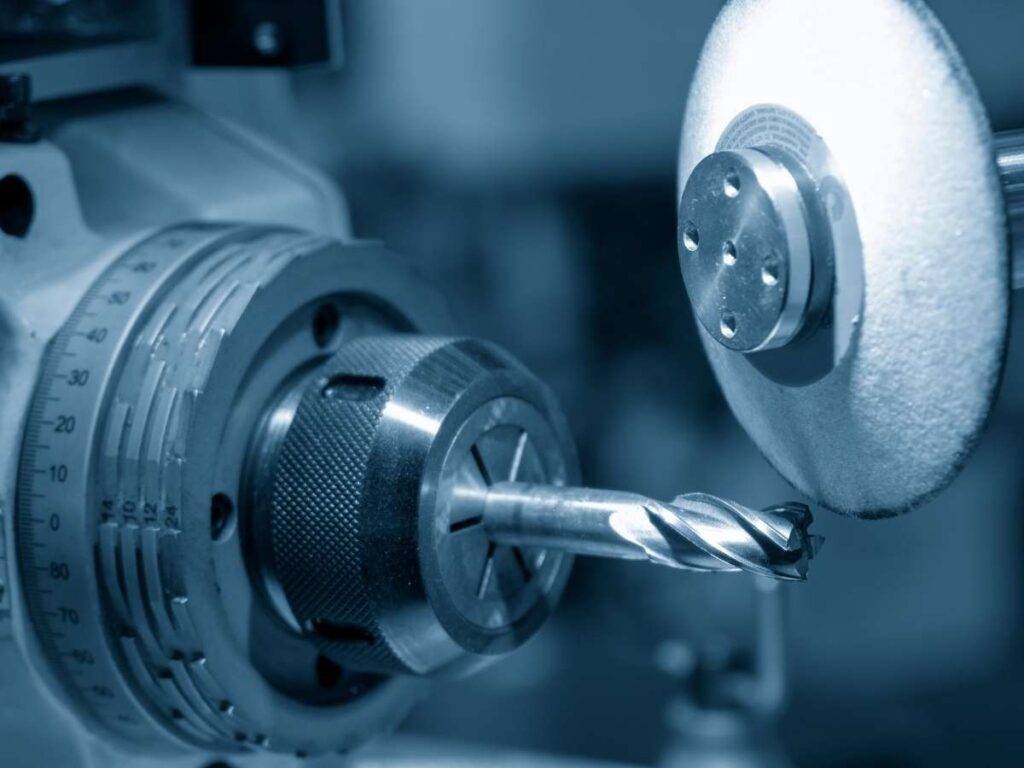

So, what exactly is grinding? It’s pretty simple at its core. Grinding is a machining process that uses an abrasive wheel to remove tiny bits of material from a workpiece. Think of it as sanding wood, but for metal. Only much more precise.

I still remember the first time I stood close to a grinder. The wheel spun so fast it was almost a blur. Sparks popped and danced. Honestly, it was a little intimidating. But over time, I learned to see grinding as one of the best ways to get super smooth finishes or exact shapes.

Why would you use grinding? Here’s what it’s great for:

- Getting tight tolerances so parts fit together just right

- Making surfaces smooth and shiny

- Shaping hard materials that other cutting tools can’t handle

Have you ever needed a part to be “just right”? Grinding is often the secret behind that. It’s not just brute force. It’s careful work that takes skill and experience.

2. Advantages of Grinding

The first time I used grinding to fix a stubborn part, I didn’t expect much. I was just hoping it would fit. But the result surprised me. Not only did the piece fit perfectly, the surface was smoother, the tolerances tighter, and everything aligned the way it was supposed to.

Here’s what makes it worth using in your workflow:

High Precision

Grinding gives you tight control over size and shape. It removes material in very small amounts sometimes in microns, so you can hit tight tolerances without overdoing it.

If your parts need to fit with minimal clearance, grinding helps you get there. That’s why it’s often used as the final step before inspection.

Superior Surface Finish

Compared to other machining steps, grinding gives you a smoother finish. That matters when your part needs to seal, slide, or meet appearance standards. You’ll get flatness, evenness, and a surface that holds up in performance or looks good in use.

Works on Hard Materials

After heat treating, many metals are too hard for normal tools. You can use grinding to finish hardened steel, ceramics, and tough alloys without damaging your tools or the part. It’s one of the few options that still works when strength matters.

Good for Post-Processing

Heat treatment and welding often lead to surface distortions, oxidation, or dimensional changes. Grinding is commonly used to correct these issues. It can restore flatness, remove residual material, and prepare parts for coating or assembly.

This step helps maintain control over part quality after other high-temperature processes are done.

