I once waited six weeks for a “rush job” that never made it to my production line.

That one delay cost us a client and a month’s worth of rework.

That’s when I realized, finding a reliable custom metal stamping partner isn’t just important. It’s business survival.

I’ve reviewed dozens of manufacturers, compared quotes, checked facility standards, and spoken with buyers in similar industries. What you’ll find here is a filtered list based on real-world checks, not marketing fluff.

You’ll see key company profiles, service highlights, and a quick breakdown of what each stamping partner does best.

If you’re looking for speed, consistency, and a team that can keep up with your specs, this list has what you need.

So, let’s jump right into it!

Quick Comparison Chart

Here’s a comprehensive comparison chart that gives you a side-by-side view of seven top custom metal stamping manufacturers.

This makes it easier to evaluate them based on key factors like services, certifications, and ideal use cases.

| Manufacturer | Location | Year Established | Core Services | Certifications | Best For | Considerations |

| Keats Manufacturing Co. | USA (Illinois, Texas, Mexico) | 1958 | Custom metal stamping, wire forming, tool & die design, assembly | ISO 9001, IATF 16949, ISO 14001 | Precision stamping with in-house tooling | US-based pricing may be higher for some buyers |

| Gestamp | Spain (global presence) | 1997 | Hot & cold stamping, hydroforming, chassis/body parts | IATF 16949, ISO 9001, ISO 14001 | High-volume automotive component production | Less ideal for small-batch or custom work |

| MachMaster | China | 2002 | CNC machining, injection molding, sheet metal, surface treatment | ISO 9001, ISO 2768-m (default tolerance) | One-stop, fast, high-precision manufacturing | – |

| Tempco Manufacturing Co. | USA (Minnesota) | 1945 | Metal stamping, fabrication, prototyping, assemblies | ISO 9001, AS9100, ISO 13485, FFL | Mid-to-large scale industrial and aerospace production | May not be ideal for ultra-rapid prototyping |

| Bruderer AG | Switzerland | 1943 | High-speed stamping presses, turnkey systems, press retrofits | ISO 9001 | Manufacturers needing advanced press machinery | Not a part supplier—equipment-focused |

| Misumi Group Inc. | Japan (global) | 1963 | Metal press components, FA parts, mold components | ISO 9001, ISO 14001 | Engineering teams sourcing custom components fast | Focuses on components, not full-service stamping |

| Interplex Holdings Pte. Ltd. | Singapore | 1958 | Precision stamping, insert molding, assemblies, tooling | ISO 9001, IATF 16949, ISO 13485, ISO 14001, FDA (design control) | Complex, high-volume, globally distributed manufacturing | Less flexible for small or low-volume |

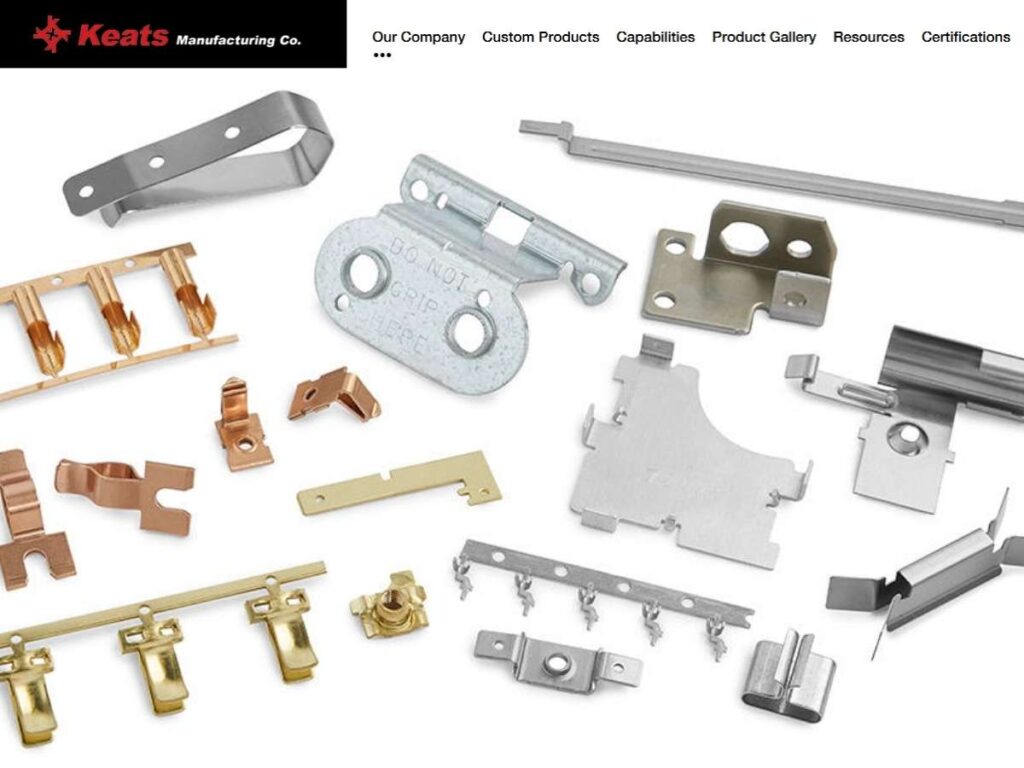

1. Keats Manufacturing Co.

Keats Manufacturing has always stood out to me for their attention to detail and long-standing reputation in the metal stamping world.

They’ve been in the game since 1958, consistently delivering high-precision components that meet demanding industry specs.

I’ve seen how well they balance old-school reliability with modern engineering tools.

With multiple facilities across North America, they’ve built a solid foundation for serving both small and large production needs.

Service Specialties

- Custom Metal Stamping: Keats produces intricate stampings like terminals, shields, clips, and brackets with impressive consistency. Their custom work supports industries where tight tolerances and precision matter most.

- Wire Forming: Using four-slide and multi-slide equipment, Keats manufactures wire forms in a variety of custom configurations. This service is ideal for complex designs in electronics, medical, and automotive sectors.

- Tool and Die Design: They design and build all tooling in-house, which means greater control over fit, function, and turnaround time. Their dies are built to handle both low- and high-volume jobs.

- Prototype and Short-Run Production: Keats offers small-batch runs and prototypes with fast turnaround. It’s a great option when you want to test a new design without committing to a full production line.

- Component Assemblies: They offer secondary services like contact staking, welding, and even plastic overmolding. This makes them a solid one-stop option for customers looking to reduce assembly complexity.

Certifications

- ISO 9001:2015 – Quality Management: This confirms Keats operates with standardized, consistent, and documented quality processes. It ensures customers get dependable output every time.

- IATF 16949:2016 – Automotive Quality Standards: This automotive-specific certification shows their systems are built to meet the strictest performance and traceability demands.

- ISO 14001:2015 – Environmental Management: Keats has taken measurable steps to minimize their environmental footprint through better resource and waste management.

Contact Information

- Website: https://www.keatsmfg.com

- Phone: (847) 520-1133

- Toll-Free: 1-800-KEATS-MFG

- Fax: (847) 520-0114

- Email: info@keatsmfg.com

- Address: 350 Holbrook Drive, Wheeling, IL 60090, USA

Bottom Line

Keats Manufacturing Co. is a dependable partner for precision metal stamping, with decades of experience and a clear commitment to quality. Their in-house tooling and broad capabilities across industries make them a versatile supplier.

The only drawback is that their U.S.-based operations may come at a higher price point compared to overseas alternatives.

2. Gestamp

Gestamp has always impressed me with its commitment to innovation in the automotive sector.

Since its inception in 1997, the company has grown into a global leader in the design, development, and manufacture of metal automotive components.

Their focus on creating safer and lighter vehicles aligns with the industry’s push towards sustainability and efficiency.

With a presence in over 20 countries and more than 100 production plants, Gestamp’s global footprint ensures they can meet the demands of clients worldwide.