Consistent Results

Once your setup is dialed in, grinding gives you stable, repeatable results. That’s useful when you need multiple parts to match.

In production runs, grinding helps you hold tolerances across hundreds or thousands of pieces. It reduces variation and keeps things within spec. Shops often rely on it for parts that can’t afford inconsistencies.

At MachMaster, they follows strict setup procedures and inspects parts batch by batch to keep results consistent and reliable.

3. Types of Grinding Processes

Grinding isn’t just one process, it comes in different forms, each suited for specific shapes, materials, or tolerance needs. When you pick the right grinding method, you save time, improve surface quality, and hit tighter specs.

Here are the most common grinding methods used in manufacturing:

Surface Grinding

Surface grinding uses a flat, spinning wheel to remove material from a flat surface. If you need even thickness or a clean, flat finish, this is a great option.

Best for:

- Mold bases

- Machine components

- Sheet metal plates

- Tooling surfaces

Use this when your part needs a smooth surface or precise flatness across the entire piece.

Cylindrical Grinding

This method shapes the outside of round parts. Your part spins while the grinding wheel moves along the outer surface.

Best for:

- Shafts

- Pins

- Bushings

- Rollers

Choose cylindrical grinding when you need a part with a perfect round shape or exact outside diameter.

Centerless Grinding

In centerless grinding, your part sits between two wheels, one grinds, the other controls movement. There’s no clamping or center hole needed.

Best for:

- Fasteners

- Dowel pins

- Small cylindrical parts

- Precision tubes

This is a smart choice when you’re running high volumes and need consistent, fast output without setups slowing you down.

Internal Grinding

Internal grinding shapes the inside of your part like a hole, sleeve, or cavity. A smaller wheel goes inside the part to remove material from the internal wall.

Best for:

- Bearings

- Bushings

- Tube ends

- Precision sleeves

Use this when you need a smooth inner surface or a tightly controlled internal diameter.

Each of these methods plays a different role. When you understand how each one works, you can choose the right type of grinding to meet your part’s needs, whether you’re working with flat plates, round shafts, or precise holes.

4. Applications of Grinding

You might not hear much about grinding, but it plays a critical role in many industries. Whether you’re running mass production or building custom parts, grinding helps you improve accuracy, surface quality, and reliability. It’s often the final step but it’s also one of the most valuable.

Here are some lists of applications where grinding fits in:

Automotive Industry

If you’re working with engine or drivetrain parts, you know how tight the tolerances can get. Grinding helps you hit those specs.

You’ll use it on crankshafts, camshafts, brake rotors, and valve train components, parts where smooth surfaces reduce wear, control oil flow, and improve performance. Whether it’s for noise reduction, better fuel efficiency, or longer service life, grinding helps your components meet those demands.

Aerospace Components

In aerospace, you can’t afford errors. Grinding is used for turbine blades, bearing seats, and gear faces, parts that must survive stress, speed, and temperature changes.

I’ve been in reviews where a small deviation on a ground surface delayed an entire flight test program. That’s how much trust is placed in the accuracy of the grind. It’s about making parts that survive extreme stress while staying stable and safe in the air

Medical and Surgical Equipment

When a part goes into or near the human body, every edge and surface matters. You’ll use grinding to finish surgical tools, implants, and stainless tubing with the smoothness and precision required for patient contact.

It helps you remove micro-burrs, polish sharp edges, and get mirror finishes that meet strict hygiene standards. Grinding also helps you hit tight tolerances for moving parts in pumps, valves, or surgical instruments.

General Manufacturing and Assembly

In everyday manufacturing, grinding helps you get parts ready for final steps like painting, plating, or fit checks.

You might use it to smooth a shaft, clean up a weld, or flatten a plate. When a part comes off the machine just a little off, grinding can save it from the scrap bin. I’ve personally salvaged brackets and plates with a quick surface grind, getting them back into spec and back into production.

5. Grinding vs Other Machining Processes

It’s easy to group all machining under one label from cutting, shaping, or finishing metal. But the methods used can make a big difference. Grinding isn’t always the first choice, but it often becomes the final solution when other methods fall short.