Service Specialties

- Hot Stamping: Gestamp is renowned for its expertise in hot stamping, a process that enhances the strength and safety of automotive components while reducing their weight. This technique is pivotal in manufacturing structural parts that meet stringent safety standards.

- Cold Stamping: Their cold stamping capabilities allow for the efficient production of complex metal parts with high precision. This process is essential for creating components that require tight tolerances and consistent quality.

- Hydroforming: Gestamp utilizes hydroforming technology to produce lightweight and structurally robust components. This method is particularly beneficial for manufacturing parts with intricate shapes and contours.

- Chassis and Body Components: The company designs and manufactures a wide range of chassis and body components, including underbody systems, frames, axles, and couplings. These parts are integral to vehicle performance and safety.

- Tooling and Dies: Gestamp offers in-house design and production of hydraulic presses and dies, supporting various stamping processes. This capability ensures the quality and efficiency of their manufacturing operations.

Certifications

- IATF 16949:2016 – Automotive Quality Management: Gestamp’s adherence to this standard demonstrates their commitment to quality management systems specific to the automotive sector, ensuring product reliability and customer satisfaction.

- ISO 14001:2015 – Environmental Management Systems: This certification reflects Gestamp’s dedication to minimizing environmental impact through effective environmental management practices across their operations.

- ISO 9001:2015 – Quality Management Systems: Gestamp’s compliance with ISO 9001:2015 underscores their focus on consistently providing products that meet customer and regulatory requirements.

Contact Information

- Website: https://www.gestamp.com

- Phone: +34 91 379 19 99

- Email: info@gestamp.com

- Address: Calle de Alfonso XII, 16, 28014 Madrid, Spain

Bottom Line

Gestamp brings world-class scale, technical innovation, and a strong global footprint to every project.

Their focus on lightweight and safe automotive components makes them a leader in the industry. However, their size and specialization may not be the best fit for small or custom short-run stamping projects.

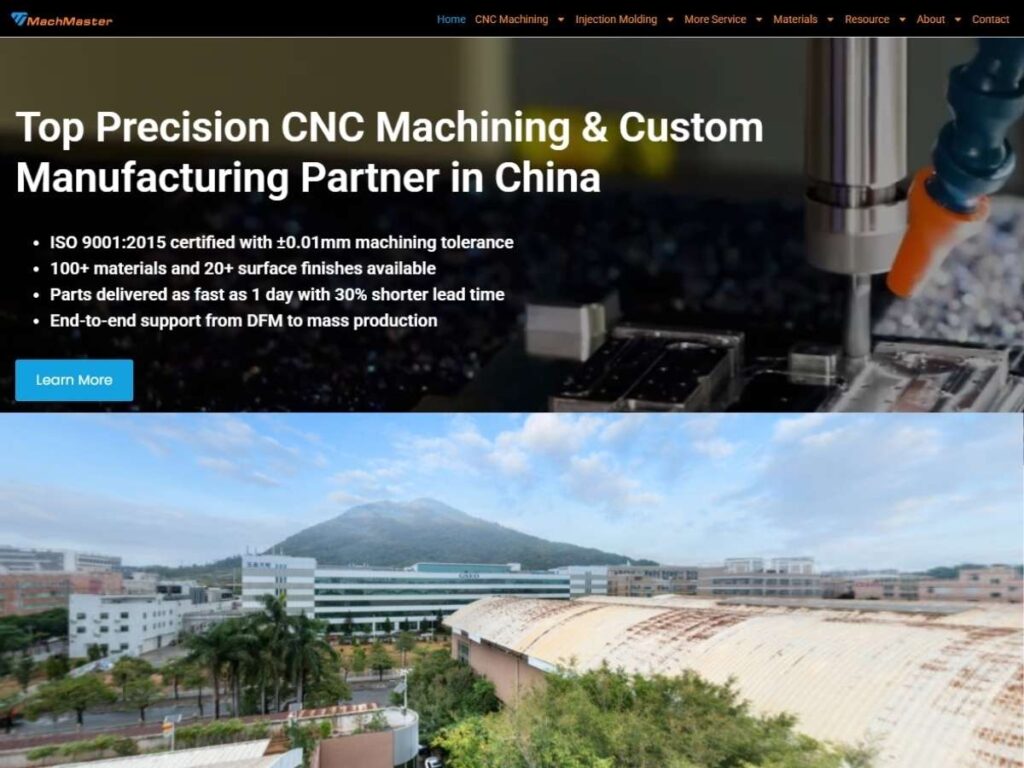

3. MachMaster

What really caught my attention about MachMaster is how well they blend precision with speed.

They’re not just another CNC shop, they’ve built a fully integrated, one-stop manufacturing platform that tackles complex production challenges without missing a beat.

Whether it’s prototypes or full-scale production, they make it easy for engineering teams to get exactly what they need.

For global clients juggling deadlines and tight specs, that kind of reliability is rare and refreshing.

Service Specialties

- CNC Machining: MachMaster delivers precision CNC parts with tolerances up to ±0.01mm. They handle multi-axis machining for aluminum, stainless steel, plastics, and more.

- Sheet Metal Fabrication: From custom brackets to full enclosures, they offer bending, punching, laser cutting, and welding. Their sheet metal team supports complex assemblies and tailored finishes.

- Plastic Injection Molding: For clients needing custom plastic parts, MachMaster provides high-quality molds and fast turnaround. They also offer insert molding and over-molding for hybrid components.

- Surface Treatments: They offer a wide range of finishes, including anodizing, electroplating, powder coating, sandblasting, and more. Each finish is inspected to meet durability and cosmetic standards.

- Rapid Prototyping: With sample lead times of 5–10 days, they support fast iterations and engineering validation. This is especially useful when testing fit, function, or design tweaks.

- Design for Manufacturing (DFM) Support: Their in-house engineers help optimize part designs for performance and cost. They’re also experienced in handling complex combinations like machined + molded assemblies.

- Quality Assurance & Traceability: Full QA process with inspection reports and third-party validation if needed. Inspection data is archived for up to 3 years for traceability.

- Global Logistics Support: Weekly progress reports, remote inspections, and smooth customs coordination make international sourcing much easier.

Certifications

- ISO 9001: Quality Management System: This certification confirms that MachMaster runs standardized and documented quality control processes. It’s a must-have for businesses needing consistent part accuracy.

- ISO 2768-m (Default Tolerance Standard): Their default tolerance standard ensures consistent quality for most parts unless tighter specs are requested. It gives peace of mind for general precision work.

Contact Information

- Website: https://machcncmaster.com/

- Address: 202 Tianfeng Road, Xiamen, Fujian, China

- Email: info@machcncmaster.com

- Phone: 0592-5782139

Bottom Line

MachMaster impresses with its blend of speed, precision, and flexibility across CNC machining, sheet metal, and surface treatments.

Their engineering support, responsive service, and one-stop manufacturing model make them especially easy to work with. They consistently deliver value without compromise.

4. Tempco Manufacturing Company, Inc.

Tempco Manufacturing has been a cornerstone in the metal stamping industry since 1945.

Their dedication to precision and quality has earned them a reputation as a trusted partner across various sectors, including aerospace, medical, and industrial equipment.

Operating from a state-of-the-art facility in St. Paul, Minnesota, Tempco combines decades of experience with modern technology to deliver exceptional metal fabrication solutions.

Their commitment to customer satisfaction and continuous improvement is evident in every project they undertake.

Service Specialties

- Custom Metal Stamping: Tempco offers precision metal stamping services, producing components ranging from miniature, thin-gauge parts to heavy-gauge stampings. Their presses range from 32 to 1,000 tons, accommodating a wide variety of part sizes and complexities.

- Sheet Metal Fabrication: Their sheet metal fabrication services include shearing, punching, drilling, forming, welding, and grinding/polishing, enabling them to produce complex assemblies and enclosures.

- Tool and Die Design: Tempco designs and builds all tooling in-house, which means greater control over fit, function, and turnaround time. Their dies are built to handle both low- and high-volume jobs.