In this section, let’s compare grinding with some common machining processes ike turning, milling, and EDM so it’s easier to see when and why grinding is the better fit.

| Consideration | Grinding | Turning | Milling | EDM | Lapping / Polishing |

| Precision / Tolerance | Very high (±0.002 mm achievable) | Moderate. Good for general fits | Moderate. May require post-processing | High. Good for small features | Very high, but only for final finish |

| Surface Finish | Smooth to mirror-like (Ra < 0.4 µm possible) | Visible tool marks. Ra usually higher | Slightly rough finish unless specialized tooling is used | Rougher surface that often needs cleanup | Extremely smooth. Ideal for sealing surfaces |

| Hard Materials | Excellent. Works well on hardened steel, ceramics, etc. | Poor. Tools wear quickly on hard materials | Poor to moderate. Hard metals cause faster tool wear | Excellent. Cuts hardened materials easily | Only for final stages. Not effective for shaping hard material |

| Material Removal Rate | Slow but controlled | Fast | Fast | Slow | Very slow |

| Flatness / Parallelism | Excellent, especially on flat surfaces (via surface grinding) | Low. Cylindrical only | Moderate. May need secondary processing | Low. Often leaves uneven surfaces | Excellent but only after prior preparation |

| Tool Complexity | Abrasive wheel. Requires correct selection and setup | Standard lathe tools | End mills and face mills | Wire or shaped electrodes | Uses soft pads with abrasive compounds |

| Post-Process Usage | Common before plating, coating, or assembly | Often needs further finishing | Often followed by grinding | Usually followed by grinding or polishing | Final step only. Needs smooth pre-ground surface |

6. Limitations and Challenges in Grinding

I used to think grinding could fix anything. Whenever a part didn’t fit or the finish didn’t look right, my first thought was, “Just grind it.” But over time, I learned that grinding isn’t always the fastest or easiest answer. It has strengths, yes, but also its limits.

Below are the most common problems with grinding, and more importantly, how to deal with them:

Slower Material Removal

Grinding removes material in very small amounts. That’s perfect for tight tolerances, but it’s slow if you’re working with thick stock or big parts.

What to do: Use grinding as a finishing step, not roughing. Start with milling or turning to take off most of the material, then use grinding to fine-tune the size and surface.

Heat Buildup and Burn Marks

Grinding creates heat at the contact point. If you don’t control it, you’ll get burn marks, discoloration, or surface damage, especially on hard metals.

What to do: Use coolant to control heat and flush away debris. Adjust your feed rate and pressure to stay cool. For tough jobs, choose wheels made for cooler cutting like ceramic abrasives.

Wheel Selection and Setup Time

Not all grinding wheels are the same. If you use the wrong one, you’ll get poor results and waste time fixing them. Wheel setup also takes time for dressing, balancing, and adjusting.

What to do: Match the wheel to your material and surface needs. Work with experienced machinists or suppliers to get it right. For repeat jobs, write down what worked so you can save time on future runs.

Tool Wear and Dressing

Grinding wheels wear out as you use them. A worn wheel creates heat and rough surfaces. You’ll need to dress the wheel to keep it sharp, but that takes time and interrupts your process.

What to do: Schedule regular dressing based on your job type and material. If your machine allows, use automated dressing. If not, keep a dressing tool close and listen for changes in sound or feel, those signs usually mean the wheel is going dull.

7. Tips on How To Choose The Best Grinding Services

Finding the right grinding service isn’t just about picking the cheapest option. I’ve worked with shops that looked great on paper but struggled with consistency. Others had fewer machines but delivered clean, reliable results every time.

Here are key tips to help you choose the right provider:

Tip#1 Understand Their Capabilities

Not every shop offers the same grinding processes. Some focus on surface and cylindrical grinding. Others might offer internal, centerless, or profile grinding.

What to check:

- Do they support the type of grinding your part needs?

- Can they handle the material you’re using?

- Do they work with small batches, large volumes, or both?

Ask for their machine list, grinding methods, and material expertise. A reliable shop will have this information ready.

Tip#2 Ask About Tolerances and Surface Finish

Different applications require different precision levels. A general-purpose shop might not hit the tolerances needed for aerospace or medical parts.

What to check:

- What are their typical tolerances?

- What surface finishes can they achieve?

- Can they meet your specific print requirements?

If you’re aiming for tight tolerances in your project, make sure they’ve done similar jobs before. Ask for sample parts or case studies if available.

Tip#3 Check Quality Control Processes

Grinding is precise but only if it’s measured and tracked. Good shops have systems in place to monitor tool wear, inspect parts, and document results.

What to check:

- Do they have in-house inspection tools (micrometers, CMM, surface testers)?

- Are they ISO 9001 certified?

- How do they verify each batch?

At MachMaster, quality control isn’t an afterthought, it’s built into every step. Their team uses calibrated tools and standardized procedures to track performance and catch issues before they reach your floor.

Conclusion

Grinding isn’t just about smoothing a surface. It’s a process that improves accuracy, part life, and performance.

In this article, we broke down what grinding is, its advantages, the different methods, where it’s used, how it compares to other machining, and what to watch out for.

Now, you know what to consider and how to move forward.

Need support from someone who knows how to do it right?

Contact MachMaster today. We offer precision grinding services that help you finish strong!