- Prototype and Short-Run Production: They offer small-batch runs and prototypes with fast turnaround. It’s a great option when you want to test a new design without committing to a full production line.

- Component Assemblies: Tempco offers comprehensive assembly services, including staking, tapping, welding, TOX, and in-die hardware insertion, providing value-added solutions to their customers.

Certifications

- ISO 9001:2015 – Quality Management Systems: This certification demonstrates Tempco’s commitment to maintaining consistent quality across their manufacturing processes.

- AS9100D:2016 – Aerospace Quality Management: This standard indicates their adherence to the stringent quality requirements of the aerospace industry.

- ISO 13485:2016 – Medical Devices Quality Management: Tempco’s certification reflects their dedication to producing medical devices that meet regulatory requirements and customer expectations.

- Federal Firearms License (FFL) – 18 U.S.C. Chapter 44: This license allows Tempco to manufacture and assemble components for the firearms industry, adhering to federal regulations.

Contact Information

- Website: https://www.tempcomfg.com

- Phone: (651) 452-1441

- Fax: (651) 452-1125

- Email: info@tempcomfg.com

- Address: 2475 Hwy. 55, St. Paul, Minnesota 55120, USA

Bottom Line

Tempco stands out for its deep experience, extensive equipment range, and strong certifications, including aerospace and medical standards. Their ability to handle everything from tooling to full assemblies makes them highly reliable.

Still, their capabilities may be better suited to mid-to-large production runs rather than ultra-fast prototyping.

5. Bruderer AG

Bruderer AG has long been synonymous with precision and innovation in the metal stamping industry.

Established in 1943 in Frasnacht, Switzerland, the company has consistently set benchmarks in high-speed stamping technology.

Their commitment to excellence is evident in their state-of-the-art machinery and global presence.

With decades of experience, Bruderer continues to be a trusted partner for businesses seeking reliable and efficient stamping solutions.

Service Specialties

- High-Speed Stamping Presses: Bruderer offers a range of high-performance stamping presses, known for their speed, precision, and reliability. These machines are designed to meet the demanding requirements of various industries.

- Turnkey Solutions: They provide comprehensive turnkey solutions, integrating their stamping presses with peripheral equipment to deliver complete production systems tailored to client needs.

- Certified Interfaces: Bruderer ensures seamless integration of their machines with existing systems through certified interfaces, enhancing productivity and reducing downtime.

- Rebuilt Presses: They offer refurbishment services for existing presses, extending the lifespan of equipment and ensuring optimal performance.

- Peripheral Equipment: Bruderer supplies a variety of peripheral equipment, including feed units and control systems, to complement their stamping presses and enhance overall production efficiency.

Certifications

- ISO 9001:2000 – Quality Management Systems: This certification underscores Bruderer’s commitment to maintaining high-quality standards across their operations.

Contact Information

- Website: https://www.bruderer.com

- Phone: +41 71 447 75 00

- Email: info@bruderer.com

- Address: Egnacherstrasse 44, 9320 Frasnacht, Switzerland

Bottom Line

Bruderer AG sets the benchmark for high-speed stamping machines, offering unmatched durability and precision for demanding applications.

Their engineering excellence and long-standing reputation make them a trusted name in the press manufacturing world. That said, their solutions are more tailored to equipment sales rather than end-to-end stamping part supply.

6. MISUMI Group Inc.

MISUMI Group Inc. stands out for its commitment to streamlining the procurement process for manufacturing components.

Established in 1963, the company has built a reputation for providing high-quality, customizable components with quick delivery times.

Their unique business model integrates manufacturing and distribution, offering a vast selection of products through an efficient e-commerce platform.

With a global presence, MISUMI continues to support various industries by reducing inefficiencies and enhancing productivity.

Service Specialties

- Metal Press Components: MISUMI offers a wide range of metal press components, including punches, dies, and guide posts, catering to various manufacturing needs.

- Plastic Mold Components: The company provides standard and custom plastic mold components, such as ejector pins and core pins, ensuring precision and durability.

- Factory Automation (FA) Components: MISUMI supplies components like linear guides, actuators, and sensors, supporting automation in manufacturing processes.

- E-Commerce Platform: Their user-friendly online platform allows customers to configure and order components with ease, offering instant quotes and rapid delivery options.

Certifications

- ISO 9001:2015 – Quality Management Systems: This certification underscores MISUMI’s commitment to maintaining consistent quality across their products and services.

- ISO 14001:2015 – Environmental Management Systems: MISUMI’s adherence to this standard reflects their dedication to environmental sustainability in their operations.

Contact Information

- Website: https://www.misumi.co.jp/english/

- Phone: +81 3 6777 7800

- Address: Kudan Kaikan Terrace, 1-6-5, Kudanminami, Chiyoda-ku, Tokyo 102-8583, Japan

Bottom Line

MISUMI offers incredible convenience through its massive catalog, fast lead times, and user-friendly online ordering platform. Their configurable components and automation support make them ideal for engineers and OEMs looking to streamline procurement.

The only challenge is that they operate more as a parts supplier than a full-service stamping manufacturer.

7. Interplex Holdings Pte. Ltd.

Interplex Holdings Pte. Ltd. is a global leader in precision engineering and custom metal stamping solutions.

Established in 1958 and headquartered in Singapore, the company has evolved to serve a diverse range of industries, including automotive, medical, and information & communications technology.

With over 11,000 employees across 13 countries and 25 manufacturing sites, Interplex combines global reach with localized expertise to deliver high-quality, customized solutions.

Service Specialties

- Precision Metal Stamping: Interplex specializes in high-speed precision metal stamping, producing complex components for various applications. Their capabilities include progressive die stamping and fine blanking, ensuring tight tolerances and high repeatability.

- Insert and Injection Molding: The company offers insert and injection molding services, enabling the integration of metal and plastic components. This is particularly beneficial for applications requiring lightweight yet durable parts.

- Electro-Mechanical Assemblies: Interplex provides comprehensive assembly services, combining mechanical and electronic components into fully integrated systems. This end-to-end solution streamlines the supply chain for clients.

- Tool and Die Design: With in-house tool and die design capabilities, Interplex ensures the production of high-quality stamping tools, leading to improved product consistency and reduced lead times.

- Surface Finishing: The company offers various surface finishing options, including plating and coating, to enhance the performance and aesthetics of metal components.

Certifications

- ISO 9001:2015 – Quality Management Systems: This certification demonstrates Interplex’s commitment to maintaining consistent quality across their manufacturing processes.

- IATF 16949:2016 – Automotive Quality Management: This standard indicates their adherence to the stringent quality requirements of the automotive industry.

- ISO 14001:2015 – Environmental Management Systems: Interplex’s certification reflects their dedication to minimizing environmental impact through effective management practices.

- ISO 13485:2016 – Medical Devices Quality Management: This certification underscores their capability to produce medical devices that meet regulatory requirements and customer expectations.

- FDA Registration – Design Control: Interplex is registered with the FDA for design control, highlighting their compliance with regulatory standards in medical device manufacturing.

Contact Information

- Website: https://interplex.com

- Phone: +65 6264 0033

- Fax: +65 6265 2510

- Address: 298 Tiong Bahru Road, #17-01 Central Plaza, Singapore 168730

Bottom Line

Interplex delivers highly engineered, high-volume solutions with global reach and deep expertise in precision metal stamping.

Their strong certifications and vertical integration across toolmaking, molding, and assembly bring added value to complex projects. However, their focus on large-scale production may not align with businesses needing smaller, low-volume orders.

Conclusion

So, remember that supplier delay I mentioned at the beginning? That never happened again once I started working with partners who actually deliver.

We just walked through seven top-tier metal stamping companies.

Each one offering unique strengths, from large-scale production to tight-tolerance prototyping.

Now it’s your turn. What’s holding you back from upgrading your supply chain?

The right partner is right here.

Contact MachMaster today.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.